Author: Site Editor Publish Time: 2025-08-27 Origin: Site

Industrial heating lamps have transformed modern manufacturing processes, offering unmatched efficiency, precision control, and significant energy savings compared to conventional heating methods. As manufacturing facilities worldwide seek to optimize production while reducing operational costs and environmental impact, infrared heating technology has emerged as the preferred solution across countless industries. This comprehensive guide explores the technical specifications, applications, and benefits of industrial heating lamps, with particular focus on their implementation in PET blow molding, paint curing systems, and food processing operations.

Infrared heating operates on the principle of electromagnetic energy transfer, where thermal energy is transmitted directly to objects without heating the surrounding air. Industrial heating lamps typically consist of a tungsten filament enclosed within a quartz glass tube filled with inert gas. When electrical current passes through the filament, it reaches temperatures exceeding 2200°C, generating infrared radiation that travels at light speed to deliver immediate thermal energy to target surfaces.

The effectiveness of infrared heating depends on the wavelength match between the emitter and the absorption characteristics of the target material. Different materials absorb infrared energy most efficiently at specific wavelengths, making proper lamp selection critical for optimal performance.

Industrial heating lamps are categorized based on their peak wavelength output:

Short-Wave Infrared Lamps (0.76-1.6μm)

Operating Temperature: 1800-2200°C

Time to Full Power: 1-3 seconds

Typical Efficiency: 90-96%

Best For: Rapid heating of surfaces, high-speed processes

Medium-Wave Infrared Lamps (1.6-4.0μm)

Operating Temperature: 800-1800°C

Time to Full Power: 30-90 seconds

Typical Efficiency: 70-85%

Best For: Balanced surface and sub-surface heating

Long-Wave Infrared Lamps (4.0-100μm)

Operating Temperature: 300-800°C

Time to Full Power: 1-3 minutes

Typical Efficiency: 60-75%

Best For: Gentle, uniform heating of thick materials

Today's advanced industrial heating lamps offer remarkable technical specifications that make them suitable for demanding manufacturing environments:

Efficiency Metrics

Electrical-Thermal Conversion: Up to 96% efficiency

Targeted Energy Delivery: 80-95% of energy reaches the product

Instant On/Off Capability: No warm-up or cool-down delays

Precision Control: ±1°C temperature stability

Physical Specifications

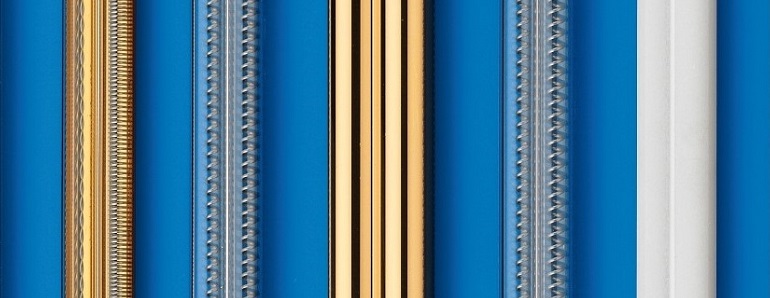

Tube Materials: Fused quartz, ceramic, or gold-doped quartz

Filament Types: Tungsten, carbon, or Kanthal®

Power Density: 10-150 W/cm² depending on configuration

Lifespan: 5,000-10,000 hours of continuous operation

Electrical Requirements

Voltage Options: 120V, 208V, 240V, 277V, 480V

Power Ratings: 500W-5000W per lamp

Control Compatibility: 0-10V, 4-20mA, PWM, phase-angle

The production of PET containers represents one of the most significant applications for industrial heating lamps. In blow molding operations, infrared lamps provide the precise thermal energy required to condition preforms before the blowing process.

Key Benefits for PET Processing:

40-50% Energy Reduction compared to conventional ovens

Precision Heating Zones for optimal material distribution

30% Faster Cycle Times through rapid heating capabilities

Improved Product Quality with consistent wall thickness

Technical Implementation:

Modern PET blow molding machines utilize rotating carousels with multiple independently controlled heating zones. Advanced systems feature real-time temperature monitoring and closed-loop control to maintain optimal heating profiles despite variations in ambient conditions or line speed.

Infrared heating lamps have revolutionized paint curing processes, particularly in automotive manufacturing where finish quality and production throughput are critical.

Performance Advantages:

50-70% Faster Curing compared to convection ovens

Reduced Floor Space requirements (up to 60% less)

Superior Finish Quality with fewer defects

Spot Repair Capability for targeted curing

Case Study: Automotive Manufacturer Implementation

A major European automotive manufacturer implemented YFR short-wave infrared lamps in their paint shop, achieving:

45% Reduction in energy consumption

60% Decrease in curing time

30% Improvement in first-time quality

Payback Period of under 14 months

Industrial heating lamps serve numerous functions in food processing, including baking, drying, sterilization, and packaging applications.

