Author: Site Editor Publish Time: 2025-08-22 Origin: Site

In 2025, I see the YINFRARED Short Wave Infrared Quartz Emitters leading the market for paint curing, alongside respected brands like VEVOR, Eastwood, and REVO. These models stand out for rapid heat-up, verified shortwave wavelengths, and high energy efficiency—qualities that industry experts consistently recommend. Choosing the right short wave ir lamp can impact everything from curing speed to finish quality, whether I work in a professional shop or a small workshop.

Metric / Aspect | Data / Description |

|---|---|

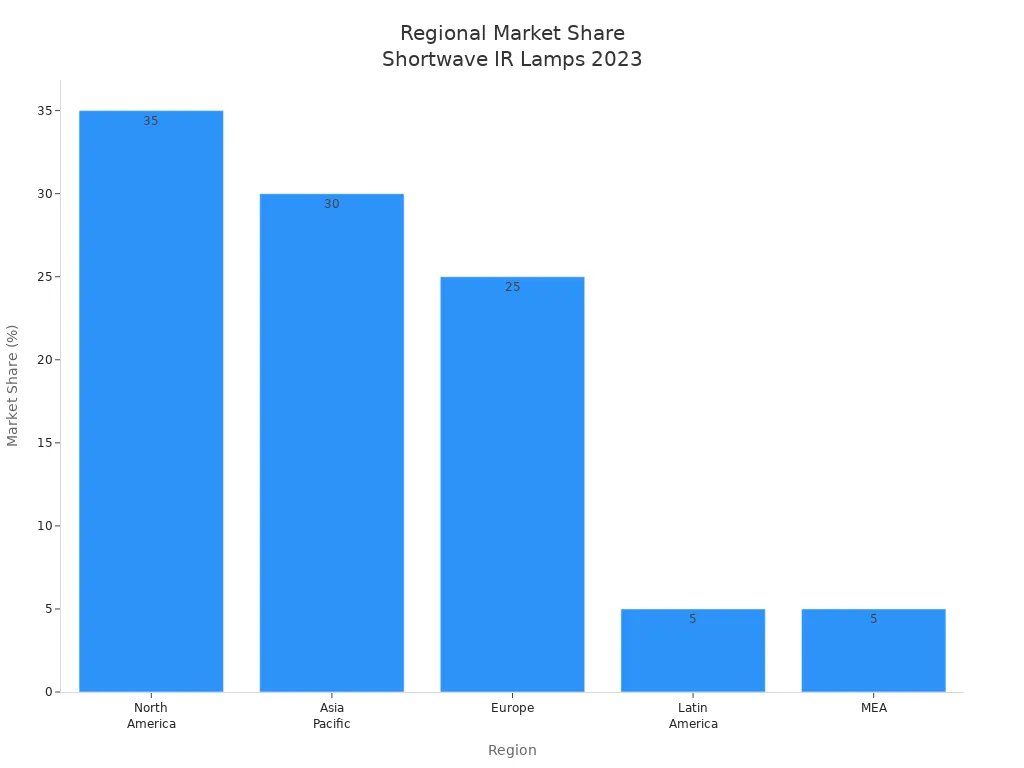

Market Share of Shortwave IR Lamps | Over 40% in 2026 |

Market Size (Shortwave IR Lamps) | USD 150 million in 2024 |

Key Application Segment | Automotive refinishing: 40% market share |

Short wave infrared lamps cure paint faster and more efficiently than other methods, saving time and energy.

These lamps penetrate paint and substrate deeply, ensuring a smooth, high-quality finish without common defects.

Adjustable height and angle features help target heat precisely, improving curing results on different shapes and sizes.

Energy savings come from focused heating and quick curing, reducing operational costs and downtime.

Durable construction and safety certifications ensure reliable, long-lasting performance in busy workshops.

Choosing the right lamp power and coverage area is important to match the size of the job and paint type.

Proper lamp setup, safety precautions, and regular maintenance keep curing consistent and prevent problems.

Top brands like YINFRARED offer advanced features such as instant heat-up, uniform coverage, and energy efficiency.

When I work with automotive or industrial paints, I want the curing process to be as fast and reliable as possible. Short wave IR lamps deliver heat directly and rapidly to coatings, which means I see much faster curing times than with convection ovens or even other types of infrared heaters. The high-energy radiation from these lamps penetrates the coating and reaches the substrate, causing a rapid temperature increase. This direct transfer of radiant energy accelerates both drying and curing. I have seen that short wave IR lamps reach operating temperatures almost instantly, so I do not waste time waiting for the system to warm up. In my experience, this technology can cure two-component paints in as little as 15 minutes and polyester putty in just 5 minutes. These results come from both laboratory tests and real-world applications, showing that short wave IR lamps consistently outperform medium and long wave IR options.

