Author: Site Editor Publish Time: 2025-12-11 Origin: Site

Vacuum tray dryers and vacuum drying boxes are a workhorse in pharmaceutical manufacturing for gentle drying of heat-sensitive APIs, intermediates, and solid dosage intermediates. At the same time, they are notoriously slow and difficult to scale. Integrating quartz infrared (IR) lamps into these systems is one practical way to shorten cycle times and improve temperature uniformity—without abandoning the basic, well-understood vacuum tray dryer concept.

This article looks at where IR belongs in pharmaceutical vacuum drying, how it can be retrofitted into existing vacuum boxes, and what ranges of power density, distance, and dwell time are realistic for process engineers.

Vacuum tray dryers in pharma are commonly used for:

Crude and purified APIs (including highly potent or oxygen-sensitive materials)

Intermediates and wet cake after filtration or centrifugation

Granules and pellets prior to milling, blending, or compression

Moisture-sensitive excipients and specialty ingredients

Small equipment parts or components that must be dried at low temperature

These products are typically:

Placed in shallow stainless-steel trays (for example, 20–60 mm fill height)

Loaded on heated shelves arranged vertically in a box-shaped chamber

Dried batchwise, with strict limits on maximum product temperature and residual solvent or moisture

A typical cycle in a pharmaceutical vacuum tray dryer includes:

Loading

Trays are filled with wet product (often 5–25 kg per tray, depending on product and dryer size) and placed on heated shelves.

Door is closed and sealed; chamber is interlocked.

Evacuation

Vacuum pump reduces chamber pressure well below atmospheric (for example, down to a few mbar), lowering boiling point of water or organic solvents.

Sometimes a nitrogen purge or inert blanket is used for safety and to control oxygen.

Heating and main drying

Shelves are heated by steam, thermal oil, or electrical heaters; heat reaches product mainly by conduction from below and weak radiation from hot surfaces.

Product temperature rises slowly; moisture or solvent evaporates at the reduced boiling point and is condensed in an external condenser.

Final drying / conditioning

Product is held at a near-constant temperature and pressure to reach target residual moisture or solvent content.

Product is often sampled and tested for LOD, residual solvent, or other CQAs.

Cooling and unloading

Heating is stopped; product cools under vacuum or inert gas until safe to remove.

Door is opened; trays are unloaded for downstream processing.

In this whole sequence, heat input is the main lever controlling cycle time, but existing designs often provide it in a slow, indirect way.

Most pharmaceutical vacuum tray dryers use one or more of the following heat sources:

Heated shelves with steam, hot water, or thermal oil

Jacketed chamber walls

Internal electrical heaters (resistance elements, sometimes embedded in shelves)

Limited internal convection, often just natural radiation and weak conduction paths under vacuum

These concepts are robust, but they introduce several drawbacks:

Slow heat-up and long cycles

Heat must travel from the heat transfer fluid into the shelf, through the tray bottom, and into the product bed.

Under deep vacuum, convection is negligible, so there is little “help” from moving air.

It can take hours for the center of a 20–30 mm bed to approach the target temperature.

Temperature non-uniformity

Shelves near the heating inlet often run hotter than those near the return line.

Edge trays can see different conditions than center trays.

Within each tray, the bottom layer can be much hotter than the upper surface.

Risk of local overheating

To dry the “coldest point” in the batch, operators sometimes push shelf temperatures close to product limits.

This increases the risk of thermal degradation where product is in best thermal contact.

High energy consumption and limited capacity

Long hold times at elevated shelf temperatures increase total energy use.

In some cases, the dryer becomes the bottleneck, limiting plant throughput.

Because IR does not rely on air as a heat transfer medium, it remains effective even in vacuum. That makes it an interesting addition to conventional shelf heating in pharmaceutical boxes.

Quartz infrared lamps can be introduced into vacuum drying boxes in several ways, from simple retrofits to full redesigns.

One straightforward approach is to use IR as a preheating or boosting stage:

Ceiling-mounted lamp frames are installed above the top tray level.

Once the chamber is sealed and partially evacuated, IR lamps are energized to quickly raise the surface temperature of the product on each tray.

Shelf heating remains active, but IR shortens the lag time before the product reaches effective drying temperature.

For example, for trays loaded with 10–20 kg of wet granules per shelf, an IR power density at product level in the range of 0.2–0.6 W/cm² for 15–40 minutes under vacuum can often cut the initial warm-up time significantly, while keeping product temperatures safely below 50–60 °C for heat-sensitive APIs (exact values must be validated per product).

