| Availability: | |

|---|---|

| Quantity: | |

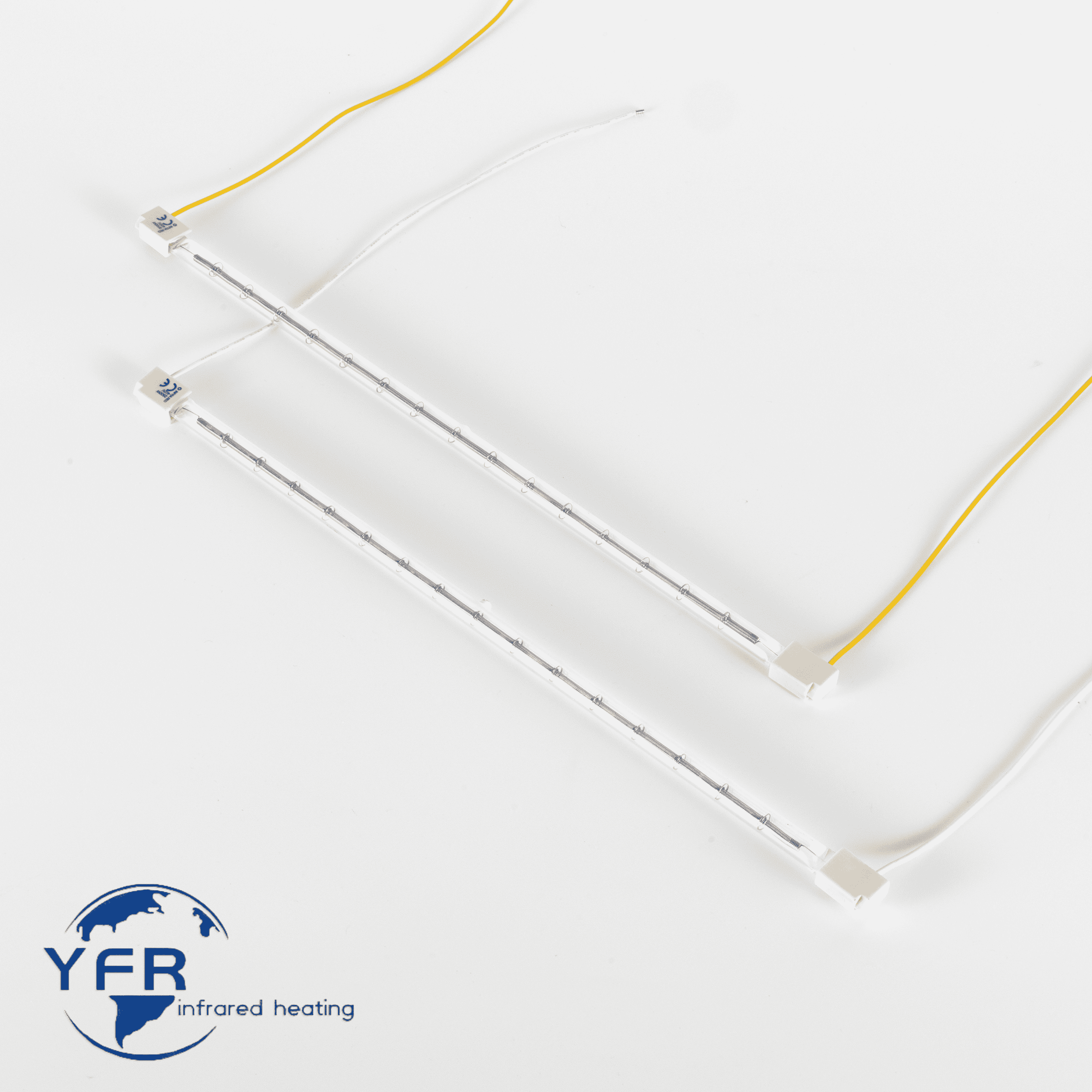

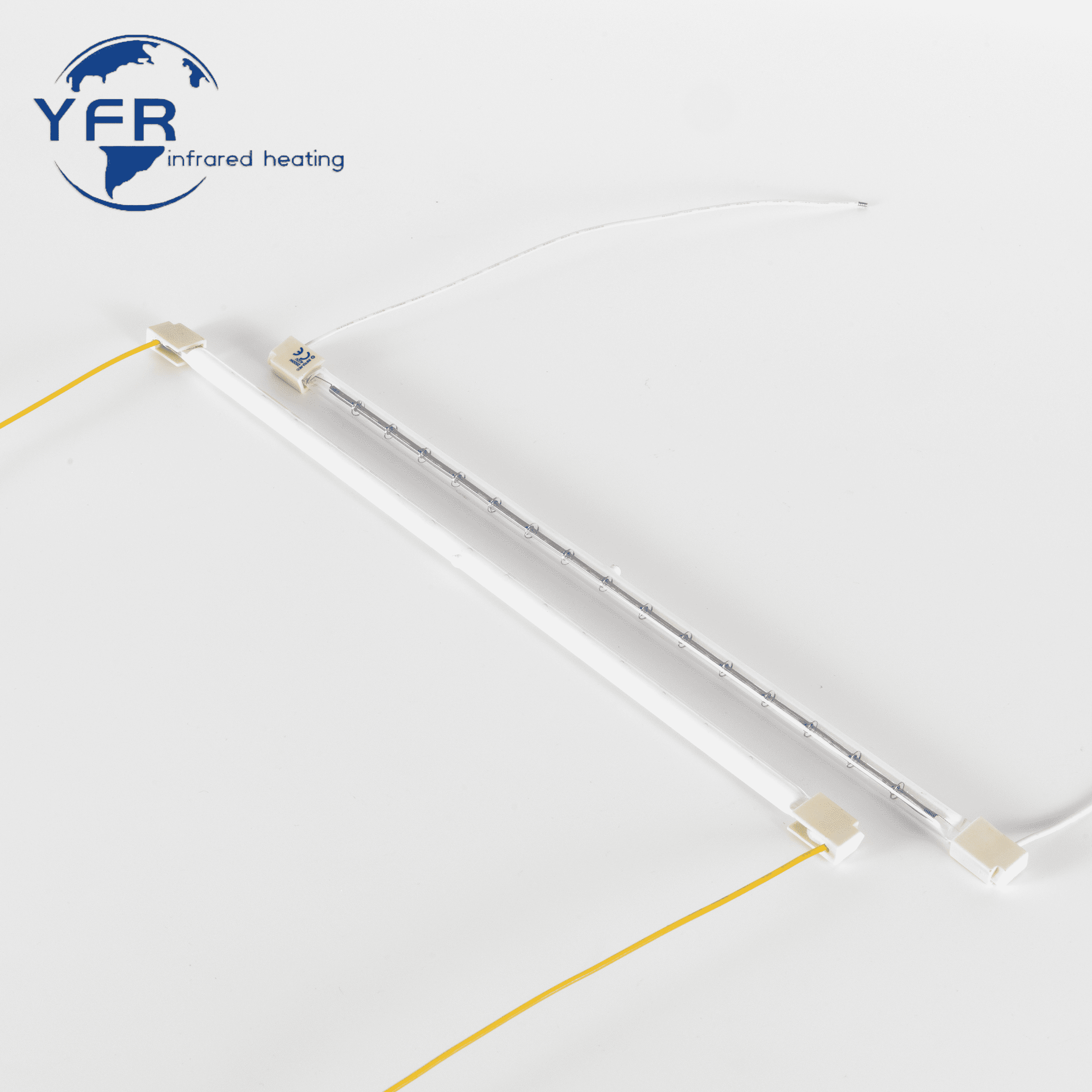

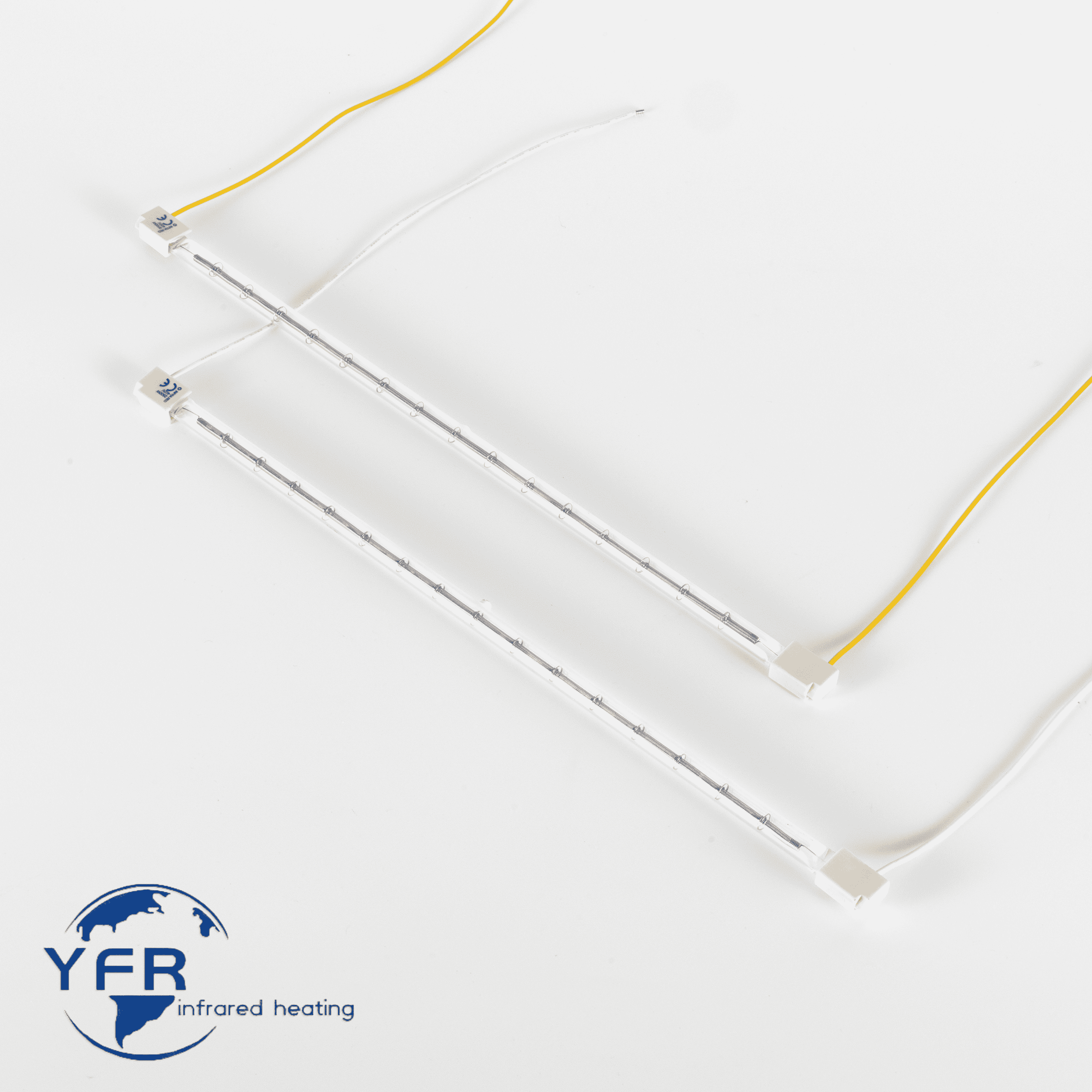

