Author: Site Editor Publish Time: 2025-08-01 Origin: Site

Infrared heating emitters, including YFR’s Gold Reflector Quartz Halogen Infrared Heaters, drive significant improvements in industrial efficiency. These advanced solutions deliver measurable benefits: higher energy efficiency, rapid heating, enhanced product quality, and minimized downtime.

Advanced systems now offer multi-zone lamp arrangements, precise temperature control, and modular designs for easy integration.

Customization options support a range of lamp types, power levels, and compatibility with automation or cleanroom environments, meeting the diverse needs of modern industries.

Infrared heating emitters deliver fast, precise heat directly to materials, improving industrial process speed and control.

YFR’s Gold Reflector Quartz Halogen Infrared Heaters offer over 92% energy efficiency, reducing electricity use and costs.

Uniform heating from these emitters ensures consistent product quality and fewer defects across manufacturing batches.

The heaters reach full temperature within seconds, minimizing downtime and increasing production throughput.

Robust quartz tube construction and IP65 protection provide long lifespan and reliable operation in harsh environments.

Infrared heating reduces environmental impact by lowering energy consumption and carbon emissions.

Compared to traditional convection or conduction methods, infrared emitters offer faster heating, better energy use, and precise temperature control.

Customization options allow easy integration into various industries, supporting flexible and efficient manufacturing.

An infrared heating emitter is a device that produces infrared radiation to transfer heat directly to objects or materials. In industrial settings, these emitters serve as efficient sources of radiant energy, delivering targeted heat without relying on air as a medium. This direct approach enables rapid temperature changes and precise control, which are essential for modern manufacturing processes. YFR Gold Reflector Quartz Halogen Infrared Heaters represent a leading example, offering advanced technology and customizable features for a wide range of industrial applications.

Infrared heating emitters come in several forms, each designed for specific industrial needs. The construction and wavelength characteristics of each type influence their performance and suitability for different processes.

Infrared Emitter Type | Construction Characteristics | Typical Industrial Applications |

|---|---|---|

Quartz Infrared Emitters | Quartz glass elements; consistent heat; fast response | Electroplating, wafer heating, PCB leveling, furnaces |

Short Wave Infrared Heaters | Tungsten halogen lamps; rapid heating; short wavelength | Reflow soldering, rapid heating processes |

Medium Wave Infrared Heaters | Medium wavelength IR; balanced penetration | Wafer processing, preheating |

Carbon Infrared Heaters | Carbon fiber elements; flexible design; energy efficient | Tailored heat profiles, specialized applications |

Quartz halogen emitters use quartz glass tubes and tungsten filaments. These devices deliver intense, short-wave infrared radiation, making them ideal for processes that require rapid heating and precise temperature control. YFR Gold Reflector Quartz Halogen Infrared Heaters enhance this technology with gold-plated reflectors, increasing energy efficiency and directing heat exactly where needed.

Ceramic infrared heating emitters feature ceramic elements that emit medium to long-wave infrared radiation. These emitters provide steady, uniform heat and excel in applications where gentle, consistent heating is necessary. Industries often use ceramic emitters for drying, curing, and heating sensitive materials.

Carbon fiber emitters utilize carbon filaments to generate infrared radiation. Their flexible design and energy efficiency make them suitable for specialized heating tasks. Carbon fiber emitters can be tailored to deliver specific heat profiles, supporting processes that demand customized thermal management.

Infrared heating emitters operate by converting electrical energy into electromagnetic waves in the infrared spectrum. These waves transfer energy directly to the surface of materials, bypassing the need to heat the surrounding air. This method ensures rapid, uniform, and efficient heating. For example, YFR Gold Reflector Quartz Halogen Infrared Heaters use tungsten filaments and halogen gases inside quartz tubes, combined with gold reflectors, to maximize radiant output and minimize energy loss. Advanced control systems and sensors enable real-time temperature monitoring, supporting integration with automated production lines. This technology reduces operational costs, improves process reliability, and supports environmentally friendly manufacturing.

Tip: Direct radiant heating from an infrared heating emitter minimizes energy waste and enhances process efficiency, making it a preferred choice for industries seeking high performance and sustainability.

