YFR heating tech provides you with temperature control and an Infrared thermometer.

The temperature controller can be a complete set equipped with a cabinet or a single power regulator connected to your PLC system, easy to operate with a touch screen panel. Furthermore, the SCR temperature insulation system can ensure the stability and safety of your equipment in the process of rapid switching on/off.

| Availability: | |

|---|---|

| Quantity: | |

Yinfrared

Master Temperature Control with a Power Regulator for Infrared Lamps

In the world of industrial heating, infrared (IR) lamps are renowned for their speed, efficiency, and clean energy transfer. However, the true potential of infrared heating is only unlocked with one critical component: a precision power regulator.

Whether you're involved in plastic welding, food processing, paint curing, or any application requiring thermal management, uncontrolled heat leads to inconsistent results, wasted energy, and damaged products. This is where a specialized power controller for infrared heating becomes indispensable.

A power regulator, often called a power controller or thyristor unit, is an electronic device that intelligently manages the electrical power delivered to a heating element—in this case, your infrared lamps.

Think of it as a highly sophisticated dimmer switch. Instead of simply turning the lamps on at full power or off completely, it can vary the voltage or use phase-angle control to deliver exactly the amount of energy needed to maintain a precise temperature. This precise management is the key to efficient and effective infrared heating.

Using a standard on/off switch with high-power IR lamps is like driving a car with only the accelerator and brake—you have no control over your speed. A dedicated power controller gives you the steering wheel and cruise control.

Here are the critical benefits:

A power regulator allows for exact temperature maintenance. This ensures every product receives the same amount of heat, leading to uniform curing, drying, or welding. The result? Superior, repeatable product quality and a drastic reduction in rejects.

By delivering only the necessary power to maintain temperature—rather than cycling full power on and off—a power controller for heating systems drastically reduces energy consumption. This "soft" management of power also reduces stress on the electrical grid and your facility's infrastructure.

Infrared lamps, like all halogens, are sensitive to thermal shock. The sudden inrush of current from a simple on/off cycle causes expansion and contraction, which shortens their life. A power regulator provides a soft start and eliminates harsh cycling, significantly extending the operational life of your expensive IR lamps.

Modern power controllers come with built-in protection features such as over-current, over-voltage, and short-circuit protection. This safeguards both your heating system and your personnel, ensuring a safer working environment and reducing downtime.

Our power regulators are ideal for a wide range of industrial processes, including:

Thermoforming and Plastic Welding

Paint Drying and Powder Coating Curing

Food Dehydration and Cooking Processes

Printing and Packaging Film Drying

Textile and Paper Drying

Laboratory and R&D Heating Setups

When selecting a power regulator for infrared lamps, consider these factors:

Load Type: Ensure the controller is compatible with resistive loads like IR lamps.

Control Mode: Do you need simple manual control, or integration with a PID temperature controller and thermocouple for a closed-loop system?

Current & Voltage Rating: The controller must be sized correctly to handle the total power (amperage and voltage) of your infrared heating array.

Features: Look for essential features like soft start, automatic bypass, and clear status indicators.

