Author: Site Editor Publish Time: 2025-07-17 Origin: Site

Infrared heating technology delivers unmatched precision, efficiency, safety, and sustainability for wafer processing. Advanced infrared heating achieves rapid thermal response and high energy conversion, making it a cornerstone in modern semiconductor manufacturing. Companies like Huai'an Infrared Heating Technology drive progress with YFR Quartz IR Emitters, which use tungsten and carbon fiber filaments, halogen cycle gases, and smart control systems. These innovations in infrared heating technology bring precise temperature control, uniform heating, and improved energy efficiency. Infrared heating in semiconductor industry now sets new standards for quality and eco-friendly production.

Infrared heating delivers fast, precise, and uniform temperature control, improving wafer quality and process consistency.

The technology heats wafers directly without warming surrounding air, saving energy and reducing heat loss.

Advanced sensors and control systems enable accurate temperature monitoring and adjustments, ensuring stable processing.

Rapid heating and cooling cycles increase production speed and reduce thermal stress on wafers.

Infrared heating uses less energy than traditional methods, lowering costs and supporting environmental sustainability.

The system design offers flexibility to adapt heating profiles for different wafer sizes and processing needs.

Infrared heating produces no harmful emissions, enhancing workplace safety and reducing environmental impact.

Integration with existing production lines and automation systems is straightforward, supporting efficient manufacturing.

Infrared heating operates by emitting electromagnetic waves that transfer energy directly to wafer surfaces. This process does not require heating the surrounding air, which allows for rapid and targeted thermal delivery.

The wavelength and frequency of the infrared radiation determine the amount of energy transferred. Shorter wavelengths deliver higher energy, which is essential for efficient heat transfer in semiconductor manufacturing.

The infrared spectrum ranges from about 700 nanometers to 10 microns. Engineers can select specific wavelengths to match the properties of the wafer material, optimizing the heating process.

Radiant heat transfer bypasses conduction and convection, reducing energy loss and enabling precise temperature control. Specialized heating elements and reflectors in modern systems maximize radiant heat delivery and minimize waste.

Infrared heating systems can reach very high temperatures quickly, making them ideal for industrial wafer processing where precise and rapid thermal control is critical.

Tip: The direct nature of infrared heating allows manufacturers to achieve uniform heating across the wafer, improving process consistency and product quality.

Infrared radiation interacts with semiconductor wafers at the atomic level. When the wafer absorbs infrared energy, it couples with optic phonons—quantized vibrations within the crystal lattice of the material. This interaction leads to the formation of surface phonon polaritons, which are electromagnetic modes bound to the wafer surface. The characteristics of these modes depend on the wafer's atomic structure and can be engineered by adjusting the composition and layering of the material. Changes at the atomic scale, such as phase transformations or defect formation during processing, can alter how the wafer absorbs and responds to infrared radiation. These atomic-level effects influence the efficiency and uniformity of infrared heating in wafer processing.

Electron transitions play a vital role in the absorption of infrared energy during wafer processing. In advanced semiconductor devices, such as quantum dot infrared photodetectors, electrons absorb infrared photons and move from their ground state to higher energy states. The design of the wafer's nanostructure enhances this process by allowing electrons to transition efficiently to resonant states in the conduction band. These transitions enable effective carrier extraction and contribute to the generation of photocurrent. Electron-phonon interactions and carrier scattering also affect how energy is absorbed and distributed within the wafer. As a result, electron transitions are central to the performance and efficiency of infrared heating in semiconductor manufacturing.

Precision

Infrared heating systems deliver exceptional precision in wafer processing. Engineers design these systems with advanced control architectures, such as individual zone PID controllers and centralized PLC-based systems. Solid state relays ensure reliable power switching and minimize electromagnetic interference. Closed-loop control uses temperature feedback from sensors like thermocouples embedded in the heater or non-contact pyrometers measuring the wafer surface. These technologies enable rapid and accurate temperature adjustments, which are essential for maintaining process integrity.

Modern infrared heating solutions also integrate advanced sensor arrays. These arrays combine thermopile sensors and NTC thermistors, managed by FPGA-based control boards. Multiparameter temperature compensation algorithms correct for sensor variations and environmental influences. Calibration techniques, including automatic and machine learning-based methods, further enhance measurement accuracy. Some systems achieve temperature control accuracy as fine as 0.2 K. These features allow manufacturers to maintain stable and precise temperatures, even in complex industrial environments.