Industrial facilities constantly seek ways to reduce energy consumption without sacrificing performance. Infrared heating emitters, such as YFR’s Gold Reflector Quartz Halogen Infrared Heaters, deliver a significant advantage in this area. Gold reflector technology maximizes the conversion of electrical energy into usable heat, reaching energy conversion rates above 92%. This advanced design directs more infrared radiation toward the target, minimizing energy loss and ensuring that nearly all input power contributes to the heating process. Compared to traditional heating systems, these emitters can improve energy efficiency by up to 30%. Operators notice immediate reductions in electricity usage, especially in high-throughput environments where heating demands remain constant.

Note: Direct radiant heating eliminates the need to warm surrounding air, further reducing wasted energy and supporting sustainable manufacturing goals.

Lower energy consumption directly translates into cost savings for industrial operations. The gold reflector technology in YFR’s infrared heating emitters increases infrared radiation efficiency to as much as 95%. This high efficiency means that facilities spend less on electricity for the same or even improved heating performance. Over time, these savings accumulate, reducing both production and operational costs. Many manufacturers report a rapid return on investment after upgrading to advanced infrared heating systems. The ability to customize power, length, and voltage ensures that each installation matches the specific needs of the process, preventing unnecessary energy expenditure.

Facilities benefit from:

Reduced utility bills due to higher energy conversion.

Lower maintenance costs, as efficient systems experience less wear.

Fewer equipment replacements, thanks to the long lifespan of quartz halogen emitters.

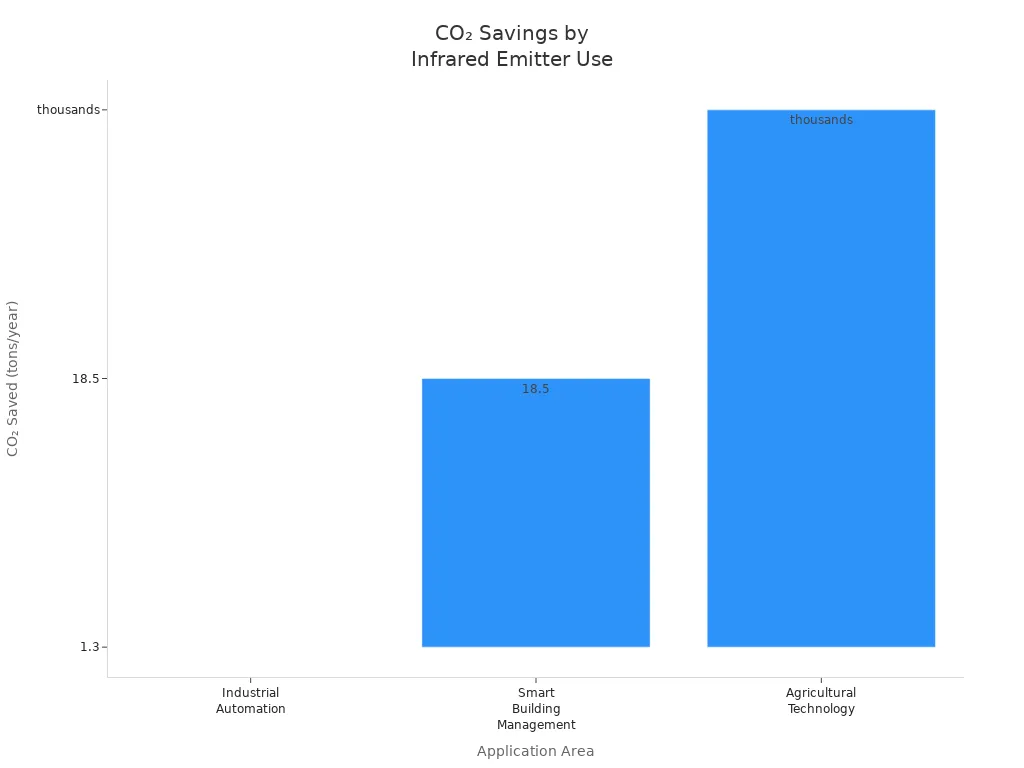

Energy-efficient heating solutions not only save money but also help protect the environment. By consuming less electricity, infrared heating emitters contribute to lower carbon emissions and a smaller ecological footprint. The following table highlights the environmental benefits associated with advanced infrared heating technologies:

Aspect | Evidence / Data |

|---|---|

Energy Efficiency | NIR LEDs use 75–90% less power than incandescent or halogen lamps, reducing electricity demand. |

