| Availability: | |

|---|---|

| Quantity: | |

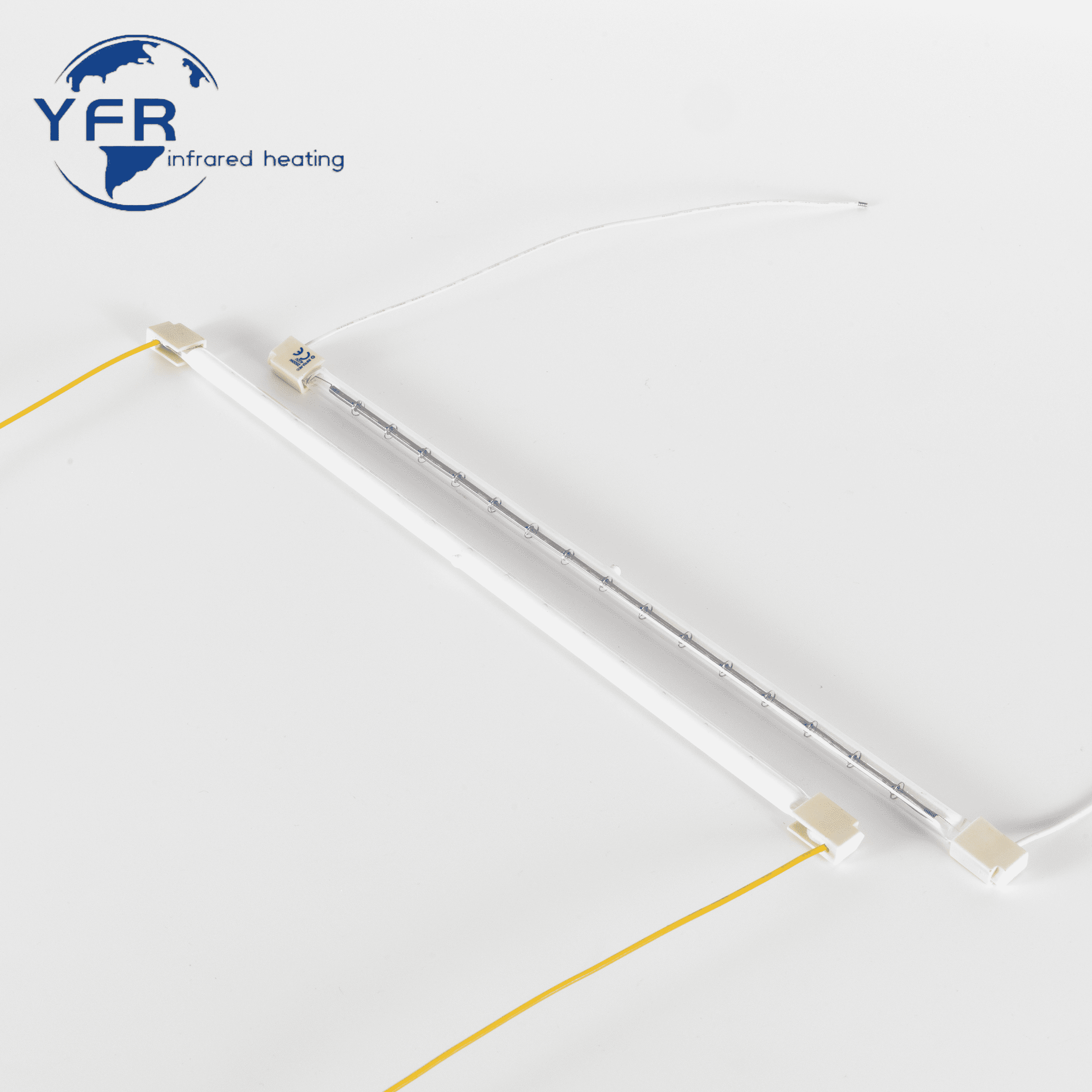

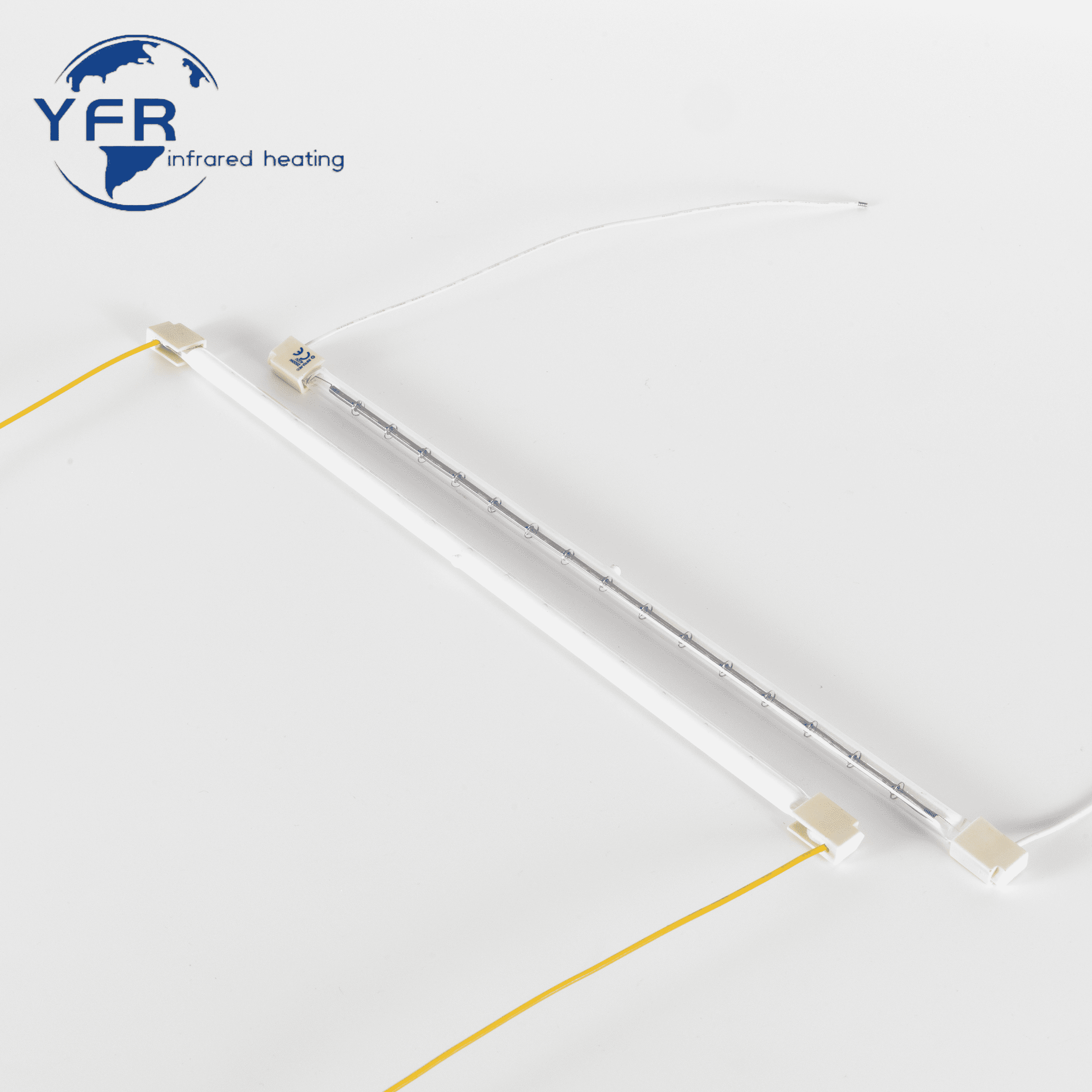

White

YFR

In high-speed PET (Polyethylene Terephthalate) bottle blow molding, it is important to preheat preforms quickly and evenly. This helps ensure good product quality, such as consistent wall thickness, high clarity, and optimal strength. It also improves production efficiency.

Traditional heating methods often struggle with energy waste, uneven temperature distribution, and slow response times. Yinfrared leverages deep expertise in infrared technology to deliver high-performance semi-white coating infrared heating lamps – engineered specifically for PET blow molding machines.

