Views: 0 Author: Site Editor Publish Time: 2025-09-30 Origin: Site

In modern industries such as food processing, pharmaceuticals, coatings, and construction materials, infrared drying is becoming an increasingly popular solution. Compared to traditional drying methods such as hot air or vacuum drying, infrared drying offers faster drying speed, lower energy consumption, and better product quality retention.

This article will guide you through the working principle, advantages, applications, and future trends of infrared drying, while also introducing professional infrared heating solutions from YFR Infrared.

Infrared drying is a technology that uses infrared radiation to heat materials directly, evaporating water or solvents efficiently. Unlike conventional heat transfer or convection methods, infrared radiation penetrates into the material, enabling faster and more energy-efficient drying.

Quartz Infrared Lamps – High-performance infrared heating elements from YFR Infrared

In practical applications, infrared drying is widely used in scenarios that require rapid drying, energy saving, and quality preservation, such as food dehydration, coating curing, and wood drying.

Compared with traditional drying methods, infrared drying offers several outstanding benefits:

High Energy Efficiency: Direct heat transfer to the material, reducing energy waste.

Fast Drying Speed: Shortens drying time, boosting productivity.

Better Uniformity: Avoids surface hardening issues often seen in hot air drying.

Quality Retention: Especially suitable for foods and sensitive materials, preserving nutrients, colors, and flavors.

Flexible Application: Easily integrated into different production lines across industries.

Infrared drying has been successfully applied in various industries:

Food Industry

Dehydration of fruits, vegetables, grains, and meat.

Preserves nutritional value, color, and natural flavor.

Pharmaceuticals & Chemicals

Drying powders, tablets, and coating materials.

Ensures production consistency and stable quality.

Textiles & Paper

Dye fixation and coating drying.

Improves surface treatment speed and uniformity.

Wood & Building Materials

Rapid moisture removal from wood to reduce processing time.

Coatings & Paints

Fast curing of coatings and paints, enhancing surface durability.

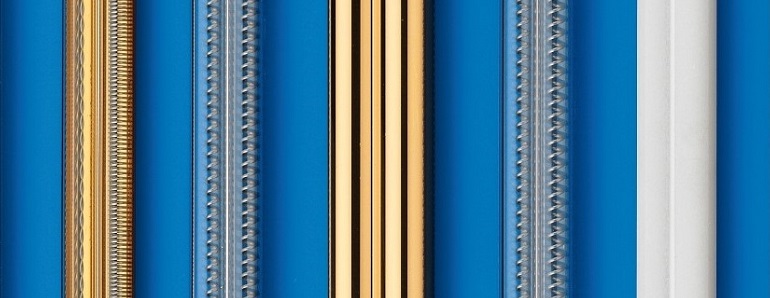

Twin Tube Infrared Heaters – Highly efficient solutions for multi-industry drying applications

For more real-world applications, visit the YFR Infrared Solutions Page.

Hot Air Drying vs. Infrared Drying: Infrared drying is faster and consumes less energy.

Microwave Drying vs. Infrared Drying: Microwaves penetrate deeper, while infrared is more efficient for surface and medium-thickness materials.

Vacuum Drying vs. Infrared Drying: Vacuum drying is suitable for sensitive materials but is costly; infrared drying offers better cost-performance.

In summary, infrared drying is often the best choice for efficiency and cost-effectiveness in industrial settings.

Initial Equipment Investment: Higher upfront costs, but long-term energy savings.

Limited Penetration Depth: Less effective for very thick materials unless combined with other technologies.

Precision Required: Temperature and wavelength must be carefully controlled to avoid product damage.

With increasing demand for automation and sustainability, infrared drying continues to evolve:

Smart & Automated Control: Integration with AI for real-time monitoring and optimization.

Energy-Saving & Eco-Friendly Design: Development of advanced, efficient infrared lamps and systems.

Hybrid Drying Systems: Combining infrared with microwave or vacuum drying for broader applications.

As a professional supplier of infrared heating solutions, YFR Infrared is constantly innovating to provide more efficient infrared lamps and heating systems, helping global customers achieve sustainable energy solutions.

With its efficiency, energy savings, and environmental benefits, infrared drying is shaping the future of drying technology. From food processing to pharmaceuticals, textiles, and construction, infrared drying is proving its value across industries.

If you are looking for high-quality infrared heating lamps or drying systems, visit YFR Infrared to explore our full product range and solutions.

Q1: What is infrared drying?

Infrared drying is a technology that uses infrared radiation to directly heat materials, achieving faster and more efficient drying.

Q2: Is infrared drying energy efficient?

Yes. Compared to traditional methods, infrared drying offers significantly higher energy efficiency and lower power consumption.

Q3: What industries use infrared drying the most?

It is widely used in food, pharmaceuticals, chemicals, textiles, wood processing, and coatings industries.

Q4: How does infrared drying compare with microwave drying?

Microwave drying penetrates deeper, while infrared is more energy-efficient for surface and medium-thickness materials.

Q5: Can infrared drying be used for sensitive materials?

Yes. By carefully controlling infrared wavelength and temperature, it is suitable for heat-sensitive materials as well.

content is empty!