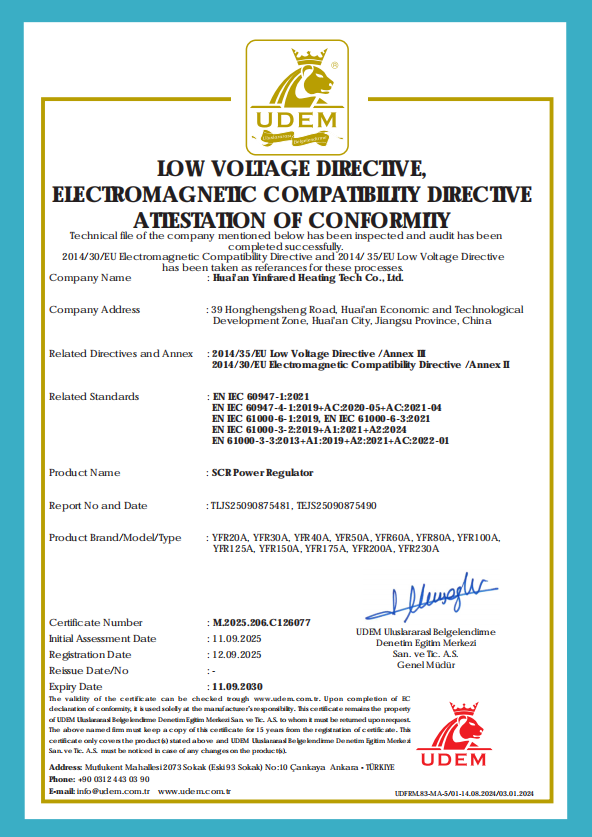

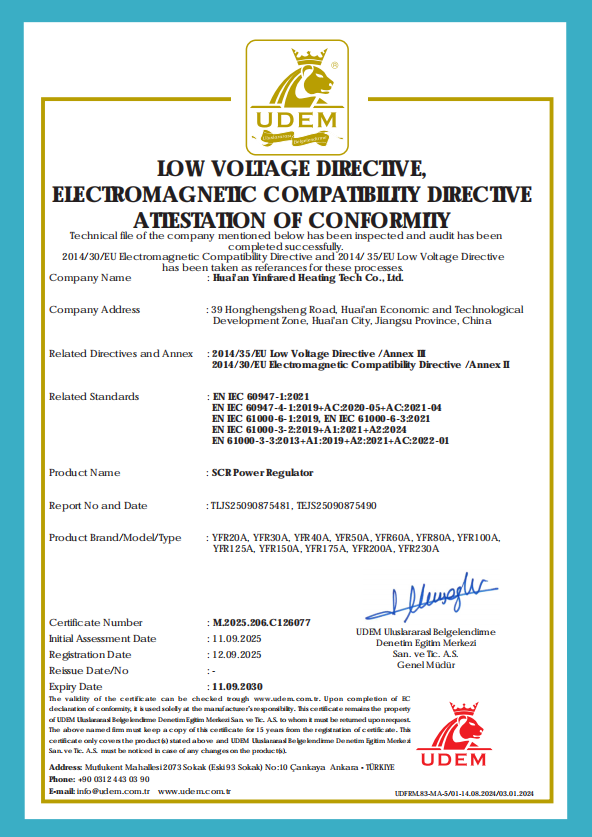

At Huaian Yinfrared Heating Tech, we specialize in providing robust and reliable power control solutions for industrial heating applications. We understand that your process is unique.

We supply high-performance power regulators and controllers designed specifically for the demands of infrared lamp heating. Our solutions are engineered to deliver:

Precise Temperature Management

Maximized Energy Efficiency

Durability in Industrial Environments

Seamless Integration with Your Existing Systems

Don't let imprecise temperature control compromise your product quality and bottom line.

Contact us today to discuss your application. Our technical experts will help you select the perfect power regulator to optimize your infrared heating process, improve efficiency, and ensure consistent results.

we can Produce the electric cabinet to control different heating zones .

Product characteristics

FD type power regulator has the following characteristics

Using the original imported CPU, high degree of digitization, work stability

Control motherboard adopted military circuit design and processing, safe and reliable

Application of original import parts for integrated circuits, quality assurance

New design concept, reasonable structure layout, fast and convenient installation

Single chip microcomputer is developed with independent embedded development system and has powerful function

The heat dissipation system has the characteristics of large heat dissipation area, small size of the whole machine, and high heat transfer ratio.

High precision PID temperature control module with high control precision Multiple communication functions

FD type electric regulator technical specifications

Master power supply | AC50V-AC1200V |

Control power. | AC220V |

Input Signal | 4-20mA/0-20mA/1-5V/0-10V/RS485 |

Output Mode | zero / phase shift output |

Output Mode | Power / current / voltage limit limit / constant current / constant voltage / constant power |

