Author: Site Editor Publish Time: 2025-06-05 Origin: Site

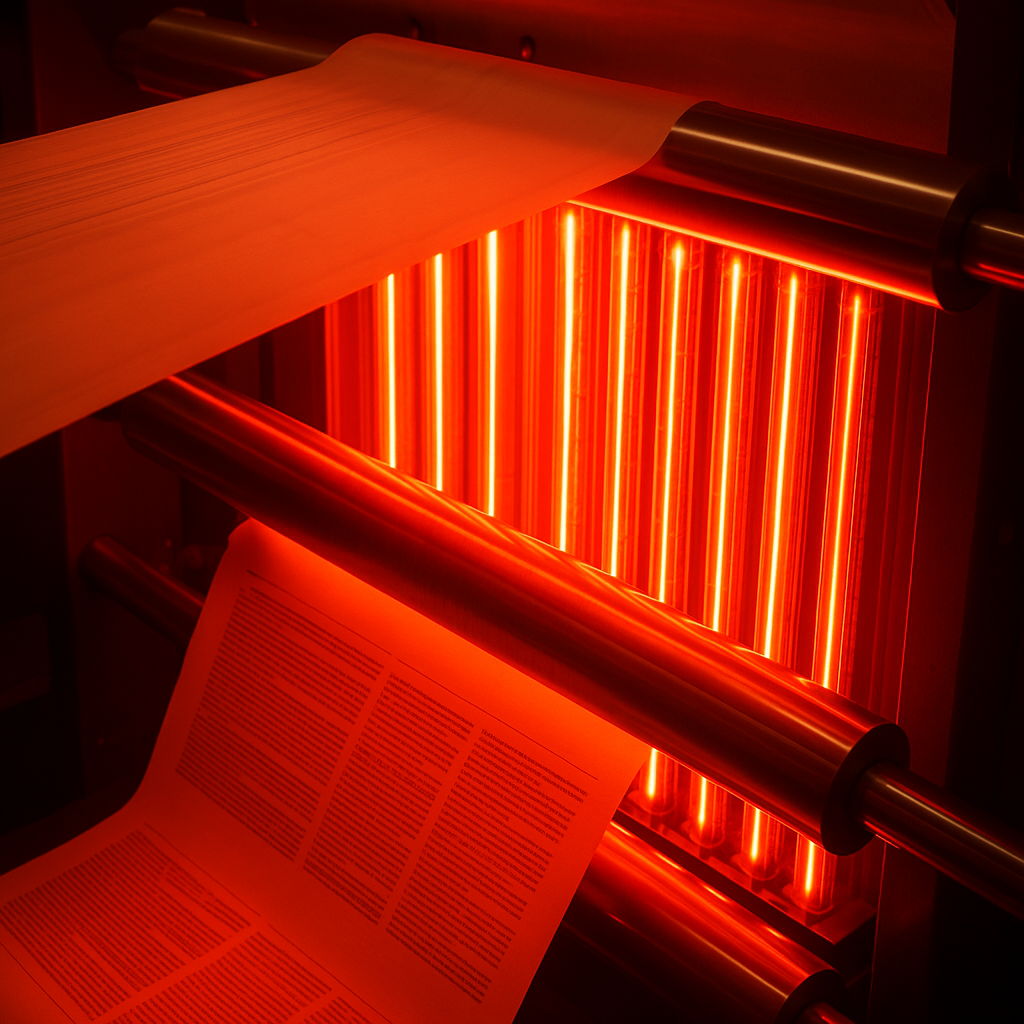

Huaian Yinfrared Heating Tech supply all kind of IR emitters for printing .

Infrared Lamp in Printing: Benefits, Applications, and How It Enhances Efficiency

Introduction

The printing industry relies on advanced technologies to improve efficiency, reduce drying times, and enhance print quality. One such technology is the infrared (IR) lamp, which plays a crucial role in drying inks, coatings, and adhesives quickly and uniformly.

In this article, we’ll explore:

What an infrared lamp is and how it works in printing

Key benefits of using IR lamps in printing processes

Different applications in the printing industry

How to choose the right IR lamp for your printing needs

By the end, you’ll understand why infrared heating is a game-changer for modern printing operations.