SW2000

Yinfrared

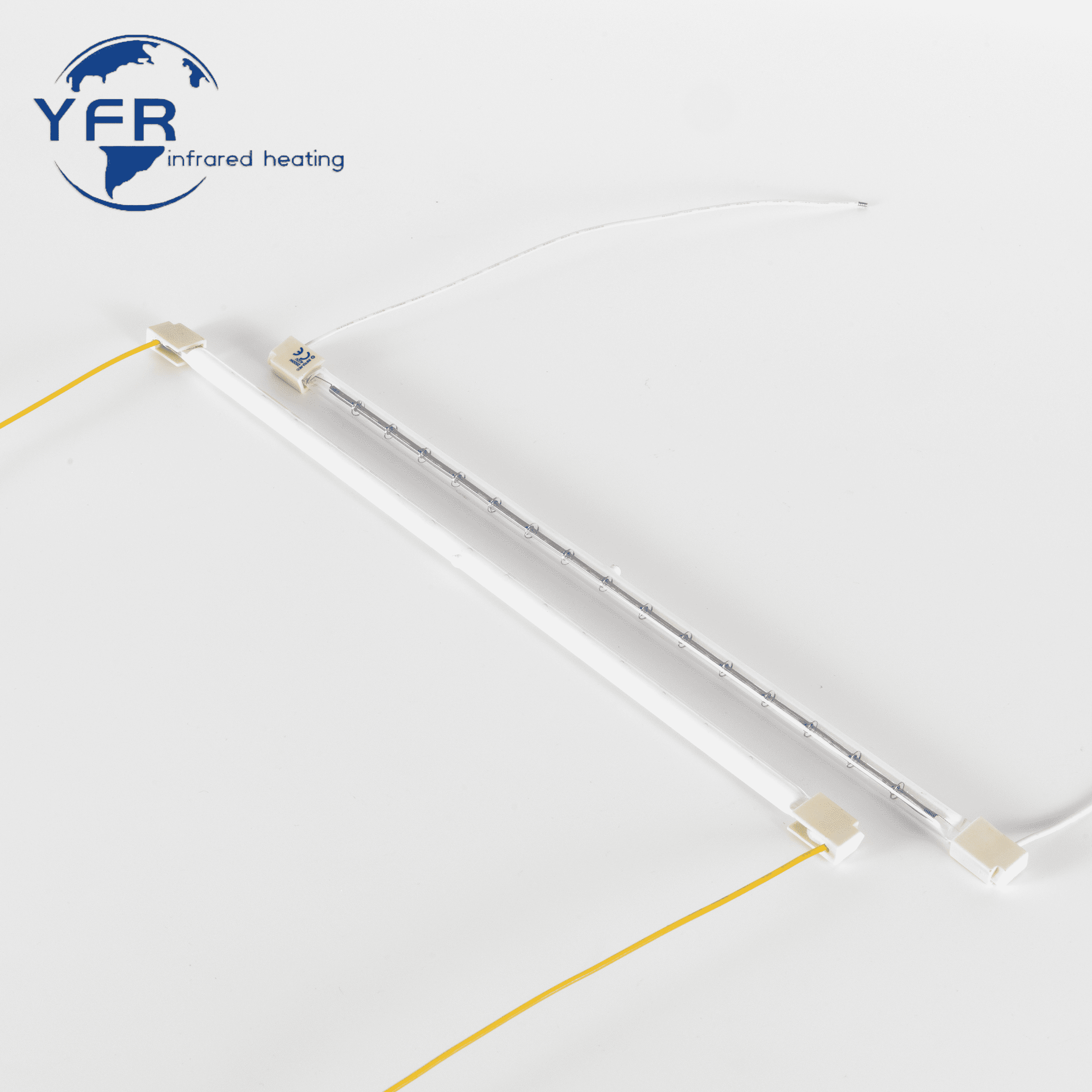

Infrared Heating Lamp for PET Blowing Machine: The Ideal Solution for Efficient Heating