In some processes, IR is used not only at the start but throughout the main drying phase:

Zoned lamp banks (ceiling or side-wall mounted) operate at a controlled fraction of their rated power.

Shelf temperatures can be held slightly lower than before, while IR maintains the desired product temperature and evaporation rate.

Control system uses product thermocouples (where allowed) or representative tray temperatures to modulate IR power.

This combined conduction + radiation approach can help:

Reduce shelf hot spots by allowing a lower shelf setpoint

Improve drying uniformity across trays by zoning the IR lamps

Shorten the constant-rate and falling-rate stages of drying

For newly designed vacuum boxes or OEM equipment, IR can be integrated more deeply:

IR modules mounted behind quartz windows in the door or walls, preserving full vacuum integrity.

Twin-tube IR emitters embedded in the chamber roof with integrated reflectors.

Hybrid shelves that retain internal fluid heating but add underside IR reflection toward the product.

In these cases, IR may carry a larger share of the heating duty—up to a majority of the total heat input—while shelves and jackets provide base-line temperature control and uniformity.

Retrofitting is often done in:

Mid-life vacuum tray dryers that are structurally sound but too slow

Pilot plants where product mix is changing and flexibility is needed

High-value API lines where added capacity is more attractive than a new dryer

Typical retrofit steps:

Mechanical: add stainless frames or rails to mount lamp modules; ensure clear line-of-sight to trays.

Vacuum: design appropriate vacuum feedthroughs for lamp power supplies; manage sealing and cable routing.

Thermal: conduct initial modeling or small-scale trials to decide lamp spacing, orientation, and reflector geometry.

Control: integrate IR lamps into the dryer PLC, including interlocks with door, vacuum level, and over-temperature alarms.

The right configuration depends on product type, tray geometry, and batch size. The following ranges are typical starting points for engineering studies and feasibility trials, not final design rules.