Load Type | Restraint / Sensibility |

Display Precision | 0.01% |

Control precision | 0.10% |

Cooling mode | cooling / water cooling |

Display Type | TFT color. LCD 2.4 / 4.3 / 7 inches |

Mode of communication |

|

Additional features | PID accurate temperature control |

Installation Method | Vertical Installation |

Number of alarm groups | 2 sets of relays output |

Variable output | 0-10V/4-20mA(apolegamy) |

Install Specification Index

Specification | Single phase | Three-phase | Size | Install size |

IS01 | (60-125) A | (30-50)A | 225*85*155 | 200*78 |

IS02 | (150-175) A | (60-125) A | 335*128*200 | 310*60 |

IS03 | (200-225) A | (150-175) A | 350*165*220 | 330*82 |

IS04 | (250-350) A | (200-225)A | 430*185*240 | 410*92 |

IS05 | (400-600) A | (250-350) A | 460*255*245 | 440*122 |

IS06 | (700-800)A | (400-600) A | 540*277*260 | 520*150 |

IS07 | (1000-1200) A | (700-800) A | 540*277*260 | 520*150 |

IS08 | / | (1000-1200) A | 640*330*260 | 620*170 |

Table of Specifications for Selection of Three-phase

Power Regulators

Model | Rated | 220V | 380V | Installation | Fixed | Cooling |

FD-5-4-020 | 020A | 5Kw | 12Kw | IS01 | M6 | Natural cooling |

FD-5-4-030 | 030 A | 6Kw | 15Kw | IS01 | M6 | wind cooling |

FD-5-4-040 | 040 A | 9 Kw | 18Kw | IS01 | M6 | wind cooling |

FD-5-4-050 | 050 A | 14Kw | 26Kw | IS01 | M6 | wind cooling |

FD-5-4-060 | 060 A | 16Kw | 30Kw | IS02 | M6 | wind cooling |

FD-5-4-075 | 075 A | 22Kw | 40Kw | IS02 | M6 | wind cooling |

FD-5-4-080 | 080 A | 25Kw | 43Kw | IS02 | M6 | wind cooling |

FD-5-4-100 | 100A | 32Kw | 56Kw | IS02 | M6 | wind cooling |

FD-5-4-125 | 125 A | 38Kw | 67 Kw | IS02 | M8 | wind cooling |

FD-5-4-150 | 150A | 45Kw | 80Kw | IS03 | M8 | wind cooling |

FD-5-4-175 | 175 A | 50Kw | 90Kw | IS03 | M8 | wind cooling |

FD-5-4-200 | 200 A | 55Kw | 100 Kw | IS04 | M8 | wind cooling |

FD-5-4-225 | 225 A | 68Kw | 120 Kw | IS04 | M8 | wind cooling |

FD-5-4-250 | 250 A | 75Kw | 145 Kw | IS04 | M8 | wind cooling |

FD-5-4-275 | 275 A | 82Kw | 150 Kw | IS05 | M8 | wind cooling |

FD-5-4-300 | 300 A | 89Kw | 160 Kw | IS05 | M10 | wind cooling |

FD-5-4-350 | 350 A | 108 Kw | 190 Kw | IS05 | M10 | wind cooling |

FD-5-4-400 | 400 A | 120 Kw | 220 Kw | IS06 | M10 | wind cooling |

FD-5-4-450 | 450 A | 135 Kw | 250 Kw | IS06 | M12 | wind cooling |

FD-5-4-500 | 500 A | 150Kw | 270Kw | IS06 | M12 | wind cooling |

FD-5-4-600 | 600 A | 180Kw | 330Kw | IS07 | M12 | wind cooling |

FD-5-4-800 | 800 A | 260 Kw | 450 Kw | IS07 | M12 | wind cooling |

FD-5-4-1000 | 1000 A | 450 Kw | 550 Kw | IS08 | M16 | Water cooling |

Specification for Type Selection of Single Phase Power Regulators

Model | Rated | 220V | 380V | Installation | Fixed | Cooling Mode |

FD-1-4-020 | 020A | 4Kw | 6Kw | IS01 | M6 | Natural cooling |

FD-1-4-030 | 030 A | 5Kw | 7 Kw | IS01 | M6 | wind cooling |

FD-1-4-040 | 040 A | 6 Kw | 9 Kw | IS01 | M6 | wind cooling |

FD-1-4-050 | 050 A | 7 Kw | 12 Kw | IS01 | M6 | wind cooling |

FD-1-4-060 | 060 A | 9 Kw | 18 Kw | IS01 | M6 | wind cooling |

FD-1-4-075 | 075 A | 14 Kw | 24 Kw | IS02 | M6 | wind cooling |

FD-1-4-080 | 080 A | 15 Kw | 26 Kw | IS02 | M6 | wind cooling |

FD-1-4-100 | 100 A | 18 Kw | 33 Kw | IS02 | M6 | wind cooling |

FD-1-4-125 | 125 A | 22 Kw | 37 Kw | IS02 | M8 | wind cooling |

FD-1-4-150 | 150A | 26 Kw | 45 Kw | IS02 | M8 | wind cooling |

FD-1-4-175 | 175 A | 30 Kw | 50 Kw | IS02 | M8 | wind cooling |

FD-1-4-200 | 200 A | 35 Kw | 62 Kw | IS03 | M8 | wind cooling |

FD-1-4-225 | 225 A | 38 Kw | 65 Kw | IS03 | M8 | wind cooling |

FD-1-4-250 | 250 A | 42 Kw | 75 Kw | IS04 | M8 | wind cooling |

