| Availability: | |

|---|---|

| Quantity: | |

Far-infrared Ceramic Heating Plate

Product Description

We are a professional maker of heating elements. We can customize different sizes and specifications for you. We provide high-quality products and great service. Please contact us if you need any assistance.

Wavelength Range and Material Compatibility

Far-infrared ceramic plate heaters are designed to emit infrared wavelengths in the 2–10 micron range. This particular spectral window is especially important because most plastics and various other materials absorb infrared energy most efficiently within these wavelengths. As a result, ceramic heaters operating in this range can deliver effective, targeted heating—making them well-suited for tasks like plastic forming, drying, and curing. If your application requires reliable and consistent heat absorption in this range, these far-infrared ceramics offer an excellent solution.

Available Models and Series

For industrial applications, our ceramic infrared heating plates are available in several standard models and series. Popular options include the PK Series, commonly used for flat heaters, as well as comparable models from trusted brands such asElstein,Watlow, andOmega. These series are designed to deliver reliable, uniform heating across a variety of operating environments.

If you require a specific standard or configuration, please let us know—customized solutions and other model series are also available to meet your unique requirements.

| Pseudolaric acid | Far Infrared Heating Brick |

| Branding | YFR |

| Product Material | Ceramics |

| Furnace wire material | Nichrome heating wire |

| Product Specification | 120mm*120mm |

| Power | Customizable |

| High degree | Customizable |

| Color | Customizable |

Maximum Temperature Resistance:The ceramic heating plates are crafted from high-quality materials, including conductors with over 95% silicon and quartz glass. This composition allows the plates to withstand temperatures up to 1800°C, ensuring reliable operation in demanding heating applications.

When exploring ceramic plate heaters, you’ll notice several different types—each suited to particular industrial and engineering tasks. Let’s break down the distinctions among electric, air plate, and flat plate models, so you can choose the best fit for your needs.

1. Electric Ceramic Plate Heaters

Power Source: These heaters use embedded resistance wires—often made of nichrome (nickel-chromium alloy)—to generate heat.

Performance: They are versatile and favored for their efficiency in providing rapid, consistent far infrared heating.

Applications: Commonly used in plastics forming, laboratory heating platforms, and food service equipment.

2. Air Plate Ceramic Heaters

Design Focus: Air plate heaters prioritize the even distribution of heat to the surrounding air, rather than direct contact heating.

Benefits: Ideal for warming enclosed spaces, air ducts, or areas where ambient air needs consistent, gentle warming.

Typical Settings: HVAC systems, industrial ovens, and incubation chambers.

3. Flat Plate Ceramic Heaters

Construction: Characterized by their slim, flat profile, these heaters deliver a broad and uniform surface temperature.

Best Use: Designed for direct contact heating, they’re perfect for applications like thermoforming, drying, and heating flat substrates.

Advantages: Their large surface area ensures efficient, even thermal transfer.

Custom Options:Many manufacturers offer customizable options for size, power rating, and temperature thresholds, allowing you to tailor the heater to your operational requirements.

In summary, electric types focus on efficient generation, air plate models are tailored for ambient warming, and flat plate designs excel at direct, even heating of surfaces. Each brings its own set of advantages depending on what—and how—you need to heat.

Operating Temperature Range :Far infrared 120V 300-watt ceramic plate heaters are designed to function efficiently within a temperature span of approximately 300°C to 700°C (572°F to 1292°F), making them suitable for a variety of heating applications.

Advantages

1.Uniform heat generation: high radiation rate, good integrity, high insulation strength, super energy-saving.

2.Glazing process: adopting glaze with high emissivity, good anti-shock performance.

3.Nichrome heating wire: high quality Nichrome heating wire, high temperature resistance, not easy to break.

4.Temperature Sensor: Built-in temperature sensor provides more convenient temperature control.

5.Cotton Ceramic Heating Brick: The back insulation cotton reduces the loss of heat in the back and side, greatly improving the heating efficiency of the front of the heating brick to the heated object.

Applications of Far-Infrared Ceramic Heating Plates

Far-infrared ceramic heating plates excel in processes where precise, efficient heat transfer is required—particularly with materials that readily absorb infrared radiation in the 2 to 10 micron range. They are especially effective for:

Plastic forming and processing: Common in industries working with PET, PVC, ABS, and other plastics, where uniform heating helps ensure optimal molding, bending, or shrinking results.

Powder coating and drying: Ideal for evenly heating coated surfaces, allowing powders to cure and bond effectively.

Food processing: Frequently used for gentle baking or drying, as many food products absorb infrared heat efficiently, preserving texture and flavor.

Textile drying and moisture removal: Excellent for speeding up drying in fabrics or garments without causing scorching.