Infrared heating is great for heating PET preforms. It works without contact, is exceptionally efficient, responds quickly, and penetrates well. PET material exhibits a strong absorption peak within specific IR wavelengths (approx. 2.5 - 4.0 μm), enabling efficient energy conversion into heat with minimal loss.

The semi-white coating is our core innovation:

Directional High-Efficiency Heating: A manufacturer puts a special white ceramic coating on one side. This coating has high reflectivity, over 95%. This coating redirects infrared energy back to the heating zone (preforms). It boosts energy use by 15-30% and reduces operational costs.

Optimized Temperature Uniformity: The reflective layer minimizes unwanted heat buildup in the oven, ensuring a stable environment and superior circumferential preform heating consistency.

Equipment Protection & Energy Savings: Reduces thermal radiation onto machine components behind the lamps, extending equipment life and lowering cooling demands.

Precision Spectral Matching: Designed to emit peak wavelengths (about 2.7 - 3.2 μm) that match PET's best absorption band. This ensures maximum energy transfer, quicker heating, and the best penetration depth.

Great Heating Uniformity: The special filament design, high-quality quartz tubing, and semi-white coating work together. They provide even heat distribution along the lamp and around the preform. This minimizes wall thickness variations and stress cracks.

Ultra-Fast Response & Precise Control: Our lamps respond in milliseconds. They work with advanced zonal temperature control systems. This allows for quick power adjustments. You can manage temperatures precisely for different preform types and production conditions.

Extended Service Life & Reliability: We make our lamps with high-quality tungsten filaments and pure low-OH quartz tubing. They go through strict manufacturing and testing. This ensures they last a long time, even in tough, high-cycling conditions. This helps reduce downtime and maintenance costs.

Energy Efficiency & Sustainability: The inherent efficiency of the semi-white design translates into significant electricity savings, lowering operational costs and carbon footprint.

Single-Stage & Two-Stage PET Blow Molding Machines (Rotary, Linear)

Preheating for: Water Bottles, Carbonated Drink Bottles, Edible Oil Bottles, Sauce Bottles, Cosmetic Bottles, Pharmaceutical Bottles.

New Machine Integration & Retrofit Upgrades for Energy Savings.

The table below outlines key specifications for our standard series. Customization is available for specific dimensions, power, and voltage requirements.

| Parameter | Specification / Description | Notes |

| Lamp Type | Medium-Short Wave Infrared Quartz Heating Tube (Single-Sided Semi-White Reflective Coating) | Directional High-Efficiency Heating |

| Peak Wavelength | ~ 2.7 - 3.2 μm | Optimized for PET Material Absorption |

| Tube Material | High-Purity Fused Quartz (Low-OH Content) | High Temp Resistance, Superior IR Transmission, Thermal Stability |

| Coating Type | High-Reflectivity White Ceramic Coating (Single Side) | Reflectivity > 95% (IR Spectrum) |

| Filament Material | High-Purity Tungsten | High-Temperature Stability, Long Life |

| Typical Power Density | 15 - 40 W/cm (Customizable) | Depends on Preform Size, Heating Distance, Production Speed |

| Surface Temp (Oper.) | 700°C - 950°C (Coated side lower) | Determined by Power Density |

| Standard Length (L) | 150mm, 200mm, 250mm, 300mm, 350mm, 400mm, ... (Customizable) | Fits Various Oven Widths |

| Standard Tube Diameter (Ø) | Ø8mm, Ø10mm, Ø12mm (Customizable) | |

| Cold End Length (C) | Standard ≥ 30mm (Customizable) | Ensures Safe Socket Temperature |

| Terminal Type | Standard Molybdenum Foil (Custom options: Screw, Bayonet, etc.) | Secure Installation |

| Standard Voltages | 110V, 120V, 220V, 230V, 240V, 380V (Customizable) | |

| Average Lifespan | ≥ 5,000 - 10,000 Hours (Rated Voltage, Adequate Cooling) | Affected by Voltage, Cycling Frequency, Cooling Conditions |

| Certifications (Opt.) | CE, RoHS | Safety & Environmental Compliance |

| Customization | Non-Standard Lengths, Power, Voltage, Terminals, Coating Patterns | Tailored Solutions for Your Machine |

Krones

Sipa

SMI

KHS

Side

Sidel

The cross-reference chart below compares some of Yinfrared's common IR lamp specifications with other manufacturers.