CO₂ Emission Factor | Approximately 0.37 kg CO₂ avoided per kWh saved (U.S. average). |

Lifespan | NIR LEDs last 50,000+ hours vs. ~1,000 hours for traditional bulbs, reducing lifecycle emissions. |

Industrial Automation | Replacing 100 halogen sensors with NIR LEDs saved ~1.3 tons CO₂ annually (36 kWh per sensor/year). |

Agricultural Technology | Drones with NIR LEDs reduce fuel use by ~90% compared to tractors, saving thousands of kg CO₂/season. |

Smart Building Management | Retrofit with NIR LED sensors saved 50,000 kWh/year, avoiding ~18.5 tons CO₂ annually. |

Global Impact Estimate | Project Drawdown estimates 14–15 gigatons CO₂ avoided by 2050 if LEDs widely adopted globally. |

Environmental Safety | NIR LEDs emit no UV radiation, contain no toxic materials, and produce minimal heat waste. |

These improvements extend beyond energy savings. Facilities that adopt efficient infrared heating technologies help reduce greenhouse gas emissions and support global sustainability initiatives. The long operational life of these systems also means fewer replacements and less waste, further minimizing environmental impact.

Industrial processes often demand immediate and consistent heat. An infrared heating emitter delivers heat almost instantly after activation. YFR’s Gold Reflector Quartz Halogen Infrared Heaters reach full operating temperature in seconds. This rapid response reduces waiting times and increases production speed. Operators can start, stop, or adjust heating cycles with minimal delay. This feature proves essential for industries like automotive painting or food processing, where timing directly affects product quality.

Tip: Instant heating minimizes energy waste during startup and shutdown, making production lines more efficient.

Manufacturers require precise temperature management to maintain product consistency. YFR’s advanced design allows for accurate control of heat output. The gold reflector technology focuses infrared energy exactly where needed. Operators can adjust power, length, and voltage to match specific process requirements. This level of control ensures uniform heating across surfaces, reducing the risk of overheating or underheating.

Key benefits of precision control:

Consistent product quality

Reduced material waste

Improved repeatability in manufacturing

A well-calibrated system helps industries like electronics and printing achieve reliable results, even with sensitive materials.

Many industrial applications need high temperatures for effective processing. YFR’s quartz tube technology withstands temperatures above 800°C. This durability supports demanding tasks such as glass annealing, metal curing, and high-temperature sterilization. The robust construction ensures long-term performance, even in harsh environments.

Feature | YFR Gold Reflector Quartz Halogen IR Heater |

|---|---|

Maximum Tube Temp | 800°C+ |

Instant Heating | Yes |

Customization | Length, Power, Voltage |

Lifespan | 10,000+ hours |

YFR’s customization options allow integration into existing systems, supporting a wide range of industrial standards. Facilities can select the exact specifications needed for their unique processes.

Note: High-temperature capability and rapid response combine to deliver unmatched performance in modern manufacturing.

Uniform heating stands as a critical factor in achieving high product quality across industrial processes. Infrared heating emitters, such as YFR’s Gold Reflector Quartz Halogen Infrared Heaters, deliver rapid and consistent heat by controlling wavelength, power, and reflector design. This technology ensures even heat distribution, which prevents local overheating or insufficient heating. The result is a stable process environment that supports consistent product outcomes.

Aspect | Explanation | Impact on Product Quality and Manufacturing Efficiency |

|---|---|---|

Uniform Heating | Infrared emitters provide rapid, consistent heating by controlling wavelength, power, and reflector design. | Ensures even heat distribution, preventing local overheating or insufficient heating. |

Infrared heating matches material absorption (e.g., PET at 1.2-1.5 µm), enabling inside-out uniform heating. | Improves bottle thickness uniformity and reduces defects, enhancing product consistency. | |

Leather Drying | Infrared penetrates leather, drying evenly and quickly, avoiding cracking or deformation. | Enhances leather softness, color fixation, and reduces defects, improving final product quality. |

EVA Films & Electroplated Parts | Uniform infrared heating improves interlayer adhesion and physical properties. | Results in better product durability and performance. |

Reflector Design | Reflective layers optimize infrared distribution, reflecting unabsorbed energy back to the product surface. | Enhances heating uniformity and energy efficiency, improving product quality. |

Control Systems | Adjustable power and fast response lamps allow precise temperature control tailored to material and process. | Enables flexible, efficient production with consistent product quality. |

YFR’s gold reflector technology further optimizes infrared distribution, reflecting unabsorbed energy back to the product surface. This approach maximizes energy efficiency and ensures every part of the product receives the necessary heat.