FD-1-4-275 | 275 A | 47 Kw | 80 Kw | IS04 | M8 | wind cooling |

FD-1-4-300 | 300 A | 52 Kw | 90 Kw | IS04 | M10 | wind cooling |

FD-1-4-350 | 350 A | 60 Kw | 105Kw | IS05 | M10 | wind cooling |

FD-1-4-400 | 400A | 70 Kw | 120Kw | IS05 | M10 | wind cooling |

FD-1-4-450 | 450 A | 80 Kw | 135Kw | IS05 | M12 | wind cooling |

FD-1-4-500 | 500 A | 90Kw | 150Kw | IS06 | M12 | wind cooling |

FD-1-4-600 | 600 A | 100 Kw | 175Kw | IS07 | M12 | wind cooling |

FD-1-4-800 | 800 A | 120 Kw | 220Kw | IS07 | M12 | wind cooling |

FD-1-4-1000 | 1000A | 140 Kw | 300Kw | IS08 | M16 | Water cooling |

Master Temperature Control with a Power Regulator for Infrared Lamps

In the world of industrial heating, infrared (IR) lamps are renowned for their speed, efficiency, and clean energy transfer. However, the true potential of infrared heating is only unlocked with one critical component: a precision power regulator.

Whether you're involved in plastic welding, food processing, paint curing, or any application requiring thermal management, uncontrolled heat leads to inconsistent results, wasted energy, and damaged products. This is where a specialized power controller for infrared heating becomes indispensable.

A power regulator, often called a power controller or thyristor unit, is an electronic device that intelligently manages the electrical power delivered to a heating element—in this case, your infrared lamps.

Think of it as a highly sophisticated dimmer switch. Instead of simply turning the lamps on at full power or off completely, it can vary the voltage or use phase-angle control to deliver exactly the amount of energy needed to maintain a precise temperature. This precise management is the key to efficient and effective infrared heating.

Using a standard on/off switch with high-power IR lamps is like driving a car with only the accelerator and brake—you have no control over your speed. A dedicated power controller gives you the steering wheel and cruise control.

Here are the critical benefits:

A power regulator allows for exact temperature maintenance. This ensures every product receives the same amount of heat, leading to uniform curing, drying, or welding. The result? Superior, repeatable product quality and a drastic reduction in rejects.

By delivering only the necessary power to maintain temperature—rather than cycling full power on and off—a power controller for heating systems drastically reduces energy consumption. This "soft" management of power also reduces stress on the electrical grid and your facility's infrastructure.

Infrared lamps, like all halogens, are sensitive to thermal shock. The sudden inrush of current from a simple on/off cycle causes expansion and contraction, which shortens their life. A power regulator provides a soft start and eliminates harsh cycling, significantly extending the operational life of your expensive IR lamps.

Modern power controllers come with built-in protection features such as over-current, over-voltage, and short-circuit protection. This safeguards both your heating system and your personnel, ensuring a safer working environment and reducing downtime.

Our power regulators are ideal for a wide range of industrial processes, including:

Thermoforming and Plastic Welding

Paint Drying and Powder Coating Curing

Food Dehydration and Cooking Processes

Printing and Packaging Film Drying

Textile and Paper Drying

Laboratory and R&D Heating Setups

When selecting a power regulator for infrared lamps, consider these factors:

Load Type: Ensure the controller is compatible with resistive loads like IR lamps.