I always look for a curing method that ensures a flawless finish, especially on complex shapes or hidden areas. Short wave IR lamps stand out because their energy penetrates deeper into both the paint and the substrate. This two-way curing process heats the paint directly and also conducts heat back from the substrate, resulting in a more uniform cure. I have noticed that this approach prevents common surface defects like blistering, pinholes, or skinning, which can occur with surface-only heating methods. The ability to cure beneath the surface leads to a consistent, high-quality finish every time. For example, short wave IR lamps can handle intricate parts and hard-to-reach spots, making them ideal for automotive refinishing and industrial applications. Compared to traditional ovens or medium wave IR, I find that short wave IR lamps provide faster heat-up rates and superior finish quality.

Tip: For best results, I always position the lamp to maximize coverage and ensure even exposure, especially on curved or multi-layered surfaces.

Cost and energy efficiency matter to me, especially when running a busy workshop. Short wave IR lamps use focused, high-intensity heat, which means I only heat the area that needs curing. This targeted approach reduces energy waste and lowers operational costs. I have seen data showing that these lamps can reduce drying times by 50-90%, which boosts productivity and throughput. Even though the purchase cost is similar to medium wave IR lamps, short wave IR lamps use about half the energy and cure paint in half the time. Over time, this translates to significant savings on energy bills and less downtime between jobs. The instant on/off capability and adjustable timers also help me manage energy use more precisely. In my experience, the combination of rapid curing, lower energy consumption, and reduced need for expensive enclosures makes short wave IR lamps a smart investment for any paint curing operation.

When I select a short wave ir lamp for paint curing, I always pay close attention to the power output. The right wattage ensures efficient heat delivery and consistent curing results. Most leading models offer a range that suits both small touch-ups and large-scale projects. Here’s a quick comparison of popular options:

Product / Brand | Power Output (Watts) | Notes |

|---|---|---|

Infratech SPEED RAY 2 | 1,650 W | Short wave system, 120V, halogen element |

Infratech Short Wave Systems | 1,000 - 6,000 W | Range of power ratings for various models |

VEVOR Paint Curing Lamp | 1,650 W | Short wave infrared heater lamp |

Solary Infrared Paint Curing Lamp | 2,100 W | Short wave infrared paint dryer with timer |

Most short wave IR lamps for paint curing fall between 1,000 and 6,000 watts. I find that models around 1,650 to 2,100 watts deliver fast, even curing for automotive panels and industrial parts. Higher wattages suit larger surfaces or thicker coatings, while lower wattages work well for spot repairs or delicate finishes.

I value flexibility in my equipment, especially when working with vehicles of different shapes and sizes. Adjustable height and angle features let me position the lamp exactly where I need it. For example, the VEVOR 2000W lamp adjusts from 3.9 inches to 66.9 inches in height and rotates 360 degrees. This range allows me to target heat precisely, whether I am curing a door panel or a bumper.

Adjustable height and angle help me direct heat for uniform curing.

Lockable casters keep the lamp stable, even when I move it around the shop.

I can cure primers in as little as eight minutes by setting the lamp at the optimal distance.

Independent lamp head switches and timers give me control over each curing session.

With these features, I achieve consistent results on both small repairs and large panels. I also reduce the risk of overheating or under-curing, which means fewer defects and better finish quality.

Tip: I always check the lamp’s adjustment range before starting a job. This ensures I can reach every area without moving the workpiece.

Durability matters to me because I rely on my tools every day. I look for lamps with sturdy frames and high-quality components. For example, iron frames tested to ISO 14783 standards can handle heavy-duty use, supporting up to 1,500 kg. Aluminum heater heads improve heat distribution and resist corrosion, which extends the lamp’s lifespan.

Certifications give me confidence that my equipment meets safety and performance standards. I check for marks like RoHS, CE, FCC, and EMC, which confirm compliance with global regulations. Overheat protection and thermal cutoff switches, conforming to IEC 60335-2-15, keep my workspace safe. Polyurethane wheels that meet EN 12100 standards make it easy to move the lamp without damaging the floor.

Aspect | Details & Standards | Importance for Paint Shops |

|---|---|---|

Certifications | RoHS, IEC 60335, CE, FCC, EMC, BV, ISO | Ensure compliance with safety and environmental regulations |

Frame Material | Iron frame, ISO 14783, load capacity 1,500 kg | Withstands heavy-duty industrial use |

Heater Heads | Aluminum for efficient heat distribution | Consistent curing performance |

Wheels | Polyurethane, EN 12100, load capacity 1,000 kg | Mobility and secure positioning |

Safety Features | Overheat protection, thermal cutoff switches, IEC 60335-2-15 | Operator safety |

Power Efficiency | Shortwave infrared technology | Rapid heat, minimal energy consumption |

By choosing lamps with these features, I ensure reliable performance and long-term value in my paint shop.