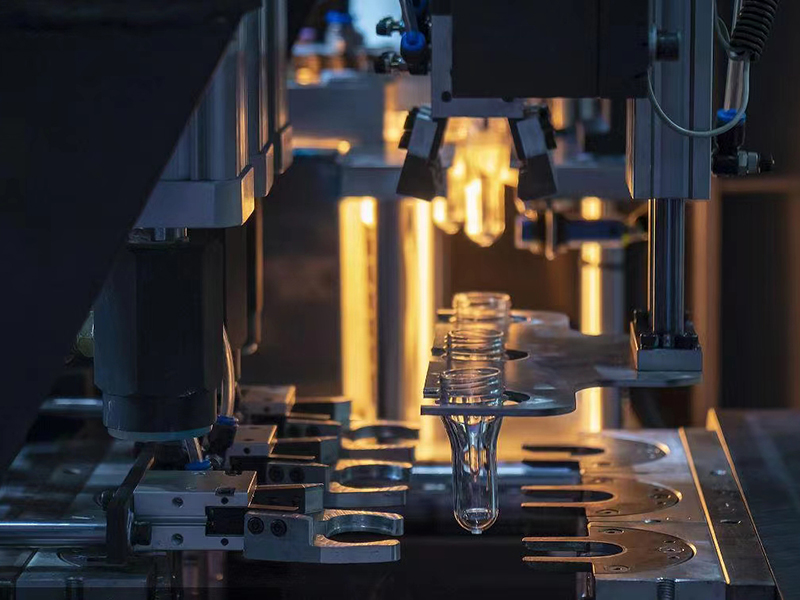

In industrial manufacturing, the PET blowing machine is crucial,it used to make bottles, containers, and other PET products. A key part of this process is the heating system. Infrared heating lamps are now one of the best and most reliable options.

