Views: 0 Author: Site Editor Publish Time: 2025-08-26 Origin: Site

Industrial infrared oven alternatives for heat processing include electric heating, gas-fired ovens, convection systems, and specialized methods such as microwave and biofuel solutions. Each method serves distinct industrial needs. Electric heating offers precise temperature control and environmental benefits, making it popular for continuous processing. Gas ovens excel in high-temperature applications with cost-effective operation, especially in sectors like automotive and food processing. Selecting the right heat solution depends on material properties, process requirements, and operational priorities. Cost, efficiency, and application challenges vary by method, so decision-makers must carefully match technology to their unique processing demands.

Industrial heat processing offers many alternatives to infrared ovens, including radiant, convective, contact, direct-impingement, gas, hybrid, and direct-fired heating methods.

Radiant heat provides fast, energy-efficient, and precise surface heating with low maintenance and is ideal for applications like paint curing and food processing.

Convective heat uses hot air circulation to deliver uniform temperature, making it suitable for complex shapes and sensitive materials in industries like medical and electronics.

Contact heat transfers energy through direct contact with heated surfaces, offering precise control for flat materials such as plastics and packaging.

Direct-impingement heating uses high-speed jets to deliver rapid, uniform heat, improving process speed and energy efficiency, especially in metal processing.

Gas ovens excel in large-scale, high-temperature, continuous operations but require proper ventilation and maintenance to ensure safety and efficiency.

Hybrid ovens combine multiple heating technologies to reduce processing times, improve heat distribution, and support energy savings and sustainability goals.

Choosing the right heating method depends on factors like material compatibility, temperature needs, cost, efficiency, safety, and specific industrial applications.

Radiant heat stands out as a leading alternative to the industrial infrared oven. This method uses high-intensity ir heat to transfer energy directly to the surface of materials. Radiant heating systems, including advanced infrared emitters, deliver energy with remarkable efficiency and speed. These systems convert up to 88% of electrical energy into usable radiant heat, making them highly energy efficient. Operators can achieve rapid heating, precise temperature control, and zonal heating for targeted processing. The compact design and minimal maintenance requirements result from the absence of moving parts and reduced system complexity.

Key Features and Applications of Radiant Heat:

High energy efficiency and rapid response times.

Precise, uniform heat distribution with zonal control.

Compact size and quiet operation.

Environmentally friendly with no combustion byproducts.

Economical operation with significant energy savings.

Used in powder coating curing, paint drying, composite bonding, food processing, electronics manufacturing, wood finishing, and sterilization.

Supports heat shrinking, stress reduction, dehydration, and fabric de-wrinkling.

Radiant heat methods offer faster processing times and enhanced product quality compared to conventional ovens. Many industries, such as automotive, electronics, and food processing, rely on radiant heating for its flexibility and superior results. Infrared thermal processing, especially with advanced technologies like Yinfrared Short Wave Automotive Infrared Heat Lamps, provides precise, energy-saving solutions for automotive paint curing, plastic forming, and adhesive drying.

Convective heat represents another widely adopted alternative heating method for industrial applications. This process uses heated air, circulated by fans and adjustable dampers, to create ideal airflow and uniform temperature distribution. Convective ovens excel in versatility, handling a broad range of materials and part shapes. Industries such as bio-chemicals, chemical, public health, medical, automotive, aerospace, pharmaceutical, laboratory, electronics, transportation, food and beverage, printing, agriculture, semiconductor, and plastics frequently use convective heating.

Convection ovens provide several advantages over industrial infrared oven systems. They distribute heat evenly throughout the load, regardless of part shape or position. Forced convection ovens offer superior uniformity control, which is essential for sensitive processes in medical and chemical fields. Natural convection ovens heat faster and suit irregularly shaped parts. Operators can adjust airflow and temperature to match specific processing needs, making convection ovens ideal for powder coating, curing, drying, and heat treating. This adaptability and control make convective heat a preferred choice for many industrial processing environments.

Contact heat delivers energy directly to materials through physical contact with heated surfaces. This method uses heated plates, rollers, or belts to transfer heat efficiently. Contact heating excels in applications requiring precise temperature control and uniform processing, such as plastic welding, lamination, and sealing. Operators benefit from direct energy transfer, which minimizes heat loss and maximizes efficiency. Contact heat methods suit flat or consistently shaped materials, ensuring even heating across the surface. Industries such as plastics, packaging, and textiles often use contact heating for reliable, repeatable results.

Direct-impingement stands out among industrial heating alternatives for its ability to deliver rapid and uniform heat transfer. This method uses high-speed jets of a premixed fuel-air mixture, which exit through nozzles embedded in refractory walls and impinge directly onto the surface of the workpiece. The jets can reach velocities close to Mach 1, combining intense convective heat with radiant energy from the hot furnace walls.

Key Advantages of Direct-Impingement:

Eliminates the need for combustion chambers or flame holders, simplifying furnace design.

Delivers very high heat fluxes, ideal for fast processing of metals.

Reduces startup times from days to minutes, increasing operational efficiency.

Lowers NOx emissions by up to three times compared to traditional systems.

Improves heating uniformity and reduces fuel consumption.

Minimizes refractory material usage, lowering maintenance costs.

Industries such as metallurgy and materials processing rely on direct-impingement for heating metal bars and tubes before rolling or forging. The technology supports stable, efficient, and high-temperature environments, making it a preferred choice for applications where rapid and even heat distribution is critical.