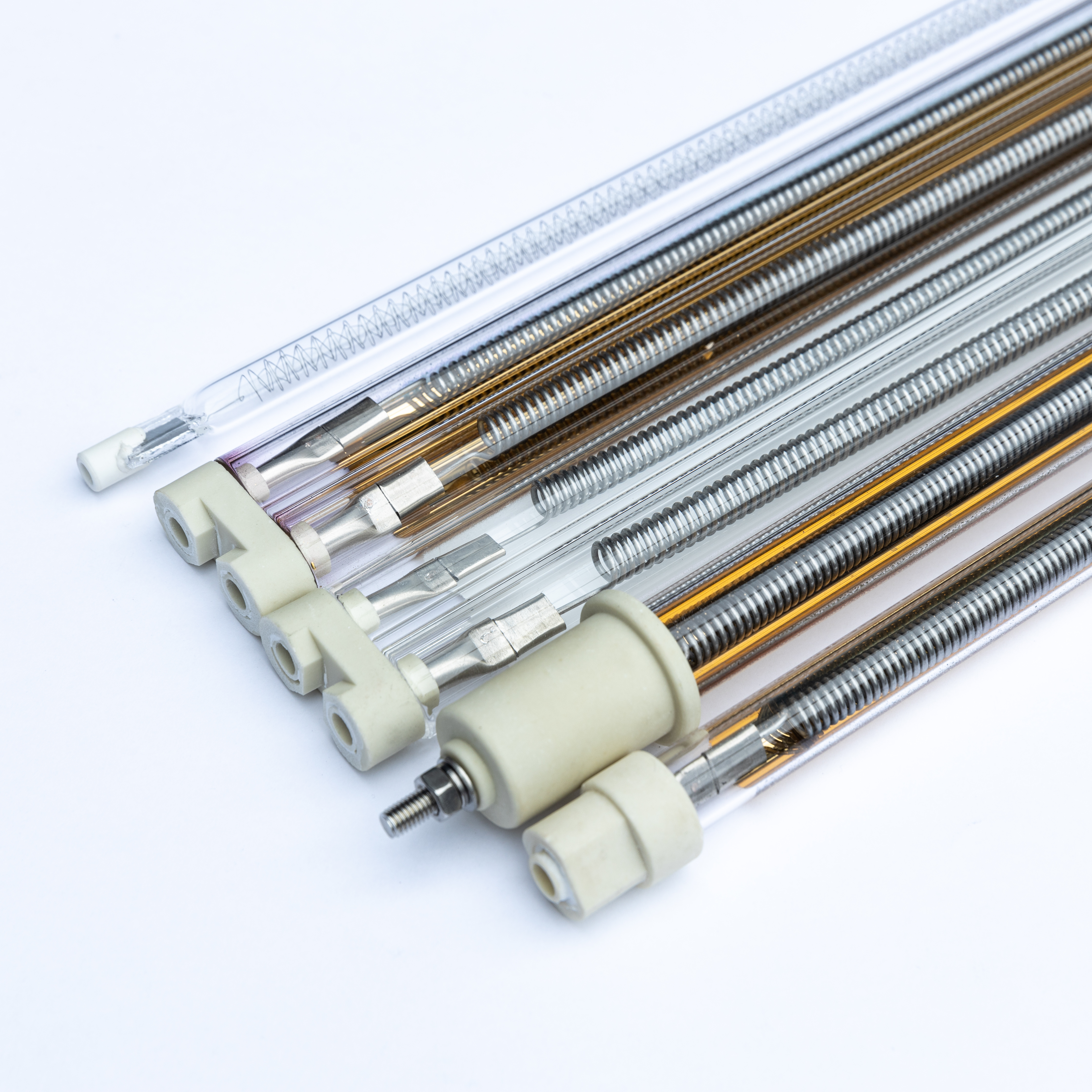

For pharmaceutical vacuum dryers, quartz IR options usually include:

Short-wave quartz IR lamps (near-IR)

Very fast response (sub-second), high possible power density.

Good for robust granules or intermediates where rapid heat-up is beneficial.

Medium-wave quartz IR lamps

Slightly slower response, more gentle surface heating.

Often preferred for heat-sensitive APIs and excipients, and where stainless steel trays dominate the optical path.

Single-tube vs. twin-tube lamps

Single-tube for tight spaces and small chambers.

Twin-tube modules for larger boxes, allowing modular arrays over each tray bank.

Industrial IR modules can deliver very high surface power densities at the emitter level, but for pharmaceutical drying the product-level intensity is typically kept much lower, on the order of 0.2–1.0 W/cm² (2–10 kW/m²) to avoid hot spots.

Inside a vacuum box, typical lamp-to-product distances are:

200–400 mm between lamp envelope and top of the tray load for ceiling-mounted arrays

150–300 mm for side-mounted lamp panels facing the tray stack

Key layout considerations:

Ensure direct line-of-sight to as much of the tray area as possible.

Use reflectors (polished stainless or coated aluminum, within GMP constraints) to redirect radiation into shadowed regions.

Maintain adequate clearance for loading equipment and operator access.

For a mid-size pharmaceutical vacuum tray dryer with:

8–16 trays

Tray area of 0.2–0.4 m² each

Product fill height 15–30 mm

Per-tray load 8–20 kg wet material

Typical starting points for feasibility tests might include:

Boost phase (start of cycle)

Product-level power density: 0.3–0.6 W/cm²

Dwell time: 15–40 minutes under vacuum as product approaches target temperature

Goal: reduce warm-up time by 20–40%, without overshooting product temperature limits.

Main drying phase

Product-level power density: 0.2–0.4 W/cm², potentially modulated as drying progresses

Total IR-assisted drying time: typically 1–3 hours, depending on solvent type, bed thickness, and end-point.

Final conditioning

IR is often reduced or turned off; shelves maintain gentle temperature for final moisture removal and equilibration.

All of the above must be adapted to:

Maximum allowable product temperature (e.g., 40–60 °C for sensitive APIs)

Solvent properties and safety limits

Customer’s existing equipment and validation strategy

To keep IR under control in a GMP environment, common approaches include:

Closed-loop temperature control

Use product probes (where allowed) or representative tray temperatures as feedback.

IR power is modulated via thyristor or SSR control (phase angle or burst firing).

Zoning

Split lamp arrays into zones (for example, top/bottom, front/back, or per shelf bank).

Adjust each zone independently to compensate for known non-uniformities.

Interlocks and safety

IR disabled unless vacuum is within defined range and door is confirmed closed.

Over-temperature and over-current protection on each lamp bank.

Integration with emergency stop and fire/safety systems.

When properly engineered and validated, IR-assisted vacuum drying can significantly change the performance envelope of a tray dryer.

Benefits often observed:

Gentler overall temperature profile

Because IR targets the product more directly, shelf and jacket temperatures can often be reduced.

Time spent near the product’s maximum allowable temperature can be shortened.

Improved uniformity across trays

Zoning and reflector design help narrow the spread between hottest and coldest trays.

This reduces the need to “over-dry” easy locations just to satisfy the worst-case point.

Reduced risk of degradation

Less thermal stress on sensitive APIs and excipients.

Potentially lower formation of impurities related to overheating or prolonged drying.