Note: High precision temperature control reduces energy waste and improves product quality, making infrared heating a preferred choice for semiconductor applications.

Uniform temperature distribution across the wafer surface is critical for consistent processing results. Infrared heating plates use high-quality materials with certified chemical composition and verified homogeneity. Precision machining creates smooth surfaces that maintain uniform heat and reduce energy consumption. Engineers design these plates with drilled and milled channels for heating medium flow, forming a comprehensive heating field that prevents hotspots.

Infrared heating applies radiant energy directly to the wafer, avoiding physical wear on heating elements and ensuring a longer operational lifespan.

The technology supports rapid heating and cooling cycles, allowing quick temperature adjustments.

Uniform heat distribution minimizes temperature gradients, which improves product quality and reduces mold wear.

Real-time feedback loops and regular calibration strategies help maintain uniformity during processing.

Temperature uniformity is measured using advanced non-contact methods, such as multi-wavelength pyrometry. Fiber optic temperature sensors provide high spatial resolution and immunity to electromagnetic interference. Wireless temperature wafer systems embed sensors in wafer-like carriers, transmitting real-time data for comprehensive thermal mapping. Systems like SensArray offer up to 65 measurement points, enabling detailed spatial temperature analysis.

Accurate temperature monitoring is essential for effective infrared heating in wafer processing. Engineers use a range of measurement tools to ensure precise control:

Feature | Description |

|---|---|

Precision Accuracy | High measurement accuracy suitable for semiconductor wafers and metals. |

Fast Response | Ultra-fast 1 ms response time for real-time temperature monitoring. |

Adjustable Focus Optics | Allows ultra-small spot sizes for precise targeting on small wafer areas. |

Temperature Range | Measures temperatures from 250°C to 3300°C, covering typical wafer processing conditions. |

Portability & Durability | Hand-held, rugged design with laser aiming and optical sighting for easy alignment and use. |

Infrared thermometers, such as the IT-270, use precision thermopile sensors and stable blackbody furnaces for calibration. These devices achieve measurement errors within ±0.4°C in the 100–200°C range. Their internal structure resists ambient temperature fluctuations and electromagnetic noise, ensuring reliable readings in demanding manufacturing environments. High spatial resolution and fast response times enable detailed temperature mapping and real-time process control.

Infrared heating delivers rapid thermal response, which is essential for wafer processing in the semiconductor industry. The technology uses electromagnetic waves to transfer energy directly to the wafer surface. This direct approach allows the wafer to reach target temperatures within seconds. For example, in rapid thermal annealing, wafers can achieve temperatures as high as 1800 K almost instantly. This fast ramp-up is critical for activating dopants and controlling diffusion, both of which are vital steps in semiconductor manufacturing.

Engineers value this speed because it reduces the time each wafer spends in the heating chamber. The quick heating and cooling cycles also help prevent unwanted changes in the wafer’s structure. As a result, manufacturers can process more wafers in less time, increasing overall productivity.

Tip: Rapid heating not only boosts production speed but also helps maintain the quality of the wafer by minimizing thermal stress.

Industrial infrared heating stands out for its impressive energy efficiency. Unlike traditional methods that heat the entire chamber or rely on conduction, infrared heating applies energy directly to the wafer. This targeted approach minimizes heat loss and maximizes energy transfer.

In wafer processing, this efficiency translates into significant energy savings. For instance, infrared heating can reduce sintering times by over 20 hours and lower power consumption to about 700 KWh. Traditional heating techniques often require much more energy for the same process. The ability to heat and cool quickly further reduces overall energy consumption, making the process more sustainable and cost-effective.

Feature | Infrared Heating | Traditional Heating |

|---|---|---|

Sintering Time | Reduced by 20+ hrs | Longer |

Power Consumption | ~700 KWh | Higher |

Heat Loss | Minimal | Significant |

Note: Lower energy use not only cuts costs but also supports environmental goals by reducing the carbon footprint of semiconductor manufacturing.

Throughput measures how many wafers a facility can process in a given time. Infrared heating plays a key role in boosting throughput. The technology’s rapid temperature ramp-up means each wafer spends less time in the heating stage. This efficiency allows manufacturers to handle more wafers per hour.

In rapid thermal annealing, precise temperature control is crucial. Infrared sensors monitor the wafer surface, ensuring even heating and preventing overheating. Accurate sensing helps maintain high yield rates and avoids defects that could slow down production. Although exact throughput gains vary, the ability to process wafers faster and with fewer errors gives manufacturers a clear competitive advantage.

