Author: Site Editor Publish Time: 2025-10-29 Origin: Site

In industrial and commercial heating environments, efficient and targeted thermal delivery has become a strategic priority. One of the technologies leading this evolution is the shortwave infrared (IR) lamp, also known as a shortwave heat IR lamp.

This article explores how shortwave IR technology works, its key advantages, major categories, and industrial applications, along with practical criteria for selecting and specifying the right system. Designed for engineers, system integrators, and procurement professionals, it delivers deep technical insights and best practices grounded in practical industrial experience.

A shortwave heat IR lamp is an infrared emitter that radiates energy primarily in the shortwave (near-infrared) region of the spectrum. It typically uses a tungsten filament enclosed in a quartz or fused silica glass tube.

The filament operates at very high temperatures, generally between 1,300°C and 2,600°C, producing wavelengths around 0.75 to 1.4 micrometers (µm). These shortwave IR rays are extremely efficient for direct radiant heating, transferring thermal energy quickly to surfaces and subsurfaces.

Unlike conventional heating systems that rely on convection (heating the surrounding air first), shortwave IR lamps transmit radiant energy directly to the object, ensuring faster, more energy-efficient heating. In industrial applications, this direct transfer often results in up to 90% faster heating times and significant energy savings.

Shortwave IR lamps are valued across industries for their performance efficiency, speed, and precision. Below are the primary benefits:

The tungsten filament and quartz envelope reach operating temperature within seconds. There’s no long warm-up phase, enabling rapid production starts and high process flexibility.

Because shortwave IR energy directly heats the target surface, very little energy is lost to ambient air. This precise targeting reduces total power consumption compared to convection or longwave systems.

When combined with engineered reflectors, shortwave IR lamps can deliver even heat distribution across product surfaces, ensuring consistent quality and preventing localized overheating.

These lamps require minimal installation space. Since air circulation systems are not essential, production lines can be more compact and cost-effective to build.

The ability to rapidly raise product temperature significantly shortens process cycles in drying, curing, or forming applications, improving productivity and output capacity.

Unlike convection systems that warm entire air volumes, shortwave IR lamps minimize ambient heat, making work environments more comfortable and energy-efficient.

While shortwave IR lamps offer many benefits, proper design and application are essential to achieving optimal performance:

Higher initial equipment cost: Quality quartz halogen emitters and control systems may have higher upfront investment than basic convection heaters.

Line-of-sight heating: Radiant energy requires direct exposure; improper layout can cause uneven heating or shadows.

Material compatibility: Some materials reflect or transmit IR differently. The substrate’s absorptivity and emissivity should be assessed before selection.

Safety and protection: High-intensity radiant energy requires shielding, interlocks, and temperature monitoring to ensure operator safety.

Maintenance requirements: Quartz tubes can degrade over time. Regular cleaning and periodic lamp replacement are necessary to maintain efficiency.

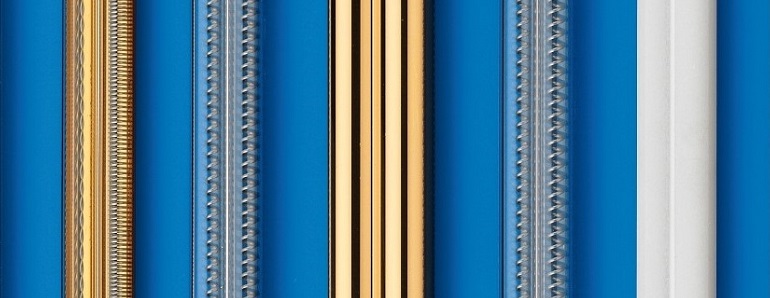

Shortwave IR lamps come in several designs, each suited for different heating profiles and integration environments.

| Category | Description | Typical Applications |

|---|---|---|

| Single-Tube Quartz Halogen Lamp | Simple linear emitter with quartz glass and tungsten filament. | General-purpose surface heating, drying, and curing. |

| Twin-Tube (U-Shaped) Lamp | Two quartz tubes joined together to increase radiant density and mechanical strength. | Conveyorized drying, compact heating zones. |

| Gold-Reflector Coated Lamp | Gold coating applied to reflect IR energy toward the target surface, enhancing efficiency. | Paint curing, polymer processing, automotive finishing. |

| Modular Cassette Arrays | Multiple emitters arranged in panels with built-in reflectors and electrical controls. | High-throughput production lines, coating ovens. |

| Hybrid Systems (IR + Convection) | Combines shortwave IR with other heating modes for deep or complex heating. | Multilayer materials, moisture removal, hybrid curing. |

Each variant offers specific performance characteristics based on power density, geometry, and optical reflection. The selection depends on process temperature requirements, substrate properties, and available space.

When specifying a shortwave IR lamp, engineers typically evaluate several critical dimensions:

Wavelength Band: Shortwave IR typically ranges from 0.75–1.4 µm, ideal for surfaces that absorb energy efficiently in this range.

Power Density: Expressed in W/cm² or W/m², indicating how much radiant energy is emitted.

