Author: Site Editor Publish Time: 2025-09-25 Origin: Site

Infrared Heating Lamps in Plastic Processing: Applications and Case Studies

As the demand for efficiency, energy savings, and precise temperature control in plastic processing increases, infrared heating lamps have become the preferred heating solution. By providing fast heating and precise control, infrared heating lamps help enhance production efficiency while reducing energy consumption.

Compared to traditional heating methods like convection, hot air, or heat plates, infrared heating offers several advantages:

Rapid Response: Infrared lamps provide fast heat-up times, reaching the desired temperature quickly.

High Efficiency: Energy is directly radiated to the plastic material, reducing energy loss.

Localized Heating Control: Infrared heating can be precisely directed to specific areas, ensuring uniform heat distribution.

Customizable: Infrared lamps can be made in various lengths, power ratings, and voltage to meet the specific needs of plastic processing operations.

Long Lifespan: When designed and used correctly, infrared heating lamps offer long-lasting performance.

Infrared heating has become a standard solution in industries such as thermoforming, blow molding, welding, and plastic film lamination.

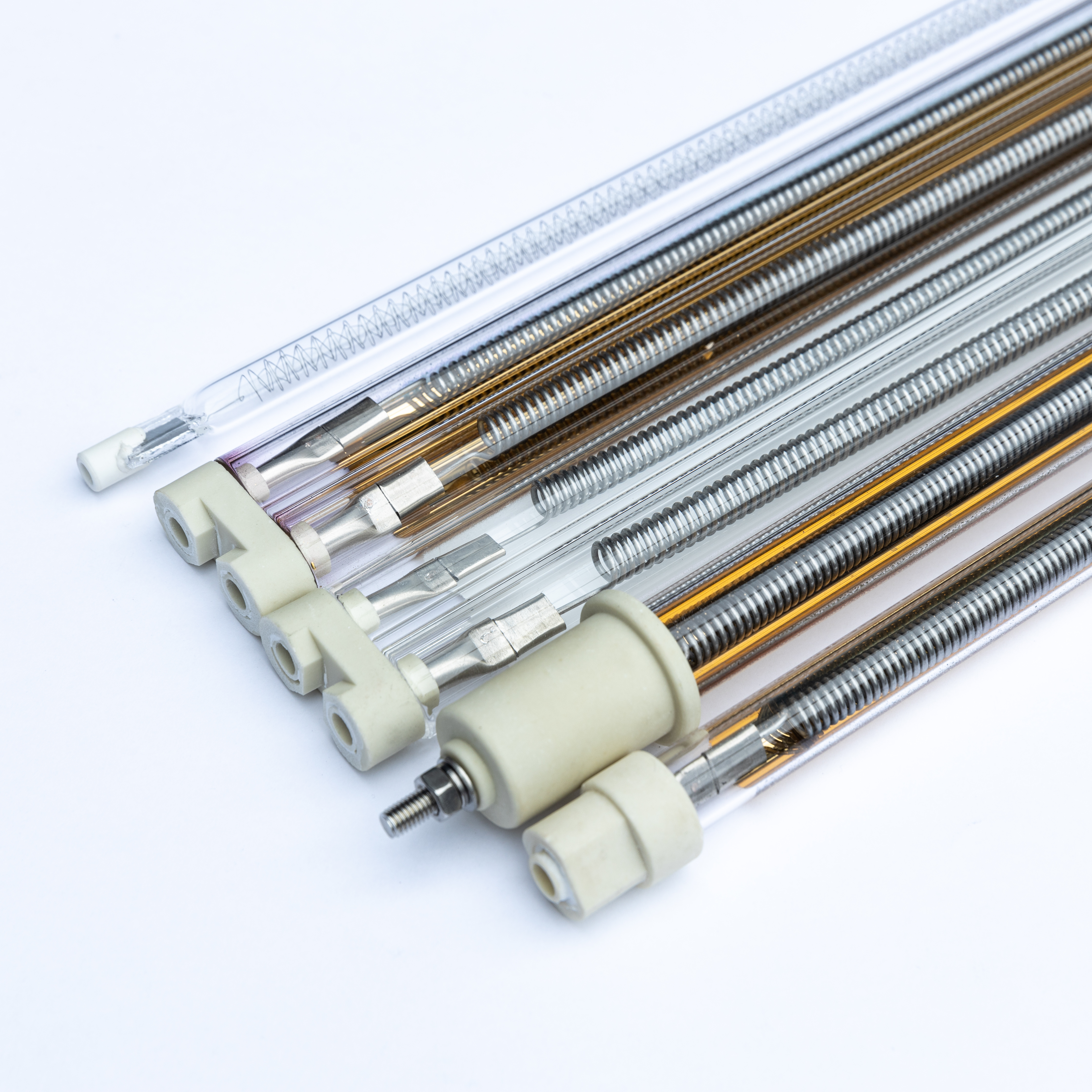

At Yinfrared, we offer a wide range of infrared heating lamps, including short-wave, medium-wave, fast medium-wave, and quartz tube infrared lamps. Our lamps come in power ratings from 200W to 12,000W and can be customized in length, power, and voltage to meet the unique needs of different plastic processing applications.

| Type | Features | Ideal Applications |

|---|---|---|

| Short-wave infrared lamps | Rapid heating, ideal for surface heating | Plastic film thermoforming, drying |

| Medium-wave / Fast medium-wave | Stronger penetration, ideal for thick plastics | Sheet heating, welding |

| Quartz tube infrared lamps | High-temperature tolerance, suitable for high-power heating | Plastic welding, bending |

When applying infrared heating in plastic processing, there are several critical technical considerations:

Different plastics absorb infrared radiation at different wavelengths. To maximize heating efficiency, it's important to match the wavelength of the infrared lamps to the plastic material. For example:

Short-wave infrared is suitable for thin films and surface heating.

Medium-wave or fast medium-wave is more effective for thicker materials with greater heat penetration.

The distance and angle between the infrared lamp and the plastic surface affect heat distribution. By designing reflectors, shields, and other components, uniform heating can be achieved, preventing hot or cold spots.

In large-scale or complex processing, infrared lamps can be divided into multiple heating zones, each with independent temperature control. This is ideal for large plastic sheets or products with varying thicknesses.

Plastic processing often requires quick adjustments to heating temperature or dynamic heating. Infrared heating systems provide a fast response, enabling quick switching or temperature adjustments to meet production needs.

