| Availability: | |

|---|---|

| Quantity: | |

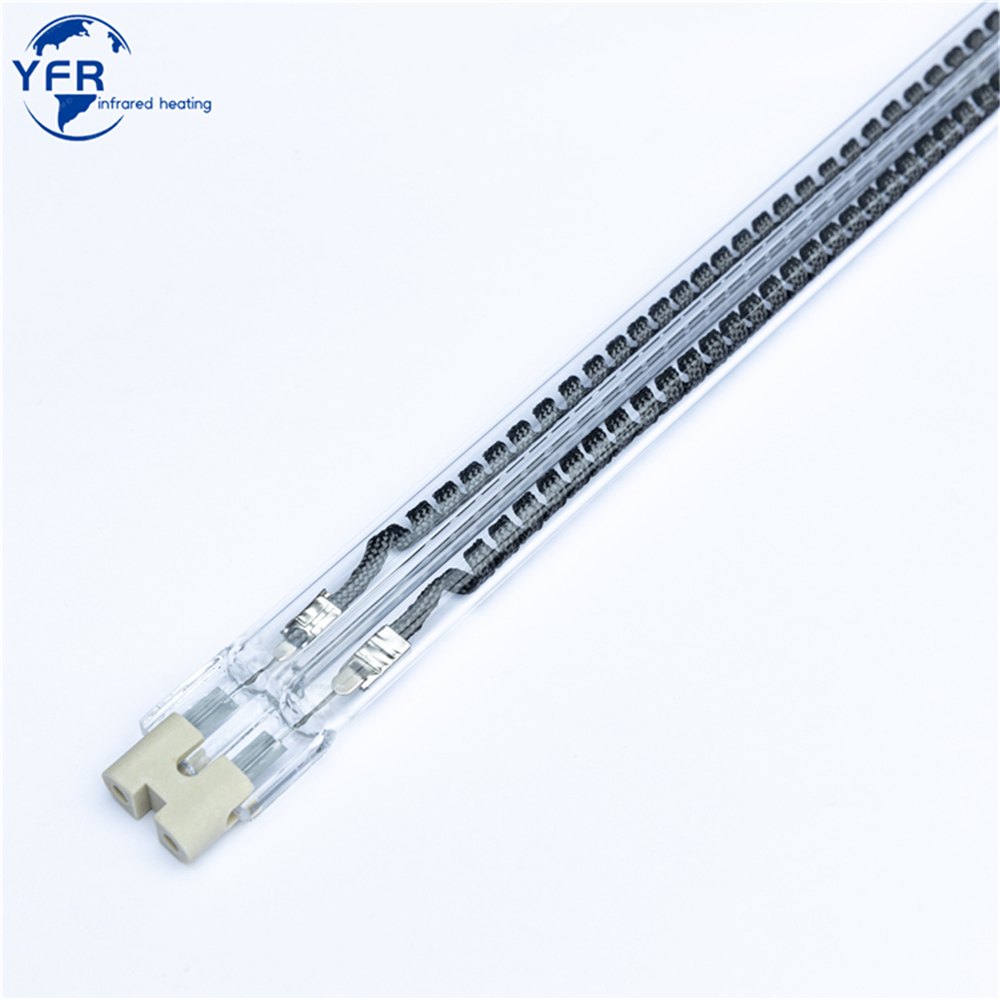

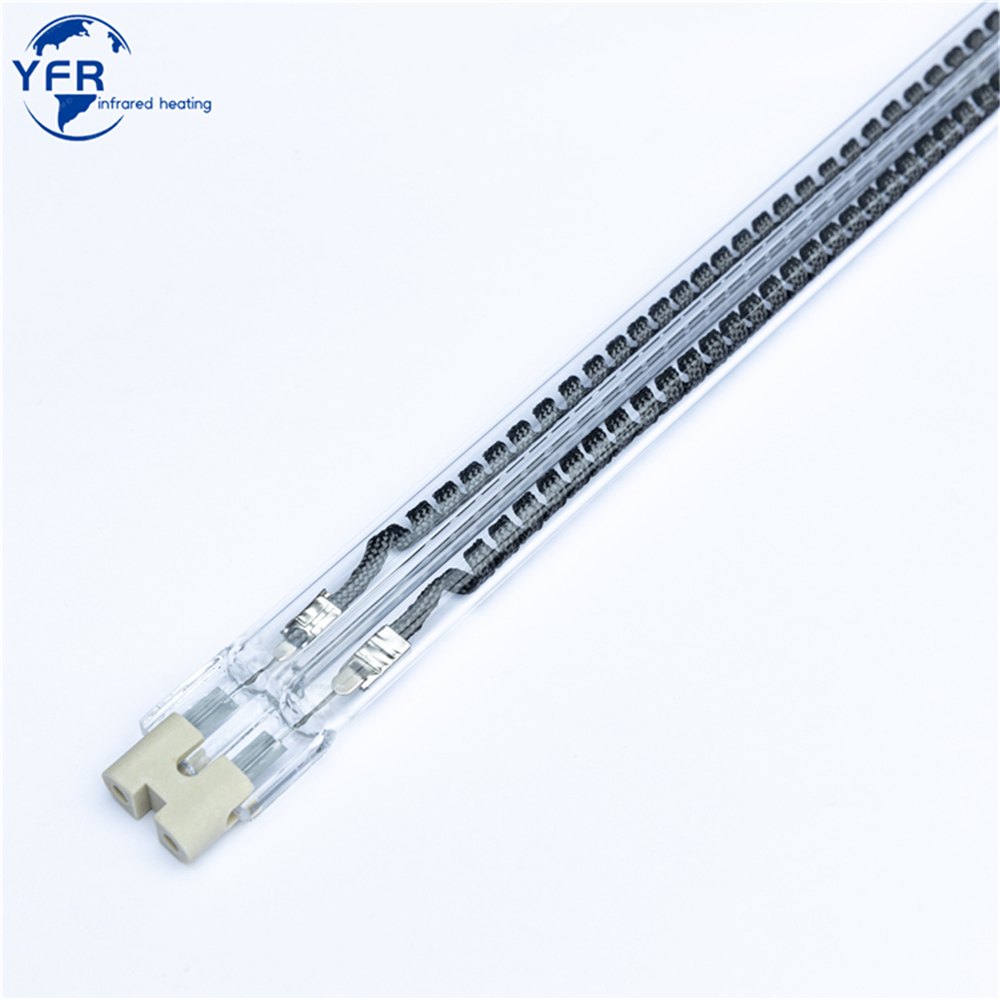

YFR1500CIR

Yinfrared

In the competitive world of PET bottle manufacturing, precise heating is not just a step. More importantly, it is a key factor in quality, speed, and profit.

Enter carbon infrared lamps. This advanced heating technology is quickly replacing traditional quartz IR systems in modern blow molding operations. Here’s why these lamps are becoming the gold standard for preform heating.

Carbn IR lamps produce far-infrared radiation with a wavelength of 3 to 10 micrometers. This radiation goes deeper into PET preforms than short or medium-wave options. This delivers:

Uniform Thermal Distribution: Eliminates hot spots, ensuring consistent material expansion.

Reduced Surface Overheating: Prevents PET yellowing or degradation.

30% Faster Heat-Up Times: Direct energy transfer slashes cycle times.

Energy Efficiency

Carbon filaments change over 95% of electricity into specific infrared radiation. This reduces energy costs by 25 to 40% compared to metal-filament lamps.

Longer Lifespan

With no tungsten degradation, carbon lamps last 15,000–20,000 hours (2–3× quartz IR), minimizing downtime.

Precision Zone Control

Adaptive wavelength output adjusts to preform thickness/color variations. Operators fine-tune heating profiles for:

Base/thick sections → Deeper penetration

Thin necks → Gentle surface heating

Cooler Operation

Surface temperatures run 30% lower than quartz lamps, reducing cooling demands and factory ambient heat.

Eco- adaptability

Zero heavy metals (lead/mercury-free) and fully recyclable. Aligns with ESG-driven manufacturing.

| Feature | Carbon IR Lamps | Quartz IR Lamps |

| Wavelength | Far-infrared (3–10 μm) | Short-wave (0.8–1.4 μm) |

| Penetratio | Deep and uniform | Surface-focused |

| Lifespan | 15,000–20,000 hours | 5,000–10,000 hours |

| Energy Use | 25–40% lower | Higher baseline |

| Heat Signature | Lower surface temperature | Extreme radiant heat |

Integration in Blow Molding Machines: Best Practices

Reflector Design: Parabolic aluminum reflectors maximize focus on preforms.