Common Applications:

Baking and Toasting: Uniform browning without drying

Sterilization: Surface pathogen reduction

Drying: Moisture removal without product damage

Package Sealing: Heat-seal activation

Sanitary Design Features:

FDA-Compliant Materials for food contact surfaces

Easy-Clean Designs with smooth surfaces

IP65 Ratings for washdown environments

Corrosion-Resistant housings and components

Industrial heating lamps offer significant environmental benefits compared to traditional heating methods:

Energy Savings:

40-70% Reduction in energy consumption

No Energy Waste on heating air or surroundings

Instant Response eliminates standby losses

Zone Control enables targeted energy application

Environmental Impact:

Zero Emissions at point of use

Reduced Carbon Footprint from lower energy use

No Combustion Byproducts or fumes

Minimal Waste Heat requiring ventilation

The precision of infrared heating enables manufacturers to achieve unprecedented process control:

Temperature Management:

±1°C Control for critical processes

Multi-Zone Programming for complex profiles

Real-Time Adjustments based on feedback

Recipe Management for different products

Quality Enhancements:

Consistent Results across production runs

Reduced Defects from precise heating

Improved Material Properties through optimized thermal profiles

Enhanced Product Performance from better processing

Selecting the appropriate industrial heating lamps requires careful analysis of several factors:

Material Characteristics:

Absorption Spectrum: Match lamp wavelength to material absorption

Thermal Sensitivity: Consider maximum safe temperatures

Physical Properties: Account for size, shape, and composition

Production Requirements: Evaluate speed and throughput needs

Process Parameters:

Temperature Requirements: Determine optimal processing temperatures

Heating Time: Calculate required exposure duration

Uniformity Needs: Assess acceptable temperature variation

Control Requirements: Identify necessary precision level

Successful implementation requires thorough planning and consideration:

System Design:

Lamp Configuration: Determine optimal arrangement and spacing

Cooling Requirements: Plan for adequate heat management

Safety Systems: Incorporate appropriate guards and interlocks

Control Integration: Ensure compatibility with existing systems

Economic Analysis:

Capital Investment: Calculate equipment costs

Operating Costs: Project energy and maintenance expenses

Return on Investment: Estimate payback period and savings

Total Cost of Ownership: Consider all lifetime costs

Industrial heating lamps must comply with numerous international standards and regulations:

Safety Certifications:

UL Certification: Underwriters Laboratories compliance

CE Marking: European conformity assessment

VDE Approval: German electrical standards

RoHS Compliance: Restriction of Hazardous Substances

Performance Standards:

ISO 9001: Quality management systems

ISO 14001: Environmental management

GB/T Standards: Chinese technical specifications

IEC Requirements: International electrotechnical standards

Industry-Specific Certifications:

FDA Compliance: For food processing applications

ATEX Certification: For explosive atmospheres

NSF Approval: For sanitary applications

CRN Registration: For pressure applications

Proper maintenance ensures optimal performance and extends equipment life:

Daily Checks:

Visual inspection for damage or discoloration

Verification of proper operation

Cleaning of reflectors and surfaces

Confirmation of cooling system function

Periodic Maintenance:

Lamp replacement based on hours of operation

Reflector cleaning and alignment

Electrical connection inspection

Control system calibration

Performance Monitoring:

Regular efficiency measurements

Temperature uniformity verification

Energy consumption tracking

Output intensity testing

Effective problem-solving minimizes downtime and maintains quality:

Common Problems and Solutions:

Uneven Heating: Check reflector condition and alignment

Reduced Efficiency: Verify lamp age and cleanliness

Control Issues: Inspect sensors and calibration

Early Failure: Examine cooling and electrical supply

The field of industrial heating continues to evolve with several promising developments:

Advanced Materials:

Ceramic Emitters: For higher temperatures and durability

Carbon Fiber Elements: For flexible heating applications

Composite Materials: For improved efficiency and life

Smart Technology Integration:

IoT Connectivity: For remote monitoring and control

AI Optimization: For predictive maintenance and optimization

Advanced Sensors: For real-time process adjustment

Sustainability Initiatives:

Renewable Integration: Compatibility with solar and wind power

Circular Economy: Recyclable materials and designs

Energy Recovery: Systems to capture and reuse waste heat

Industrial heating lamps represent a transformative technology that offers manufacturers significant advantages in efficiency, quality, and sustainability. As production facilities face increasing pressure to reduce costs while improving environmental performance, infrared heating technology provides a proven solution that delivers measurable results.

The implementation of industrial heating lamps requires careful consideration of technical specifications, application requirements, and operational factors. However, with proper planning and execution, manufacturers can achieve substantial benefits that justify the investment in this advanced technology.

As the technology continues to evolve, we can expect even greater efficiency, improved control capabilities, and enhanced integration with smart manufacturing systems. For forward-thinking manufacturers, industrial heating lamps represent not just a heating solution, but a strategic investment in future competitiveness.

Discover the Benefits of Advanced Industrial Heating Lamps

Contact our technical team today to discuss your specific application requirements and learn how our industrial heating solutions can improve your product quality while reducing energy consumption and operating costs. Request a comprehensive thermal analysis and process evaluation to identify opportunities for implementation in your operation.

YFR Manufacturing Co., Ltd. - Engineering Excellence in Infrared Heating Technology

Certificate Verification and Technical Support:

Download complete certification documents

Access technical specifications and data sheets

Request application engineering consultation

Schedule on-site process evaluation

content is empty!