Shorter drying cycles translate naturally into higher throughput:

If a traditional cycle is 10–16 hours, and IR integration allows a 20–40% reduction in total time for suitable products (to be proven in trials), the same dryer can handle more batches per week.

In some cases, IR can turn a long overnight cycle into a single-shift operation, simplifying staffing and scheduling.

Because the same physical dryer is being upgraded rather than replaced, floor space (footprint) does not increase, and existing containment and utility connections can remain in place.

Energy savings stem from:

Shorter time at high heater duty

Potentially lower shelf temperatures, reducing losses to the environment and thermal oil system

More targeted heating of the actual product instead of mainly the metal structure

Although the IR lamps themselves require electrical power, the combination of reduced cycle time and improved transfer efficiency often leads to a net reduction in kWh per kg dried, especially for moisture-rich, heat-sensitive loads.

For pharmaceutical applications, process engineers should approach IR integration methodically.

General guidance:

Favor medium-wave quartz IR for highly heat-sensitive APIs, amorphous solids, or products with sensitive color attributes.

Consider short-wave quartz IR where product is mechanically and thermally robust, and where the objective is aggressive throughput increase on intermediates.

Evaluate the optical path: stainless-steel trays, foil liners, or glassware can reflect or absorb IR differently; small-scale tests are essential.

To achieve consistent drying:

Use CAD layouts and simple ray-tracing concepts to position lamps and reflectors.

Avoid placing very high-power lamps too close to tray edges, where empty metal may heat faster than product.

Consider baffles or diffusers (compatible with cleaning and inspection) if direct line-of-sight creates hot spots.

In early development:

Start with conservative power densities and shorter IR dwell times.

Record detailed weight loss curves (tray by tray) vs. time to identify bottlenecks.

Implement stepwise or ramped IR profiles (e.g., 30%–50%–70% of rated power) synchronized with vacuum and shelf temperature profiles.

Integration must respect pharmaceutical GMP expectations:

Ensure lamp housings, reflectors, and mounting frames are accessible for cleaning and inspection.

Use smooth, crevice-free surfaces where possible.

Define preventive maintenance for lamp replacement, cleaning, and requalification.

Document the impact of IR on critical quality attributes, supported by risk assessments and validation protocols.

Some typical issues seen in IR retrofits and how to prevent them:

Too much power, too soon

Pitfall: starting feasibility tests with power densities closer to those used in non-pharma applications, causing localized overheating.

Avoid by starting near the low end (0.2–0.3 W/cm²) and stepping up gradually.

Ignoring tray loading patterns

Pitfall: trays partially filled or unevenly loaded, leading to different absorptivity and temperature responses.

Avoid by defining standardized tray loading patterns and designing IR zones around them.

Poor reflector design

Pitfall: lambertian reflections from untreated stainless walls causing hot spots.

Avoid by using engineered reflector geometries and testing with thermal imaging (where allowed) or dense temperature mapping.

Weak integration with controls and safety systems

Pitfall: IR lamps controlled separately from the main dryer, creating inconsistencies and safety risks.

Avoid by fully integrating IR into the dryer PLC, with clear recipes, interlocks, and alarms.

Underestimating validation workload

Pitfall: treating IR as a simple “add-on” and not updating risk assessments, URS, and validation documents.

Avoid by treating IR integration as a change-control project, with full documentation and stakeholder involvement.

For pharmaceutical customers, Huai’an Yinfrared typically supports vacuum drying projects in a staged, engineering-driven way:

Feasibility discussions

Review existing dryer design, batch size, utility constraints, and critical product limitations (max temperature, solvents, toxicity).

Identify whether IR is likely to address the true bottleneck (heat transfer vs. mass transfer).

Lab or pilot-scale trials

Use representative IR modules and quartz lamps under controlled vacuum conditions (customer facility or partner lab).

Screen lamp types, wavelengths, power density ranges, and ramp profiles.

Generate initial data on drying time, product temperature profiles, and key CQAs.

Thermal and mechanical design

Define lamp arrangement, reflectors, mounting hardware, and vacuum feedthrough solutions tailored to the customer’s chamber geometry.

Prepare engineering drawings and integration guidelines for OEMs or in-house engineering teams.

Control integration and commissioning

Assist with control concepts, zoning strategies, and safety interlocks.

Support FAT/SAT, initial batches, and recipe optimization.

Long-term support

Supply spare lamps and modules with consistent specifications.

Help troubleshoot any observed non-uniformities or cycle-time drift.

Collaborate on continuous improvement, e.g., further energy savings or new product introductions.