Consistent and targeted heating directly reduces the occurrence of defects in manufactured goods. Infrared emitters accelerate drying by penetrating material layers, ensuring uniform moisture removal and preventing surface cracking or deformation. In the leather industry, this method enhances softness and color fixation, while also reducing microbial contamination for improved hygiene and longevity.

Infrared heating softens fibers, making materials more flexible and easier to process.

The technology improves dye fixation, resulting in more vivid and lasting colors.

Quartz infrared radiators offer faster drying and higher energy efficiency, which increases production speed and lowers costs.

Manufacturers experience fewer rejected products and less waste, which translates to higher yields and better resource utilization.

Repeatability defines the ability to produce identical results in every production cycle. Infrared heating emitters support this goal through precise temperature control and stable, efficient radiation. The use of quartz glass lamps and tungsten filaments ensures consistent heating quality and lamp longevity. Advanced control systems allow operators to tailor temperature profiles to specific materials and processes, maintaining strict tolerances.

Reliable repeatability means manufacturers can guarantee product quality batch after batch, meeting industry standards and customer expectations.

YFR’s customizable solutions enable seamless integration into automated production lines, supporting flexible and efficient manufacturing. This consistency not only improves product quality but also builds trust with clients who demand uniformity in every order.

Industrial environments demand equipment that can withstand harsh conditions and continuous operation. YFR Gold Reflector Quartz Halogen Infrared Heaters deliver exceptional durability. Each heater features a robust quartz tube that endures temperatures above 800°C. The gold reflector not only boosts efficiency but also protects internal components from thermal stress. With a lifespan exceeding 10,000 hours, these heaters outlast many traditional heating elements. The IP65 protection rating ensures resistance to dust, moisture, and even explosive atmospheres. This level of protection makes YFR heaters suitable for production lines where reliability and safety are critical.

A comparison of typical lifespans across heating technologies highlights the advantage of advanced infrared solutions:

Heating Technology | Typical Lifespan (hours) | Key Advantages Compared to Others |

|---|---|---|

Near-Infrared (NIR) LEDs | 25,000 to 50,000+ | Much longer lifespan; mercury-free; higher energy efficiency; less frequent replacements |

YFR Quartz Halogen IR Heaters | 10,000+ | High durability; rapid heating; industrial-grade reliability |

Incandescent Infrared Sources | Few thousand | Short lifespan; higher heat output; may contain hazardous materials |

Fluorescent Infrared Sources | Few thousand | Short lifespan; contains mercury; less energy efficient |

YFR heaters stand out for their combination of long service life and robust construction, making them a dependable choice for demanding industrial applications.

YFR Gold Reflector Quartz Halogen Infrared Heaters require minimal maintenance. The quartz tube resists corrosion and thermal shock, reducing the need for frequent inspections or replacements. Operators benefit from a design that minimizes moving parts and eliminates the risk of filament sagging or breakage. The gold reflector maintains its efficiency over time, so performance remains consistent throughout the heater’s lifespan.

Tip: Regular cleaning of the quartz surface ensures optimal infrared transmission and extends operational life.

Facilities that use YFR heaters experience fewer interruptions for repairs or part replacements. This reliability allows maintenance teams to focus on other critical tasks, improving overall plant efficiency.

Unplanned downtime can disrupt production schedules and increase costs. YFR heaters help minimize these risks through their robust design and long operational life. The instant heating capability means that production lines can resume full operation within seconds after a stop. The IP65-rated enclosure protects against dust and moisture, reducing the likelihood of failures caused by environmental factors.

Key benefits of YFR heaters for downtime reduction:

Fewer unexpected breakdowns

Quick replacement and integration due to modular design

Consistent performance in harsh environments

Manufacturers who choose YFR Gold Reflector Quartz Halogen Infrared Heaters gain a reliable heating solution that supports continuous, high-quality production. The combination of durability, low maintenance, and reduced downtime translates into higher productivity and lower total cost of ownership.