If you are unable to see the light you need, please contact our customer service team and they will be happy to assist you.

| Yinfrared | OEM | Philips | Toshiba | Tube Dia. (mm) | OAL (mm) | Wattage | Volts | Cap |

| 54242055-ESE | SIDEL | 13213z/98 | JHC 235V 2000W 280 BH2 | 10.5 | 353 | 2000W | 235 | SK15 |

| 64402555-ESE | SIDEL | 14106Z/98 | JHC 400V 2500W 315 BH | 11 | 380 | 2500W | 400 | SK15 |

| 64403055-ESE | SIDEL | 14111Z/98 | JHC 400V 3000W 315 BH | 11 | 380 | 3000W | 400 | SK15 |

| 64231251-ESE | KRONES | 14134Z/98 | JHC 235V 1200W 155BfH1 | 10.5 | 222 | 1200W | 235 | SK15 |

| 64231652-ESE | KRONES | 14135Z98 | JHC 235V 1600W 155BfH1 | 10.5 | 222 | 1600W | 235 | SK15 |

| 64402551-ESE | KRONES | 14143Z/98 | JHC 400V 2500W 280 BH | 10.5 | 354 | 2500W | 400 | SK15 |

| 64403050-ESE | KRONES | 14144Z/98 | JHC 400V 3000W 280 BH | 10.5 | 354 | 3000W | 400 | SK15 |

| 64231251-ESE | SIG (KRUGG) | 14134Z/98 | JHC 235V 1200W 155 BfH1 | 10.5 | 222 | 1200W | 235 | SK15 |

| 64141252-ESE | SIG (KRUGG) | 13561Z/98 | JHC 144V 1200W 155 BfH1 | 10.5 | 222 | 1200W | 144 | SK15 |

| 64141253-ESE | SIG (KRUGG) | 13561Y/98 | JHC 144V 1200W 155 JcH | 10.5 | 222 | 1200W | 144 | SK15 |

| 64231652-ESE | SIG (KRUGG) | 14135Z/98 | JHC 235V 1600W 155 BfH1 | 10.5 | 222 | 1600W | 235 | SK15 |

| 64141653-ESE | SIG (KRUGG) | 13568Z/98 | JHC 235V 1600W 155 BfH1 | 10.5 | 222 | 1600W | 144 | SK15 |

| 64141652-ESE | SIG (KRUGG) | 13568Y/98 | JHC 144V 1600W 155 JcH | 10.5 | 222 | 1600W | 144 | Metal Cap |