Gas ovens remain a cornerstone in industrial heat processing, especially for large-scale and high-temperature operations. These ovens use natural gas or propane as the primary energy source, providing robust and flexible heating capabilities. Operators often choose gas ovens for continuous production lines that require consistent and powerful heat delivery.

Aspect | Gas Ovens | Electric Ovens |

|---|---|---|

Energy Efficiency | Up to 75% | 85-90% |

Operational Cost Factors | Fuel consumption, burner maintenance, regulatory inspections, gas connection costs | Mainly heating elements replacement, insulation checks |

Cost per Hour (Example) | €12/hour (220 kW at 350°C, 10 m³ oven) | €15/hour (180 kW at 350°C, 10 m³ oven) |

Suitability | Large volume, high temperature, continuous 24/7 production, sites with gas network | Intermittent use, smaller volumes |

Maintenance Complexity | Moderate to high (burner tuning, combustion control, inspections) | Low (heating elements, insulation) |

Heating Speed (Large Volumes) | Faster heating due to higher power density | Limited heating speed |

Maximum Power Capability | Very high | Limited |

Additional Costs | Gas network connection (€15,000-€50,000), safety systems, regulatory compliance | Minimal additional costs |

Cost Difference Over 10 Years | Typically less than 15% difference | Typically less than 15% difference |

Flexibility | Output modulation from 10% to 100% | Less flexible |

Operators can optimize gas oven performance by tuning burners, improving combustion air control, and upgrading insulation. Managing startup and shutdown cycles also reduces energy waste. Gas ovens excel in environments where high heat loads and continuous processing are essential. Their ability to deliver rapid heating and handle large volumes makes them indispensable in sectors such as automotive, food processing, and heavy manufacturing.

Hybrid ovens represent a modern approach to industrial heating by combining multiple technologies to maximize efficiency and product quality. These ovens often integrate infrared emitters with electric coils or direct gas-fired sections, creating a flexible system that adapts to various processing needs.

Hybrid ovens reduce baking and processing times by nearly 28%, supporting faster production cycles.

The combination of heating methods ensures uniform heat distribution and better moisture retention, which improves product consistency.

Modular designs allow operators to scale and adapt the oven to different products or batch sizes.

Energy management systems in hybrid ovens help industries meet sustainability goals by optimizing energy use.

Recipe-controlled burner systems enable quick product changes and flexible operation, which is valuable for diverse manufacturing environments.

Direct gas-fired sections can deliver high output, supporting demanding industrial production rates.

Hybrid ovens find applications in food processing, electronics, and materials manufacturing, where precise control over heat and processing speed is essential. By leveraging the strengths of different heating technologies, hybrid ovens offer a versatile solution for industries seeking to enhance efficiency, quality, and adaptability.

Direct-fired heating stands out as one of the most powerful and efficient industrial heat processing methods. This approach burns fuel directly within the heating chamber, releasing combustion gases into the same space as the material or air being heated. The result is nearly 100% fuel efficiency and extremely rapid temperature rise, making direct-fired systems ideal for applications that demand speed and deep heat penetration.

Operators often choose direct-fired heating for its ability to deliver intense, immediate heat. The method excels in scenarios where rapid whole-structure treatment is necessary. For example, pest control professionals use direct-fired heaters to eliminate bed bugs, termites, and cockroaches by quickly raising temperatures to lethal levels. Restoration specialists rely on this technology for structural drying after water damage, as it can penetrate building materials and reach target temperatures faster than other methods.

Key Advantages of Direct-Fired Heating:

Delivers almost instantaneous heat with minimal energy loss.

Simple system design reduces maintenance and operational costs.

Adaptable to a wide range of sizes and configurations.

Provides precise temperature control for demanding industrial processes.

Direct-fired heating finds use in commercial spaces such as restaurants, theaters, warehouses, and multi-unit housing complexes. The method also supports travel and hospitality environments, including aircraft, buses, cruise cabins, and hotels, where rapid and thorough heat treatment is essential.

However, direct-fired systems introduce combustion gases into the heated space. This characteristic requires proper ventilation to ensure safety, especially in enclosed or sensitive environments. Operators must consider the potential for toxic exhaust and the risk of product degradation when processing high-value or heat-sensitive materials. In these cases, indirect-fired or direct-heat rotary dryers may offer a better solution, as they separate combustion gases from the product.

The following table highlights the main differences between direct-fired and indirect-fired heating systems:

Feature | Direct-Fired Heating | Indirect-Fired Heating |

|---|---|---|

Combustion | Fuel burns directly; combustion gases released inside | Combustion occurs in heat exchanger; gases separated |

Efficiency | Nearly 100% fuel efficiency | Lower efficiency (about 70–85%) |

Heat Transfer | Direct flame contact with air or material | Heat transferred via heat exchanger; no flame contact |

Temperature Control | More precise temperature control | Less precise; heat varies within a few degrees |

Maintenance | Simpler design; easier and cheaper maintenance | More complex; higher maintenance costs |

Size and Customization | Highly adaptable; can be built to specific sizes | Fixed sizes; less customizable |

Safety and Ventilation | Requires ventilation due to toxic exhaust | No combustion byproducts released into heated space |

Suitable Environments | Not suitable for enclosed or sensitive spaces | Ideal for enclosed spaces and contamination-sensitive materials |

Typical Use Cases | Rapid heating, pest control, structural drying | Food processing, enclosed environments requiring clean air |

Direct-fired heating remains a top choice for industries that prioritize speed, power, and operational simplicity. Its ability to deliver immediate, high-intensity heat makes it indispensable for pest control, restoration, and large-scale industrial drying. However, operators must weigh the benefits against safety requirements and product sensitivity to ensure optimal results.

