| Availability: | |

|---|---|

| Quantity: | |

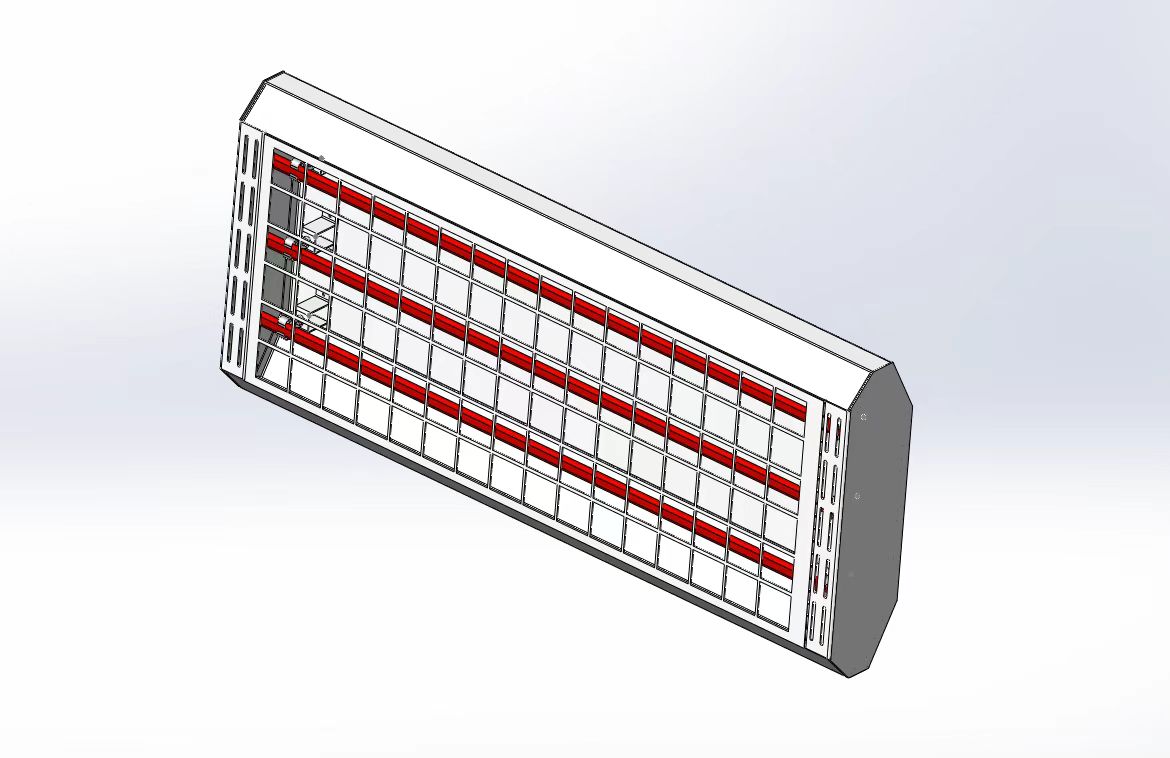

YFR3000SW

Yinfrared

Huaian yinfrared heating tech produce quality IR lamps for paint curing .

The YFR Difference in Infrared Curing Technology

YFR's infrared curing lamps are crafted with precision and expertise, harnessing advanced technology to optimize

paint curing processes across diverse applications. Here’s how YFR sets itself apart:

Advanced Engineering: YFR integrates cutting-edge engineering principles to design infrared curing lamps that

offer unparalleled efficiency and reliability. Each lamp is meticulously engineered to deliver consistent and uniform

heat distribution, ensuring optimal curing results.

Quality Materials: Utilizing high-quality materials and components, YFR ensures durability and longevity in every

infrared curing lamp. From robust housing to advanced heating elements, these lamps are built to withstand rigorous

industrial environments.

Customization Options: Recognizing the unique needs of various industries, YFR provides customizable options

for its infrared curing lamps. Whether adjusting wavelength specifications or designing portable models,

YFR ensures solutions that meet specific customer requirements.

Advantages of Choosing YFR's Infrared Curing Lamps

Enhanced Productivity: YFR's lamps accelerate curing times, optimizing production cycles and reducing downtime.

Cost Efficiency: By minimizing energy consumption and maximizing operational efficiency, YFR's lamps offer

significant cost savings over their lifespan.

Industry Applications: From automotive refinishing to aerospace coatings, YFR’s infrared curing lamps cater to

a wide range of applications, ensuring superior finish quality and durability.

Commitment to Sustainability and Innovation

YFR is dedicated to sustainability practices, designing energy-efficient infrared curing solutions that minimize environmental

impact while maximizing performance. By investing in research and development, YFR continues to innovate and

push the boundaries of infrared technology.

Partner with YFR for Your Curing Needs

Experience the difference with YFR's quality infrared curing lamps. Whether you're enhancing production efficiency

or upgrading your curing capabilities, YFR offers solutions that redefine industry standards. Contact us today to

explore how YFR can elevate your manufacturing processes with reliable and efficient infrared curing solutions.