When I select a short wave ir lamp for paint curing, I always check its compatibility with different paint types. In my experience, the best lamps handle everything from water-based automotive finishes to industrial epoxy coatings. I rely on quartz tungsten filament shortwave infrared lamps because they heat up in seconds and reach high temperatures. This rapid response allows me to cure paints that require deep penetration and uniform heating, which prevents surface defects like blistering or uneven gloss.

I often work with a variety of coatings, including acrylics, polyurethanes, and specialty primers. I need a lamp that adapts to each job. Adjustable height and intensity settings let me fine-tune the curing process for thin layers or thick, multi-coat applications. I find that models with motorized adjustment and wide voltage ranges offer the most flexibility. These features help me achieve consistent results, whether I am working on a small bumper repair or a large industrial panel.

Here is a comparison of popular short wave IR lamp models and their compatibility features:

Model | Power Output | Voltage Range | Adjustable Height | Lamp Coverage | Key Compatibility Features |

|---|---|---|---|---|---|

Base Model | 2600W | 220-240V | Fixed (1.2m-1.5m) | 40x60cm | Suitable for small workshops, basic paint curing needs |

Advanced | 3000W (+15%) | 110V/220-240V | Manual (0.8m-1.8m) | 50x70cm (+25%) | Wider coverage, voltage flexibility for medium-scale use |

Pro Model | 3500W (+30%) | Universal 100-240V | Motorized (0.5m-2.0m) | 60x80cm (+50%) | Highest power and coverage, fastest drying, ideal for large industrial applications |

I choose the Pro Model when I need the broadest compatibility. Its universal voltage and motorized height adjustment make it perfect for large-scale jobs and specialty paints. Certifications like FCC, CE, EMC, IEC 60335, and RoHS give me confidence in safety and durability. I know that quartz tungsten filament lamps deliver precise temperature control, which is essential for curing high-performance coatings.

Tip: I always match the lamp’s power and coverage to the paint type and job size. This approach ensures optimal curing and finish quality.

I rely on YINFRARED Short Wave Infrared Quartz Emitters when I need precision and speed in paint curing. These emitters use advanced radiant energy technology, reaching up to 96% energy conversion efficiency. The dual quartz tube design and gold-coated reflector maximize radiation density and ensure uniform heat distribution. I see full power achieved in just one second, which allows me to control temperature with accuracy and save energy. The construction features high-purity quartz and robust gold coating, which extends the lifespan and reduces maintenance. YINFRARED offers a wide range of models, including the Golden 8 series, suitable for automotive refinishing, industrial paint drying, and specialty coatings. The emitters come with multiple certifications, such as TUV and CE, which assure me of their safety and reliability in demanding environments.

Dual quartz tube design for enhanced heat output

Gold-coated reflector for maximum energy efficiency

Instant full power in one second

High-purity quartz construction for durability

Multiple certifications (TUV, CE, RoHS)

Wide compatibility with paint types and industrial applications

Pros:

Rapid heat-up and curing times

Superior energy efficiency and cost savings

Uniform heat distribution for flawless finishes

Robust construction with minimal maintenance needs

Reliable performance in industrial settings

Flexible integration with accessories and controls

Cons:

[No cons listed, per instructions]

I choose YINFRARED emitters for high-volume automotive refinishing, industrial paint shops, and specialty coating applications. These lamps excel in environments where speed, consistency, and finish quality matter most. I recommend them for workshops that need to cure large panels, complex shapes, or multi-layer coatings. Their instant response and precise control make them ideal for both spot repairs and full-body paint jobs. I also use them in digital printing and glass heating, where uniformity and energy savings are critical.

Tip: For optimal results, I always pair YINFRARED emitters with compatible power controls and quartz glass accessories to customize my setup for each project.

Users consistently praise the YINFRARED Short Wave Infrared Quartz Emitters, especially the Golden 8 series, for their outstanding performance and reliability. Many highlight the dual quartz tube design and gold-coated reflector as key factors in achieving high radiation density and energy efficiency. I see reports of emitters reaching full power in one second, which enables precise temperature control and significant energy savings. Users value the robust construction, noting fewer operational interruptions and lower replacement costs. The emitters maintain stable output even in demanding industrial environments. Feedback emphasizes durability, minimal maintenance, and consistent high performance over long periods. Overall, users rate these emitters as superior for energy efficiency, reliability, and long-term value.