Radiant heat thermal processing relies on electromagnetic radiation, primarily in the infrared spectrum, to deliver energy directly to materials. Any object above absolute zero emits radiant energy, and the amount of energy increases rapidly as temperature rises. In industrial settings, radiant heat transfer becomes especially significant at temperatures above 700°C. The Stefan-Boltzmann law quantifies this relationship, showing that energy transfer depends on the temperature raised to the fourth power. This makes radiant heat ideal for high-temperature processing, such as in combustors and burners.

Radiant energy moves in all directions, allowing for homogeneous heat distribution. Engineers often select materials and fluids with high absorption properties to maximize energy transfer and minimize losses. For example, high carbon content fuels absorb more radiant energy than natural gas. Reflective media around heating vessels further reduce energy loss to the environment. Modern computational tools, such as Computational Fluid Dynamics (CFD), help design and control radiant heat transfer systems, ensuring precise and efficient thermal processing.

Industrial radiant heat systems use several types of thermal processing equipment. Common options include infrared emitters, quartz tube heaters, and ceramic panels. These devices generate and direct radiant energy toward the target material. Advanced systems, such as those used in automotive paint curing, employ short wave infrared lamps for rapid and uniform heating. Radiant panels and tube heaters often appear in applications requiring large-area coverage or zonal control.

Operators select equipment based on the specific heat transfer characteristics needed for their process. For example, quartz tube heaters provide fast response times and precise control, while ceramic panels offer durability and even heat distribution. The choice of equipment impacts the efficiency and quality of the radiant heat process, making it essential to match the system to the material and processing requirements.

Convective thermal processing uses moving air to transfer heat to materials. Industrial ovens achieve this by circulating hot air with fans, which ensures even temperature distribution throughout the chamber. Forced convection, created by centrifugal fans, enhances heat transfer by moving air at controlled speeds and configurations. Adjustments to air outlet placement and air volume reduce temperature gradients, which is critical for consistent processing results.

Uniform airflow prevents hot or cold spots, improving product quality and process reliability. Operators can fine-tune airflow systems to match the needs of different materials and batch sizes. This flexibility makes convection a preferred method for applications such as powder coating, curing, and baking.

Oven design plays a key role in the effectiveness of convective heat transfer. A single-zone convection system provides uniform heating for simple processes, while multi-zone ovens allow for precise temperature control across different sections. The structure of the oven, including insulation and air distribution, affects how well it maintains consistent temperatures.

Manufacturers often use fan-assisted ovens for industrial processing, as these promote even heat distribution and efficient energy use. The design of the oven must align with the specific requirements of the process, ensuring that all materials receive the necessary heat for optimal results.

Contact thermal processing involves direct transfer of heat from a heated surface to the material. Heated plates, rollers, or belts touch the material, delivering energy efficiently and minimizing heat loss. This method works best for flat or consistently shaped items, such as plastic sheets or packaging films. The direct contact ensures uniform heating across the surface, which is essential for processes like lamination, sealing, and welding.

Modern contact thermal processing equipment includes advanced control features to maintain precise temperature and pressure. Operators can adjust settings to match the material’s properties and the desired outcome. Sensors monitor surface temperatures and provide feedback to the control system, ensuring consistent results. These features help reduce waste, improve product quality, and increase process reliability.

Tip: For best results, select contact heat equipment with adjustable controls and real-time monitoring to optimize processing conditions.

Direct-impingement technology uses high-velocity fluid jets to transfer heat directly to surfaces. Engineers design these systems to disrupt the thermal boundary layer, increasing turbulence and enhancing convective heat transfer. Jet impingement delivers superior thermal performance compared to traditional methods. Industrial applications include cooling high-power density components, treating metals, and managing heat in turbine blades and electronic devices.

Aspect | Explanation |

|---|---|

Mechanism | High-velocity fluid jet directly impinges on heated surface, disrupting thermal boundary layer and increasing turbulence, enhancing convective heat transfer. |

Heat Transfer Modes | Effective in both single-phase and two-phase (boiling) heat transfer scenarios. |

Influencing Parameters | Jet velocity, Reynolds number, jet-to-surface distance, jet configuration, fluid properties (e.g., nanofluids). |

Surface and Combined Techniques | Surface modifications, hybrid structured surfaces, combination with pin fins or phase change materials improve performance. |

Industrial Applications | Cooling of high-power density components, turbine blades, solar air heaters, electronic devices, metal processing. |

Performance Improvement | Heat transfer enhancement up to 1.65 times; improved hydraulic performance compared to traditional methods. |

Research Methods | Experimental and numerical investigations support findings. |

Jet impingement systems allow for compact heat exchanger designs and energy savings. Both experimental and numerical studies confirm the effectiveness of this approach. Operators can adjust jet velocity and configuration to optimize heat transfer for specific industrial needs.

Uniform heating remains a critical advantage of direct-impingement technology. The high-speed jets distribute heat evenly across the target surface, minimizing temperature gradients. This uniformity ensures consistent product quality and reduces the risk of thermal damage. Industries rely on direct-impingement for processes that demand rapid and even heating, such as metal forging and electronic component manufacturing.

Tip: Operators should monitor jet configuration and surface characteristics to maintain optimal uniformity and maximize heat transfer rates.