In this article, we will look at the benefits of using infrared heating lamps in PET blowing machines. We will also see how they improve the production process.

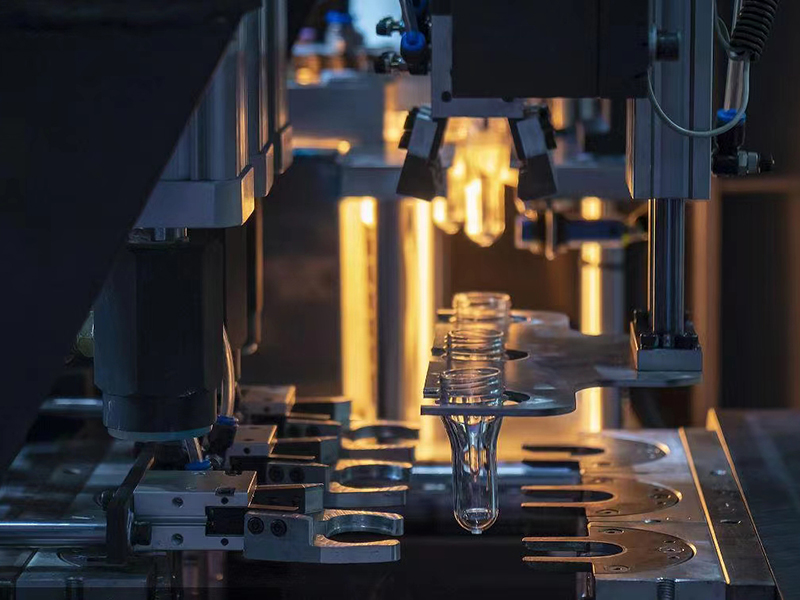

Working principle of bottle blowing machine

A PET blowing machine shapes PET (Polyethylene Terephthalate) plastic into bottles, jars, and other containers. The process involves heating PET preforms to a certain temperature, it makes them soft and easy to shape.

Then, we use air pressure to inflate them into the desired form. The heating stage is critical, as it ensures the material becomes soft enough for molding without degrading its quality.

Why Choose Infrared Heating Lamps for PET Blowing?

Infrared heating lamps are becoming the go-to solution for PET blowing machines because of their numerous advantages:

1.Fast and Efficient Heating

Infrared lamps emit concentrated heat directly to the PET preform without the need for heating air or surrounding environments. This direct heat transfer leads to faster and more energy-efficient heating, reducing overall production time.

2.Energy Saving

Compared to conventional heating methods, infrared heating lamps offer significant energy savings. The targeted heating minimizes heat loss, making it more efficient than traditional methods that rely on heated air.

3.Precise Temperature Control

Infrared heating provides consistent, even heating across the entire PET preform. This ensures that every part of the preform reaches the correct temperature. This leads to consistent quality and fewer defects during molding.

4.Enhanced Product Quality

Manufacturers can use infrared heating for better control over the heating process. This leads to fewer defects, like uneven shaping or material stress. This contributes to improved product quality and consistency.

5.Longer Equipment Lifespan

Infrared lamps use less energy, which helps the machine work better. This leads to lower maintenance costs and a longer life for your PET blowing machine.

How Do Infrared Heating Lamps Work in PET Blowing?

Infrared heating lamps utilize infrared radiation to heat PET preforms. The material surface absorbs this radiation and converts it into thermal energy. Typically, we classify infrared heating lamps into three types: short-wave, medium-wave, and long-wave. Users select the appropriate infrared heating lamp based on specific requirements during different stages of the heating process.

Short-wave infrared provides intense, quick heating and is ideal for the initial heating phase of the PET preform.

Medium-wave infrared provides a more balanced approach and often serves in the intermediate heating stages.

Long-wave infrared is slower but provides excellent penetration, ideal for the final stages where uniform heating is crucial.