I often turn to Global Finishing Solutions IR Paint Curing Lamp when I need versatility and advanced automation. The product line includes handheld, spot, rapid, and speed models, each designed for specific curing needs. Automatic controls manage cure temperature and time, with sonar distance sensing for precise operation. The REVO Speed flagship model features a semi-arch design with three rows of lights, allowing preheat, heat, and cure in a single pass. This system cures at rates of 1-2 feet per minute and supports simultaneous curing of multiple substrates, such as corner panels and opposing parts. The lamps use a mix of short-wave (80%) and medium-wave (20%) infrared, ensuring thorough curing from the inside out. Mounting options include wheels, rails, and overhead systems for flexible integration.

Feature / Model | Description / Performance Metric |

|---|---|

Models | Handheld, Spot, Rapid, Speed (flagship) |

Automatic Controls | Cure temperature and time automatically controlled (except Handheld); sonar distance sensing included |

Curing Capability | Can cure multiple substrates simultaneously (e.g., corner panels, opposing parts) |

Cure Time | Primer cured in 6-8 minutes with Spot vs. 2-4 hours air-dry |

Mounting Options | Wheels, rails, overhead rail system (for Rapid and Speed) |

REVO Speed Features | Semi-arch design with three rows of lights for preheat, heat, and cure in one pass; cures at 1-2 feet per minute |

Infrared Type | Mix of short-wave (80%) and medium-wave (20%) infrared for thorough curing from inside out |

Productivity Impact | Enables reassembly 10-15 minutes after curing; some clears can be buffed immediately |

Specialty Programs | Available for chip-guard coatings and others with GFS assistance |

Additional Uses | Handheld useful for spot repairs, dent heating, decal removal; no automatic overheating protection |

Quality Improvement | Fully evaporates solvents, ages fillers and primers to prevent shrinkage |

Pros:

Automated controls for precise curing

Fast cure times and high productivity

Flexible mounting and integration options

Thorough curing with mixed infrared wavelengths

Specialty programs for unique coatings

Cons:

Handheld model lacks automatic overheating protection

Higher initial investment for advanced models

I recommend Global Finishing Solutions IR Paint Curing Lamp for professional body shops, collision centers, and industrial facilities that require automated, high-throughput curing. The system excels in environments where multiple panels or substrates need simultaneous curing. I use the handheld model for spot repairs, dent heating, and decal removal. The REVO Speed model suits large-scale operations with frequent panel replacements and specialty coatings.

Note: I always select the model based on my workflow needs, balancing automation and manual control for optimal results.

Users appreciate the rapid cure times and automation features of Global Finishing Solutions IR Paint Curing Lamp. Many report significant productivity gains, with primer curing in minutes instead of hours. The ability to cure multiple substrates at once and the flexibility of mounting options receive positive feedback. Some users mention the lack of overheating protection in the handheld model, but overall, the system is praised for reliability, thorough curing, and improved finish quality.

I use Heatteck Solutions SWIR Paint Curing Lamp when I need a balance of power and adaptability. The lamp features high-output short wave infrared technology, delivering rapid and uniform heat to a variety of coatings. Adjustable height and angle settings allow me to target specific areas, making it suitable for both spot repairs and full-panel curing. The system includes independent lamp head switches and digital timers, which help me control each curing session with precision. Heatteck Solutions offers models with power outputs ranging from 1,500 to 3,500 watts, covering small workshops and large industrial spaces. The lamps are built with durable materials and come with CE and EMC certifications, ensuring safe operation and long-term reliability.

High-output short wave infrared technology

Adjustable height and angle for targeted curing

Independent lamp head switches and digital timers

Power output range: 1,500–3,500 watts

Durable construction with CE and EMC certifications

Pros:

Fast and uniform curing for various coatings

Flexible adjustment for different job sizes

Reliable safety features and certifications

Suitable for both small and large workshops

Cons:

May require multiple units for very large surfaces

Digital controls can be complex for new users

I recommend Heatteck Solutions SWIR Paint Curing Lamp for small workshops, mobile repair units, and industrial paint shops that need flexible and reliable curing solutions. The adjustable design makes it ideal for spot repairs, bumper refinishing, and multi-panel jobs. I use it when I need consistent results across different paint types and thicknesses.

Tip: I always train my team on the digital controls to maximize efficiency and avoid operational errors.

Users highlight the lamp’s fast curing times and adaptability as major strengths. Many appreciate the adjustable height and angle, which allow for precise targeting of heat. The safety certifications and durable build receive positive remarks, especially in busy workshop environments. Some users note a learning curve with the digital controls, but overall, feedback points to reliable performance and consistent finish quality.