Industrial gas ovens use advanced combustion systems to deliver reliable and efficient heat. Burner control methods include pulse firing, fuel-only control, proportional control, and mass flow control. Each system offers distinct advantages for temperature uniformity and fuel efficiency.

Control System Type | Description | Key Features and Applications | Considerations/Disadvantages |

|---|---|---|---|

Zero Control (Atmospheric) | Uses ambient air via venturi effect without air flow control | Simple, inefficient energy use | Inefficient combustion due to uncontrolled air flow |

Fuel-Only Control | Gas flow regulated; air supplied constantly by turbo fan | Economical, good temperature uniformity for uniform loads; suitable for low-temp furnaces and ceramics | High gas consumption due to heating all air regardless of load size |

Proportional Control | Air and gas controlled proportionally; flame size grows with temperature | Achieves optimal combustion and fuel use; suitable for aging, tempering, forging, normalizing | Initial temperature uniformity may be poor; not ideal for fragile parts |

Mass Flow Control | Controls air/gas ratio dynamically during combustion | Optimizes fuel use; allows air adjustment during stages; suitable for fragile products and various heat treatments | More expensive technology |

Pulse Control | Fixed air/gas ratio; burners cycle between high and low fire every 15–60 seconds | Provides immediate temperature uniformity; fuel efficient; suitable for fragile ceramics and various treatments | Flame radiation may affect products; additional controls can mitigate this |

Safety mechanisms in gas ovens include gas strainers, pressure regulators, automatic and manual shut-off valves, flame supervision systems, and purge cycles before ignition. These features ensure safe operation and efficient combustion control.

Temperature control in gas ovens relies on modulated valves, variable frequency drives, and remote emergency shut-off systems. Pulse firing achieves tight temperature uniformity and wide control ranges. Fuel-only control suits lower temperature applications, while on-ratio control supports higher temperatures. Operators select control systems based on process requirements, product sensitivity, and energy efficiency goals.

Note: Proper temperature control reduces energy consumption and maintains consistent product quality in industrial heat treatment.

Hybrid oven systems integrate multiple heating technologies to optimize industrial heat processing. Manufacturers combine electric, gas, and infrared heating to enhance adaptability and efficiency. Hybrid electricity/gas ovens use rapid electric heating for initial temperature rise and economical gas maintenance for sustained operation. This approach reduces energy costs by 15–25%, depending on local rates.

Hybrid ovens blend gas, electric, and infrared heating for flexible operation.

These systems adapt to fluctuating energy prices and support sustainability goals.

Hybrid process heating enables waste heat recovery and process energy optimization.

Hybrid ovens serve diverse industrial applications. Lambda Technology's hybrid oven system, for example, integrates near-infrared and infrared radiation with recirculating air and nozzle air. The system recycles waste heat, improving energy efficiency by up to 80%. Operators control heat input, air flow, humidity, and solvent removal with precision, optimizing drying and curing processes.

Hybrid ovens suit industries requiring targeted heat input and efficient energy use.

Warm exhaust air recirculation utilizes otherwise wasted heat.

Air movement aids in drying and removing volatile substances from substrates.

Hybrid oven technology continues to evolve, offering manufacturers versatile solutions for complex thermal processing needs.

Industrial decision-makers often evaluate thermal processing methods based on how effectively each system converts energy into usable heat. Efficiency directly impacts operational costs, environmental footprint, and production timelines. Infrared heating systems, such as those used in automotive paint curing, deliver rapid and targeted heat. These systems convert up to 95% of input energy into radiant heat, minimizing waste and reducing warm-up times to just a few minutes. Gas heating systems, while robust and suitable for high-volume operations, typically achieve 80–90% efficiency. Electric resistance heaters reach 100% energy conversion but often result in higher running costs due to the price of electricity.