Electronics manufacturing: Used for soldering and preheating components, offering stable, uniform heat crucial for delicate assemblies.

Laminating and bonding: Ensures strong, bubble-free bonds by evenly heating adhesives or laminating films.

Their ability to provide consistent and targeted heat makes them a versatile solution across these and other thermal processing tasks.

Typical Industrial Applications

Ceramic infrared heating plates are widely used across various industries thanks to their durability and efficient heat delivery. Here are some of the most common applications:

Thermoforming: Essential for heating plastic sheets before molding, ensuring uniform material softening for sharp, accurate forms.

Packaging: Used in sealing, shrinking, and blister packaging lines to deliver consistent, controlled heat.

Textile and Printing: Supports rapid drying of inks and coatings, helping fabrics and printed materials move quickly through production.

Electronics Manufacturing: Facilitates soldering, pre-heating, and curing processes with precise temperature control.

Food Processing: Maintains steady temperatures for drying, warming, or baking products like baked snacks and ready meals.

Paint and Powder Coating: Ideal for curing finishes on automotive parts, household appliances, and metal components.

Thanks to their high radiation rate, safety, and adaptability, ceramic infrared heaters have become a staple in both continuous and batch production environments—anywhere fast, targeted, and reliable heat is needed.

Why Choose Us

We are a manufacturer of Quartz IR emitters and infrared heating systems. With 13 years of experience in this industry, we always provide professional and flexible service. We deliver on time and respond quickly after sales.

If you have customized needs, please feel free to contact us.

We will choose the most suitable mode of transportation so that the goods can reach you as soon as possible.

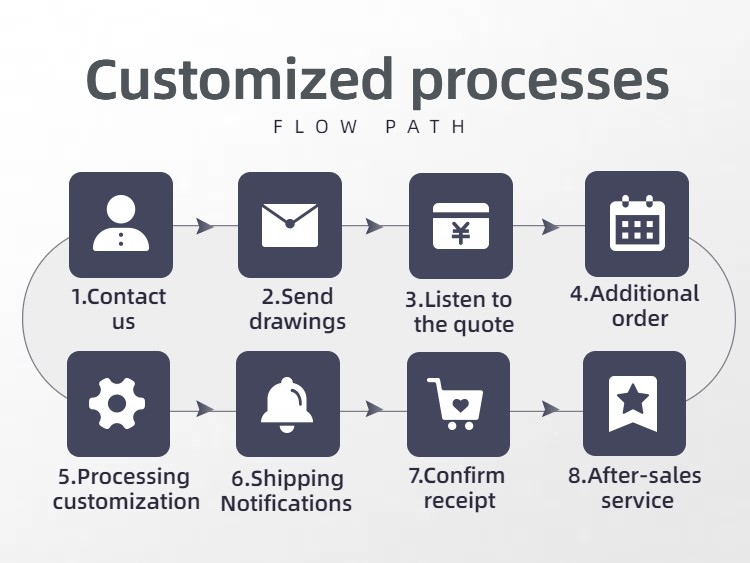

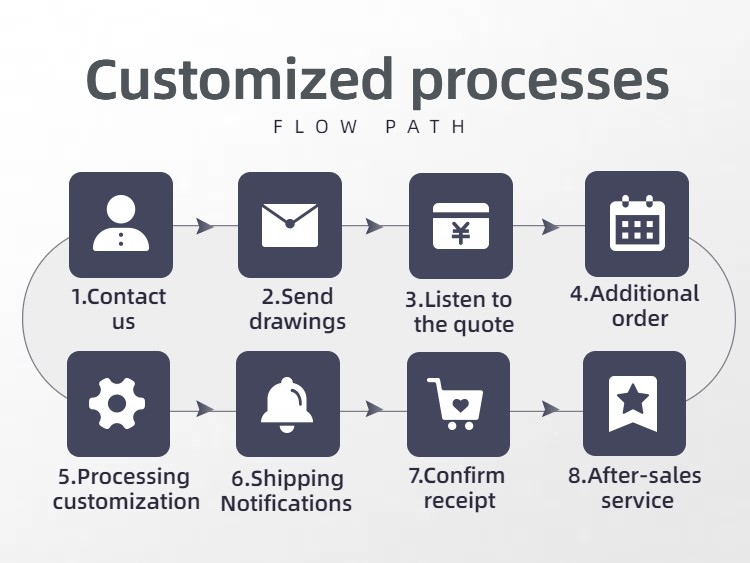

How to customize

Frequently asked questions

1.Are you a factory or trading company?

Yinfrared is a factory,we are professional manufacturer of infrared heater.You are warmily welcome to our factory, we will be happy to show you our production, quality control, warehouse,etc.

2.Can I have samples?Is it free?