Faster processing cycles

Improved yield due to precise temperature control

Reduced downtime between batches

Callout: Enhanced throughput means semiconductor companies can meet growing market demands without sacrificing quality.

Infrared heating stands out in wafer processing for its clean operation. The technology does not rely on combustion, so it avoids producing pollutants such as carbon monoxide, nitrogen oxides, or particulate matter. Instead, infrared systems emit non-ionizing radiation and use electricity as their energy source. This approach results in no direct emissions during wafer processing. Facilities that use infrared heating do not need to install complex ventilation systems to manage harmful gases, unlike those that use gas heaters. The absence of combustion also means that air quality remains high, with no release of dust or allergens. When powered by renewable energy, infrared heating can operate with almost no carbon footprint, making it a responsible choice for modern semiconductor manufacturing.

Infrared heating improves workplace safety and environmental quality by eliminating harmful byproducts and supporting cleanroom standards.

Resistive heating elements in infrared systems contribute significantly to safety in semiconductor environments. These elements do not depend on fluid flow, so they eliminate the need for flow sensors required by certain safety standards. The design avoids common maintenance issues found in traditional IR lamps, such as socket failures or the need for cooling systems. External housing temperatures remain low, usually not exceeding 50°C, which reduces the risk of accidental burns. The heating elements maintain direct contact with quartz surfaces, ensuring efficient heat transfer and better absorption by chemicals used in wafer processing. This setup minimizes the risk of overheating or uneven heating. Operators can monitor resistive heaters to optimize performance under different conditions, supporting stable and controlled heating. Unlike flow-dependent systems, resistive heating continues to function safely even if liquid flow stops, further enhancing operational reliability.

Non-flow dependent operation eliminates extra safety devices.

Low external temperatures reduce burn risk.

Direct contact with quartz ensures efficient and safe heat transfer.

Maintenance needs decrease, supporting continuous production.

Infrared heating supports sustainability goals in wafer processing through several key advantages. The technology delivers uniform heat distribution, which ensures consistent product quality and reduces material waste. Rapid heating and cooling cycles increase production efficiency and lower energy consumption. By focusing heat directly on the wafer, infrared systems use less power than conventional methods, reducing operational costs. The precise temperature control also extends the lifespan of molds and equipment by minimizing thermal stress, which decreases the frequency of replacements and further reduces waste. Infrared heating produces no harmful by-products, making it a cleaner alternative to gas-based systems. When facilities use renewable electricity, the environmental impact drops even further.

Uniform heating reduces defects and waste.

Fast cycles boost efficiency and save energy.

Lower power consumption supports cost savings.

Cleaner operation aligns with environmental regulations.

Infrared heating enables semiconductor manufacturers to meet both production and sustainability targets, positioning the technology as a forward-thinking solution for the industry.

Infrared heating systems offer remarkable design flexibility for wafer processing. Engineers can configure these systems with multi-zone lamp arrangements, such as axisymmetric illuminators featuring concentric rings of lamps. Each zone operates independently, allowing precise control over the radial heat flux. This flexibility enables manufacturers to tailor the heating profile to different wafer sizes and specific process requirements. Advanced control models, including nonlinear multiple-input multiple-output (MIMO) systems, manage temperatures at multiple points on the wafer simultaneously. These models ensure uniform temperature distribution, which is essential for high-quality semiconductor production. Adaptive strategies, such as gain-scheduled PID controllers and decoupling control systems, further enhance the system’s ability to maintain stable and repeatable thermal environments. These features allow infrared heating systems to adapt quickly to changes in wafer surface properties or process demands, supporting a wide range of manufacturing scenarios.

Design flexibility in infrared heating supports innovation and process optimization in semiconductor fabrication.

The uses of infrared radiant heating extend across many stages of wafer processing and related semiconductor applications. The following table highlights several key applications and their purposes:

Application | Description and Purpose |

|---|---|

Infrared Preheating for Flux Soldering | Raises PCB temperature to activate flux and evaporate moisture or solvents. Especially effective for multi-layer boards using twin tube gold reflector lamps for faster heating. |

Solar Cell Sintering | Sintering of electrodes printed on silicon wafers at high temperatures (up to 1000°C). Independent temperature control in different chambers optimizes the sintering process. |

PCB Circuit Board Leveling | Provides stable, uniform radiation to level multi-layer PCB boards. Improves production efficiency and reduces deformation by heating both sides simultaneously with quartz infrared lamps. |