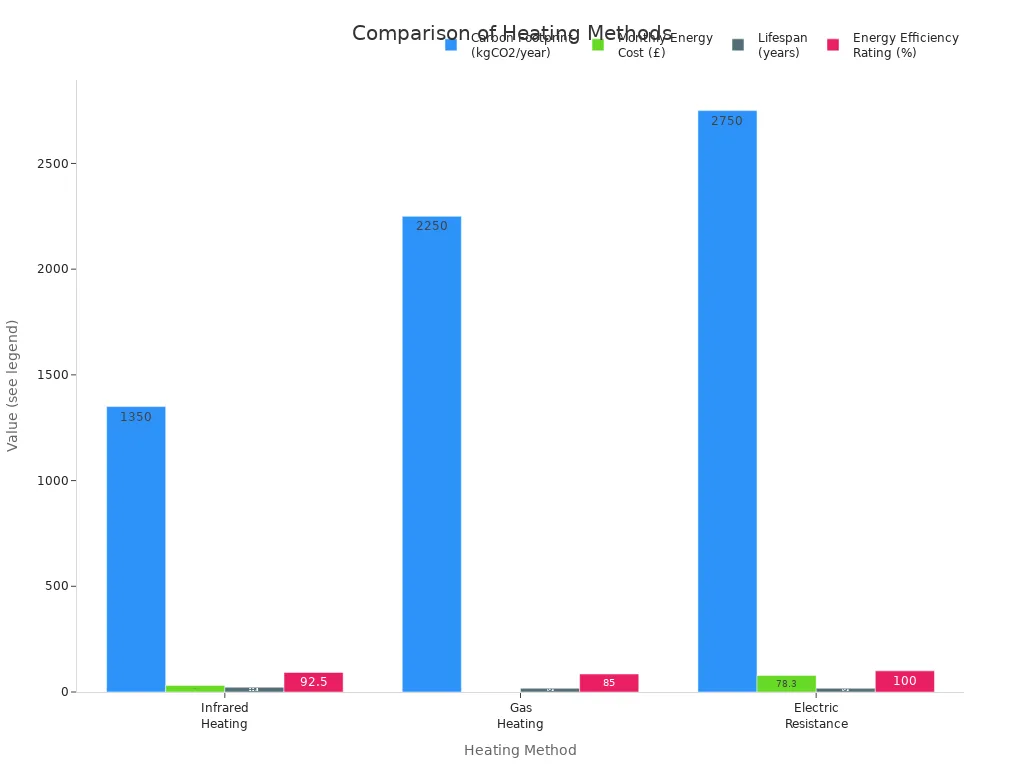

The following table compares the efficiency, energy consumption, carbon footprint, lifespan, and monthly energy cost of major industrial heating methods:

Heating Method | Energy Efficiency Rating | Energy Consumption Compared to Infrared | Carbon Footprint (kgCO2/year) | Lifespan (years) | Monthly Energy Cost (Example) |

|---|---|---|---|---|---|

Infrared Heating Systems | 90-95% | Baseline (30-50% less than conventional) | 1,200 - 1,500 | 20-25 | £31.32 (600W, 6 hrs/day) |

Gas Heating Systems | 80-90% | Higher energy use | 2,000 - 2,500 | 15-20 | N/A |

Electric Resistance Heaters | 100% (energy conversion) | Higher cost despite efficiency | 2,500 - 3,000 | 15-20 | £78.30 (1500W, 6 hrs/day) |

Infrared systems stand out for their ability to heat objects directly, reducing energy lost to the surrounding air. This characteristic leads to lower energy bills and a smaller carbon footprint. In automotive manufacturing, Yinfrared’s Short Wave Automotive Infrared Heat Lamps demonstrate how high efficiency translates into faster curing times and improved product quality.

Selecting the right thermal processing methods depends on the compatibility between the heating technology and the materials involved. Infrared heating works best with surfaces that absorb radiant energy efficiently, such as metals, plastics, and coated substrates. This method excels in applications like automotive paint curing, plastic forming, and adhesive drying, where precise surface heating is critical.

Gas ovens and direct-fired systems handle large volumes and high-mass materials, including metals and ceramics. These methods suit processes that require deep heat penetration or continuous operation. Electric resistance heaters provide uniform heating for sensitive materials, such as electronic components and specialty polymers, where tight temperature control is essential.

Hybrid ovens offer flexibility by combining multiple heating technologies. Manufacturers can process a wide range of materials, from food products to advanced composites, by adjusting the heating profile to match specific requirements. Direct-impingement systems deliver rapid and uniform heating for metals and high-density materials, making them ideal for forging and heat treatment.

Tip: Always match the thermal processing method to the material’s absorption characteristics and the desired end-use properties to ensure optimal results.

Cost considerations play a major role in selecting industrial heating solutions. Initial installation expenses, ongoing operational costs, and maintenance requirements all contribute to the total cost of ownership. Infrared heating systems often require a higher upfront investment due to specialized emitters and control systems. However, their lower energy consumption and longer lifespan can offset these costs over time.

Gas ovens typically involve moderate installation costs but may require additional infrastructure, such as gas lines and safety systems. Operational costs depend on fuel prices and maintenance needs, including burner tuning and combustion control. Electric resistance heaters have straightforward installation but can lead to higher monthly energy bills, especially in regions with expensive electricity.

Thermal batteries, a newer alternative, illustrate the balance between capital and operational expenses. Their levelized cost of heat ranges from $20 to $87 per megawatt hour, with 20–40% attributed to installation and equipment, and 60–80% to ongoing electricity costs. Some manufacturers now offer thermal batteries as a service, shifting capital expenses into recurring service fees.

Hybrid ovens and direct-impingement systems may require more complex installation but can deliver significant energy savings and process flexibility. Over time, the choice of thermal processing methods should reflect not only the initial investment but also the long-term operational and maintenance costs.

Note: Evaluating both short-term and long-term costs ensures that the selected heating method aligns with production goals and budget constraints.

Industrial operators encounter several application challenges when implementing alternative heating methods for heat processing. Each technology presents unique obstacles that require careful consideration and strategic planning.

Electric heat pumps demand a significant increase in renewable electricity supply. Operators must expand infrastructure to meet projected growth, which can strain existing resources.

Green hydrogen, biomass, and solar thermal power introduce resource demands. These methods require access to renewable electricity, large land areas, and advanced heat storage solutions. Operators often face high costs and logistical hurdles when scaling these technologies.

Geothermal heat depends on suitable geological sites. Exploration involves risk and requires substantial capital investment. Not every location offers the necessary conditions for geothermal systems.

Power-to-Heat devices rely on a consistent supply of green electricity. Operators must ensure grid stability, especially during peak load management, to maintain reliable performance.

Heat storage technologies help balance supply and demand. However, these systems typically incur high levelized costs of heat production, which can impact overall project viability.

Economic challenges include capital expenditure, operational costs, and fuel expenses. Operators must conduct detailed technoeconomic assessments to determine the feasibility of each method.

Technological complexity, resource scarcity, and infrastructure investment present ongoing challenges. Local economic factors also influence the adoption and success of alternative heating solutions.