| 54242053-ESE | SIG (KRUGG) | 14136Z/98 | JHC 235V 2000W 280 BfH4 | 10.5 | 353 | 2000W | 235 | SK15 |

| 64242550-ESE | SIG (KRUGG) | 14137Z/98 | JHC 235V 2500W 280 BfH3 | 10.5 | 354 | 2500W | 240 | SK15 |

| 64242525-ESE | SIPA | 14103Z/98 | JHC 235V 2000W 280 BfH | 10.5 | 354 | 2500W | 240 | SK15 |

| 6423205N-ESE | SIPA | 6423205N | JHC230V 2000W 500 BfH | 10.5 | 656 | 2000W | 230 | SK15 |

| 64243055-ESE | SIPA | 14121Z/98 | JHC235V 3000W 280 BH | 10.5 | 354 | 3000W | 240 | SK15 |

| 64233050-ESE | SIPA | 14107Z/98 | JHC 235V 3000W 700 BfH2 | 10.5 | 785.5 | 3000W | 230 | SK15 |

| 64402580-ESE | SMI | N/A | JHC 400V 2500W 500 NH | 2500W | ||||

| 64241052-ESE | ADS | 13195Z/98 | JHC 235V 1000W 272 BfU1 | 10.5 | 346 | 1000W | 240 | SK15 |

| 64242052-ESE | ADS | N/A | JHC 235V 2000W 280 BfU1 | 10.5 | 346 | 2000W | 240 | SK15 |

| 64241052-ESE | SIDE | 13195Z/98 | JHC 235V 1000W 270 BfU1 | 10.5 | 346 | 1000W | 240 | SK15 |

| 64242052-ESE | SIDE | 13213Z/98 | JHC 235V 2000W 280 BfU1 | 10.5 | 346 | 2000W | 240 | SK15 |

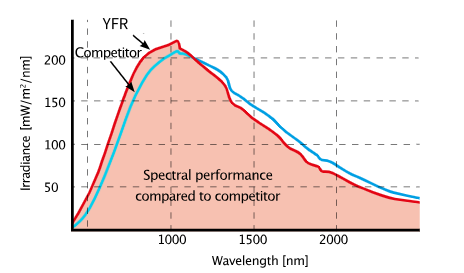

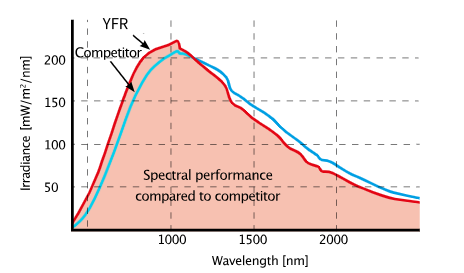

Tests of YFR PET lamps against a major competitor show that they provide more heat energy per Watt, so will save money for the user. They also have longer life than many competitors, which reduces replacement cost.

That is why YFR PET lamps are used by many OEM equipment suppliers throughout the world, and are the first choice of replacement lamp by PET manufacturers.

Yinfrared is dedicated to the R&D and manufacturing of cutting-edge infrared heating solutions. We understand the challenges of PET blow molding. Our semi-white IR lamps are not just parts. They are key partners in increasing productivity, lowering costs, and ensuring quality.

Optimize Your Production Line Today:

Replace Aging Lamps: Gain efficiency, longevity, and reliability.

Enhance Preform Quality: Achieve unmatched heating uniformity for superior bottles.

Cut Energy Costs: Experience significant savings with semi-white technology.

Visit www.yinfrared.com to find product details. You can also download technical whitepapers. Contact our experts for a custom heating solution for your blow molding machine!

In high-speed PET (Polyethylene Terephthalate) bottle blow molding, it is important to preheat preforms quickly and evenly. This helps ensure good product quality, such as consistent wall thickness, high clarity, and optimal strength. It also improves production efficiency.

Traditional heating methods often struggle with energy waste, uneven temperature distribution, and slow response times. Yinfrared leverages deep expertise in infrared technology to deliver high-performance semi-white coating infrared heating lamps – engineered specifically for PET blow molding machines.

Infrared heating is great for heating PET preforms. It works without contact, is exceptionally efficient, responds quickly, and penetrates well. PET material exhibits a strong absorption peak within specific IR wavelengths (approx. 2.5 - 4.0 μm), enabling efficient energy conversion into heat with minimal loss.

The semi-white coating is our core innovation:

Directional High-Efficiency Heating: A manufacturer puts a special white ceramic coating on one side. This coating has high reflectivity, over 95%. This coating redirects infrared energy back to the heating zone (preforms). It boosts energy use by 15-30% and reduces operational costs.

Optimized Temperature Uniformity: The reflective layer minimizes unwanted heat buildup in the oven, ensuring a stable environment and superior circumferential preform heating consistency.

Equipment Protection & Energy Savings: Reduces thermal radiation onto machine components behind the lamps, extending equipment life and lowering cooling demands.

Precision Spectral Matching: Designed to emit peak wavelengths (about 2.7 - 3.2 μm) that match PET's best absorption band. This ensures maximum energy transfer, quicker heating, and the best penetration depth.

Great Heating Uniformity: The special filament design, high-quality quartz tubing, and semi-white coating work together. They provide even heat distribution along the lamp and around the preform. This minimizes wall thickness variations and stress cracks.

Ultra-Fast Response & Precise Control: Our lamps respond in milliseconds. They work with advanced zonal temperature control systems. This allows for quick power adjustments. You can manage temperatures precisely for different preform types and production conditions.