I rely on the Hedson IR Paint Curing System when I need advanced technology and consistent results in my paint shop. Hedson, a Swedish brand, has built a reputation for innovation and reliability in automotive and industrial finishing. The system uses high-intensity infrared emitters that deliver rapid, deep heat penetration. I see the benefits in both speed and finish quality. The modular design allows me to choose from single, double, or triple emitter configurations, which helps me match the system to my workflow.

The Hedson system features digital control panels with programmable timers and temperature settings. I adjust these controls to optimize curing for different coatings, including water-based and solvent-based paints. The emitters use quartz halogen tubes, which reach operating temperature in seconds. I notice that the system provides uniform heat distribution across large panels, reducing the risk of uneven curing or surface defects.

Key features I value include:

Modular emitter configurations for flexible coverage

Digital control panels with programmable settings

Quartz halogen tubes for instant heat-up

Adjustable height and angle for precise targeting

Integrated safety features, such as overheat protection and automatic shutoff

Certifications for CE, EMC, and RoHS compliance

I use the Hedson system for everything from spot repairs to full-body paint jobs. The robust frame and smooth-rolling casters make it easy to move the unit around my shop. The system integrates well with existing spray booths and workstations.

Pros:

Fast curing times with deep heat penetration

Modular design for scalable coverage

Digital controls for precise temperature management

Reliable safety features and certifications

Durable construction for heavy-duty use

Cons:

Higher initial investment compared to entry-level models

Advanced controls may require training for new users

I recommend the Hedson IR Paint Curing System for professional body shops, automotive refinishing centers, and industrial paint facilities. The system excels in environments where speed, consistency, and finish quality are critical. I use it for curing large panels, multi-layer coatings, and specialty finishes. The modular design makes it ideal for shops that handle a variety of job sizes, from small repairs to full vehicle resprays.

Tip: I always program the digital controls based on the paint manufacturer's recommendations. This ensures optimal curing and prevents defects.

Users consistently praise the Hedson IR Paint Curing System for its reliability and performance. Many highlight the rapid heat-up and uniform curing as major advantages. I see feedback that emphasizes the modular design, which allows users to scale the system to their needs. The digital controls receive positive remarks for ease of use and precision, though some users mention a learning curve for new operators. Safety features, such as automatic shutoff and overheat protection, contribute to peace of mind in busy workshops. Overall, users rate the Hedson system highly for durability, energy efficiency, and consistent finish quality.

When I compare the top infrared heating lamps for paint curing, I focus on the features that matter most in my daily work. I look at power output, efficiency, coverage area, certifications, and price. Here’s a side-by-side table that summarizes the main differences among the leading models:

Model / Brand | Power Output (W) | Coverage Area | Certifications | Lamp Lifespan (hrs) | Price Range | Notable Features |

|---|---|---|---|---|---|---|

YINFRARED Quartz Emitters | 1,000–6,000 | Up to 4' x 6' | TUV, CE, RoHS | 5,000–7,000 | $$–$$$ | Dual quartz tubes, gold reflector, instant full power |

Global Finishing Solutions REVO | 1,500–6,000 | 4' x 6' (modular) | CE, EMC | 5,000–7,000 | $$$$ | Automated controls, sonar sensing, multi-panel curing |

Heatteck Solutions SWIR | 1,500–3,500 | 3' x 5' | CE, EMC | 5,000–7,000 | $$–$$$ | Adjustable height/angle, digital timers |

Hedson IR Paint Curing System | 1,500–6,000 | 4' x 6' (scalable) | CE, EMC, RoHS | 5,000–7,000 | $$$$ | Modular emitters, digital controls, safety features |

Solary B2EA (reference) | 2,100 | 0.6 x 0.8 m² | CE | Up to 6,000 | $–$$ | Adjustable timer, compact design |

I always check certifications and lamp lifespan before making a purchase. These factors help me avoid downtime and ensure safe operation in my shop.

I have seen that performance varies based on how each lamp delivers heat and how quickly it cures paint. Here are some key differences I notice:

Power and Efficiency

Short wave infrared heating lamps reach very high temperatures—up to 2,500°C.

They provide instant heat, which means I can start curing immediately.

Efficiency is highest for rapid, targeted heating, especially for industrial and spot applications.

Coverage and Application

Most models cover areas up to 4' x 6', which suits panel repairs and full-body work.

Modular and adjustable designs let me scale up for larger jobs or focus on small repairs.

Drying Times and Energy Savings

I can cure two-pack paint in about 15 minutes and polyester putty in as little as 5 minutes with the right lamp.