Benefits of Using YINFRARED's Infrared Heating Lamps

As a leading manufacturer of infrared heating solutions, YINFRARED provides high-quality, reliable infrared lamps specifically designed for PET blowing machines. Our infrared lamps offer:

Customizable Heating Solutions – Tailored to meet the specific needs of your production line.

High Durability – Long-lasting lamps with resistance to high temperatures.

Energy Efficiency – Helping you reduce energy consumption and operational costs.

Excellent Support – YINFRARED offers expert installation and maintenance services, ensuring optimal performance.

Conclusion

Using infrared heating lamps in PET blowing machines is changing how manufacturers heat PET containers. By choosing YINFRARED's advanced heating solutions, businesses can ensure faster production, reduced energy consumption, and enhanced product quality. If you are looking to upgrade your PET blowing machine, consider incorporating infrared heating technology today!

For more information on how our infrared heating lamps can improve your production line, visit our website: www.yinfrared.com.

Infrared Heating Lamp for PET Blowing Machine: The Ideal Solution for Efficient Heating

In industrial manufacturing, the PET blowing machine is crucial,it used to make bottles, containers, and other PET products. A key part of this process is the heating system. Infrared heating lamps are now one of the best and most reliable options.

In this article, we will look at the benefits of using infrared heating lamps in PET blowing machines. We will also see how they improve the production process.

Working principle of bottle blowing machine

A PET blowing machine shapes PET (Polyethylene Terephthalate) plastic into bottles, jars, and other containers. The process involves heating PET preforms to a certain temperature, it makes them soft and easy to shape.

Then, we use air pressure to inflate them into the desired form. The heating stage is critical, as it ensures the material becomes soft enough for molding without degrading its quality.

Why Choose Infrared Heating Lamps for PET Blowing?

Infrared heating lamps are becoming the go-to solution for PET blowing machines because of their numerous advantages:

1.Fast and Efficient Heating

Infrared lamps emit concentrated heat directly to the PET preform without the need for heating air or surrounding environments. This direct heat transfer leads to faster and more energy-efficient heating, reducing overall production time.

2.Energy Saving

Compared to conventional heating methods, infrared heating lamps offer significant energy savings. The targeted heating minimizes heat loss, making it more efficient than traditional methods that rely on heated air.

3.Precise Temperature Control

Infrared heating provides consistent, even heating across the entire PET preform. This ensures that every part of the preform reaches the correct temperature. This leads to consistent quality and fewer defects during molding.

4.Enhanced Product Quality

Manufacturers can use infrared heating for better control over the heating process. This leads to fewer defects, like uneven shaping or material stress. This contributes to improved product quality and consistency.

5.Longer Equipment Lifespan

Infrared lamps use less energy, which helps the machine work better. This leads to lower maintenance costs and a longer life for your PET blowing machine.

How Do Infrared Heating Lamps Work in PET Blowing?

Infrared heating lamps utilize infrared radiation to heat PET preforms. The material surface absorbs this radiation and converts it into thermal energy. Typically, we classify infrared heating lamps into three types: short-wave, medium-wave, and long-wave. Users select the appropriate infrared heating lamp based on specific requirements during different stages of the heating process.

Short-wave infrared provides intense, quick heating and is ideal for the initial heating phase of the PET preform.

Medium-wave infrared provides a more balanced approach and often serves in the intermediate heating stages.

Long-wave infrared is slower but provides excellent penetration, ideal for the final stages where uniform heating is crucial.

Benefits of Using YINFRARED's Infrared Heating Lamps

As a leading manufacturer of infrared heating solutions, YINFRARED provides high-quality, reliable infrared lamps specifically designed for PET blowing machines. Our infrared lamps offer:

Customizable Heating Solutions – Tailored to meet the specific needs of your production line.

High Durability – Long-lasting lamps with resistance to high temperatures.

Energy Efficiency – Helping you reduce energy consumption and operational costs.

Excellent Support – YINFRARED offers expert installation and maintenance services, ensuring optimal performance.

Conclusion

Using infrared heating lamps in PET blowing machines is changing how manufacturers heat PET containers. By choosing YINFRARED's advanced heating solutions, businesses can ensure faster production, reduced energy consumption, and enhanced product quality. If you are looking to upgrade your PET blowing machine, consider incorporating infrared heating technology today!

For more information on how our infrared heating lamps can improve your production line, visit our website: www.yinfrared.com.