Closed-Loop Control: Pair with pyrometers for real-time temperature feedback.

Modular Zones: Group lamps by preform height (base/body/neck) for gradient heating.

Maintenance: Quarterly reflector cleaning + annual electrical checks sustain peak efficiency.

Installation Precautions & Safety Guidelines

To ensure optimal performance and longevity, follow these best practices:

Handle Lamps Properly: When installing new bulbs, always use a cloth or gloves. Oils from bare hands can shorten lamp life.

Mounting Height Matters: Because carbon IR lamps emit intense heat, position them higher than conventional quartz units. This allows for even heat dispersion and prevents hot spots. Never allow direct access by personnel or animals.

Avoid Enclosed Spaces: Do not install lamps in sealed barrels or tight enclosures. Adequate ventilation ensures heat escapes and prevents overheating.

Extension Cord Caution: Avoid extension cords if possible. If you must use one, select a heavy-duty outdoor cord rated for at least 10 amps (1200 watts) continuous.

Electrical Safety: Only connect lamps to circuits protected by a GFCI (ground-fault circuit interrupter). When in doubt, consult a qualified electrician.

Leading manufacturers (e.g.,Sidel,Krones) now prioritize carbon IR systems for:

Lightweighting: Enables thinner preforms without strength loss.

Hybrid Energy Systems: Compatibility with solar/renewable power grids.

AI Optimization: Machine learning adjusts heating profiles autonomously during job changeovers.

Carbon infrared lamps are not just an upgrade—they are a strategic investment that can reduce energy costs.

They also increase production and extend service life. This leads to a return on investment in less than 18 months. This also helps make bottle production more sustainable for the future.

Carbon infrared lamps utilize high-purity carbon fiber filaments sealed in quartz tubes under inert gas. Unlike metal filaments, carbon's structure gives off peak radiation at 3–10 μm wavelengths. This matches PET's absorption spectrum perfectly. This resonance effect converts >95% of energy into usable heat, versus <70% in conventional short-wave systems.

The result? Preforms reach target temperatures 40% faster with zero surface scorching.

Energy Inflation Countermeasures

With electricity comprising ~30% of bottle production costs, carbon IR’s 380V/220V compatibility slashes kWh consumption.

Example: A 72-lamp SBM machine running 24/7 saves €18,000/year at €0.20/kWh versus quartz IR.

Downtime Reduction

Carbon lamps withstand 500,000+ on/off cycles without filament degradation. For high-speed lines that make 50,000 bottles per hour, this cuts out 6 to 8 shutdowns each year for lamp changes. This saves over 200 production hours every year.

Quality Assurance

Deep far-infrared penetration stops "cold spots" in thick preforms. These cold spots can cause stress cracks in carbonated drink bottles. Manufacturers report <0.1% rejection rates versus 1–2% with quartz systems.

Technical Integration Checklist

Parameter Specification Impact Voltage Stability ±2% tolerance This prevents early filament failure. Cooling Airflow of 15–20 m/s across lamps. This keeps the surface temperature below 600°C. Reflector Coating Gold-plated aluminum with 98% reflectivity. (85% for standard) Lamp Pitch 25–40mm between units Eliminates shadow gaps on preforms Installation & Safety Recommendations

Mounting Height: Due to their high heat output, carbon IR lamps should be positioned higher above the production area than traditional lamps. This ensures uniform heat dispersion and prevents “hot spots” on preforms or equipment surfaces.

Clearance: Never enclose carbon IR lamps in confined spaces or barrels. Adequate airflow around each unit is essential for efficient cooling and consistent lamp life.

Electrical Supply: Avoid using extension cords unless absolutely necessary. If required, always opt for heavy-duty outdoor extension cords rated for at least 10 amps (1200 watts) for continuous operation.

Shock Prevention: Always connect lamps to a branch circuit protected by a ground-fault circuit interrupter (GFCI). If uncertain, consult a qualified electrician to ensure GFCI protection is in place.

By following these integration and safety guidelines, you’ll maximize the performance, longevity, and reliability of your carbon IR system—keeping your line running smoothly and safely.