Control Mode: Do you need simple manual control, or integration with a PID temperature controller and thermocouple for a closed-loop system?

Current & Voltage Rating: The controller must be sized correctly to handle the total power (amperage and voltage) of your infrared heating array.

Features: Look for essential features like soft start, automatic bypass, and clear status indicators.

At Huaian Yinfrared Heating Tech, we specialize in providing robust and reliable power control solutions for industrial heating applications. We understand that your process is unique.

We supply high-performance power regulators and controllers designed specifically for the demands of infrared lamp heating. Our solutions are engineered to deliver:

Precise Temperature Management

Maximized Energy Efficiency

Durability in Industrial Environments

Seamless Integration with Your Existing Systems

Don't let imprecise temperature control compromise your product quality and bottom line.

Contact us today to discuss your application. Our technical experts will help you select the perfect power regulator to optimize your infrared heating process, improve efficiency, and ensure consistent results.

we can Produce the electric cabinet to control different heating zones .

Product characteristics

FD type power regulator has the following characteristics

Using the original imported CPU, high degree of digitization, work stability

Control motherboard adopted military circuit design and processing, safe and reliable

Application of original import parts for integrated circuits, quality assurance

New design concept, reasonable structure layout, fast and convenient installation

Single chip microcomputer is developed with independent embedded development system and has powerful function

The heat dissipation system has the characteristics of large heat dissipation area, small size of the whole machine, and high heat transfer ratio.

High precision PID temperature control module with high control precision Multiple communication functions

FD type electric regulator technical specifications

Master power supply | AC50V-AC1200V |

Control power. | AC220V |

Input Signal | 4-20mA/0-20mA/1-5V/0-10V/RS485 |

Output Mode | zero / phase shift output |

Output Mode | Power / current / voltage limit limit / constant current / constant voltage / constant power |