Convection heating remains a common method in many industrial processes. This approach uses heated air circulated by fans or blowers to transfer energy to the product. The hot air envelops the material, gradually raising its temperature. Convection ovens often require significant time to reach operating temperature and to cool down after use. The process works well for complex shapes and mixed loads because the moving air can reach into recesses and contours, ensuring uniform heating.

However, convection systems tend to consume more energy. They heat large volumes of air, much of which escapes or dissipates before reaching the product. This inefficiency leads to higher operational costs. The equipment footprint also grows larger, as convection ovens need more space to accommodate airflow and maintain temperature consistency. Operators must monitor airflow and oven profiling to ensure even results.

A direct comparison between convection and infrared heating emitter technologies highlights several important differences:

Aspect | Infrared Heating Emitters | Convection Heating Methods |

|---|---|---|

Heating Mechanism | Direct radiation heating of powder and substrate | Circulation of hot air around the part |

Curing Speed | 50-75% faster curing times; parts cure in minutes | Slower curing; requires longer dwell times |

Energy Efficiency | More energy efficient due to direct heating; less wasted heat | Less efficient; heats large air volumes, higher energy use |

Equipment Footprint | More compact ovens, shorter length needed | Larger ovens with longer footprint required |

Responsiveness | Heats up and cools down quickly; good for batch processing | Long thermal inertia; slow to heat and cool |

Uniformity | Can have shadowing issues on complex geometries | Excellent uniformity; hot air reaches recesses and contours |

Sensitivity to Color | Dark colors absorb IR better; light colors reflect IR | Color agnostic; cures all colors consistently |

Handling Thickness Variations | Requires precise control; thin parts risk over-cure, thick parts under-cure | More forgiving; slower conductive heat transfer handles variations better |

Monitoring Needs | Requires surface temperature monitoring with pyrometers | Focus on oven profiling and airflow maintenance |

Operational Complexity | Demands precise engineering and tuning | Established, widely understood method |

Suitable Applications | High throughput, simple shapes, tight space, energy cost sensitive | Complex shapes, mixed loads, consistent uniformity prioritized |

This table shows that an infrared heating emitter delivers faster curing and greater energy efficiency. Convection heating, while reliable for uniformity, often results in higher energy use and slower processing.

Conduction heating transfers energy through direct contact between a hot surface and the material. Industrial presses, heated plates, and molds use this method. The process works best for flat or simple-shaped items where full surface contact is possible. Conduction provides steady, predictable heating, but it struggles with uneven or complex geometries. The heat must travel through the material, which can lead to temperature gradients and slower processing times.

Operators often find conduction heating less flexible for high-throughput or variable production lines. The system requires regular maintenance to keep surfaces clean and ensure efficient heat transfer. Scaling up conduction systems for large or irregular products can prove challenging. In contrast, an infrared heating emitter can deliver targeted energy without direct contact, reducing the risk of contamination and improving process speed.

Radiant gas heaters use combustion to generate infrared energy. These systems burn natural gas or propane within a ceramic or metal emitter, which then radiates heat toward the product. Radiant gas heating works well for large spaces or outdoor environments, such as warehouses or drying rooms. The technology provides robust heating power and can cover broad areas.

However, radiant gas systems introduce combustion byproducts into the workspace. Operators must ensure proper ventilation and safety measures. The heaters also take longer to reach full temperature and may lack the precise control found in electric infrared systems. Maintenance involves regular inspection of burners and fuel lines. Infrared heating emitters, especially electric models, offer cleaner operation, faster response, and easier integration with automated controls.

Tip: Choosing the right heating method depends on the product, process requirements, and facility constraints. Infrared heating emitters often provide the best balance of speed, efficiency, and control for modern industrial applications.

