Views: 0 Author: Site Editor Publish Time: 2025-11-04 Origin: Site

In the global spices industry, where aroma, flavour, colour, and shelf life matter enormously, drying is a cornerstone operation. For a supplier such as Huai’an Yinfrared Heating Technology, offering industrial infrared heating solutions tailored for spice processing presents a strategic opportunity.

This article explores how infrared heaters for spices deliver value, what selection criteria spice processors should apply, and how to align system design, operation, and maintenance for optimal performance.

Drying spices removes moisture to inhibit microbial growth, stabilise flavour and aroma compounds, and ensure safe storage. Traditional methods—such as sun-drying or hot-air drying—often suffer from long drying times, thermal damage of volatile compounds, and uneven results.

Infrared (IR) heating offers clear advantages:

IR radiation heats the product directly through electromagnetic energy, enabling rapid and uniform heating of surfaces and near-surface moisture.

Drying time is significantly shorter, improving throughput and reducing energy consumption.

Infrared drying produces superior product quality by retaining aroma, colour, and essential oils.

Compact equipment footprint and faster response times allow greater flexibility in plant layout and operations.

IR systems can be designed to reduce production cost and improve drying uniformity across batches.

Preservation of volatile compounds: Spices contain delicate oils and aromas easily lost during excessive heating.

Uniform drying: Essential for consistent moisture content and microbial safety.

Energy efficiency: Lower energy cost per kilogram compared to convection drying.

Hygiene and compactness: Infrared dryers are suitable for clean, continuous production with smaller floor space.

When evaluating infrared heater systems for spice drying, processors should consider several crucial factors.

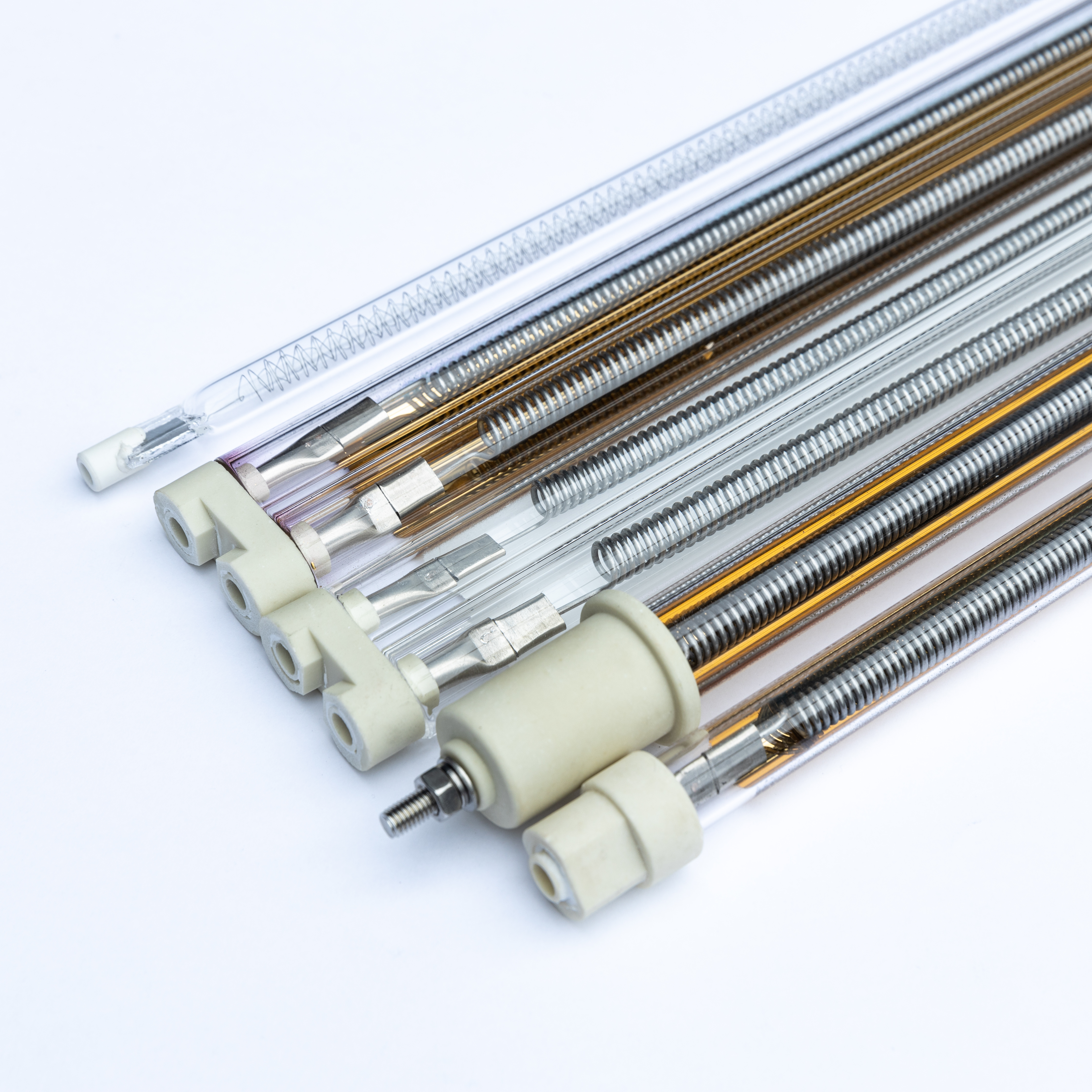

Infrared heaters are categorized by wavelength—short-wave, medium-wave, and far-infrared.

Each wavelength has a different penetration depth and interaction with the product surface.