Yes, we are happy to offer samples for you to check and test. Depending on sample quantity and product model, we will confirm with you whether it is a free sample or not.

3.What is a far infrared ceramic heating plate?

Far-infrared ceramic heating plate adopts nickel-chromium heating wire, which has high radiation rate, high heating efficiency, strong shock resistance, energy saving and emission reduction.

This advanced heating plate technology has become the preferred choice in various industries due to its reliable performance and durability. Widely used for applications requiring consistent and even heat distribution, these plates excel in environments where efficiency and stability are crucial. Their robust construction ensures a long service life, while the high-quality ceramic materials provide excellent resistance to thermal shock. Whether you're seeking a solution for industrial, commercial, or specialty heating needs, far-infrared ceramic heating plates offer the dependable operation and customizable options to meet a wide range of requirements.

4.What are the power options available for far infrared ceramicheaters, such as 500w and 300w models?

Power Customizable Far infrared ceramic plate heaters are available in a range of power options, including 120v 300-watt and 500-watt variants, to suit various heating needs. These heaters operate efficiently at temperatures from 300°C up to 700°C (572°F – 1292°F), generating infrared wavelengths in the 2–10 micron range—a sweet spot for optimal absorption by most plastics and many other materials. Constructed with materials like high-silicon conductors and quartz glass, these panels are designed to withstand high temperatures, ensuring durability and consistent performance. With customizable power settings, you can tailor the heater to your precise application, whether you need gentle warmth or high-intensity infrared output.

If you have any other questions, please feel free to contact us.

Far-infrared Ceramic Heating Plate

Product Description

We are a professional maker of heating elements. We can customize different sizes and specifications for you. We provide high-quality products and great service. Please contact us if you need any assistance.

Wavelength Range and Material Compatibility

Far-infrared ceramic plate heaters are designed to emit infrared wavelengths in the 2–10 micron range. This particular spectral window is especially important because most plastics and various other materials absorb infrared energy most efficiently within these wavelengths. As a result, ceramic heaters operating in this range can deliver effective, targeted heating—making them well-suited for tasks like plastic forming, drying, and curing. If your application requires reliable and consistent heat absorption in this range, these far-infrared ceramics offer an excellent solution.

Available Models and Series

For industrial applications, our ceramic infrared heating plates are available in several standard models and series. Popular options include the PK Series, commonly used for flat heaters, as well as comparable models from trusted brands such asElstein,Watlow, andOmega. These series are designed to deliver reliable, uniform heating across a variety of operating environments.

If you require a specific standard or configuration, please let us know—customized solutions and other model series are also available to meet your unique requirements.

| Pseudolaric acid | Far Infrared Heating Brick |

| Branding | YFR |

| Product Material | Ceramics |

| Furnace wire material | Nichrome heating wire |

| Product Specification | 120mm*120mm |

| Power | Customizable |

| High degree | Customizable |

| Color | Customizable |

Maximum Temperature Resistance:The ceramic heating plates are crafted from high-quality materials, including conductors with over 95% silicon and quartz glass. This composition allows the plates to withstand temperatures up to 1800°C, ensuring reliable operation in demanding heating applications.

When exploring ceramic plate heaters, you’ll notice several different types—each suited to particular industrial and engineering tasks. Let’s break down the distinctions among electric, air plate, and flat plate models, so you can choose the best fit for your needs.

1. Electric Ceramic Plate Heaters

Power Source: These heaters use embedded resistance wires—often made of nichrome (nickel-chromium alloy)—to generate heat.

Performance: They are versatile and favored for their efficiency in providing rapid, consistent far infrared heating.

Applications: Commonly used in plastics forming, laboratory heating platforms, and food service equipment.

2. Air Plate Ceramic Heaters

Design Focus: Air plate heaters prioritize the even distribution of heat to the surrounding air, rather than direct contact heating.

Benefits: Ideal for warming enclosed spaces, air ducts, or areas where ambient air needs consistent, gentle warming.

Typical Settings: HVAC systems, industrial ovens, and incubation chambers.

3. Flat Plate Ceramic Heaters

Construction: Characterized by their slim, flat profile, these heaters deliver a broad and uniform surface temperature.

Best Use: Designed for direct contact heating, they’re perfect for applications like thermoforming, drying, and heating flat substrates.

Advantages: Their large surface area ensures efficient, even thermal transfer.

Custom Options:Many manufacturers offer customizable options for size, power rating, and temperature thresholds, allowing you to tailor the heater to your operational requirements.

In summary, electric types focus on efficient generation, air plate models are tailored for ambient warming, and flat plate designs excel at direct, even heating of surfaces. Each brings its own set of advantages depending on what—and how—you need to heat.

Operating Temperature Range :Far infrared 120V 300-watt ceramic plate heaters are designed to function efficiently within a temperature span of approximately 300°C to 700°C (572°F to 1292°F), making them suitable for a variety of heating applications.