Harnessing Efficiency and Precision: The Power of Infrared Paint Curing Lamps

In today's fast-paced manufacturing industry, achieving efficient production cycles without compromising on quality

is crucial. Enter infrared paint curing lamps, the cutting-edge technology revolutionizing paint curing processes

across various sectors.

Understanding Infrared Paint Curing Lamps

Infrared paint curing lamps utilize specialized infrared radiation to expedite the curing of paint coatings. Unlike

traditional methods reliant on convection or conduction, these lamps emit targeted heat directly onto painted

surfaces, accelerating the curing process while maintaining superior finish quality.

Benefits That Drive Industry Efficiency

Speed and Efficiency:Infrared paint curing lamps significantly reduce curing times compared to conventional methods. By

focusing

infrared heat precisely where it's needed, these lamps enhance production speed without compromising the

integrity of the paint finish.

Precision Heating:

The ability to control the wavelength and intensity of infrared radiation ensures precise heating tailored to

different paint types and thicknesses. This capability minimizes energy consumption and reduces operational

costs, making it a sustainable choice for modern manufacturing facilities.

Versatile Applications:

From automotive refinishing to aerospace coatings, infrared paint curing lamps find widespread application

across industries requiring rapid and efficient curing processes. They ensure uniform curing even on complex

surfaces, enhancing product durability and aesthetic appeal.

Advanced Features and Customization Options

Modern infrared paint curing lamps come equipped with a range of advanced features:

Adjustable Wavelengths: Tailor infrared radiation to match specific curing requirements and optimize energy efficiency.

Portable and Stationary Models:

Provide flexibility for use in different areas of the production line or workshop.

Integrated Controls:

Ensure precise temperature management and monitoring for consistent curing results.

Driving Innovation with Infrared Technology

Infrared paint curing lamps represent a significant advancement in paint curing technology, offering unmatched

efficiency, precision, and cost-effectiveness. Their ability to streamline production processes while reducing

environmental impact positions them as indispensable tools in today's competitive manufacturing landscape.

Conclusion

Embrace the future of manufacturing efficiency with infrared paint curing lamps. Whether enhancing automotive

paint durability or accelerating aerospace coating processes, these lamps empower industries to achieve more with

less. Discover how [Your Company Name]'s advanced infrared paint curing solutions can elevate your production

capabilities. Contact us today to explore customized solutions tailored to your specific needs.

we also supply reflector (lampshade) for target heating . the size and material can customized according to working temperature .

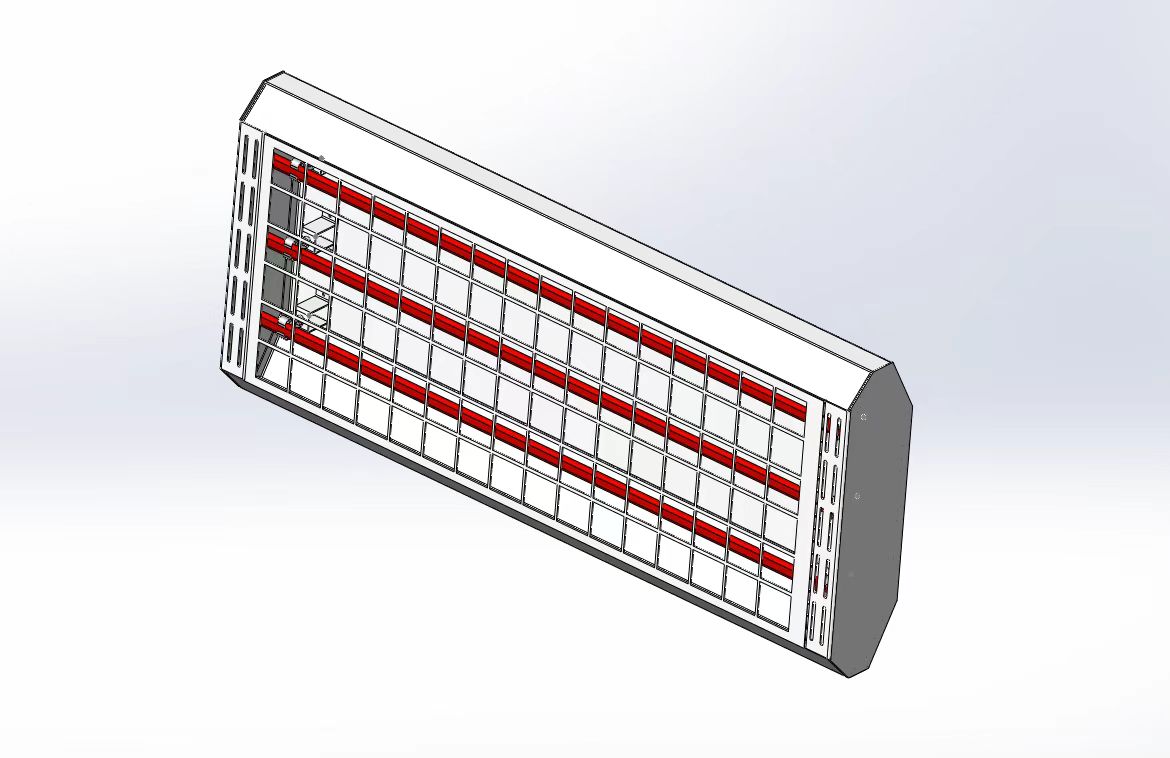

Huaian yinfrared heating tech produce quality IR lamps for paint curing .

