Author: Site Editor Publish Time: 2025-08-12 Origin: Site

The smart choice: high-performance replacement heating tubes for Heraeus Noblelight America systems

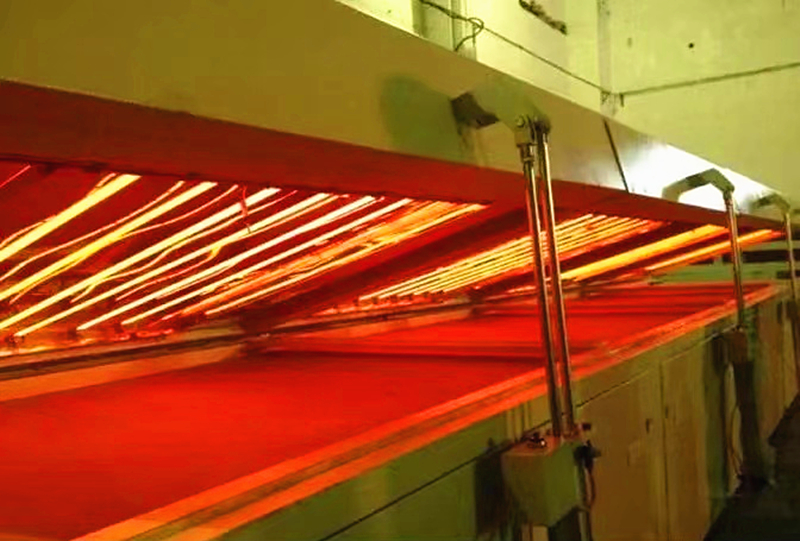

For decades, Heraeus Noblelight America has set the standard in industrial infrared heating technology. Their systems are suitable for multiple fields. These areas include aerospace composite fabrication and precision coating curing. These systems demonstrate advanced German engineering.

However, a significant challenge remains: long lead times and high pricing

An automotive coatings plant reported up to 12 weeks of downtime waiting to replace Noblelight components. This is unacceptable in today's just-in-time manufacturing environment.

100% compatible with Heraeus black.infraredhumm3 technology in your production line.

Infrared (IR) heating has revolutionized heat treatment by transitioning from inefficient ambient heating to precise electromagnetic energy transfer. Unlike traditional ovens that heat air, IR emitters transfer energy directly to the material through light waves, reducing energy waste by 35-50% and increasing process speed by 300% Consideration:

Material-specific efficiency: Medium-wave infrared (such as Heraeus' black.infrared) can evenly heat dark/light materials at a surface temperature of 1,000°C without "cooking" dark surfaces5

Material-specific efficiency: Medium-wave infrared (such as Heraeus' black.infrared) can evenly heat dark/light materials at a surface temperature of 1,000°C without "cooking" dark surfaces5

Process Flexibility: Shortwave IR tubes, like ruby quartz, can reach full output in just 1-2 seconds. This makes them great for quick thermal control.

Applications span composite AFP stackup, paint drying, plastic welding, and semiconductor processing – all requiring precise, repeatable thermal profiles. But when OEM tubes fail, most factories face a dilemma: pay a premium from Heraeus and wait weeks, or risk producing with mismatched generics.

Heraeus Noblelight's technology dominates the high-end industrial heating sector, and for good reason:

black.infrared system: Provides a power density of 200 kW/m² – three times faster than conventional infrared

HUMM3 Pulsed Xenon System: Laser Precise Heating of Aerospace Thermoplastic Composites at 1m/sec AFP Rate (50°C–600°C)

Specialty Quartz Tubes: Used in process chambers with SiO₂-bonded quartz walls for rapid thermal cycling

However, the operational reality is distressing:

A Heraeus 09755054 dual-tube IR lamp (230V/2000W) costs $500+ with a lead time of 8-12 weeks

Replacement of UV amalgam lamps, such as HUE034453T2, requires a proprietary external heating protocol

Electrodeless UV bulbs, such as Miltec's Heraeus Alternative #380-00001, highlight Heraeus' reliance on high-priced consumables

This creates a costly dependency – a $1,000 pipe stops a $10,000 per hour line.

