Huaian Yinfrared Heating tech supply quality Ir lamp heater for industrial use .

In today's fast-paced industrial world, speed, efficiency, and high-quality finishes are not just nice to have. They are essential for staying competitive. If you have slow drying times, uneven curing, high energy costs, or poor product finishes, there is a solution. You can use High-Quality Infrared (IR) paint Curing Lamps.

As a leading IR lamp manufacturer, YFR understand the critical role precise, reliable infrared technology plays in your success. Let's explore why investing in a top-tier IR curing lamp is a game-changer for your process.

Beyond Heat: The Science of IR heat lamps

Unlike regular convection ovens that heat the air, infrared light heating elements emit radiation. The substrate, coating, ink, or adhesive directly absorbs this radiation during the curing process. This direct energy transfer offers significant advantages:

Blazing Speed: Dramatically reduce curing times – often by 50% or more compared to convection methods. Get products out the door faster.

Targeted Energy: Focused IR energy heats only the product. It does not heat the surrounding air or machinery. This leads to better energy efficiency and lower operating costs.

Superior Quality: Precise control of the wavelength ensures even and consistent curing. This reduces defects like blistering, pinholing, and under-curing.

Space Savings: Compact IR lamp systems require significantly less floor space than bulky ovens.

Instant On/Off: No lengthy warm-up or cool-down periods. Start and stop production instantly, boosting flexibility.

What Defines a Quality IR Curing Lamp? Not all lamps have the same quality.

Choosing the right IR lamps for heating is paramount. Here's what sets exceptional lamps apart:

Precise Wavelength Control: Different materials absorb IR energy best at specific wavelengths (Short, Medium, or Long Wave). A good lamp emits the best wavelength for your needs. This can be for surface drying or deep heating. Look for lamps designed for your specific curing needs.

Unmatched Emitter Quality & Durability: The heart of the lamp is the emitter (quartz tube, halogen element, ceramic element). Premium materials and robust construction resist thermal shock, vibration, and degradation, ensuring long service life and consistent output. Avoid lamps prone to premature failure.

some times you may need infrared heater with lamps covers . what can ensure the infrared radiation for better target heating .

Great Reflector Design: High-quality, well-shaped aluminum reflectors, like anodized or gold-coated, boost efficiency. They direct over 95% of the IR energy to the target. This minimizes wasted energy and ensures uniform intensity across the curing zone.

Robust Construction & Sealing: Industrial environments are tough. Quality lamps have strong housings, high-temperature connectors, and good seals. They are often IP rated to resist dust, moisture, and chemicals.

Consistent Power Density: Uniform output across the entire lamp surface is crucial for even curing. Quality manufacturing ensures no "hot" or "cold" spots.

Thermal Management: Effective heat dissipation designs prevent overheating of the lamp housing and electrical components, enhancing safety and longevity.

Compatibility & Ease of Integration: Look for lamps that have standard mounting options and electrical connections. This makes it easy to integrate them into new or existing curing lines.

Versatile Mounting Options:Another advantage of high-quality IR curing lamps is their flexible installation. You can mount most industrial-grade IR lamps either horizontally or vertically, depending on your specific setup and workspace constraints. This versatility allows seamless integration into diverse production lines—whether you need overhead, wall, or side mounting—ensuring optimal coverage and efficient use of available floor space.

Carbon heat lamp is more suitable water based paint curing . short wave infrared paint curing lamp has high intensity,ideal for metal material paint drying .

medium wave infrared heater not that fast response but it's cheaper and much longer working life. at highest working temperature it is similar performance.

Typical Specifications for a Portable IR Curing Lamp

When evaluating portable infrared curing lamps, you’ll want to keep a close eye on a few key specs that directly impact performance and fit in your workflow:

Voltage: Most units operate on standard 120V electrical systems, making them compatible with typical shop outlets.

Amperage: Expect lamps to draw around 8–9 amps, so you can safely run them on most circuits without worries about overload.

Head Size: A common curing head size is about 18 inches, providing enough coverage for various substrates without being cumbersome.

Weight: Portable models usually weigh in around 20 lbs—light enough to move where you need them, sturdy enough for industrial use.

Origin: Top-tier IR curing lamps are often manufactured in the

USA, ensuring quality build and components.

These specs strike a balance between portability, efficient coverage, and compatibility with standard shop setups.

Flexible Positioning and Safety Features of Portable IR Curing Lamps

To further enhance your curing setup, a quality portable infrared lamp should deliver on both flexibility and safety—without compromising performance. Look for engineering details like:

An extended adjustable arm (commonly around 14 inches or more), allowing you to position the heat source precisely where it's needed—whether you're reaching up, angling downward, or targeting hard-to-access spots.

A built-in timer function, typically up to 60 minutes, to automate shutoff and help prevent over-baking or accidental overheating of sensitive finishes. This hands-off safety measure keeps your workflow on track and safeguards your product.

