Views: 0 Author: Site Editor Publish Time: 2025-08-25 Origin: Site

Infrared (IR) heating technology has become an indispensable component of modern industrial manufacturing, offering unmatched efficiency, precision control, and significant energy savings compared to conventional heating methods. From rapidly drying paint on automotive panels to evenly heating plastic preforms for water bottles, industrial infrared lamps provide a clean, efficient, and highly controllable heat source. This article explores the critical role of infrared heating technology, focusing on its applications in PET blow molding machines, industrial paint curing systems, and numerous other sectors, while highlighting the technical advantages that make it the preferred choice for engineers and system integrators worldwide.

Infrared radiation is a form of electromagnetic energy that transfers heat directly to objects without heating the surrounding air. Industrial infrared lamps typically consist of a tungsten filament enclosed within a gas-filled quartz tube. When electrical current passes through the filament, it heats up and generates infrared radiation that travels at the speed of light, carrying substantial thermal energy.

Industrial infrared heating systems are classified based on their wavelength characteristics:

Short-wave infrared lamps (wavelength 0.76-1.6μm) offer extremely rapid heating and cooling cycles, achieving operational temperature in just 1-3 seconds. These lamps feature gold-doped reflective coatings that achieve up to 96% radiation efficiency, making them ideal for applications requiring precise, rapid thermal control1. Their ability to rapidly heat surfaces makes them particularly effective for drying water-based materials and curing coatings.

Operating in the 1.6-4.0μm wavelength range, medium-wave infrared lamps provide a balance between penetration depth and surface heating, suitable for a wide range of industrial processes where moderate heating rates are desirable.

Long-wave infrared lamps (wavelength >4.0μm) generate gentle, uniform heating with excellent thermal uniformity. While slower to reach operating temperature than short-wave lamps (typically 1-3 minutes), they offer exceptional energy conversion efficiency of 60-75% and are less likely to cause thermal shock to sensitive materials.

Table: Comparison of Infrared Lamp Types by Wavelength and Characteristics

| Parameter | Short-Wave Infrared | Medium-Wave Infrared | Long-Wave Infrared |

|---|---|---|---|

| Wavelength Range | 0.76-1.6μm | 1.6-4.0μm | >4.0μm |

| Time to Operating Temp | 1-3 seconds | 30-90 seconds | 1-3 minutes |

| Typical Efficiency | Up to 96% | 70-85% | 60-75% |

| Heating Character | Rapid surface heating | Balanced surface/sub-surface | Deep, uniform heating |

| Common Applications | High-speed drying, PET heating | Paint curing, textile drying | Food warming, space heating |

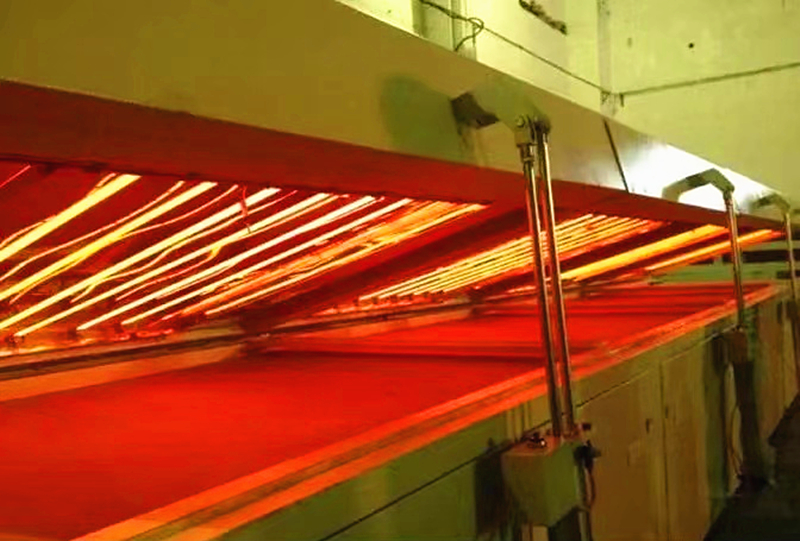

The production of PET containers through blow molding processes represents one of the most significant applications of industrial infrared technology. In PET blow molding machines, infrared lamps provide the critical thermal energy necessary to condition preforms before the blowing process.

Modern PET blow molding equipment utilizes specially engineered infrared heating systems with rotating carousels that ensure uniform thermal distribution around the preform. Advanced systems feature multi-zone control capabilities that allow different heating profiles along the preform's length and circumference, ensuring optimal material distribution in the final container.