Industrial heating technology has evolved rapidly, with infrared heating emitters now offering clear advantages over traditional methods. The most significant differences appear in speed, efficiency, control, and adaptability. The following table summarizes these distinctions:

Feature | Infrared Heating | Traditional Heating |

|---|---|---|

Heating Speed | Rapid thermal response; reaches ~1800 K almost instantly | Slower; heats entire chamber or relies on conduction |

Energy Efficiency | Significant energy savings; reduces sintering time by over 20 hours; power consumption ~700 KWh | Higher energy consumption; longer sintering times |

Heat Loss | Minimal due to direct energy transfer | Significant due to indirect heating methods |

Temperature Control | Precise with high accuracy and 1 ms response time | Less precise, slower response |

Throughput | Higher throughput due to faster cycles and reduced wafer heating time | Lower throughput due to longer processing times |

Integration | Modular, adaptable, supports automation and sustainability | Less flexible and harder to integrate |

Infrared heating emitters transfer energy directly to the target surface using electromagnetic waves. This direct approach enables rapid temperature ramp-up, which is essential for processes like semiconductor wafer manufacturing. Traditional methods, such as convection or conduction, heat the entire chamber or rely on contact, resulting in slower and less efficient energy transfer.

Manufacturers benefit from several key advantages when choosing infrared heating emitters:

Faster Processing: Infrared systems reach operating temperatures almost instantly. This speed reduces waiting times and allows for shorter production cycles.

Improved Energy Efficiency: Direct energy transfer minimizes heat loss. Facilities report significant reductions in power consumption and operational costs.

Precise Temperature Control: Infrared emitters offer high accuracy and rapid response, often within milliseconds. This precision helps prevent overheating and thermal stress, improving product quality.

Higher Throughput: Faster heating and cooling cycles increase the number of products processed in a given time frame.

Flexible Integration: Modular designs and automation compatibility make infrared systems easy to adapt to existing production lines.

Note: Infrared heating not only improves process efficiency but also supports sustainability goals by reducing energy waste and emissions.

The food industry relies on precise and efficient heating for processes such as drying, sterilization, and packaging. YFR Gold Reflector Quartz Halogen Infrared Heaters deliver rapid and uniform heat, which helps maintain the quality and safety of food products. These heaters support applications like drying fruits, baking, and sterilizing packaging materials. Operators can adjust the length, power, and voltage of each heater to match specific production requirements. This flexibility ensures seamless integration into existing lines and compliance with international food safety standards.

YFR’s technology enables instant heating, which reduces waiting times and energy consumption. The gold reflector design directs heat exactly where needed, minimizing waste and supporting consistent product outcomes. Food manufacturers benefit from shorter processing cycles, improved product texture, and reduced risk of contamination. The robust construction and IP65 protection rating allow these heaters to operate reliably in humid or demanding environments.

Tip: Customizable infrared heating solutions help food processors adapt quickly to new product lines or regulatory changes.

Printing operations demand fast, even drying and curing to achieve high-quality results. An infrared heating emitter provides targeted energy that penetrates materials like paper, textiles, and leather. This approach accelerates moisture evaporation and shortens drying times. YFR Gold Reflector Quartz Halogen Infrared Heaters offer precise control, which prevents defects such as cracking or deformation.

Infrared heating emitters enable uniform and rapid heating, reducing the risk of uneven drying.

The technology enhances color fixation, resulting in more vivid and lasting prints.

Energy efficiency improves significantly, with potential savings of over 50% compared to traditional drying methods.

Faster processing and simpler equipment design lower production costs.

The heat softens materials, making them easier to handle in subsequent steps.

Printing facilities experience higher throughput, better product consistency, and lower operational expenses. YFR’s customizable options ensure compatibility with a wide range of printing equipment and global industry standards.

Glass and packaging industries require high temperatures and precise control for processes such as annealing, coating, PET bottle blowing, and laminating. YFR Gold Reflector Quartz Halogen Infrared Heaters deliver instant, focused heat that supports these demanding applications. Operators can select the exact heater specifications needed for each process, ensuring optimal performance and energy use.

In glass manufacturing, uniform heating prevents stress and cracking during annealing. The gold reflector technology maximizes energy transfer, which improves process speed and product quality. In packaging, these heaters enable rapid molding and drying of materials, supporting high-speed production lines. The robust design withstands harsh industrial environments, while the IP65 rating ensures safe operation even in areas exposed to moisture or dust.

YFR’s deep customization capabilities allow seamless replacement of existing lamps and easy integration into automated systems. Manufacturers benefit from reduced downtime, consistent product quality, and compliance with international packaging standards.

Automotive manufacturing demands precise, reliable, and efficient heating solutions. YFR Gold Reflector Quartz Halogen Infrared Heaters play a vital role in several automotive processes. These heaters deliver instant, targeted heat, which supports high-speed production lines and strict quality requirements.