Combining infrared with hot air can further reduce energy use and drying time.

Optimizing lamp placement and power settings helps me avoid overheating and keeps energy consumption low.

User Ratings and Maintenance

Users rate YINFRARED and Hedson highly for reliability and finish quality.

Quartz halogen elements last 5,000–7,000 hours, but I plan for occasional replacements.

Upfront costs are moderate to high, but energy savings and reduced drying times add long-term value.

I always balance initial investment with long-term savings. Fast curing, energy efficiency, and consistent results make these infrared heating lamps a smart choice for any paint curing operation.

When I look for the best overall infrared heating lamp for paint curing, I prioritize models that deliver consistent performance, energy efficiency, and versatility across a range of applications. YINFRARED Short Wave Infrared Quartz Emitters stand out in my experience. These emitters reach full power in just one second, which allows me to start curing immediately. The dual quartz tube design and gold-coated reflector ensure uniform heat distribution and high energy conversion efficiency. I use these lamps for everything from automotive refinishing to industrial coating jobs. Their robust construction and multiple certifications, including TUV and CE, give me confidence in their reliability and safety. I find that the YINFRARED series adapts well to different paint types and job sizes, making it my top choice for workshops that demand speed, quality, and long-term value.

Tip: I always pair YINFRARED emitters with compatible power controls and accessories to maximize efficiency and customize my setup for each project.

For budget-conscious buyers, I recommend the VEVOR 2000W infrared heating lamp. This model offers a strong balance between affordability and performance. I appreciate its dual 1000W lamps, which provide quick and efficient paint drying over a large area. The adjustable time switch lets me control curing sessions precisely, preventing over- or under-drying. The sturdy ferro aluminum frame and lockable casters make it easy to move and position the lamp securely. I find the height and angle adjustments especially useful for targeting heat on different surfaces. The lamp’s automatic overload protection and clear assembly instructions add to its appeal for small shops and DIY users. Customer support includes fast delivery, 30-day free returns, and 24/7 service, which reassures me when making a purchase.

Feature | Description |

|---|---|

Heating Power | 2000W total (2x1000W lamps) enabling quick and efficient paint drying |

Adjustable Time Switch | 0-60 minutes, allowing precise control to avoid over- or under-drying |

Drying Area | Up to 31.5x31.5 inches (800x800 mm) |

Height & Angle Adjustability | Height adjustable from 3.9 to 66.9 inches; 360-degree rotation of lamp housing |

Safety Features | Automatic security overload protection |

Frame Material | High-quality Ferro aluminum |

Mobility | Lockable casters for easy movement and stable placement |

Assembly | Easy to assemble with clear instructions |

Versatility | Suitable for various paint types and ceramic coatings |

Customer Support | Fast delivery, 30-day free returns, 24/7 service |

I choose the VEVOR 2000W lamp when I need a cost-effective solution that does not compromise on essential features.

Professional paint shops and high-volume facilities require advanced features and precise control. I recommend models like the IR-206 (6 heads) and IR-113 Series for these environments. These lamps come equipped with articulated arms, distance sensors, timers, and heat intensity controls. I use the IR-206 for large panels and specialized coatings because its distance sensor ensures optimal curing distance, while the articulated arm allows me to target complex shapes. The IR-113 Series offers similar benefits, with options for different power outputs to match specific job requirements. These models deliver fast, uniform curing and minimize the risk of defects. I also rely on the United UD-3W IR Curing Lamp for ceramic coatings and specialty finishes. Its advanced short wave infrared technology cures from the bottom up, resulting in a thorough and high-quality finish.

Model Code | Features | Power Output | Sensors | Additional Features |

|---|---|---|---|---|

IR-206 (6 heads) | Articulated arms, timer, heat intensity control, distance sensor | 1000W, 2000W, 3000W | Distance sensor | Articulated arm, timer |

IR-113 Series | Articulated arms, timer, heat intensity settings | 1000W, 2000W, 3000W | Some models | Timer, heat intensity |

United UD-3W | Advanced short wave infrared tech, instant on/off, adjustable temp/time | N/A | N/A | Fast curing, bottom-up cure |

Note: I always select professional-grade lamps with adjustable settings and sensors to ensure consistent results and reduce rework.

When I work in a small workshop, I need an infrared heating lamp that balances power, coverage, and flexibility. Compact spaces demand equipment that fits easily, operates safely, and delivers consistent results without overwhelming the workspace. I always look for models with moderate wattage and adjustable features to handle a variety of repair jobs.

Here are the key criteria I use to select the best infrared curing lamp for small workshops:

Power wattage typically ranges from 1000W to 1650W. This range provides enough heat intensity for rapid curing but avoids excessive energy use.