The YFR Difference in Infrared Curing Technology

YFR's infrared curing lamps are crafted with precision and expertise, harnessing advanced technology to optimize

paint curing processes across diverse applications. Here’s how YFR sets itself apart:

Advanced Engineering: YFR integrates cutting-edge engineering principles to design infrared curing lamps that

offer unparalleled efficiency and reliability. Each lamp is meticulously engineered to deliver consistent and uniform

heat distribution, ensuring optimal curing results.

Quality Materials: Utilizing high-quality materials and components, YFR ensures durability and longevity in every

infrared curing lamp. From robust housing to advanced heating elements, these lamps are built to withstand rigorous

industrial environments.

Customization Options: Recognizing the unique needs of various industries, YFR provides customizable options

for its infrared curing lamps. Whether adjusting wavelength specifications or designing portable models,

YFR ensures solutions that meet specific customer requirements.

Advantages of Choosing YFR's Infrared Curing Lamps

Enhanced Productivity: YFR's lamps accelerate curing times, optimizing production cycles and reducing downtime.

Cost Efficiency: By minimizing energy consumption and maximizing operational efficiency, YFR's lamps offer

significant cost savings over their lifespan.

Industry Applications: From automotive refinishing to aerospace coatings, YFR’s infrared curing lamps cater to

a wide range of applications, ensuring superior finish quality and durability.

Commitment to Sustainability and Innovation

YFR is dedicated to sustainability practices, designing energy-efficient infrared curing solutions that minimize environmental

impact while maximizing performance. By investing in research and development, YFR continues to innovate and

push the boundaries of infrared technology.

Partner with YFR for Your Curing Needs

Experience the difference with YFR's quality infrared curing lamps. Whether you're enhancing production efficiency

or upgrading your curing capabilities, YFR offers solutions that redefine industry standards. Contact us today to

explore how YFR can elevate your manufacturing processes with reliable and efficient infrared curing solutions.

Harnessing Efficiency and Precision: The Power of Infrared Paint Curing Lamps

In today's fast-paced manufacturing industry, achieving efficient production cycles without compromising on quality

is crucial. Enter infrared paint curing lamps, the cutting-edge technology revolutionizing paint curing processes

across various sectors.

Understanding Infrared Paint Curing Lamps

Infrared paint curing lamps utilize specialized infrared radiation to expedite the curing of paint coatings. Unlike

traditional methods reliant on convection or conduction, these lamps emit targeted heat directly onto painted

surfaces, accelerating the curing process while maintaining superior finish quality.

Benefits That Drive Industry Efficiency

Speed and Efficiency:Infrared paint curing lamps significantly reduce curing times compared to conventional methods. By

focusing

infrared heat precisely where it's needed, these lamps enhance production speed without compromising the

integrity of the paint finish.

Precision Heating:

The ability to control the wavelength and intensity of infrared radiation ensures precise heating tailored to

different paint types and thicknesses. This capability minimizes energy consumption and reduces operational

costs, making it a sustainable choice for modern manufacturing facilities.

Versatile Applications:

From automotive refinishing to aerospace coatings, infrared paint curing lamps find widespread application

across industries requiring rapid and efficient curing processes. They ensure uniform curing even on complex

surfaces, enhancing product durability and aesthetic appeal.

Advanced Features and Customization Options

Modern infrared paint curing lamps come equipped with a range of advanced features:

Adjustable Wavelengths: Tailor infrared radiation to match specific curing requirements and optimize energy efficiency.

Portable and Stationary Models:

Provide flexibility for use in different areas of the production line or workshop.

Integrated Controls:

Ensure precise temperature management and monitoring for consistent curing results.

Driving Innovation with Infrared Technology

Infrared paint curing lamps represent a significant advancement in paint curing technology, offering unmatched

efficiency, precision, and cost-effectiveness. Their ability to streamline production processes while reducing

environmental impact positions them as indispensable tools in today's competitive manufacturing landscape.

Conclusion

Embrace the future of manufacturing efficiency with infrared paint curing lamps. Whether enhancing automotive

paint durability or accelerating aerospace coating processes, these lamps empower industries to achieve more with

less. Discover how [Your Company Name]'s advanced infrared paint curing solutions can elevate your production

capabilities. Contact us today to explore customized solutions tailored to your specific needs.

we also supply reflector (lampshade) for target heating . the size and material can customized according to working temperature .