Versatile mounting capability, supporting horizontal, vertical, or even custom angles, so your lamp adapts to any workstation layout or irregular part geometry with ease.

These practical features make portable IR curing lamps an invaluable tool across demanding industrial environments, facilitating precision, efficiency, and peace of mind during every cure cycle.

Applications Where Quality IR Curing Lamps Excel:

Coatings & Paints: Powder coating curing, liquid paint drying (automotive, industrial, wood finishing).

Printing & Decorating: Drying inks, varnishes, and adhesives on paper, plastic, metal, glass (flexo, offset, screen, digital printing).

Plastics: Heating for forming, welding, laminating, and drying.

Textiles: Drying dyes, coatings, and finishes.

Adhesives & Sealants: Curing hot melts, PSAs, and reactive adhesives.

Food Processing: Drying, baking, toasting.

Electronics: PCB solder reflow (specific wavelengths), conformal coating curing.

The True Cost of Compromise: Why Quality Matters

Choosing a cheaper, inferior lamp might save upfront costs, but leads to:

Higher Downtime: Frequent failures and replacements halt production.

Inconsistent Results: Uneven curing leads to rejects, rework, and customer dissatisfaction.

Increased Energy Costs: Poor efficiency and reflectivity waste electricity.

Safety Risks: Substandard components or overheating can pose hazards.

Shortened System Lifespan: Inferior lamps can stress the entire curing system.

Partner with Experts for Optimal Curing Performance

As a dedicated IR Halogen lamp bulb manufacturer, we don't just sell components; we provide precision curing solutions. We engineer our lamps with the highest quality materials and stringent processes to deliver:

Maximum Uptime: Engineered for reliability in demanding environments.

Peak Efficiency: Advanced reflectors and optimized emitters minimize energy consumption.

Superior Curing Results: Consistent, uniform output for flawless finishes.

Long-Term Value: Durable construction reduces total cost of ownership.

Application Expertise: Guidance on selecting the optimal wavelength and configuration.

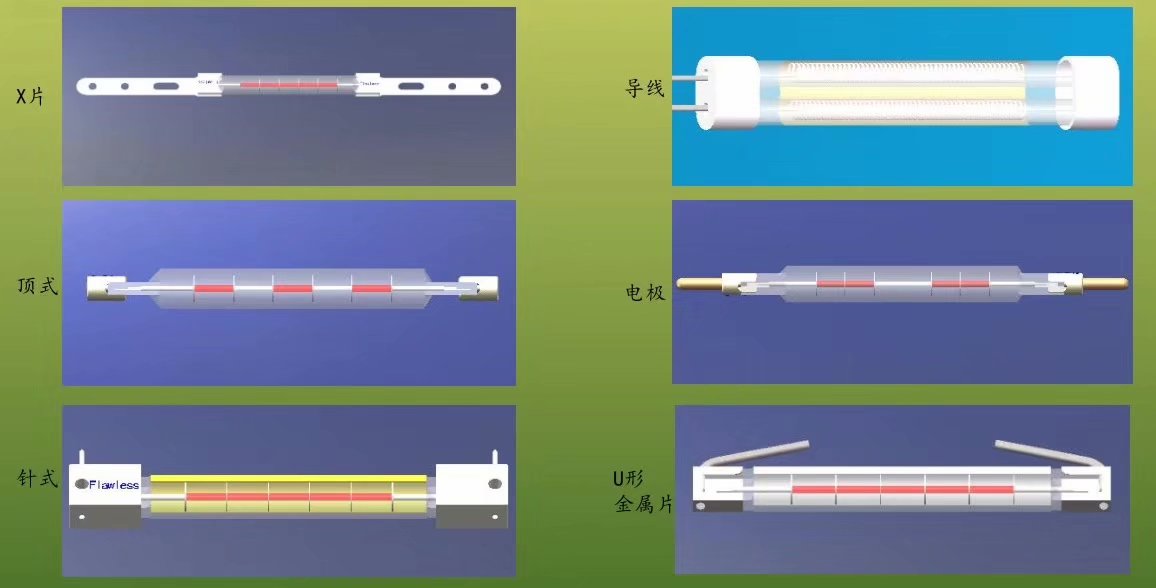

we customize all kind of infrared lamp .which include SW infrared lamp . Medium wave and long wave , the models depends on what object need to heating . YFR will make a whole solution for your project . meanwhile , we supply power regulator for controlling.

Illuminate your production line with the power, precision, and reliability of truly high-quality Infrared Curing Lamps. Ditch the bottlenecks and quality issues – step into the fast lane of efficient, superior curing.

Ready to transform your curing process? Contact us today to discuss your needs. Learn how our IR lamp solutions can improve your productivity and quality.