Lamp Geometry: Single-tube, twin-tube, or modular arrays affect heat distribution and mechanical integration.

Electrical Characteristics: Voltage, wattage, and control method (such as phase-angle or SCR dimming).

Reflector Material: Gold, ceramic, or aluminum reflectors improve directional efficiency.

Lamp Length and Mounting: Determines coverage area and intensity uniformity.

Expected Lifetime: High-quality shortwave lamps typically last between 5,000–7,000 hours, depending on use conditions.

Shortwave IR lamps are highly adaptable and serve a wide range of industrial processes.

Used extensively in automotive refinishing, industrial coatings, and furniture manufacturing, these lamps rapidly cure paints, varnishes, and powder coatings. They deliver consistent, defect-free finishes and shorten curing cycles.

In plastic sheet heating and forming, shortwave IR ensures precise temperature control and rapid preheating. The high-intensity radiant heat improves product definition and reduces energy consumption.

Glass preheating, tempering, and annealing processes benefit from shortwave IR’s rapid, uniform heat transfer. The lamps help reduce stress gradients and improve dimensional stability.

Shortwave IR is used for drying inks, glazes, and coatings on high-speed production lines. The ability to instantly control output supports synchronization with moving substrates.

In specialized systems, shortwave IR can be applied for sterilization, drying, or surface treatment, provided materials and process temperatures are compatible with product safety standards.

Shortwave IR enables precise preheating before coating, welding, or adhesive bonding. Its responsiveness helps maintain tight thermal control during manufacturing cycles.

Selecting the optimal shortwave IR lamp involves balancing performance, integration, and lifecycle considerations. Below is a recommended framework for industrial buyers and system designers.

Define the target surface temperature and desired heating rate.

Measure or estimate the absorption characteristics of the material or coating.

Determine the heating distance and required uniformity.

Calculate necessary power density (W/cm²) to reach process specifications.

Verify that the wavelength spectrum matches the material’s absorption range.

Choose the reflector design (gold, ceramic, or aluminum) based on efficiency and heat focus.

Plan the lamp layout to minimize hot spots and shadows.

Specify electrical power control—on/off switching, dimming, or closed-loop temperature feedback.

Ensure ventilation and cooling for nearby components and enclosures.

Confirm safety compliance with industrial standards and provide shielding and interlocks.

Schedule routine cleaning of quartz tubes and reflectors.

Replace lamps at recommended intervals to avoid spectral degradation.

Keep spare parts stocked to minimize downtime.

Monitor lamp performance (output, discoloration, response time) for predictive maintenance.

Estimate operating cost per hour based on wattage and duty cycle.

Compare energy efficiency versus alternative heating technologies.

Include total cost of ownership (installation, power, maintenance, downtime) in ROI calculations.

Scenario:

A furniture factory needs to dry water-based lacquer on panels measuring 1.2 × 2.4 meters. The target surface temperature is 120 °C, with a total drying time under 90 seconds.

Specification Process:

Calculate energy demand: approximately 0.6–0.7 kWh per panel, including heat losses.

Choose twin-tube shortwave lamps with gold reflectors for optimal focus.

Arrange lamps in a modular array covering the conveyor width, ensuring even heat distribution.

Implement SCR-based control for variable power adjustment.

Validate through thermal profiling with infrared sensors to ensure ±5 °C uniformity.

Outcome:

Cycle time reduced by over 60%, energy consumption dropped by 30%, and product finish quality improved significantly.

Maintain an optimal distance-to-target ratio for maximum radiant efficiency.

Keep reflectors clean to prevent performance degradation.

Avoid overheating by using temperature sensors and power modulation.

Combine shortwave IR with medium-wave IR if deeper penetration is needed for thick or multilayer materials.

Implement interlocks and shields for operator safety.

Record performance data to guide maintenance and predict lamp life.

For manufacturers and integrators, adopting shortwave IR heating technology provides tangible operational benefits:

Improved productivity through shorter heating cycles.

Reduced energy consumption and lower operational costs.

Higher process quality due to uniform, controllable heating.

Smaller footprint and simplified installation versus convection systems.

Alignment with sustainability goals by reducing waste heat and energy use.

By selecting and integrating shortwave IR lamps correctly, businesses can enhance both performance and sustainability, creating long-term value in production environments.

Shortwave heat IR lamps represent one of the most efficient and responsive heating technologies available for industrial applications today. Their ability to deliver rapid, uniform, and energy-efficient heat makes them indispensable for processes such as paint curing, plastic forming, glass tempering, and coating drying.

The key to success lies in precise selection and system design—matching the lamp’s wavelength, power density, and geometry with material properties and process goals. When properly integrated, shortwave IR systems can significantly enhance throughput, quality, and operational efficiency.

Huai’an Yinfrared Heating Technology provides technical expertise and tailored design support for industrial users seeking reliable, high-performance IR heating solutions. Our engineering team assists in lamp selection, system integration, and performance optimization—helping your business achieve faster, cleaner, and more efficient heating outcomes.