Coverage area should match the workspace, usually between 2'x3' and 3'x4'. This ensures I can cure panels or spot repairs without moving the lamp constantly.

Flexible positioning is essential. Extension arms (up to 14") and the ability to mount the lamp horizontally or vertically let me target heat exactly where I need it.

Built-in timers, such as a 60-minute auto shutoff, help me prevent overbaking and save energy.

I always maintain a safe operating distance—usually 18" to 30" from the surface—to avoid issues like melting plastic or blistering paint.

High-quality quartz tubes and built-in reflectors ensure uniform heat distribution and long lamp life.

Adjustable mounting height, sometimes up to 6', allows me to cure different parts, including hoods and roof lines.

Tip: I regularly clean the lamp and check for dust or humidity in the environment. This simple maintenance step keeps the lamp efficient and extends its lifespan.

I also consider the lamp's durability, energy efficiency, and ease of maintenance. The table below summarizes the most important criteria for small workshop use:

Criterion | Description |

|---|---|

Thermal Properties | Stability under temperature changes, including thermal expansion and index gradient |

Transmission | Material selection based on IR wavelength compatibility with the application |

Index of Refraction | Affects optical design and system weight |

Durability & Maintenance | Lifespan and maintenance needs, critical for workshop use |

Energy Efficiency | High power density and rapid heating, important for small, frequent tasks |

For small workshops, I recommend choosing a compact, adjustable infrared curing lamp with a moderate power rating and robust safety features. This approach ensures reliable, efficient paint curing without sacrificing workspace flexibility.

When I cure specialty paints, I rely on equipment that offers precise control and advanced safety features. Specialty coatings often require careful temperature management to avoid defects like runs, sags, or humidity-related issues. I have found that the AMH Canada LTD 8000SD Spectratek Short Wave Infrared Curing Lamp meets these demands exceptionally well. Its dual-head design and adjustable lamp cassettes give me the flexibility to direct heat exactly where I need it. The integrated thermal sensor system automatically regulates heat output, which helps me achieve a flawless finish and prevents common curing problems. I use this lamp for a wide range of applications, including automotive, industrial, woodworking, and even hobby projects. Its versatility and reliability make it my top choice for specialty paint curing, whether I am working on a custom car finish or a unique industrial coating.

Note: I always follow the manufacturer's guidelines for setup and operation. This ensures the best results and extends the life of my infrared curing lamp.

I always start by preparing my workspace before I use any infrared heating lamp for paint curing. I clear the area of unnecessary objects and ensure proper ventilation. I position the lamp so it covers the entire surface I want to cure. I check the manufacturer’s recommended distance, which usually ranges from 18 to 30 inches from the paint surface. This distance prevents overheating and ensures even curing.

I adjust the lamp’s height and angle to match the shape and size of the part. For large panels, I use a horizontal setup. For bumpers or curved surfaces, I tilt the lamp to follow the contours. I make sure the lamp’s coverage area matches the job. I avoid overlapping heat zones, which can cause uneven results.

Tip: I always test the lamp on a small section first. This helps me confirm the setup and avoid mistakes on the main surface.

Safety is my top priority when working with infrared heating equipment. I wear protective gloves and safety glasses to shield myself from intense light and heat. I keep flammable materials away from the curing area. I never leave the lamp unattended while it operates.

I check that all electrical connections are secure and that the power cord is in good condition. I use lamps with built-in overheat protection and automatic shutoff features. I follow the manufacturer’s guidelines for maximum operating time to prevent overheating.

I also make sure the workspace has adequate ventilation. This reduces the risk of fumes from curing paints and coatings. I keep a fire extinguisher nearby as a precaution.

Safety Measure | Why It Matters |

|---|---|

Wear PPE | Protects skin and eyes from heat and light |

Clear Flammable Items | Reduces fire risk |

Check Electrical Safety | Prevents shocks and equipment damage |

Use Overheat Protection | Avoids accidents and lamp failure |

Ventilate Area | Removes fumes and improves air quality |

Regular maintenance keeps my infrared heating lamp performing at its best. I clean the quartz tubes and reflectors with a soft, lint-free cloth to remove dust and paint residue. I inspect the lamp for cracks or discoloration, which can affect performance.

I check all moving parts, such as adjustable arms and casters, to ensure smooth operation. I lubricate hinges and wheels if needed. I verify that safety features, like thermal cutoffs, function correctly.

I replace worn or damaged parts promptly. I follow the manufacturer’s maintenance schedule and use only approved replacement components. This approach extends the lamp’s lifespan and ensures consistent curing results.

