Author: Site Editor Publish Time: 2025-08-21 Origin: Site

When a major automotive parts factory in Tianjin slashed its heating costs by 50% and reduced carbon emissions by 90% after installing infrared heating systems, it didn't just improve its bottom line—it transformed its entire operational model

As an industrial energy efficiency specialist with over twelve years of experience, I've witnessed firsthand how infrared heating technology has revolutionized numerous industries. From manufacturing facilities to food processing plants, infrared heaters are replacing traditional heating methods with remarkable improvements in efficiency, cost savings, and environmental performance. In this comprehensive guide, I'll share insights drawn from real-world applications and technical data to help you understand how infrared heating solutions can transform your industrial operations.

Infrared heaters operate on a fundamentally different principle than conventional heating systems. Instead of heating the air, they emit infrared radiation that directly heats objects, materials, and people within their path. This direct transfer of thermal energy eliminates the massive energy losses associated with traditional heating methods.

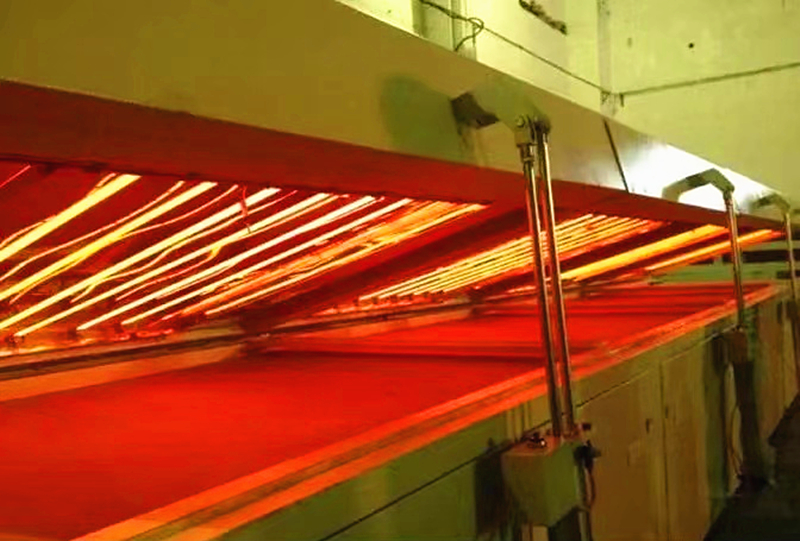

The technology typically uses quartz glass tubes with tungsten filaments that emit infrared radiation when electrified. These systems can achieve electrical-to-thermal conversion efficiencies exceeding 90%, compared to roughly 50-70% for conventional heating methods.

Infrared radiation is part of the electromagnetic spectrum, lying between visible light and microwaves. Industrial infrared heaters typically operate in three wavelength ranges:

Short-wave infrared (0.76-1.5 μm): Characterized by rapid heating capabilities (1-3 seconds to full intensity), high power density, and deep penetration into materials

Medium-wave infrared (1.5-3 μm): Balanced performance for various industrial applications

Long-wave infrared (3-1000 μm): Lower temperature heating suitable for surface treatments and comfort heating

The key to infrared heating's efficiency lies in its direct energy transfer. Unlike conventional systems that heat air (which then heats objects), infrared radiation travels through space without heating the air until it strikes an object, where it converts to thermal energy

Infrared heating technology has found applications across virtually every industrial sector. Here are some of the most significant use cases:

Paint curing and drying: Infrared heaters provide uniform curing for automotive paints, powder coatings, and industrial finishes

Plastic processing: Used for softening, forming, and welding plastic components

Metal pretreatment: Heating metal parts before painting or coating improves adhesion and finish quality

Food drying and dehydration: Infrared heating effectively removes moisture from various food products while preserving nutritional quality

Baking and cooking: Provides rapid, consistent heating for food production lines

Grain and agricultural product drying: Gentle drying that preserves product quality

Textile drying and curing: Even heating for textile treatments without damaging delicate fabrics

Paper drying: Efficient moisture removal without excessive heat damage

Paint drying and curing: Uniform finishing for vehicle bodies and components

Adhesive activation: Rapid curing of adhesives used in vehicle assembly

Component manufacturing: Heating for various forming and assembly processes

Table: Industrial Infrared Heating Applications by Sector

| Industry Sector | Primary Applications | Typical Benefits |

|---|---|---|

| Automotive | Paint curing, adhesive activation, component heating | 30-50% faster processing, 40% energy savings |

| Food Processing | Dehydration, baking, cooking | Preserves nutrients, reduces drying time by 30-50% |

| Textiles | Fabric drying, curing treatments | Prevents damage, uniform heating |

| Plastics | Softening, forming, welding | Targeted heating, reduced energy use |

| General Manufacturing | Paint drying, preheating, process heating | 30%+ energy savings, faster processing |

Industrial infrared heating systems typically achieve 90% or higher energy conversion efficiency, compared to 50-70% for conventional heating methods4. This dramatic improvement stems from the direct energy transfer to target materials rather than heating the surrounding air.