Industrial processes such as electrified adsorption face additional hurdles. Operators must achieve uniform heating of adsorption beds, develop rapid desorption and cooling cycles, and optimize power-to-heat transformation efficiency. Technoeconomic and life-cycle analyses play a critical role in assessing the viability of these advanced processes.

Tip: Operators should evaluate both technical and economic factors before selecting an alternative heating method. A thorough assessment ensures that the chosen solution aligns with production goals and resource availability.

Industrial heating methods vary widely in their environmental impact. Operators must consider emissions, energy consumption, and overall sustainability when selecting a thermal processing solution.

Electric infrared heaters produce no direct emissions during operation. These systems deliver heat directly to materials, minimizing energy loss and maximizing efficiency. The environmental footprint of infrared heating depends on the electricity generation mix. When powered by renewable energy sources, infrared heaters offer a clean and sustainable option for industrial applications.

Gas ovens and heaters emit greenhouse gases such as methane and nitrogen oxides. These emissions contribute to indoor air pollution and climate change. Operators must implement ventilation systems to manage air quality and reduce health risks. Propane heaters also release greenhouse gases and require careful fuel management.

Wood-fired heaters present a mixed environmental profile. While wood can be a sustainable fuel source, these heaters produce emissions and demand ongoing fuel management. Operators must balance sustainability with operational requirements.

Hybrid heating systems, which combine infrared and hot air, demonstrate improved energy efficiency. Research shows that optimizing infrared radiation intensity and airflow can significantly reduce drying time and energy consumption. Advanced control systems, including artificial intelligence, further enhance thermal efficiency and lower energy use compared to conventional methods.

Infrared heating methods stand out for their ability to reduce harmful gas emissions. These systems do not burn fuel, eliminating the release of carbon monoxide, nitrogen dioxide, and formaldehyde. Infrared cooktops and heaters consume less energy due to direct heating and faster processing times. Switching to infrared heating improves indoor air quality and reduces global energy waste.

Heating Method | Direct Emissions | Energy Efficiency | Air Quality Impact | Sustainability Potential |

|---|---|---|---|---|

Electric Infrared | None | High | Improves | High (with renewables) |

Gas Ovens | Yes | Moderate | Reduces | Moderate |

Propane Heaters | Yes | Moderate | Reduces | Low |

Wood-Fired Heaters | Yes | Variable | Reduces | Variable |

Hybrid Infrared/Hot Air | Minimal | High | Improves | High |

Operators who prioritize sustainability and energy efficiency should consider electric infrared and hybrid heating systems. These technologies offer significant reductions in emissions and energy consumption, supporting cleaner and more responsible industrial practices.

Selecting the best heating method for industrial heat processing begins with a thorough needs assessment. Decision-makers evaluate several factors to ensure the chosen solution aligns with production goals and material requirements. They start by defining the application and environment, such as drying, curing, or bonding. The choice between batch or continuous product load influences oven design and throughput. Chamber size must match product dimensions and expected production volume.

Temperature requirements play a critical role. Operators identify the necessary temperature range and uniformity for optimal quality. For convection ovens, airflow type affects heat distribution and process consistency. Design and construction requirements, including integration with automation and safety systems, must be considered. Special processing needs, such as programmable recipes or real-time monitoring, often dictate control system selection.

A comprehensive needs assessment includes:

Temperature range required for the process or material

Heating technology options based on energy availability and application

Chamber size and throughput to match production volume

Control systems for digital management and monitoring

Integration capabilities with existing workflow and safety systems

Service and support reputation of suppliers

Compliance with industry standards and safety features

Operators also evaluate suppliers by researching capabilities, requesting quotes, and checking references. Certification compliance with OSHA, ISO, and other regulations ensures safe and reliable operation. Expert consultation, such as with Yinfrared, helps tailor solutions to specific requirements, supporting optimal performance and long-term reliability.

Effective process control determines the success of industrial heat processing. Operators rely on advanced control systems to maintain precise temperature, airflow, and timing. Digital controls and programmable logic controllers (PLCs) enable real-time monitoring and adjustment. Recipe management allows for consistent results across multiple production runs.

Modern heating systems offer features such as:

Programmable temperature profiles

Automated safety interlocks

Remote monitoring and diagnostics

Data logging for process optimization

These capabilities support repeatable quality and reduce human error. Integration with factory automation streamlines workflow and enhances productivity. Operators select control systems that match the complexity of their process and the sensitivity of their materials.

Maintenance plays a vital role in the life cycle cost and reliability of industrial heating systems. Operators schedule regular inspections and servicing to prevent unexpected downtime. Gas ovens and boilers require burner tuning, combustion control checks, and safety system verification. Electric heating systems need periodic replacement of heating elements and insulation checks.

Air source heat pumps and solar hot water systems tend to have lower maintenance costs compared to gas boilers, although they may incur higher initial capital expenses. Replacement costs for mechanical and electrical components represent significant refurbishment investments. Operators consider maintenance requirements when selecting a heating method, balancing upfront costs with long-term reliability.

Routine maintenance ensures consistent performance and extends equipment lifespan. Suppliers with strong technical support and spare parts availability contribute to reduced downtime and improved operational efficiency.

Industrial heat processing environments demand a strong focus on safety. Each alternative heating method introduces unique risks and requires specific controls to protect workers and facilities. Operators must understand these risks and implement robust safety measures to maintain a secure workplace.

Thermal health management forms the foundation of safety in industrial settings. Effective core temperature regulation and heat dissipation prevent physiological strain on workers. International and national standards, such as DIN EN ISO 15265 and GBZ 1-2010, provide guidelines for assessing heat exposure and designing safe thermal environments. The World Health Organization also offers recommendations for managing heat-related health risks. These frameworks help organizations set occupational exposure limits and develop industrial HVAC systems that support worker safety and comfort.