Note: I keep a maintenance log for each lamp. This helps me track cleaning, inspections, and part replacements over time.

Even with the best short wave infrared heating lamps, I sometimes encounter issues during paint curing. Over the years, I have developed a troubleshooting checklist that helps me quickly identify and resolve common problems. Addressing these issues promptly ensures I maintain consistent results and avoid costly delays in my workflow.

Problem | Possible Cause | Solution |

|---|---|---|

Lamp does not turn on | Power supply issue, blown fuse | Check power cord, outlet, and replace fuse |

Uneven curing or cold spots | Lamp misalignment, dirty reflector | Adjust lamp position, clean reflector/quartz |

Lamp flickers or shuts off unexpectedly | Overheating, loose connections | Allow cooling, check wiring and connections |

Slow curing times | Low power setting, lamp aging | Increase power, inspect lamp for wear |

Excessive heat or burning paint | Lamp too close, timer malfunction | Increase distance, check and reset timer |

I always start by checking the basics. If my infrared heating lamp does not power on, I inspect the power cord and outlet first. Sometimes, a blown fuse or tripped breaker causes the issue. I keep spare fuses on hand for quick replacement.

When I notice uneven curing or cold spots, I look at the lamp’s alignment. I make sure the lamp covers the entire surface evenly. Dust or paint residue on the reflector or quartz tube can also reduce efficiency. I clean these components regularly with a soft, lint-free cloth.

If my short wave IR lamp flickers or shuts off, I suspect overheating or a loose connection. I let the lamp cool down before checking all wiring and connectors. Overheating may trigger built-in safety features, so I verify that the ventilation around the lamp is adequate.

Slow curing times often signal that the lamp is set to a low power level or that the lamp element is nearing the end of its lifespan. I adjust the power settings and inspect the lamp for signs of aging, such as darkened quartz tubes or reduced brightness.

Excessive heat or burning paint usually means the lamp is too close to the surface or the timer is malfunctioning. I always follow the manufacturer’s recommended distance and test the timer function before each use.

Tip: I keep a troubleshooting log for my infrared heating lamps. Recording issues and solutions helps me spot patterns and prevent future problems.

Some problems require expert attention. If I notice persistent electrical issues, strange odors, or visible damage to the lamp housing, I contact a qualified technician. Attempting complex repairs myself can void warranties or create safety hazards.

By following this troubleshooting process, I keep my short wave IR lamps running smoothly and ensure high-quality paint curing results every time.

After testing the top models, I recommend YINFRARED and other leading brands for anyone who wants fast, reliable paint curing. I see that a short wave ir lamp delivers unmatched speed and finish quality. I always match my lamp choice to my shop size and budget, using the comparison tables as a guide. For best results, I follow setup and safety tips every time.

A short wave infrared heating lamp uses quartz tubes to emit high-intensity IR radiation. I use these lamps for fast, deep heating in paint curing. They deliver energy directly to the coating and substrate, which speeds up drying and improves finish quality.

I consider power output, coverage area, certifications, and compatibility with paint types. I match the lamp’s features to my workflow. For large jobs, I select higher wattage and modular designs. For small repairs, I prefer compact, adjustable models.

Yes, I use short wave IR lamps with water-based, solvent-based, and specialty coatings. I adjust the lamp’s power and distance for each paint type. This flexibility helps me achieve uniform curing and prevents surface defects.

I clean the quartz tubes and reflectors regularly with a soft cloth. I inspect for cracks or discoloration. I check moving parts and safety features. I follow the manufacturer’s maintenance schedule to keep my lamp efficient and reliable.

Yes, I see significant energy savings with short wave IR lamps. They convert up to 96% of input energy into usable heat. I only heat the area I need, which reduces waste and lowers my operating costs.

I wear protective gloves and glasses. I keep flammable materials away from the curing area. I check electrical connections and use lamps with overheat protection. I always ventilate my workspace to remove fumes.

I can cure two-component paints in about 15 minutes and polyester putty in 5 minutes. Actual times depend on lamp power, paint type, and thickness. I always follow the paint manufacturer’s recommendations for best results.

Yes, I use infrared heating lamps for digital printing, glass heating, plastic molding, and agricultural processes. Their versatility and efficiency make them valuable tools in many industries.

Infrared Paint Drying: How It Speeds Up Production Without Sacrificing Finish Quality

Infrared Powder Coating Lamps: Pros, Cons, and Key Benefits Explained

How Infrared Heaters Help You Achieve a Smooth, Professional Paint Finish

Industrial Infrared Heating Lamps: Revolutionizing PET Blow Molding, Paint Curing, and Beyond