The Tianjin automotive factory case study demonstrates the potential impact: after switching to infrared heating, they reduced their annual heating costs from approximately ¥3 million to ¥1.5 million while cutting carbon emissions from 1,200 tons to just 120 tons.

Short-wave infrared heaters can reach full operational temperature in just 1-3 seconds, compared to minutes for conventional heaters. This capability allows for:

Faster production line startup

Precise temperature control for sensitive processes

Reduced energy waste during startup and shutdown cycles

Infrared heating systems typically require less physical space than conventional heating equipment. Their compact design allows for integration into existing production lines without major modifications.

The direct heating method provides more uniform temperature distribution, reducing product defects caused by uneven heating. In painting applications, this translates to smoother finishes with better adhesion and durability.

With no moving parts and simple construction, infrared heating systems typically require less maintenance than conventional heating systems. Most systems offer lifespans exceeding 8,000 hours of continuous operation.

Before implementing infrared heating, consider these factors:

Process requirements: Temperature needs, heating speed, and uniformity requirements

Material characteristics: How your products or materials respond to infrared radiation

Production layout: Space constraints and integration possibilities

Energy infrastructure: Electrical capacity and existing heating systems

Proper installation is crucial for optimal performance:

Positioning: Ensure appropriate distance and angle to target areas

Reflection: Use appropriate reflectors to maximize efficiency

Safety: Implement proper guarding and safety interlocks

Control systems: Integrate precise temperature controls for process optimization

Regular maintenance: Clean reflectors and check electrical connections periodically

Monitoring: Implement temperature monitoring to ensure consistent performance

Training: Educate operators on proper use and safety procedures

The initial investment in infrared heating technology typically yields rapid returns through multiple savings channels:

Most industrial facilities report 30-50% reductions in energy consumption after switching to infrared heating. For a medium-sized manufacturing facility spending $100,000 annually on process heating, this translates to $30,000-$50,000 in annual savings.

Infrared heating's rapid response time can increase production line speeds by 20-35%. This capacity increase represents additional revenue generation without corresponding increases in energy costs.

With maintenance requirements typically 40-60% lower than conventional systems, infrared heaters generate additional savings through reduced downtime and maintenance labor.

The dramatic reduction in carbon emissions (90% in the Tianjin case study) helps facilities meet increasingly stringent environmental regulations and may qualify them for carbon reduction incentives.

Table: Financial Analysis of Infrared Heating Implementation

| Cost Factor | Traditional Heating | Infrared Heating | Savings |

|---|---|---|---|

| Energy Costs | $100,000 (baseline) | $50,000-$70,000 | 30-50% |

| Maintenance | $15,000 (baseline) | $6,000-$9,000 | 40-60% |

| Production Capacity | 100% (baseline) | 120-135% | 20-35% increase |

| Carbon Emissions | 100% (baseline) | 10-30% | 70-90% reduction |

Advanced control systems incorporating IoT connectivity and AI algorithms are making infrared heating more precise and efficient. These systems can automatically adjust heating parameters based on real-time process conditions.

Combining infrared with other technologies creates systems that leverage the strengths of multiple approaches. For example, infrared systems for rapid heating coupled with convection systems for maintaining temperature.

Ongoing research is developing more efficient emitter materials and optimized reflector designs that further improve efficiency and lifespan.

As the technology advances, new industrial applications continue to emerge, including specialized medical equipment sterilization and advanced composite material processing.

Infrared heating technology represents a fundamental advancement in industrial heating methodology. With its exceptional efficiency, rapid response times, and superior process results, it offers industrial operators an opportunity to simultaneously reduce costs, improve productivity, and minimize environmental impact.

The technology has proven effective across countless applications, from automotive manufacturing to food processing. As the case studies show, the benefits are both immediate and substantial: energy savings of 30-50%, production increases of 20-35%, and carbon emission reductions of up to 90%.

For industrial operations considering heating system upgrades or expansions, infrared technology deserves serious consideration. The combination of rapid ROI, operational benefits, and environmental advantages makes it an increasingly compelling choice for forward-thinking industrial enterprises.

As we look to the future, ongoing advancements in control systems, materials science, and application knowledge will likely expand infrared heating's capabilities even further, solidifying its position as a cornerstone technology for efficient industrial operations.

Ready to explore how infrared heating can transform your industrial operations? Visit yinfrared.com to discover customized solutions for your specific needs and request a free energy efficiency assessment today!

content is empty!