Advantages

1.Uniform heat generation: high radiation rate, good integrity, high insulation strength, super energy-saving.

2.Glazing process: adopting glaze with high emissivity, good anti-shock performance.

3.Nichrome heating wire: high quality Nichrome heating wire, high temperature resistance, not easy to break.

4.Temperature Sensor: Built-in temperature sensor provides more convenient temperature control.

5.Cotton Ceramic Heating Brick: The back insulation cotton reduces the loss of heat in the back and side, greatly improving the heating efficiency of the front of the heating brick to the heated object.

Applications of Far-Infrared Ceramic Heating Plates

Far-infrared ceramic heating plates excel in processes where precise, efficient heat transfer is required—particularly with materials that readily absorb infrared radiation in the 2 to 10 micron range. They are especially effective for:

Plastic forming and processing: Common in industries working with PET, PVC, ABS, and other plastics, where uniform heating helps ensure optimal molding, bending, or shrinking results.

Powder coating and drying: Ideal for evenly heating coated surfaces, allowing powders to cure and bond effectively.

Food processing: Frequently used for gentle baking or drying, as many food products absorb infrared heat efficiently, preserving texture and flavor.

Textile drying and moisture removal: Excellent for speeding up drying in fabrics or garments without causing scorching.

Electronics manufacturing: Used for soldering and preheating components, offering stable, uniform heat crucial for delicate assemblies.

Laminating and bonding: Ensures strong, bubble-free bonds by evenly heating adhesives or laminating films.

Their ability to provide consistent and targeted heat makes them a versatile solution across these and other thermal processing tasks.

Typical Industrial Applications

Ceramic infrared heating plates are widely used across various industries thanks to their durability and efficient heat delivery. Here are some of the most common applications:

Thermoforming: Essential for heating plastic sheets before molding, ensuring uniform material softening for sharp, accurate forms.

Packaging: Used in sealing, shrinking, and blister packaging lines to deliver consistent, controlled heat.

Textile and Printing: Supports rapid drying of inks and coatings, helping fabrics and printed materials move quickly through production.

Electronics Manufacturing: Facilitates soldering, pre-heating, and curing processes with precise temperature control.

Food Processing: Maintains steady temperatures for drying, warming, or baking products like baked snacks and ready meals.

Paint and Powder Coating: Ideal for curing finishes on automotive parts, household appliances, and metal components.

Thanks to their high radiation rate, safety, and adaptability, ceramic infrared heaters have become a staple in both continuous and batch production environments—anywhere fast, targeted, and reliable heat is needed.

Why Choose Us

We are a manufacturer of Quartz IR emitters and infrared heating systems. With 13 years of experience in this industry, we always provide professional and flexible service. We deliver on time and respond quickly after sales.

If you have customized needs, please feel free to contact us.

We will choose the most suitable mode of transportation so that the goods can reach you as soon as possible.

How to customize

Frequently asked questions

1.Are you a factory or trading company?

Yinfrared is a factory,we are professional manufacturer of infrared heater.You are warmily welcome to our factory, we will be happy to show you our production, quality control, warehouse,etc.

2.Can I have samples?Is it free?

Yes, we are happy to offer samples for you to check and test. Depending on sample quantity and product model, we will confirm with you whether it is a free sample or not.

3.What is a far infrared ceramic heating plate?

Far-infrared ceramic heating plate adopts nickel-chromium heating wire, which has high radiation rate, high heating efficiency, strong shock resistance, energy saving and emission reduction.

This advanced heating plate technology has become the preferred choice in various industries due to its reliable performance and durability. Widely used for applications requiring consistent and even heat distribution, these plates excel in environments where efficiency and stability are crucial. Their robust construction ensures a long service life, while the high-quality ceramic materials provide excellent resistance to thermal shock. Whether you're seeking a solution for industrial, commercial, or specialty heating needs, far-infrared ceramic heating plates offer the dependable operation and customizable options to meet a wide range of requirements.

4.What are the power options available for far infrared ceramicheaters, such as 500w and 300w models?

Power Customizable Far infrared ceramic plate heaters are available in a range of power options, including 120v 300-watt and 500-watt variants, to suit various heating needs. These heaters operate efficiently at temperatures from 300°C up to 700°C (572°F – 1292°F), generating infrared wavelengths in the 2–10 micron range—a sweet spot for optimal absorption by most plastics and many other materials. Constructed with materials like high-silicon conductors and quartz glass, these panels are designed to withstand high temperatures, ensuring durability and consistent performance. With customizable power settings, you can tailor the heater to your precise application, whether you need gentle warmth or high-intensity infrared output.

If you have any other questions, please feel free to contact us.