Carbon IR lamps align with global manufacturing mandates:

Zero Heavy Metals: Meets EU RoHS 3/China GB Standards

Recyclability: Quartz tubes & aluminum housings = 100% recoverable

Carbon Footprint: 380kg CO₂ reduction per machine annually

Data Point: Switching a 120-cavity SBM line to carbon IR cuts yearly emissions equivalent to 54 gasoline-powered cars.

Predictive AI Systems

Sensors monitor filament resistance drift, auto-scheduling replacements 200hrs before failure.

Dynamic Wavelength Tuning

Adjusts IR spectrum in real-time for colored/rPET preforms (absorbs heat differently).

Hybrid Renewable Integration

DC-powered lamps directly interface with solar arrays – cutting grid dependence by 60%.

Audit Phase

Map preform temp profiles via thermal imaging

Measure baseline energy use per 1,000 bottles

Retrofit Kit Installation

Plug-and-play lamp holders/power supplies

48–72hr downtime (typical)

Validation & Calibration

72hr test run with pyrometer feedback

Optimize zone % settings ±0.5%

For PET producers facing margin pressures, carbon infrared lamps deliver triple gains:

Cost: 25–40% lower OPEX

Quality: Near-zero thermal defects

Sustainability: ESG compliance + carbon credits

In the competitive world of PET bottle manufacturing, precise heating is not just a step. More importantly, it is a key factor in quality, speed, and profit.

Enter carbon infrared lamps. This advanced heating technology is quickly replacing traditional quartz IR systems in modern blow molding operations. Here’s why these lamps are becoming the gold standard for preform heating.

Carbn IR lamps produce far-infrared radiation with a wavelength of 3 to 10 micrometers. This radiation goes deeper into PET preforms than short or medium-wave options. This delivers:

Uniform Thermal Distribution: Eliminates hot spots, ensuring consistent material expansion.

Reduced Surface Overheating: Prevents PET yellowing or degradation.

30% Faster Heat-Up Times: Direct energy transfer slashes cycle times.

Energy Efficiency

Carbon filaments change over 95% of electricity into specific infrared radiation. This reduces energy costs by 25 to 40% compared to metal-filament lamps.

Longer Lifespan

With no tungsten degradation, carbon lamps last 15,000–20,000 hours (2–3× quartz IR), minimizing downtime.

Precision Zone Control

Adaptive wavelength output adjusts to preform thickness/color variations. Operators fine-tune heating profiles for:

Base/thick sections → Deeper penetration

Thin necks → Gentle surface heating

Cooler Operation

Surface temperatures run 30% lower than quartz lamps, reducing cooling demands and factory ambient heat.

Eco- adaptability

Zero heavy metals (lead/mercury-free) and fully recyclable. Aligns with ESG-driven manufacturing.

| Feature | Carbon IR Lamps | Quartz IR Lamps |

| Wavelength | Far-infrared (3–10 μm) | Short-wave (0.8–1.4 μm) |

| Penetratio | Deep and uniform | Surface-focused |

| Lifespan | 15,000–20,000 hours | 5,000–10,000 hours |

| Energy Use | 25–40% lower | Higher baseline |

| Heat Signature | Lower surface temperature | Extreme radiant heat |

Integration in Blow Molding Machines: Best Practices

Reflector Design: Parabolic aluminum reflectors maximize focus on preforms.

Closed-Loop Control: Pair with pyrometers for real-time temperature feedback.

Modular Zones: Group lamps by preform height (base/body/neck) for gradient heating.

Maintenance: Quarterly reflector cleaning + annual electrical checks sustain peak efficiency.

Installation Precautions & Safety Guidelines

To ensure optimal performance and longevity, follow these best practices:

Handle Lamps Properly: When installing new bulbs, always use a cloth or gloves. Oils from bare hands can shorten lamp life.

Mounting Height Matters: Because carbon IR lamps emit intense heat, position them higher than conventional quartz units. This allows for even heat dispersion and prevents hot spots. Never allow direct access by personnel or animals.

Avoid Enclosed Spaces: Do not install lamps in sealed barrels or tight enclosures. Adequate ventilation ensures heat escapes and prevents overheating.

Extension Cord Caution: Avoid extension cords if possible. If you must use one, select a heavy-duty outdoor cord rated for at least 10 amps (1200 watts) continuous.

Electrical Safety: Only connect lamps to circuits protected by a GFCI (ground-fault circuit interrupter). When in doubt, consult a qualified electrician.

