Author: Site Editor Publish Time: 2025-10-28 Origin: Site

Infrared heat lamps are among the most efficient and adaptable heating technologies in modern industry. They transform electrical energy directly into radiant heat, targeting materials and surfaces with minimal energy loss to the surrounding air. This precise, controllable form of heat transfer makes infrared lamps invaluable for processes requiring speed, accuracy, and cleanliness—such as drying coatings, preheating plastics, curing paints, and heating food products.

Unlike conventional convection heaters, which rely on air circulation, infrared heat lamps deliver energy through electromagnetic radiation within the infrared spectrum (0.78 to 1000 micrometers). This allows the heat to penetrate surfaces directly, achieving rapid thermal response and higher process efficiency.

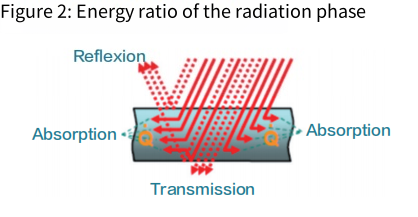

Infrared heat lamps emit electromagnetic radiation that lies beyond the visible light spectrum. When this radiation strikes an object, it is absorbed by the surface molecules, which then convert the radiant energy into heat. The heating efficiency depends on the wavelength of the infrared energy and the absorption characteristics of the material being heated.

Infrared lamps are typically designed with a tungsten filament enclosed in a quartz glass tube. When current passes through the filament, it heats up to temperatures between 1,500°C and 2,500°C, emitting infrared radiation in the near or medium wavelength range. The quartz enclosure allows high transmittance of IR energy while resisting thermal shock.

Infrared lamps are broadly classified based on their emission wavelength and construction type. Each category serves specific process requirements such as drying, forming, or heating. Below is a summary table illustrating the main categories and their characteristics.

| Category | Wavelength Range | Filament Temperature | Typical Applications | Key Features |

|---|---|---|---|---|

| Short-Wave (Near IR) | 0.78–1.4 µm | 1,800–2,500°C | Metal preheating, plastic welding, paint drying | Fast response, deep penetration, high intensity |

| Medium-Wave (Mid IR) | 1.4–3.0 µm | 1,000–1,800°C | Paper drying, powder coating, glass processing | Balanced absorption for most materials |

| Fast Medium-Wave | 1.4–2.0 µm | 1,500–2,200°C | Automotive paint curing, PET preforms, coatings | Quicker heating, energy-efficient replacement for short-wave |

| Long-Wave (Far IR) | 3.0–10 µm | 400–1,000°C | Textile drying, food warming, curing adhesives | Gentle surface heating, ideal for moisture-sensitive materials |

| Carbon Fiber Infrared Lamps | 2.0–6.0 µm | 1,200–1,800°C | Printing, film drying, composite curing | High efficiency, uniform heat, lower energy cost |

| Quartz Tungsten Lamps | 0.8–2.0 µm | 2,000–2,400°C | Rapid heating for industrial lines | Precise control, compact size, long life |

This table highlights the importance of wavelength matching to optimize absorption and efficiency. For instance, plastics and water absorb mid-to-long infrared radiation more effectively, while metals respond better to short-wave IR.

Infrared heat lamps offer multiple operational and economic benefits over traditional heating methods. Their versatility and energy efficiency make them suitable for a wide range of industries.

High Energy Efficiency

Up to 90% of input energy is converted into usable heat.

No heat loss through convection or intermediate media.

Fast Response Time

Infrared lamps reach full operating temperature within seconds.

Ideal for processes requiring frequent start-stop operation.

Precision Heating

Radiant energy can be focused or reflected for targeted heating zones.

Reduces risk of overheating and material deformation.

Clean, Contactless Operation

No combustion or air contamination.

Suitable for cleanroom, medical, and food applications.

Compact and Modular Design

Easy to integrate into existing production lines.

Can be scaled for localized or full-surface heating.

The effectiveness of infrared lamps depends on their construction materials and design specifications:

| Component | Material/Type | Purpose |

|---|---|---|

| Filament | Tungsten or Carbon Fiber | Determines wavelength and heat intensity |

| Tube Material | Quartz Glass | High thermal shock resistance and IR transparency |

| Reflector Coating | Gold or Ceramic | Directs IR radiation toward the target |

| Gas Filling | Halogen or Inert Gas | Extends lamp life, reduces oxidation |

| Mounting Base | Metal or Ceramic | Ensures mechanical stability and electrical safety |

Each design feature contributes to lifespan, response time, and emission stability. For instance, gold-coated quartz tubes improve directional efficiency by reflecting up to 95% of radiation toward the target surface.