Extended Service Life & Reliability: We make our lamps with high-quality tungsten filaments and pure low-OH quartz tubing. They go through strict manufacturing and testing. This ensures they last a long time, even in tough, high-cycling conditions. This helps reduce downtime and maintenance costs.

Energy Efficiency & Sustainability: The inherent efficiency of the semi-white design translates into significant electricity savings, lowering operational costs and carbon footprint.

Single-Stage & Two-Stage PET Blow Molding Machines (Rotary, Linear)

Preheating for: Water Bottles, Carbonated Drink Bottles, Edible Oil Bottles, Sauce Bottles, Cosmetic Bottles, Pharmaceutical Bottles.

New Machine Integration & Retrofit Upgrades for Energy Savings.

The table below outlines key specifications for our standard series. Customization is available for specific dimensions, power, and voltage requirements.

| Parameter | Specification / Description | Notes |

| Lamp Type | Medium-Short Wave Infrared Quartz Heating Tube (Single-Sided Semi-White Reflective Coating) | Directional High-Efficiency Heating |

| Peak Wavelength | ~ 2.7 - 3.2 μm | Optimized for PET Material Absorption |

| Tube Material | High-Purity Fused Quartz (Low-OH Content) | High Temp Resistance, Superior IR Transmission, Thermal Stability |

| Coating Type | High-Reflectivity White Ceramic Coating (Single Side) | Reflectivity > 95% (IR Spectrum) |

| Filament Material | High-Purity Tungsten | High-Temperature Stability, Long Life |

| Typical Power Density | 15 - 40 W/cm (Customizable) | Depends on Preform Size, Heating Distance, Production Speed |

| Surface Temp (Oper.) | 700°C - 950°C (Coated side lower) | Determined by Power Density |

| Standard Length (L) | 150mm, 200mm, 250mm, 300mm, 350mm, 400mm, ... (Customizable) | Fits Various Oven Widths |

| Standard Tube Diameter (Ø) | Ø8mm, Ø10mm, Ø12mm (Customizable) | |

| Cold End Length (C) | Standard ≥ 30mm (Customizable) | Ensures Safe Socket Temperature |

| Terminal Type | Standard Molybdenum Foil (Custom options: Screw, Bayonet, etc.) | Secure Installation |

| Standard Voltages | 110V, 120V, 220V, 230V, 240V, 380V (Customizable) | |

| Average Lifespan | ≥ 5,000 - 10,000 Hours (Rated Voltage, Adequate Cooling) | Affected by Voltage, Cycling Frequency, Cooling Conditions |

| Certifications (Opt.) | CE, RoHS | Safety & Environmental Compliance |

| Customization | Non-Standard Lengths, Power, Voltage, Terminals, Coating Patterns | Tailored Solutions for Your Machine |

Krones

Sipa

SMI

KHS

Side

Sidel

The cross-reference chart below compares some of Yinfrared's common IR lamp specifications with other manufacturers.

If you are unable to see the light you need, please contact our customer service team and they will be happy to assist you.

| Yinfrared | OEM | Philips | Toshiba | Tube Dia. (mm) | OAL (mm) | Wattage | Volts | Cap |