Wafer Heating Device | Removes impurities, activates materials, adjusts shapes, and enhances silicon wafer quality. Infrared pyrometers and tungsten halogen lamps ensure precise and uniform heating. |

Vacuum Reflow Soldering Furnace | Uses infrared radiation in a vacuum to prevent oxidation, improve weld quality, reduce porosity, and enable stable, uniform, low-temperature soldering for high-precision products. |

Vacuum Electroplating Furnace | Provides precise temperature control and uniformity during electroplating in vacuum. Improves the quality and durability of electroplated layers while ensuring process safety and stability. |

These diverse applications demonstrate the adaptability of infrared heating technology in supporting both traditional and advanced semiconductor manufacturing processes.

Manufacturers can easily integrate infrared heating systems into existing wafer processing lines. The modular design of many infrared emitters allows for straightforward installation and retrofitting. Engineers can select from a variety of lamp types, such as short wave, medium wave, or carbon infrared heaters, to match specific process requirements. Integration with automated control systems enables real-time monitoring and adjustment of heating parameters. This compatibility ensures that infrared heating solutions work seamlessly with other process equipment, such as temperature feedback sensors, robotic wafer handlers, and cleanroom automation systems. The ability to integrate with digital control platforms also supports data-driven process optimization and traceability, which are increasingly important in modern semiconductor manufacturing.

Seamless integration of infrared heating technology enhances process efficiency and supports continuous improvement in wafer processing environments.

Wafer heating devices play a crucial role in preparing semiconductor wafers for subsequent processing steps. Manufacturers use these devices to remove impurities, activate materials, and adjust the physical properties of the silicon wafer. Companies such as Cast Aluminum Solutions (CAS) have developed advanced pedestal heaters with multi-zone heating and integrated cooling tubes. These systems ensure precise temperature control and uniform heating, which are essential for high-yield semiconductor fabrication. In practice, engineers often employ infrared cameras in test labs to validate temperature uniformity across both atmospheric and vacuum chamber environments. This approach highlights the importance of infrared heating technology in achieving consistent results during wafer preparation.

Huai'an Infrared Heating Technology exemplifies innovation in this field. Their YFR Quartz IR Emitters deliver rapid, direct radiant heat to wafer surfaces, supporting efficient impurity removal and material activation. The company’s diverse product portfolio, including short wave and medium wave infrared lamps, allows customization for different wafer sizes and process requirements.

Accurate temperature feedback is vital for maintaining process integrity in wafer heating devices. Engineers integrate advanced sensors and control systems to monitor real-time temperature at multiple points on the wafer. Infrared thermometry, combined with embedded thermocouples, provides high-resolution data that supports closed-loop control. This feedback ensures that the wafer receives uniform heating, reducing the risk of thermal gradients and defects.

Manufacturers like Huai'an Infrared Heating Technology equip their systems with sophisticated power controls and feedback mechanisms. These features enable precise adjustments, ensuring that each silicon wafer meets strict quality standards. Certifications such as TUV and certificates of conformity further guarantee the reliability and safety of these devices in demanding semiconductor environments.

Reflow soldering is a critical process in wafer assembly, where achieving uniform temperature distribution is essential for reliable solder joints. Infrared heating technology directly transfers energy to the solder paste and components, enabling rapid and efficient heating. However, different materials on the printed circuit board (PCB) absorb infrared radiation at varying rates, which can lead to temperature variations. To address this challenge, engineers often combine infrared heating with forced hot air convection. This hybrid approach equalizes temperature differences caused by material absorption and shadowing, resulting in a more uniform temperature profile across the PCB.

Uniform heating during reflow soldering minimizes the risk of cold joints and ensures consistent electrical performance in semiconductor devices.

Infrared heating has become a preferred method for reflow soldering, especially for double-sided assembled substrates. Its cost-effectiveness and rapid thermal response make it suitable for high-volume manufacturing. Leading brands, including Huai'an Infrared Heating Technology, offer specialized infrared emitters designed for reflow soldering applications. These products support precise temperature control and fast cycle times, which are critical for meeting industry demands.

The market for reflow soldering equipment continues to grow, driven by the need for miniaturization and automation in semiconductor assembly. Infrared heating technology remains at the forefront, providing manufacturers with the tools to achieve high throughput and consistent quality.