Heating equipment selection plays a critical role in minimizing hazards. Explosion-proof electric heaters use reinforced enclosures to prevent ignition of flammable gases or dust. These devices comply with standards like ATEX or IECEx, making them suitable for hazardous locations. Hazardous location fan heaters feature enclosed motors and heating elements, which prevent sparks or high temperatures from escaping. This design ensures safe operation in large industrial spaces. Self-regulating heating cables adjust their output based on ambient temperature, reducing the risk of overheating. These cables are essential for preventing pipe freeze in hazardous zones. Convection heaters designed for hazardous areas use sealed elements to avoid contact with flammable materials, providing even heat distribution without direct air movement.

Tip: Always verify that heating equipment meets relevant safety certifications for the intended environment.

A comprehensive approach to safety includes both engineering controls and workplace practices. Organizations should establish a Heat Illness Prevention Program (HIPP) that covers risk assessment, medical monitoring, emergency response, and worker training. Regular workplace evaluations help identify heat sources and environmental factors that contribute to heat stress. Medical monitoring, such as pre-season screening and core temperature checks, supports early detection of health risks. Emergency action plans prepare teams to respond quickly to heat-related incidents, including first aid and evacuation procedures. Ongoing education ensures that workers and supervisors can recognize and prevent heat stress. Open communication channels encourage early reporting of symptoms and feedback on safety measures.

The following table summarizes key safety features for common industrial heating methods:

Heating Method | Key Safety Features | Typical Certifications |

|---|---|---|

Explosion-Proof Electric Heaters | Reinforced enclosures, spark prevention | ATEX, IECEx |

Hazardous Location Fan Heaters | Enclosed motors/elements, spark containment | UL, CSA, ATEX |

Self-Regulating Heating Cables | Output adjustment, overheat prevention | IEC, UL |

Convection Heaters (Hazardous) | Sealed elements, indirect heat distribution | CE, ATEX |

Safety remains a top priority in industrial heat processing. By selecting certified equipment, following established standards, and maintaining strong workplace programs, organizations can protect both people and assets. Consulting with experts or manufacturers, such as Yinfrared, ensures that safety considerations align with operational needs and regulatory requirements.

Automotive manufacturers rely on a range of alternative heating methods to achieve precise and efficient thermal processing. Forced convection ovens handle tasks such as annealing, baking, curing, drying, powder coating, and preheating. These ovens deliver improved speed and uniformity. Gas-fired models heat faster and offer greater adjustability, which reduces operational costs. Contact thermal systems provide zonal control for annealing and thermoforming, although they may not suit adhesive processes due to sticking issues. Infrared heating stands out for drying inks, flash curing, and activating adhesives on surfaces. This method proves effective for surface treatments and can activate adhesives on carpet backsides without damaging the visible surface. Radiant heat methods target thick parts and plastics, such as polycarbonates, and often combine with infrared to optimize processing for complex materials.

Heating Method | Common Automotive Applications | Reported Results and Considerations |

|---|---|---|

Forced Convection | Annealing, baking, curing, drying, powder coating, preheating | Improves speed and uniformity; gas-fired ovens heat faster, more adjustable, and cheaper. |

Contact Thermal | Annealing, curing, thermoforming ovens | Precise zonal control; less energy efficient; not ideal for adhesives; sometimes replaced by convection or IR. |

Infrared (IR) | Drying inks/liquids, flash curing, activating adhesives | Effective for surface treatments; activates adhesives on carpet backsides without surface damage. |

Radiant Heat | Thick parts, plastics, combined radiant/IR for carpets | Suitable for thick parts; combined radiant and IR optimize processing for different material sides. |

Yinfrared’s Short Wave Automotive Infrared Heat Lamps play a key role in automotive paint curing, plastic forming, adhesive drying, and component testing. These lamps provide fast, uniform heating, which reduces curing times and improves product quality. Automotive plants benefit from the flexibility of portable and wall-mounted infrared lamps, which support both small repairs and large-scale production.

Food processing facilities increasingly adopt alternative heating methods to improve product quality and operational efficiency. Infrared heating uses radiation to transfer heat rapidly, penetrating 2–3 millimeters into food. This approach heats both the surface and center efficiently. The result is high energy efficiency, rapid heating, and better nutrient preservation. Infrared systems also feature compact equipment size and environmental friendliness.

Microwave heating excites water molecules within food, delivering fast internal heating. However, it may not produce the desired surface browning or texture when used alone. Hybrid infrared-microwave ovens combine the strengths of both methods. The microwave component heats food quickly, while the infrared element ensures surface browning and crisping. This combination leads to more homogeneous cooking, improved texture, and color similar to conventional ovens.

Heating Method | Mechanism and Use in Food Processing | Benefits over Traditional Infrared Ovens |

|---|---|---|

Infrared Heating | Rapid heat transfer via radiation; penetrates 2–3 mm into food; heats surface and center efficiently | High energy efficiency, rapid heating, improved product quality, nutrient preservation, environmental friendliness, small equipment size |

Microwave Heating | Uses electromagnetic waves to heat food quickly by exciting water molecules | Faster heating but may cause poor surface browning and texture if used alone |

Hybrid Infrared-Microwave Oven | Combines microwave rapid heating with infrared surface browning and crisping | More homogeneous cooking, improved texture and color, eliminates poor baking quality of microwave alone |

Food processors select the heating method based on the desired product characteristics. Hybrid systems address the limitations of single-method ovens, delivering consistent results and supporting a wide range of food products.