The precision of infrared heating prevents overheating of critical areas such as the neck and thread regions, which must remain crystalline to maintain structural integrity and sealing properties. Simultaneously, the lamp configuration ensures sufficient heating in the body area to allow proper stretching and blowing characteristics.

Infrared heating systems offer PET manufacturers several distinct advantages:

Energy Efficiency: Modern infrared-based blow molding machines demonstrate 40% greater energy efficiency compared to conventional heating systems, significantly reducing operational costs.

Process Control: PLC-controlled independent zoning capabilities allow precise temperature profiling along the preform length, enabling manufacturers to optimize material distribution for complex container designs.

Production Flexibility: Adjustable lamp positions (both vertically and horizontally) accommodate various preform sizes and shapes without requiring complete system overhaul.

Enhanced Quality: Uniform heating eliminates cold spots that can lead to thin areas in the final container, improving mechanical strength and barrier properties.

Leading blow molding equipment manufacturers such as Sidel, SIPA, and Krones have extensively integrated infrared heating technology into their systems, recognizing its superior performance characteristics for PET container production.

The application of infrared heating technology has dramatically transformed industrial paint curing processes, particularly in the automotive sector where finish quality and production throughput are critical concerns.

Infrared technology has proven particularly valuable in automotive paint drying applications, where traditional convection ovens require substantial space and energy resources. Modern infrared paint curing systems offer dramatically reduced processing times, with certain short-wave infrared systems achieving cure times 50% faster than conventional methods.

The mechanism of infrared paint curing involves penetrative heating that initiates drying from the substrate-paint interface outward, preventing the formation of surface skin that can trap solvents and cause defects. This approach eliminates common finishing problems such as orange peel texture and sagging, while improving adhesion strength and surface gloss by up to 30%.

Advanced infrared paint curing systems incorporate multiple technological innovations:

Intelligent Control Systems: Modern infrared curing stations feature programmable controllers with multiple preset programs tailored to different paint chemistries (water-based, solvent-based, high-solid formulations). These systems maintain temperature precision within ±2°C, ensuring consistent results across production runs.

Safety Integration: Premium systems incorporate comprehensive safety packages including thermal cutoff switches, tip-over protection, and automatic shutdown when objects approach too closely (typically <50cm).

Ergonomic Design: Modular lamp assembly designs facilitate quick replacement (typical lamp life exceeds 2000 hours) and minimize maintenance downtime.

The implementation of infrared technology has been particularly transformative for automotive repair and refinishing operations, where portable infrared systems enable spot repairs without requiring entire vehicle panels to be heated. This capability significantly reduces energy consumption and enables faster turnaround for collision repair centers.

Beyond PET processing and paint curing, infrared heating technology finds application across numerous industrial sectors:

Infrared lamps extensively serve drying and curing functions in printing processes. High-speed printing equipment utilizes short-wave infrared lamps with gold reflectors to achieve rapid drying of inks and coatings on various substrates. Major printing press manufacturers including Heidelberg, Roland, KOMORI, and Ryobi integrate infrared drying systems into their equipment to enable higher production speeds and immediate downstream processing.

Beyond blow molding, infrared heating facilitates numerous plastic processing operations including sheet thermoforming, plastic welding, and film processing. The technology's rapid response characteristics enable precise thermal conditioning of plastic materials immediately before forming operations, improving material distribution and reducing cycle times.

Infrared heating systems serve multiple functions in food processing, including baking, drying, toasting, and sterilization. The technology's ability to transfer heat without direct contact makes it ideal for hygienic processing environments. Food packaging applications include shrink wrapping, sealing operations, and heat-based labeling systems.

The textile industry employs infrared technology for dye fixation, fiber drying, and fabric heating processes. Infrared systems provide uniform heating across textile substrates without contact, preventing marking or distortion of sensitive fabrics.

Infrared heating accelerates paint drying, adhesive curing, and wood bending operations in furniture manufacturing. The technology's ability to penetrate wood substrates ensures uniform curing of coatings and adhesives throughout the product cross-section.

The electronics industry utilizes infrared heating for printed circuit board soldering, component curing, and semiconductor processing operations including CVD and RTP applications. Precision infrared heating systems provide the thermal control necessary for delicate electronic components.