Automotive factories use infrared heating emitters for a variety of tasks:

Sunlight Simulation: Engineers test vehicle interiors and components for UV and heat resistance. YFR heaters simulate sunlight conditions, helping manufacturers ensure durability and comfort.

Sealing Strip and Wire Harness Heating: The assembly process often requires heating rubber sealing strips and wire harnesses. Infrared heaters provide uniform heat, which improves adhesion and flexibility.

Paint Curing and Drying: Automotive painting lines rely on rapid, even drying. YFR’s technology reduces cycle times and prevents defects such as blistering or uneven finishes.

Interior Bonding: Adhesive activation for dashboards, door panels, and upholstery benefits from precise temperature control. The gold reflector design ensures consistent results, reducing rework and waste.

Note: YFR’s customization options allow automotive manufacturers to specify heater length, power, and voltage. This flexibility supports integration into robotic arms, conveyor systems, and specialized workstations.

A comparison of key automotive applications and the benefits of YFR heaters:

Application | Benefit Provided by YFR Heaters |

|---|---|

Sunlight Simulation | Accurate, repeatable heat exposure |

Sealing Strip Heating | Improved adhesion, reduced cycle time |

Paint Curing | Faster drying, fewer surface defects |

Interior Bonding | Consistent adhesive activation, less waste |

Automotive plants often operate in challenging environments. The IP65 protection rating of YFR heaters ensures safe, reliable performance even in areas exposed to dust, moisture, or chemicals. The robust quartz tube construction withstands high temperatures and continuous use, supporting 24/7 production schedules.

Manufacturers benefit from:

Reduced downtime due to long heater lifespan (10,000+ hours)

Lower energy consumption and operational costs

Compliance with international automotive standards

YFR Gold Reflector Quartz Halogen Infrared Heaters help automotive companies achieve higher throughput, better product quality, and greater process flexibility. This advanced technology supports the evolving needs of modern vehicle manufacturing.

Every successful upgrade to infrared heating begins with a thorough process assessment. Facility managers and engineers must evaluate current heating methods, production goals, and material requirements. They often start by identifying bottlenecks or inefficiencies in existing systems. This step helps determine where infrared heating emitters can deliver the most value.

Key factors to consider during assessment include:

Material Properties: Different materials absorb infrared energy at different rates. Engineers analyze thickness, color, and surface finish.

Process Requirements: Each production line has unique temperature, speed, and uniformity needs.

Space Constraints: Available installation space influences emitter size and configuration.

Energy Consumption: Reviewing current energy usage highlights potential savings.

Tip: Collecting accurate data on current heating performance allows teams to set measurable improvement targets.

A detailed assessment ensures that the selected infrared solution, such as YFR’s Gold Reflector Quartz Halogen Infrared Heaters, aligns with operational objectives and maximizes return on investment.

Integrating infrared heating emitters into existing production lines requires careful planning. Engineers must match the new system’s specifications with current equipment and process flows. YFR’s heaters offer deep customization, which simplifies this step.

The integration process typically involves:

Specification Matching: Teams select the correct length, power, and voltage for each emitter.

Mechanical Installation: Mounting brackets and protective enclosures secure the heaters in place.

Electrical Connection: Electricians connect the heaters to power supplies and control panels.

Control System Integration: Operators link the emitters to automation systems for real-time monitoring and adjustment.

Integration Step | Consideration |

|---|---|

Specification Matching | Ensure compatibility with process |

Mechanical Installation | Maintain safety and accessibility |

Electrical Connection | Follow local electrical codes |

Control Integration | Enable precise temperature control |

YFR’s modular design and global compatibility make system upgrades straightforward. Teams can often replace old lamps without major modifications.

Safety remains a top priority during the implementation of infrared heating systems. YFR Gold Reflector Quartz Halogen Infrared Heaters feature IP65 protection, which guards against dust, moisture, and explosion risks. Proper installation and operation further enhance workplace safety.

Best practices for safe implementation include:

Training: Staff receive instruction on safe operation and emergency procedures.

Protective Barriers: Shields or covers prevent accidental contact with hot surfaces.

Routine Inspections: Regular checks identify wear, damage, or electrical issues.

Compliance: All installations follow local safety codes and industry standards.