Load Type | Restraint / Sensibility |

Display Precision | 0.01% |

Control precision | 0.10% |

Cooling mode | cooling / water cooling |

Display Type | TFT color. LCD 2.4 / 4.3 / 7 inches |

Mode of communication |

|

Additional features | PID accurate temperature control |

Installation Method | Vertical Installation |

Number of alarm groups | 2 sets of relays output |

Variable output | 0-10V/4-20mA(apolegamy) |

Install Specification Index

Specification | Single phase | Three-phase | Size | Install size |

IS01 | (60-125) A | (30-50)A | 225*85*155 | 200*78 |

IS02 | (150-175) A | (60-125) A | 335*128*200 | 310*60 |

IS03 | (200-225) A | (150-175) A | 350*165*220 | 330*82 |

IS04 | (250-350) A | (200-225)A | 430*185*240 | 410*92 |

IS05 | (400-600) A | (250-350) A | 460*255*245 | 440*122 |

IS06 | (700-800)A | (400-600) A | 540*277*260 | 520*150 |

IS07 | (1000-1200) A | (700-800) A | 540*277*260 | 520*150 |

IS08 | / | (1000-1200) A | 640*330*260 | 620*170 |

Table of Specifications for Selection of Three-phase

Power Regulators

Model | Rated | 220V | 380V | Installation | Fixed | Cooling |

FD-5-4-020 | 020A | 5Kw | 12Kw | IS01 | M6 | Natural cooling |

FD-5-4-030 | 030 A | 6Kw | 15Kw | IS01 | M6 | wind cooling |

FD-5-4-040 | 040 A | 9 Kw | 18Kw | IS01 | M6 | wind cooling |

FD-5-4-050 | 050 A | 14Kw | 26Kw | IS01 | M6 | wind cooling |

FD-5-4-060 | 060 A | 16Kw | 30Kw | IS02 | M6 | wind cooling |

FD-5-4-075 | 075 A | 22Kw | 40Kw | IS02 | M6 | wind cooling |

FD-5-4-080 | 080 A | 25Kw | 43Kw | IS02 | M6 | wind cooling |

FD-5-4-100 | 100A | 32Kw | 56Kw | IS02 | M6 | wind cooling |

FD-5-4-125 | 125 A | 38Kw | 67 Kw | IS02 | M8 | wind cooling |

FD-5-4-150 | 150A | 45Kw | 80Kw | IS03 | M8 | wind cooling |

FD-5-4-175 | 175 A | 50Kw | 90Kw | IS03 | M8 | wind cooling |

FD-5-4-200 | 200 A | 55Kw | 100 Kw | IS04 | M8 | wind cooling |

FD-5-4-225 | 225 A | 68Kw | 120 Kw | IS04 | M8 | wind cooling |

FD-5-4-250 | 250 A | 75Kw | 145 Kw | IS04 | M8 | wind cooling |

FD-5-4-275 | 275 A | 82Kw | 150 Kw | IS05 | M8 | wind cooling |

FD-5-4-300 | 300 A | 89Kw | 160 Kw | IS05 | M10 | wind cooling |

FD-5-4-350 | 350 A | 108 Kw | 190 Kw | IS05 | M10 | wind cooling |

FD-5-4-400 | 400 A | 120 Kw | 220 Kw | IS06 | M10 | wind cooling |

FD-5-4-450 | 450 A | 135 Kw | 250 Kw | IS06 | M12 | wind cooling |

FD-5-4-500 | 500 A | 150Kw | 270Kw | IS06 | M12 | wind cooling |

FD-5-4-600 | 600 A | 180Kw | 330Kw | IS07 | M12 | wind cooling |

FD-5-4-800 | 800 A | 260 Kw | 450 Kw | IS07 | M12 | wind cooling |

FD-5-4-1000 | 1000 A | 450 Kw | 550 Kw | IS08 | M16 | Water cooling |

Specification for Type Selection of Single Phase Power Regulators

Model | Rated | 220V | 380V | Installation | Fixed | Cooling Mode |

FD-1-4-020 | 020A | 4Kw | 6Kw | IS01 | M6 | Natural cooling |

FD-1-4-030 | 030 A | 5Kw | 7 Kw | IS01 | M6 | wind cooling |

FD-1-4-040 | 040 A | 6 Kw | 9 Kw | IS01 | M6 | wind cooling |

FD-1-4-050 | 050 A | 7 Kw | 12 Kw | IS01 | M6 | wind cooling |

FD-1-4-060 | 060 A | 9 Kw | 18 Kw | IS01 | M6 | wind cooling |

FD-1-4-075 | 075 A | 14 Kw | 24 Kw | IS02 | M6 | wind cooling |

FD-1-4-080 | 080 A | 15 Kw | 26 Kw | IS02 | M6 | wind cooling |

FD-1-4-100 | 100 A | 18 Kw | 33 Kw | IS02 | M6 | wind cooling |

FD-1-4-125 | 125 A | 22 Kw | 37 Kw | IS02 | M8 | wind cooling |

FD-1-4-150 | 150A | 26 Kw | 45 Kw | IS02 | M8 | wind cooling |

FD-1-4-175 | 175 A | 30 Kw | 50 Kw | IS02 | M8 | wind cooling |

FD-1-4-200 | 200 A | 35 Kw | 62 Kw | IS03 | M8 | wind cooling |

FD-1-4-225 | 225 A | 38 Kw | 65 Kw | IS03 | M8 | wind cooling |

FD-1-4-250 | 250 A | 42 Kw | 75 Kw | IS04 | M8 | wind cooling |

FD-1-4-275 | 275 A | 47 Kw | 80 Kw | IS04 | M8 | wind cooling |

FD-1-4-300 | 300 A | 52 Kw | 90 Kw | IS04 | M10 | wind cooling |

FD-1-4-350 | 350 A | 60 Kw | 105Kw | IS05 | M10 | wind cooling |

FD-1-4-400 | 400A | 70 Kw | 120Kw | IS05 | M10 | wind cooling |

FD-1-4-450 | 450 A | 80 Kw | 135Kw | IS05 | M12 | wind cooling |

FD-1-4-500 | 500 A | 90Kw | 150Kw | IS06 | M12 | wind cooling |

FD-1-4-600 | 600 A | 100 Kw | 175Kw | IS07 | M12 | wind cooling |

FD-1-4-800 | 800 A | 120 Kw | 220Kw | IS07 | M12 | wind cooling |

FD-1-4-1000 | 1000A | 140 Kw | 300Kw | IS08 | M16 | Water cooling |