To ensure long lifespan and stable performance in industrial environments, infrared heating lamps require proper cooling, sealing, and material selection. This helps to withstand high temperatures and prevent premature failure.

Here are several common applications and case studies showing how infrared heating lamps are used in the plastic processing industry:

Customer Challenge: The customer used a hot air system for preheating PET preforms, but the heating time was too long, leading to low production efficiency and high energy consumption.

Solution: We designed a system with 6 short-wave infrared heating modules, improving preheating speed and reducing energy consumption.

Result: Preheating time was reduced by 35%, and energy consumption decreased by approximately 22%. The customer reported a more stable production process with better temperature consistency.

Customer Challenge: Traditional hot air heating led to warping of acrylic sheets and poor forming precision.

Solution: We provided custom curved quartz infrared lamps to heat the bending areas, ensuring uniform heating and precision forming.

Result: Bending cycle time was reduced from 30 seconds to 10-15 seconds, with minimal warping and better product quality.

Customer Challenge: In the lamination process of optical films, the customer struggled with the need to heat the adhesive layer quickly without overheating or warping the base material.

Solution: We provided medium-wave infrared lamps positioned above and below the film, enabling even and rapid heating.

Result: Lamination speed increased by 40%, with a reduction in product defects and better lamination consistency.

Q: What is the lifespan of infrared heating lamps?

A: With proper design and usage, infrared heating lamps can last over 10,000 hours, depending on operating conditions.

Q: Do you offer customized infrared heating lamps?

A: Yes, we offer customized infrared lamps in various lengths, power ratings, and voltages to meet the specific requirements of your plastic processing needs.

Q: How do infrared lamps compare to traditional heating methods?

A: Infrared lamps provide faster heating, greater energy efficiency, and more precise temperature control. They are ideal for applications requiring rapid temperature changes or localized heating.

Q: Can infrared heating be used for all types of plastics?

A: Yes, infrared heating is suitable for a wide range of plastics, including PET, ABS, PMMA, PVC, and more. The specific wavelength and heating power can be tailored to the material's properties.

Infrared heating lamps (infrared heating lamps, industrial heating lamps, ir lamps, and ir heaters) are transforming the plastic processing industry by improving heating efficiency, reducing energy consumption, and ensuring precise temperature control. With numerous applications in thermoforming, blow molding, welding, and film lamination, infrared heating is becoming the go-to solution for many industries.

If you're looking to upgrade your plastic processing systems for better efficiency, lower energy consumption, and more consistent production, feel free to contact us for a free custom solution and technical support.

content is empty!