| 54242055-ESE | SIDEL | 13213z/98 | JHC 235V 2000W 280 BH2 | 10.5 | 353 | 2000W | 235 | SK15 |

| 64402555-ESE | SIDEL | 14106Z/98 | JHC 400V 2500W 315 BH | 11 | 380 | 2500W | 400 | SK15 |

| 64403055-ESE | SIDEL | 14111Z/98 | JHC 400V 3000W 315 BH | 11 | 380 | 3000W | 400 | SK15 |

| 64231251-ESE | KRONES | 14134Z/98 | JHC 235V 1200W 155BfH1 | 10.5 | 222 | 1200W | 235 | SK15 |

| 64231652-ESE | KRONES | 14135Z98 | JHC 235V 1600W 155BfH1 | 10.5 | 222 | 1600W | 235 | SK15 |

| 64402551-ESE | KRONES | 14143Z/98 | JHC 400V 2500W 280 BH | 10.5 | 354 | 2500W | 400 | SK15 |

| 64403050-ESE | KRONES | 14144Z/98 | JHC 400V 3000W 280 BH | 10.5 | 354 | 3000W | 400 | SK15 |

| 64231251-ESE | SIG (KRUGG) | 14134Z/98 | JHC 235V 1200W 155 BfH1 | 10.5 | 222 | 1200W | 235 | SK15 |

| 64141252-ESE | SIG (KRUGG) | 13561Z/98 | JHC 144V 1200W 155 BfH1 | 10.5 | 222 | 1200W | 144 | SK15 |

| 64141253-ESE | SIG (KRUGG) | 13561Y/98 | JHC 144V 1200W 155 JcH | 10.5 | 222 | 1200W | 144 | SK15 |

| 64231652-ESE | SIG (KRUGG) | 14135Z/98 | JHC 235V 1600W 155 BfH1 | 10.5 | 222 | 1600W | 235 | SK15 |

| 64141653-ESE | SIG (KRUGG) | 13568Z/98 | JHC 235V 1600W 155 BfH1 | 10.5 | 222 | 1600W | 144 | SK15 |

| 64141652-ESE | SIG (KRUGG) | 13568Y/98 | JHC 144V 1600W 155 JcH | 10.5 | 222 | 1600W | 144 | Metal Cap |

| 54242053-ESE | SIG (KRUGG) | 14136Z/98 | JHC 235V 2000W 280 BfH4 | 10.5 | 353 | 2000W | 235 | SK15 |

| 64242550-ESE | SIG (KRUGG) | 14137Z/98 | JHC 235V 2500W 280 BfH3 | 10.5 | 354 | 2500W | 240 | SK15 |

| 64242525-ESE | SIPA | 14103Z/98 | JHC 235V 2000W 280 BfH | 10.5 | 354 | 2500W | 240 | SK15 |

| 6423205N-ESE | SIPA | 6423205N | JHC230V 2000W 500 BfH | 10.5 | 656 | 2000W | 230 | SK15 |

| 64243055-ESE | SIPA | 14121Z/98 | JHC235V 3000W 280 BH | 10.5 | 354 | 3000W | 240 | SK15 |

| 64233050-ESE | SIPA | 14107Z/98 | JHC 235V 3000W 700 BfH2 | 10.5 | 785.5 | 3000W | 230 | SK15 |

| 64402580-ESE | SMI | N/A | JHC 400V 2500W 500 NH | 2500W | ||||

| 64241052-ESE | ADS | 13195Z/98 | JHC 235V 1000W 272 BfU1 | 10.5 | 346 | 1000W | 240 | SK15 |

| 64242052-ESE | ADS | N/A | JHC 235V 2000W 280 BfU1 | 10.5 | 346 | 2000W | 240 | SK15 |

| 64241052-ESE | SIDE | 13195Z/98 | JHC 235V 1000W 270 BfU1 | 10.5 | 346 | 1000W | 240 | SK15 |

| 64242052-ESE | SIDE | 13213Z/98 | JHC 235V 2000W 280 BfU1 | 10.5 | 346 | 2000W | 240 | SK15 |

Tests of YFR PET lamps against a major competitor show that they provide more heat energy per Watt, so will save money for the user. They also have longer life than many competitors, which reduces replacement cost.

That is why YFR PET lamps are used by many OEM equipment suppliers throughout the world, and are the first choice of replacement lamp by PET manufacturers.

Yinfrared is dedicated to the R&D and manufacturing of cutting-edge infrared heating solutions. We understand the challenges of PET blow molding. Our semi-white IR lamps are not just parts. They are key partners in increasing productivity, lowering costs, and ensuring quality.

Optimize Your Production Line Today:

Replace Aging Lamps: Gain efficiency, longevity, and reliability.

Enhance Preform Quality: Achieve unmatched heating uniformity for superior bottles.

Cut Energy Costs: Experience significant savings with semi-white technology.

Visit www.yinfrared.com to find product details. You can also download technical whitepapers. Contact our experts for a custom heating solution for your blow molding machine!