What Is an Infrared Lamp in Printing?

An infrared lamp emits electromagnetic radiation in the infrared spectrum, which generates heat upon absorption by materials. In printing, IR lamps are used to:

Dry inks and coatings rapidly without smudging

Cure UV-sensitive inks for faster production

Reduce energy consumption compared to conventional drying methods

How Does an Infrared Lamp Work in Printing?

Emission of IR Waves – The lamp produces infrared radiation, which penetrates the printed material.

Absorption by Ink/Coating – The ink or coating absorbs the IR energy, converting it into heat.

Fast Drying/Curing – The heat evaporates solvents (in liquid inks) or triggers polymerization (in UV inks).

Unlike hot air drying, IR heating is direct and efficient, minimizing energy waste.

Key Benefits of Using Infrared Lamps in Printing

1. Faster Drying Times

IR lamps reduce drying time from minutes to seconds, increasing production speed.

Ideal for high-speed printing presses (e.g., flexographic, offset, digital).

2. Improved Print Quality

Prevents smudging, offsetting, or ink bleeding by drying ink instantly.

Ensures consistent color vibrancy without over-drying.

3. Energy Efficiency

IR lamps consume less power than convection ovens or hot air dryers.

Targeted heating reduces heat loss, lowering operational costs.

4. Compact & Space-Saving

Unlike bulky drying tunnels, IR lamps can be integrated directly into printing machines.

Perfect for smaller printing shops with limited space.

5. Eco-Friendly Option

No harmful emissions (unlike solvent-based drying).

Supports water-based and UV-curable inks, reducing VOC (volatile organic compounds).

Applications of Infrared Lamps in the Printing Industry

1. Flexographic & Offset Printing

Used for drying water-based and solvent-based inks on packaging, labels, and corrugated boards.

Prevents set-off (ink transferring to the next sheet).

2. Digital & Inkjet Printing

Speeds up drying for high-resolution prints (e.g., banners, posters, textiles).

Helps latex and UV inks cure efficiently.

3. Screen Printing

Ensures quick drying of plastisol inks on apparel (T-shirts, hoodies).

Reduces curing time for durable prints.

4. Label & Packaging Printing

Prevents ink smearing on glossy or laminated surfaces.

Used in shrink sleeve labeling and food-safe packaging.

5. 3D Printing & Specialty Coatings

Helps cure resins and specialty coatings in additive manufacturing.

How to Choose the Right Infrared Lamp for Printing

When selecting an IR lamp for printing, consider:

1. Wavelength (Short, Medium, or Long IR)

Short-wave IR (NIR) – Fastest heating, best for thin films and quick-drying inks.

Medium-wave IR – Balanced for most printing applications.

Long-wave IR (Far IR) – Deep penetration, ideal for thick coatings.

2. Power & Heating Capacity

Match the wattage to your printing speed (e.g., 1kW–10kW for industrial printers).

3. Cooling Mechanism

Air-cooled – Standard for most applications.

Water-cooled – For high-intensity, continuous use.

4. Compatibility with Ink Type

UV inks require specific IR wavelengths for curing.

Water-based inks need controlled heating to avoid bubbling.

5. Safety & Control Features

Adjustable intensity for different materials.

Overheat protection to prevent damage.

FAQs About Infrared Lamps in Printing

Q1: Can IR lamps be used for all types of inks?

Yes, but settings must be adjusted. UV inks need precise IR curing, while water-based inks require gentle drying.

Q2: Do IR lamps increase printing costs?

No! They reduce energy costs by up to 50% compared to traditional drying methods.

Q3: How long do IR lamps last?

Typically 5,000–10,000 hours, depending on usage and maintenance.

Q4: Are IR lamps safe for heat-sensitive materials?

Yes, with temperature control, IR can be used on plastics, films, and paper.

Q5: Can I retrofit an IR lamp into an existing printer?

Many printers can be upgraded with IR drying modules for faster production.

Conclusion

Infrared lamps are revolutionizing the printing industry by speeding up production, improving print quality, and reducing energy costs. Whether you’re in packaging, textiles, or commercial printing, integrating IR drying can give you a competitive edge.

Looking to upgrade your printing process? Consider an IR lamp system tailored to your needs for faster, more efficient, and higher-quality results!