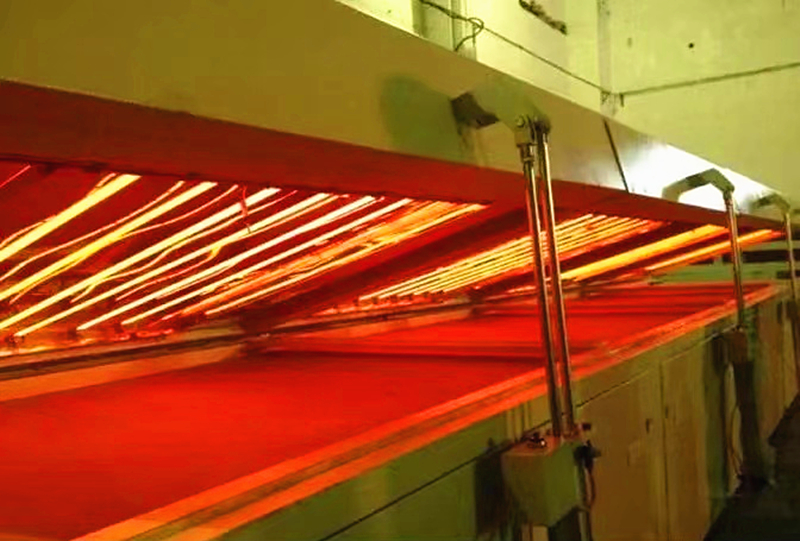

Infrared lamps have revolutionized thermal processing across multiple industries due to their adaptability and precise control. Typical industrial applications include:

Coating and Paint Drying: Ensures smooth, uniform finishes without solvent trapping.

Textile and Paper Drying: Rapid moisture removal while maintaining fabric integrity.

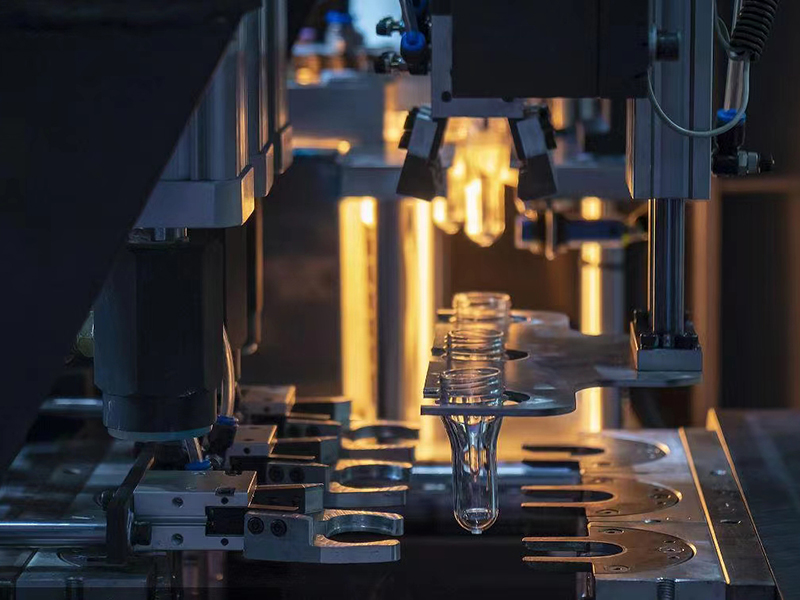

Plastic Forming and Welding: Efficient heating of thermoplastic sheets and parts.

Food Processing and Warming: Maintains hygiene and temperature consistency.

Electronics Manufacturing: Curing adhesives and soldering without direct contact.

Glass and Metal Processing: Preheating and annealing with uniform heat distribution.

While infrared heat lamps are highly reliable, their lifespan and performance can be influenced by several factors:

On/Off Frequency

Frequent switching may stress the filament, especially in tungsten lamps. Selecting a fast-response model like a carbon fiber or halogen infrared lamp minimizes degradation.

Operating Voltage

Lamps should always operate within ±5% of rated voltage. Overvoltage increases temperature and shortens lifespan.

Mounting and Cooling

Adequate airflow prevents localized overheating and ensures uniform temperature distribution.

Surface Cleanliness

Dust or contaminants on quartz tubes can absorb IR energy, causing hot spots and reducing efficiency.

Ambient Environment

Moisture, vibration, and corrosive gases can affect lamp integrity and output stability.

When selecting infrared heat lamps for industrial use, engineers should consider:

| Parameter | Consideration | Effect |

|---|---|---|

| Wavelength | Match with material absorption spectrum | Maximizes energy efficiency |

| Lamp Form | Tube, emitter panel, or modular unit | Affects installation and coverage |

| Power Density | Wattage per area | Determines process speed |

| Response Time | Seconds to reach operating temp | Impacts production flexibility |

| Control Compatibility | PWM or phase-angle dimming | Allows precision temperature control |

Infrared heating contributes to sustainability goals by reducing total energy consumption and process time. Its directional nature ensures minimal waste, making it a preferred choice in industries striving for carbon reduction. Additionally, modern infrared systems can be integrated with smart sensors and feedback loops for automatic temperature regulation—further enhancing energy efficiency and safety.

Infrared heat lamps continue to transform industrial heating by combining speed, efficiency, and precision in a compact design. Their ability to deliver instant, targeted heat without physical contact makes them indispensable across drying, curing, and processing applications. For engineers and plant designers, the key to achieving optimal results lies in selecting the correct wavelength, lamp construction, and power density for the specific material and process.