Electroplating processes in semiconductor manufacturing require precise temperature control to ensure the quality and durability of metal layers deposited on wafers. Infrared heating devices deliver uniform radiant energy, which helps maintain stable bath temperatures and promotes even metal deposition. This uniformity reduces the risk of defects such as pinholes or uneven thickness, which can compromise device performance.

Huai'an Infrared Heating Technology’s YFR Quartz IR Emitters are engineered to provide consistent heat distribution, supporting high-quality electroplating outcomes. The company’s commitment to product diversity allows customers to select the optimal emitter type for their specific electroplating requirements.

Process stability is a key concern in electroplating. Infrared heating systems offer rapid response times and precise control, enabling operators to maintain tight temperature tolerances throughout the plating cycle. This stability enhances the reproducibility of results and extends the lifespan of process equipment.

Manufacturers prioritize energy efficiency and environmental responsibility. Infrared heating technology stands out for its ability to reduce energy consumption while maintaining process stability. The industry also values products that meet rigorous safety and quality standards. Certifications such as ISO 9000, QC-1, and international safety marks like ATEX and IECEx demonstrate a manufacturer’s commitment to compliance and reliability.

The combination of product diversity, energy efficiency, and certified quality makes infrared heating technology a cornerstone of modern wafer processing.

Key Strengths of Infrared Heating in Wafer Processing:

Wide product range tailored to various applications and wafer sizes

High energy efficiency and rapid thermal response

Advanced temperature control for process precision

Compliance with international safety and quality standards

Feature | Benefit |

|---|---|

Product Diversity | Solutions for preparation, soldering, and plating |

Energy Efficiency | Lower operational costs and reduced carbon footprint |

Certifications | Assurance of safety and quality |

Manufacturers like Huai'an Infrared Heating Technology continue to drive innovation, supporting the evolving needs of the semiconductor industry with reliable and efficient infrared solutions.

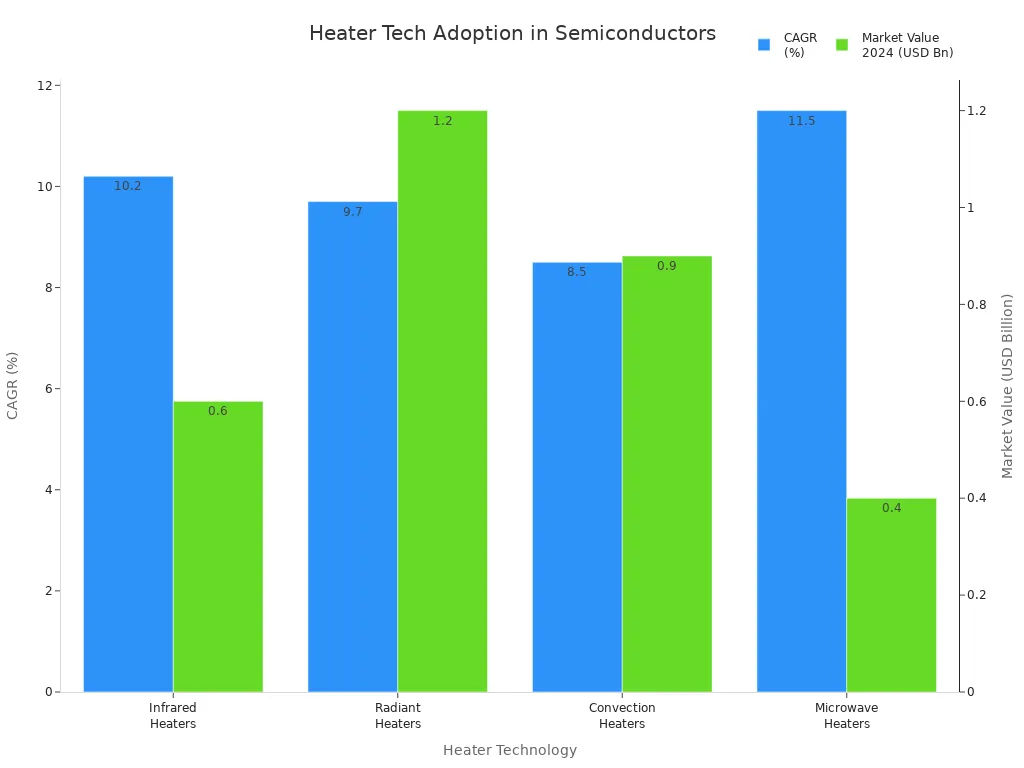

Infrared heating in semiconductor industry continues to gain momentum as manufacturers seek advanced thermal solutions. The adoption rate reflects strong growth, with infrared heaters showing a compound annual growth rate (CAGR) of 10.2% and a projected market value of $0.6 billion by 2024. This technology supports rapid heating and precise temperature control, making it a preferred choice for bonding and curing processes. The following table compares the adoption rates and market values of different heater technologies in the semiconductor sector:

Heater Technology | CAGR (%) | Projected Market Value by 2024 (USD Billion) | Key Application Highlights |

|---|---|---|---|

Infrared Heaters | 10.2 | 0.6 | Rapid heating, precise temperature control; used in bonding and curing |

Radiant Heaters | 9.7 | 1.2 | Precise, localized heating; used in reflow soldering and curing |

Convection Heaters | 8.5 | 0.9 | Uniform heat distribution; used in drying and preheating |

Microwave Heaters | 11.5 | 0.4 | Rapid, uniform volumetric heating; used in plasma etching and RTP |

Manufacturers worldwide recognize the value of infrared heating in semiconductor industry for its ability to deliver fast, accurate, and targeted heat. This trend aligns with the industry's push for higher throughput and quality.

Infrared heating in semiconductor industry offers several key advantages that drive its widespread adoption:

Precise thermal application supports critical processes such as etching, annealing, and doping.

Consistent heat reduces defects and ensures high product quality.

Energy efficiency lowers operational costs and supports eco-friendly manufacturing.

Smart heating systems improve operational efficiency and sustainability.

Fast, targeted heating prevents damage to delicate components and extends product life.

Advanced ceramic and quartz infrared heaters enhance heat distribution, response times, and durability.

Customizable solutions allow manufacturers to tailor heating systems for specific needs, improving process reproducibility.

Infrared heating in semiconductor industry enables better control of temperature and heating time, supporting automation and high-yield production.

The future of infrared heating in semiconductor industry points toward greater integration of digital and sustainable technologies. Artificial intelligence (AI) will optimize wafer heating by predicting temperature fluctuations and adjusting parameters in real time. Sustainability remains a top priority, driving the development of energy-efficient and green heating solutions. The rise of automation and digitization, including IoT and smart sensors, will further improve operational efficiency and enable predictive maintenance.

Industry experts forecast rapid advancements in heater precision, energy efficiency, and uniform temperature distribution. Regulatory frameworks and government incentives encourage investments in innovative, eco-friendly wafer heating equipment. The Asia-Pacific region stands out as a key growth area due to its expanding semiconductor manufacturing base. Manufacturers invest heavily in research and development to enhance heater efficiency, durability, and modularity, ensuring that infrared heating in semiconductor industry remains at the forefront of technological progress.

Infrared heating delivers unmatched precision, efficiency, safety, and environmental benefits for wafer processing. Leading companies like Huai'an Infrared Heating Technology set industry standards with innovative solutions such as YFR Quartz IR Emitters.

Precision temperature control improves product quality.

Rapid heating increases throughput and reduces energy use.

Clean operation supports sustainability goals.

The future of semiconductor manufacturing will see even smarter, more sustainable infrared heating technologies driving progress worldwide.

Infrared heating provides rapid, uniform, and precise temperature control. Manufacturers achieve higher energy efficiency and improved product quality. The technology supports cleanroom standards and reduces operational costs.

YFR Quartz IR Emitters deliver direct, efficient radiant heat. Engineers use them to achieve fast thermal response and stable temperature profiles. These emitters support high throughput and consistent wafer quality.

Manufacturers can easily integrate infrared heating systems into current wafer processing lines. Modular designs and digital controls allow seamless compatibility with automation and monitoring equipment.

Infrared heating produces no direct emissions or harmful byproducts. Facilities using renewable electricity further reduce their carbon footprint. The technology supports sustainability goals in semiconductor manufacturing.

Manufacturers offer short wave, medium wave, and carbon infrared lamps. Each type suits different heating applications. Engineers select the optimal lamp based on process requirements and wafer material.

Infrared systems use resistive heating elements with low external temperatures. These designs reduce burn risks and eliminate the need for flow sensors. Certified products meet international safety standards.

Top brands, such as Huai'an Infrared Heating Technology, hold certifications like TUV, ISO 9000, and certificates of conformity. These certifications guarantee product reliability, safety, and compliance with industry regulations.

Infrared heating offers faster ramp-up times, lower energy consumption, and precise temperature control. These benefits lead to higher yields, reduced waste, and improved process efficiency.