At Yinfrared, we make heating tubes that directly replace those from Heraeus Noblelight America. Our tubes match their form, fit, and function. They also improve reliability and reduce costs. Our approach combines material innovation, spectral engineering, and lean US manufacturing:

Ruby Quartz Tubes: Engineered to block 99% of UV and harsh visible light while maximizing short-wave IR transmittance. Unlike standard Heraeus quartz, our ruby tubes emit a uniform rose glow—reducing eye strain in operator areas

Carbon-Enhanced IR Tubes: Our CF tubes use German-textured carbon fiber felt. They achieve 95% electrical-thermal efficiency. This is better than Heraeus’s metal-halogen options. Our tubes last 50% longer, with over 5,000 hours of use.

Fused Microcrystalline Glass Panels: Our flat-panel IR emitters provide 99% thermal conversion rates. They also save 35% more power compared to Heraeus’s traditional tubular heaters.

Every yInfrared replacement undergoes spectral irradiance mapping to mirror Heraeus outputs:

Mid-Wave (1.4–2.0 μm): Matches Heraeus’s fast-cycling tubes for paint drying or plastic forming

Short-Wave (0.8–1.4 μm): Ideal for high-penetration processes like composite prepreg curing

Custom Profiles: Need a drop-in replacement for Heraeus’s #558492 UV bulb? We replicate spectral peaks at 365nm/254nm

Thermal Responsiveness: Reach operating temps in 1–2 seconds (vs. 15–30 sec for low-end alternatives)—matching Heraeus’s rapid-start capability

Uniformity: ±5°C temperature variance across emitter surfaces—critical for semiconductor/curing applications

Vacuum/Tough Environment Rated: Works in temperatures from -60°C to 1,200°C. Perfect for aerospace AFP or PV film processing.

Problem: A Midwest auto supplier used Heraeus NIR tubes for curing polyurethane dashboards. Failures caused:

4-hour changeovers per tube

$1,820/tube cost + 10-week lead times

15% scrap from uneven heating after third-party tube swaps

yInfrared Solution:

Deployed ruby quartz tubes (matching Heraeus’s 09755054 specs)

Implemented water-cooled housings to extend tube life

Results:

63% cost reduction ($675/tube)

2-year lifespan (vs. Heraeus’s 14 months)

0 scrap—emitted IR profile matched Heraeus within 2% deviation

Cost Efficiency: Save 30-60% per tube with bulk discounts (e.g., 500+ units)

US-Based Speed: Receive replacements in 72 hours (not 12 weeks) from our Ohio plant

Performance Gains: Our ceramic-backing tech reduces thermal inertia—accelerating cycle times 8-15%

No Requalification Needed: Spectral certifications ensure identical output to Heraeus OEM parts

Technical Partnership: Get IR mapping, tube profiling, and retrofit support—not just transactional sales

While Heraeus pioneers systems like pulsed-xenon AFP heating, their core consumables remain stagnant. We’re advancing:

AI-Optimized Tubes: Embedded sensors predicting failure via resistance drift

Graphene-Enhanced Emitters: For 20% higher thermal conductivity than quartz

Sustainable Designs: 95% recyclable tubes with conflict-free minerals

Heraeus Noblelight built an empire on excellence—but their replacement tubes exploit captive audiences. yInfrared breaks this model: same performance, superior durability, American speed, and ethical pricing.

Act Now:

✅ Upload your Heraeus tube specs

✅ Get a spectral compatibility report in 24 hours

Stop overpaying. Start producing.

Heraeus Holding GmbH owns the registered trademark Heraeus Noblelight. yInfrared does not affiliate with Heraeus. We provide compatible replacements based on public technical specifications.