Leading manufacturers (e.g.,Sidel,Krones) now prioritize carbon IR systems for:

Lightweighting: Enables thinner preforms without strength loss.

Hybrid Energy Systems: Compatibility with solar/renewable power grids.

AI Optimization: Machine learning adjusts heating profiles autonomously during job changeovers.

Carbon infrared lamps are not just an upgrade—they are a strategic investment that can reduce energy costs.

They also increase production and extend service life. This leads to a return on investment in less than 18 months. This also helps make bottle production more sustainable for the future.

Carbon infrared lamps utilize high-purity carbon fiber filaments sealed in quartz tubes under inert gas. Unlike metal filaments, carbon's structure gives off peak radiation at 3–10 μm wavelengths. This matches PET's absorption spectrum perfectly. This resonance effect converts >95% of energy into usable heat, versus <70% in conventional short-wave systems.

The result? Preforms reach target temperatures 40% faster with zero surface scorching.

Energy Inflation Countermeasures

With electricity comprising ~30% of bottle production costs, carbon IR’s 380V/220V compatibility slashes kWh consumption.

Example: A 72-lamp SBM machine running 24/7 saves €18,000/year at €0.20/kWh versus quartz IR.

Downtime Reduction

Carbon lamps withstand 500,000+ on/off cycles without filament degradation. For high-speed lines that make 50,000 bottles per hour, this cuts out 6 to 8 shutdowns each year for lamp changes. This saves over 200 production hours every year.

Quality Assurance

Deep far-infrared penetration stops "cold spots" in thick preforms. These cold spots can cause stress cracks in carbonated drink bottles. Manufacturers report <0.1% rejection rates versus 1–2% with quartz systems.

Technical Integration Checklist

Parameter Specification Impact Voltage Stability ±2% tolerance This prevents early filament failure. Cooling Airflow of 15–20 m/s across lamps. This keeps the surface temperature below 600°C. Reflector Coating Gold-plated aluminum with 98% reflectivity. (85% for standard) Lamp Pitch 25–40mm between units Eliminates shadow gaps on preforms Installation & Safety Recommendations

Mounting Height: Due to their high heat output, carbon IR lamps should be positioned higher above the production area than traditional lamps. This ensures uniform heat dispersion and prevents “hot spots” on preforms or equipment surfaces.

Clearance: Never enclose carbon IR lamps in confined spaces or barrels. Adequate airflow around each unit is essential for efficient cooling and consistent lamp life.

Electrical Supply: Avoid using extension cords unless absolutely necessary. If required, always opt for heavy-duty outdoor extension cords rated for at least 10 amps (1200 watts) for continuous operation.

Shock Prevention: Always connect lamps to a branch circuit protected by a ground-fault circuit interrupter (GFCI). If uncertain, consult a qualified electrician to ensure GFCI protection is in place.

By following these integration and safety guidelines, you’ll maximize the performance, longevity, and reliability of your carbon IR system—keeping your line running smoothly and safely.

Carbon IR lamps align with global manufacturing mandates:

Zero Heavy Metals: Meets EU RoHS 3/China GB Standards

Recyclability: Quartz tubes & aluminum housings = 100% recoverable

Carbon Footprint: 380kg CO₂ reduction per machine annually

Data Point: Switching a 120-cavity SBM line to carbon IR cuts yearly emissions equivalent to 54 gasoline-powered cars.

Predictive AI Systems

Sensors monitor filament resistance drift, auto-scheduling replacements 200hrs before failure.

Dynamic Wavelength Tuning

Adjusts IR spectrum in real-time for colored/rPET preforms (absorbs heat differently).

Hybrid Renewable Integration

DC-powered lamps directly interface with solar arrays – cutting grid dependence by 60%.

Audit Phase

Map preform temp profiles via thermal imaging

Measure baseline energy use per 1,000 bottles

Retrofit Kit Installation

Plug-and-play lamp holders/power supplies

48–72hr downtime (typical)

Validation & Calibration

72hr test run with pyrometer feedback

Optimize zone % settings ±0.5%

For PET producers facing margin pressures, carbon infrared lamps deliver triple gains:

Cost: 25–40% lower OPEX

Quality: Near-zero thermal defects

Sustainability: ESG compliance + carbon credits