Author: Site Editor Publish Time: 2025-10-20 Origin: Site

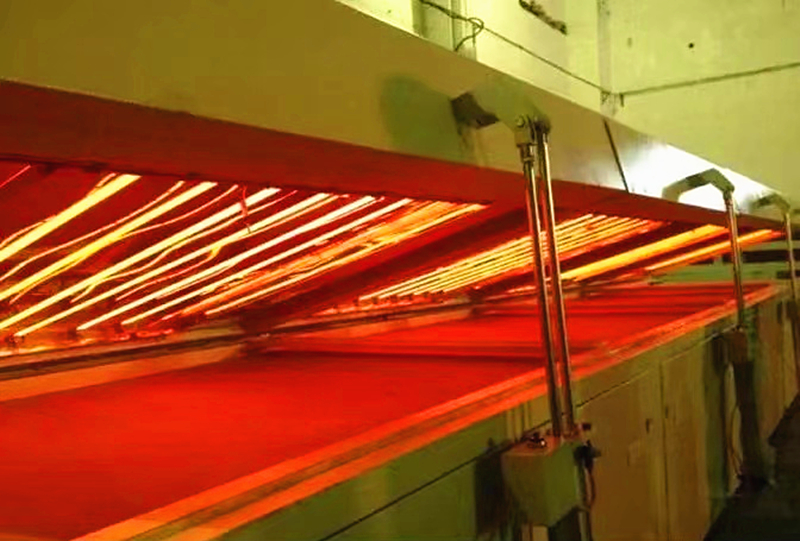

In the fast-paced world of industrial printing, the efficient drying of inks on PET (Polyethylene Terephthalate) film is a critical step that determines both product quality and production speed. Traditional hot-air drying systems often struggle with uneven heat distribution, excessive energy consumption, and potential film deformation.

To address these challenges, many industries are turning to quartz infrared heating lamps, a technology known for its rapid response, precise control, and superior energy efficiency. This article explores how infrared heating lamps, particularly quartz-based ones, revolutionize the ink drying process for PET films.

PET film is a widely used substrate in packaging, labels, and flexible electronic applications due to its durability, clarity, and resistance to chemicals. However, its smooth, heat-sensitive surface poses challenges during the ink drying process.

Inks used on PET films—such as solvent-based, UV-curable, or water-based inks—require controlled drying at moderate temperatures. Excessive heat can distort the film, while insufficient heating leads to incomplete ink curing or poor adhesion. The ideal drying system must therefore deliver uniform, fast, and precise heat without direct contact or excessive energy loss.

Infrared heating lamps generate heat through infrared radiation, which transfers energy directly to the material’s surface without relying on air as a medium. This makes them far more efficient than conventional convective heating systems.

Quartz infrared lamps consist of a tungsten filament enclosed in a high-purity quartz tube. When electricity passes through the filament, it emits infrared radiation—typically in the short-wave or medium-wave range—capable of penetrating ink layers and heating the substrate evenly.

The quartz envelope offers excellent thermal stability and allows the lamp to reach operating temperature in seconds, providing instant, controllable heat precisely where it is needed.

Quartz infrared lamps reach their target temperature almost instantly, allowing immediate heating and faster production speeds. Unlike hot-air systems that require preheating large volumes of air, IR lamps transfer energy directly to the ink and substrate, resulting in higher energy utilization and shorter drying cycles.

The radiation emitted from quartz IR lamps distributes heat uniformly across the film’s width, preventing common issues such as streaks, incomplete curing, or color inconsistencies. The non-contact nature of infrared heating minimizes the risk of surface contamination or damage.

Infrared heating systems can be finely controlled using electronic regulators and feedback sensors. Operators can adjust power levels or wavelengths to suit different inks or film thicknesses. This level of precision ensures stable temperature profiles and consistent drying performance even in high-speed printing lines.

PET films can soften or warp under uneven heat exposure. Quartz infrared lamps produce radiant heat that penetrates efficiently without overheating the substrate. This allows ink to dry quickly while keeping the PET film’s dimensional stability intact.

Quartz IR lamps are lightweight and compact, making them ideal for integration into existing film printing and coating lines. They occupy less space than hot-air ovens and are easier to retrofit or maintain, offering greater flexibility in industrial setups.

Because IR lamps heat only the target area rather than the surrounding air, they consume significantly less power. This leads to reduced operational costs and lower carbon emissions. Additionally, quartz IR systems operate quietly and generate minimal dust or fumes, creating a cleaner and safer production environment.

When implementing quartz infrared heating lamps in PET film drying systems, several factors must be optimized:

Wavelength selection: Matching the IR wavelength to the absorption characteristics of the ink and film improves efficiency. Medium-wave IR often works well for PET films.

Lamp spacing and power density: Uniform coverage ensures consistent drying and prevents localized overheating.

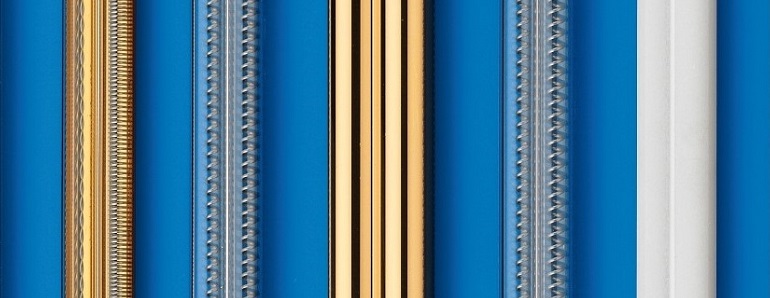

Reflector design: Gold or ceramic reflectors can enhance energy focus and reduce heat loss.

Temperature monitoring: Real-time feedback controls prevent film damage and maintain product consistency.

Maintenance: Regular cleaning of quartz tubes and reflectors helps maintain performance and extend lamp lifespan.

In high-speed PET film printing operations, replacing traditional hot-air dryers with quartz infrared heating lamps can reduce drying time by up to 40%, improve ink adhesion, and cut energy consumption by nearly 30%. The result is a smoother workflow, improved print clarity, and lower overall operating costs—without compromising product quality.

| Challenge | Solution |

|---|---|

| Overheating of PET film | Adjust lamp distance and power output; use wavelength matching. |

| Uneven drying across the film width | Employ multiple lamps with reflective housings for even coverage. |

| Contamination or reduced efficiency over time | Clean quartz tubes and reflectors regularly. |

| Excessive power consumption | Use temperature sensors and phase-angle controllers for efficient regulation. |

Quartz infrared heating lamps represent a significant advancement in PET film ink drying technology. They combine fast response, energy efficiency, and precise thermal control to ensure uniform ink curing and high-quality results.

By integrating these lamps into modern printing lines, manufacturers can achieve faster production speeds, lower energy costs, and improved sustainability—key advantages in a competitive and environmentally conscious market.