Medium-wave emitters are generally optimal for spices because they gently heat the surface while allowing controlled internal moisture migration.

Short-wave IR may overheat delicate materials, while far-infrared offers slower, deeper heating suited to certain dense materials.

Selection should be based on spice type, layer thickness, and desired drying rate.

Adequate power density ensures efficient evaporation without scorching.

Uniform emitter spacing and proper reflector geometry guarantee even radiation distribution.

Airflow or convective assistance helps carry away moisture and improve drying uniformity.

A balance between IR power and air exchange determines final moisture and product quality.

A controlled drying curve—rapid initial surface heating followed by a gentle finish—is essential.

Product temperature and residence time must be managed to prevent aroma loss.

Zoned control allows precise adjustment for different spice varieties and moisture levels.

Retaining natural aroma and colour is a primary target.

Moderate IR intensity preserves essential oils and pigments.

Clean, stainless-steel housings and easy-access designs prevent contamination.

Infrared systems typically reduce drying energy by 20–50% due to higher heat transfer rates.

Reflector optimization, zone control, and waste-heat recovery further enhance efficiency.

Maintenance and emitter lifespan should be factored into total cost of ownership.

Choose between batch and continuous systems depending on production volume.

Integration with upstream cleaning and downstream cooling or packaging ensures a smooth workflow.

Sensors for temperature and moisture, coupled with programmable controls, improve consistency and traceability.

Infrared systems must include safety interlocks, shielding, and reliable temperature monitoring.

Construction materials should comply with food-industry standards.

Proper ventilation and dust control are required in spice processing facilities.

Ideal for smaller operations or high-value spices.

Easy to switch between different products.

Requires manual handling but offers excellent flexibility and control.

Designed for large-scale production with consistent product quality.

Features adjustable conveyor speed and multi-zone heating control.

Delivers high throughput and low labour cost.

Combines IR’s rapid heating with convective airflow to remove moisture.

Suitable for heat-sensitive or thick-layer spices.

Offers balanced drying time and quality preservation.

Suitable for particulate or irregular spices like peppercorns and chilli flakes.

Provides uniform exposure and gentle mixing.

Effective for coatings, blends, or granular products.

Maintain a uniform layer, typically 20–40 mm for whole spices and thinner for powders.

Prevent shading or uneven exposure by ensuring consistent loading.

Proper emitter distance determines heat flux and uniformity.

Reflectors focus radiation efficiently—routine cleaning prevents efficiency loss.

Drying follows two phases: rapid surface evaporation and slower internal moisture removal.

Continuous monitoring of product temperature is vital to avoid aroma loss.

Integrated airflow removes humid air and enhances drying rate.

Proper exhaust systems prevent re-condensation and maintain hygiene.

Advanced control systems adjust IR power, conveyor speed, and airflow automatically.

Data logging helps maintain consistency and trace performance over time.

Regular cleaning of reflectors and emitters ensures energy efficiency.

Establish preventive maintenance schedules for sensors and components.

Implement dust management and operator protection measures.

Infrared drying can reduce processing time by up to 60%, increasing plant capacity.

Energy use per kilogram decreases significantly, improving cost efficiency.

Higher aroma retention and brighter colour translate into higher market value.

Reduced rejects and uniform moisture content enhance shelf life and customer satisfaction.

IR dryers occupy less floor space, enabling streamlined factory design.

Automated controls reduce operator workload and human error.

Though emitters require periodic replacement, long-term savings from energy efficiency and reduced downtime yield fast payback—often within two years.

Baseline Assessment

Measure current drying time, energy use, and product quality benchmarks. Identify inefficiencies.

Pilot Testing

Run small-scale trials to determine the optimal emitter type, intensity, and residence time for each spice.

System Design

Collaborate with your equipment supplier to configure zone layouts, airflow paths, and control logic.

Economic Modelling

Calculate capital costs, projected savings, and expected payback period.

Installation and Commissioning

Validate control parameters and develop standard operating procedures (SOPs).

Continuous Optimization

Monitor performance metrics—energy per kilogram, product temperature, moisture uniformity—and fine-tune system settings.

A medium-scale spice processor producing turmeric slices and peppercorns transitioned from conventional hot-air drying to a hybrid infrared-convection tunnel.

Results:

Drying time reduced from 8 hours to 3.5 hours.

Energy consumption decreased by 35%.

Colour and aroma retention significantly improved.

Payback achieved within two years.

This demonstrates how data-driven IR system selection and optimisation can yield measurable performance gains.

| Challenge | Potential Impact | Mitigation Strategy |

|---|---|---|

| Uneven heating | Hotspots, burns | Uniform emitter spacing, reflectors, airflow balancing |

| Dust accumulation | Reduced efficiency, safety risk | Regular cleaning, dust extraction systems |

| Overheating delicate spices | Aroma loss | Lower IR intensity, multi-zone control |

| High initial cost | Budget constraint | ROI justification through energy and quality savings |

| Maintenance needs | Downtime | Preventive schedule, modular emitter replacement |

Infrared drying is transforming the spice industry by offering faster, cleaner, and more efficient moisture removal. For spice processors, adopting infrared heaters for spices delivers tangible benefits:

Shorter drying time and lower energy cost

Enhanced aroma, colour, and quality retention

Compact equipment layout and reduced labour

Better hygiene and sustainability performance

Rapid ROI through higher productivity and reduced waste

By selecting the correct wavelength, power density, and process control strategy, manufacturers can significantly enhance product value while meeting modern production standards.

Infrared technology is not merely an alternative—it is a key enabler of quality-driven, energy-efficient spice processing.

Last modified: 2025-11-03

content is empty!