Table: Industrial Applications of Infrared Heating by Sector

| Industry Sector | Primary Applications | Typical Lamp Type | Key Benefits |

|---|---|---|---|

| Packaging (PET) | Blow molding, container heating | Short-wave | Energy savings, precise zoning |

| Automotive | Paint curing, adhesive bonding | Short/Medium-wave | Rapid curing, spot repair capability |

| Printing | Ink drying, coating curing | Short-wave | High-speed processing, instant on/off |

| Food Processing | Baking, sterilization, sealing | Medium/Long-wave | Hygienic, non-contact heating |

| Textiles | Dye fixation, fabric drying | Medium-wave | Uniform heating, no contact marking |

| Electronics | Soldering, component curing | Short-wave | Precision control, rapid cycling |

Successful implementation of industrial infrared heating requires careful consideration of several technical factors:

Choosing the appropriate infrared wavelength represents the most critical decision in system design. As a general principle, materials absorb infrared energy most efficiently when the lamp's peak wavelength correlates with the molecular absorption characteristics of the target material. Short wavelengths (0.76-1.6μm) work best for rapidly heating thin materials and surfaces, while longer wavelengths (>4.0μm) provide deeper penetration for thicker materials.

Proper lamp arrangement ensures uniform thermal distribution across the target surface. Engineers must consider lamp spacing, distance to target, and reflective surfaces to optimize efficiency and prevent hot spots. For conveyorized processes, the relationship between lamp intensity and line speed must be carefully balanced to achieve the required thermal dose.

Modern infrared systems employ advanced control strategies including phase-angle fired SCR controllers, pulse-width modulation, and closed-loop temperature feedback to maintain precise thermal conditions. Multi-zone control capabilities enable different thermal profiles across the target workpiece, essential for complex manufacturing processes.

While infrared systems generate less waste heat than conventional ovens, proper cooling remains essential for component protection and process stability. Strategic placement of cooling blowers and heat shielding protects sensitive components from thermal damage.

Industrial infrared systems must incorporate appropriate safety measures including thermal overload protection, ground fault interruption, and physical guarding to prevent operator exposure. Safety-interlocked access doors and emergency stop circuits ensure compliance with industrial safety regulations.

Infrared heating technology continues to evolve, with several promising developments on the horizon:

Advancements in distributed control architecture and real-time thermal imaging will enable unprecedented precision in thermal processing. Integrated temperature profiling systems will automatically adjust lamp output to maintain consistent thermal conditions despite variations in line speed or ambient conditions.

Ongoing materials research focuses on developing advanced reflector coatings and filament materials that will further improve electrical-to-thermal conversion efficiency. These developments will reduce energy consumption while increasing system output capabilities.

Combining infrared with other heating technologies such as hot air convection or ultrasonic energy will create synergistic effects that optimize processing efficiency and product quality. These hybrid approaches will address limitations of single-technology systems.

Infrared heating systems will increasingly incorporate network connectivity and data analytics capabilities to enable predictive maintenance, remote monitoring, and seamless integration with smart factory initiatives. These capabilities will reduce downtime and optimize energy utilization.

Infrared heating technology has established itself as a critical enabling technology across numerous industrial sectors, offering combination of energy efficiency, process control, and operational flexibility unmatched by conventional heating methods. From the precise thermal conditioning required in PET blow molding to the rapid curing capabilities essential for automotive refinishing, infrared systems provide manufacturing engineers with powerful tools to optimize their processes.

As industrial manufacturers face increasing pressure to improve efficiency, reduce environmental impact, and enhance product quality, infrared heating technology will continue to grow in importance. The ongoing development of more sophisticated control strategies, improved lamp designs, and intelligent system integration will further expand the applications for this versatile technology.

For manufacturing professionals considering thermal process improvements, infrared heating represents a proven technology with demonstrated benefits across countless applications. By carefully matching infrared system characteristics to specific process requirements, engineers can achieve substantial improvements in productivity, quality, and operational efficiency.

Discover How Our Infrared Heating Solutions Can Transform Your Industrial Process

Contact our engineering team today to discuss your specific application requirements and learn how our customized infrared heating solutions can improve your product quality while reducing energy consumption and operating costs. Request a comprehensive thermal analysis and process evaluation to identify opportunities for implementation of infrared technology in your operation.

YFR Manufacturing Co., Ltd. - Engineering Excellence in Infrared Heating Technology

Infrared Powder Coating Lamps: Pros, Cons, and Key Benefits Explained

How Infrared Heaters Help You Achieve a Smooth, Professional Paint Finish

Industrial Infrared Heating Lamps: Revolutionizing PET Blow Molding, Paint Curing, and Beyond

Paint Curing Efficiency Short Wave IR Lamps Compared to Medium Wave