Note: YFR’s robust construction and advanced safety features help facilities maintain a secure working environment, even in harsh industrial settings.

By following these steps, companies ensure that their transition to infrared heating technology delivers both performance and peace of mind.

When evaluating the implementation of infrared heating emitters in industrial environments, decision-makers focus on both immediate and long-term cost-benefit outcomes. YFR’s Gold Reflector Quartz Halogen Infrared Heaters offer a compelling value proposition by combining operational savings, process improvements, and sustainability advantages.

Key cost-benefit considerations include:

Energy Efficiency and Reduced Power Consumption:

Infrared heating emitters convert over 92% of electrical energy into usable heat. This high efficiency leads to lower utility bills and significant reductions in overall energy consumption. Facilities that switch to these systems often see a measurable decrease in monthly operating expenses.

Improved Product Quality and Throughput:

Rapid and precise temperature control enables faster processing cycles. Consistent heating reduces the risk of defects, which means fewer rejected products and less wasted material. Higher throughput allows manufacturers to increase production volumes without sacrificing quality.

Lower Maintenance and Downtime:

The robust design of YFR’s heaters, including quartz tubes and gold reflectors, minimizes the need for frequent maintenance. The system’s non-flow dependent operation eliminates many common failure points found in traditional heating methods. Reduced downtime translates directly into higher productivity and lower labor costs.

Environmental and Safety Benefits:

Infrared systems produce no harmful emissions, so facilities do not need to invest in complex ventilation or exhaust systems. The low external temperatures of the heaters reduce burn risks for operators. The elimination of flow sensors and other ancillary safety devices simplifies compliance with workplace safety standards.

Customization and Certified Quality:

YFR offers a wide range of customization options, allowing each installation to match specific process requirements. Certified quality, such as ISO 9000 and ATEX compliance, ensures that the heaters meet international standards and support regulatory compliance.

Sustainability and Waste Reduction:

Uniform heating minimizes material waste, while fast heating cycles save additional energy. Compatibility with renewable energy sources further enhances the sustainability profile of the facility.

Facilities that invest in advanced infrared heating technology often achieve a rapid return on investment. The combination of energy savings, improved product quality, and reduced maintenance costs creates a strong business case for upgrading legacy systems.

Benefit Area | Impact on Operations |

|---|---|

Energy Savings | Lower utility bills, reduced carbon footprint |

Product Quality | Fewer defects, higher consistency |

Maintenance | Less downtime, lower repair costs |

Safety & Compliance | Simpler safety protocols, regulatory support |

Sustainability | Reduced waste, renewable energy compatibility |

By considering these factors, industrial leaders can make informed decisions that balance upfront investment with long-term operational gains. YFR’s Gold Reflector Quartz Halogen Infrared Heaters stand out as a reliable solution for companies seeking both economic and environmental advantages.

Infrared heating emitter technology transforms industrial processes by delivering rapid, precise, and energy-efficient heat. YFR’s Gold Reflector Quartz Halogen Infrared Heaters set a new standard for reliability and customization. Facilities benefit from lower energy costs, improved product quality, and reduced downtime. These solutions adapt to diverse industries and production needs. Facility managers should evaluate their current systems and consider upgrading to modern infrared heating emitter solutions for long-term operational gains.

YFR’s gold reflector technology directs over 92% of electrical energy as usable heat. This design minimizes energy loss and reduces operational costs for industrial facilities.

Yes. YFR offers deep customization. Users can specify length, power, and voltage to match process requirements. This flexibility ensures seamless integration with existing equipment.

Infrared emitters deliver uniform, targeted heat. This approach reduces defects, enhances material properties, and ensures consistent results across production batches.

YFR heaters feature IP65 protection. This rating ensures resistance to dust, moisture, and explosion risks. The robust quartz tube construction supports safe operation in demanding settings.

Industries such as food processing, printing, glass, packaging, automotive, textiles, and electronics use YFR heaters. The technology supports rapid heating, precise control, and high product quality.

These heaters provide instant heating. They reach full operating temperature within seconds, which increases production speed and reduces downtime.

Each heater offers a lifespan exceeding 10,000 hours. This durability reduces replacement frequency and maintenance costs for industrial users.

YFR’s modular design and global compatibility allow for straightforward integration. Facilities can often replace old lamps without major modifications or downtime.