Electronics manufacturing demands precise thermal control to ensure product reliability and performance. Infrared heating systems excel in soldering, drying coatings, and curing adhesives on circuit boards. These systems deliver targeted heat, which minimizes thermal stress on sensitive components. Forced convection ovens support reflow soldering and component drying, providing uniform temperature distribution across complex assemblies. Contact heating methods, such as hot plates, serve in bonding and lamination processes for flexible circuits and display panels.

Manufacturers often use hybrid ovens to combine the benefits of infrared and convection heating. This approach enables rapid ramp-up and uniform heat distribution, which is critical for high-throughput production lines. Advanced control systems monitor temperature and airflow, ensuring consistent quality and reducing the risk of defects. Electronics producers select the appropriate heating technology based on component sensitivity, throughput requirements, and desired end-product characteristics.

Plastics processing industries demand precise and efficient heat management to ensure high-quality products. Manufacturers use a variety of alternative heating methods to meet these requirements. Radiant heat, convection, and hybrid systems have become essential in modern plastics manufacturing plants.

Radiant heating, especially with advanced short wave infrared lamps, delivers targeted energy directly to plastic surfaces. This approach enables rapid heating and precise temperature control. Operators can achieve uniform softening, welding, or bending of plastic sheets and components. Yinfrared’s Short Wave Automotive Infrared Heat Lamps provide a reliable solution for processes such as plastic forming, welding, and bending. These lamps offer fast response times and energy savings, which help reduce production cycle times and operational costs.

Convection ovens play a key role in applications that require even heat distribution across large or irregularly shaped plastic parts. Forced air systems ensure that every section of the material reaches the desired temperature. This uniformity is critical for processes like thermoforming and annealing, where temperature consistency affects product strength and appearance.

Hybrid ovens combine the strengths of radiant and convective heating. These systems allow operators to fine-tune the heating profile for complex plastic assemblies. Hybrid technology supports faster throughput and improved product consistency, making it ideal for high-volume manufacturing environments.

Innovative methods such as catalytic pyrolysis have transformed the way industries handle plastic waste. This process breaks down plastic in an oxygen-free environment, producing high-quality raw materials suitable for demanding applications. Rotary kiln technology processes large volumes of waste efficiently, converting it into valuable outputs like pyrolysis oil and reclaimed polycarbonate. These materials meet strict performance standards in sectors such as automotive, electronics, construction, and medical devices. Catalytic pyrolysis reduces energy consumption and CO2 emissions by up to 60% compared to traditional recycling, supporting sustainability goals.

Injection molding has also seen significant advancements. Many manufacturers now use fully electric, hybrid, or electro-mechanical machines instead of traditional hydraulic or pneumatic systems. These modern machines increase processing speed and energy efficiency. As a result, plastics manufacturers can optimize production while lowering energy costs.

Tip: Selecting the right heating method for plastics processing depends on the material type, product design, and desired performance characteristics. Consulting with experienced suppliers ensures the best match for specific applications.

Alternative heating technologies continue to drive progress in plastics manufacturing. They enable higher efficiency, better product quality, and more sustainable operations across the industry.

Industrial infrared ovens deliver direct, targeted heating, resulting in fast startup, precise temperature control, and energy savings. Convection systems provide uniform heat distribution, making them ideal for complex assemblies and mixed materials. Operators should consider temperature range, control precision, cost, throughput, and special material requirements when selecting a thermal processing method. Consulting with experienced manufacturers ensures solutions match specific needs. Evaluating cost, efficiency, and suitability helps organizations achieve optimal results for both small-scale and large-scale projects.

Infrared heating transfers energy directly to the material’s surface. Convection heating uses moving air to distribute heat throughout the chamber. Infrared systems heat faster and more efficiently, while convection ovens provide uniform temperature for complex or irregularly shaped items.

A manufacturer should select a hybrid oven for processes that require both rapid heating and uniform temperature control. Hybrid ovens combine technologies, allowing operators to optimize energy use, improve product quality, and adapt to different materials or batch sizes.

Gas ovens work best in large-scale, high-temperature, or continuous operations. Facilities must have proper ventilation and access to a gas supply. Operators should consider safety regulations and maintenance requirements before choosing gas ovens for sensitive or enclosed environments.

Direct-impingement heating uses high-velocity jets to deliver intense, uniform heat directly to the material. This method reduces startup times and increases throughput. Industries such as metallurgy benefit from faster processing and improved energy efficiency.

Operators should prioritize equipment with certified enclosures, automatic shut-off systems, and temperature monitoring. Explosion-proof designs and compliance with standards like ATEX or IECEx ensure safe operation in hazardous or flammable environments.

Yes. Methods such as infrared and hybrid ovens often lower energy consumption by delivering targeted heat and reducing warm-up times. Operators can achieve significant savings on operational costs and improve sustainability by selecting efficient heating technologies.

Material compatibility ensures that the chosen heating method delivers the desired results without damaging the product. Different materials absorb and respond to heat in unique ways. Selecting the right technology improves quality, reduces waste, and extends equipment life.

Yinfrared offers customizable Short Wave Automotive Infrared Heat Lamps. The company provides tailored solutions, including custom lengths, power ratings, and accessories. Their technical support helps manufacturers integrate advanced heating systems for specific industrial applications.

content is empty!