Author: Site Editor Publish Time: 2025-08-05 Origin: Site

In 2025, I find infrared drying systems offer significant advantages over conventional drying methods. I see faster drying time and improved energy efficiency because heat transfers directly to the material, not the air. This approach reduces both energy use and carbon footprint. Many industries now favor these drying methods for better product quality and less color or nutrient loss. While some applications still benefit from traditional methods, I recommend carefully matching drying methods to each product and process for the best results.

Infrared drying systems dry products faster and use energy more efficiently than conventional methods.

These systems preserve nutrients, color, and texture better, improving product quality and consumer appeal.

Infrared drying requires higher initial investment and skilled operation but offers long-term savings and lower maintenance.

Conventional drying methods are simpler, cheaper to start, and reliable for bulk or less sensitive products.

Uniform drying with infrared reduces waste and spoilage, while conventional methods may dry unevenly.

Safety is crucial; infrared systems need shielding and training to prevent burns and overheating risks.

Hybrid and AI-driven drying systems improve efficiency and quality, pointing to a smarter, sustainable future.

Choosing the right drying method depends on product type, quality needs, budget, and production scale.

I have seen infrared drying systems transform the way we approach drying in industrial settings. These systems use electromagnetic waves in the infrared range, typically between 0.7 and 6 microns, to transfer heat directly to the product. Unlike traditional methods that heat the surrounding air, infrared drying systems focus radiant energy straight onto the material. This direct heat transfer means I can achieve rapid and targeted heating, which is especially useful for delicate or heat-sensitive products.

Infrared heaters use elements like tungsten, quartz, or ceramic to generate infrared radiation. Reflectors then direct this energy toward the product, maximizing efficiency and minimizing heat loss. I appreciate that this method does not require physical contact, so it works well for moving or fragile items. The radiant energy travels as electromagnetic waves, allowing heat to reach the product even through air or a vacuum with minimal energy loss. This principle sets infrared drying systems apart from conduction or convection-based systems.

In my experience, infrared drying systems have become essential in several industries, especially for food drying. I often see these systems used in the food processing sector to dry fruits and vegetables such as apples, bananas, mushrooms, carrots, and ginseng. The table below summarizes some common applications and outcomes:

Industry | Products | Outcomes |

|---|---|---|

Food processing | Apple, quince, grapefruit, lemon, persimmon, banana, peach, mushroom, carrot, pumpkin, garlic, onion, ginseng | Up to 51.1% energy saving, shorter drying times, uniform heating, high-quality dried food |

Agro-industrial | Kiwi, chives, sweet potatoes, grapes, mangoes, potatoes, exotic fruits | Better preservation of sensory and nutritional qualities, improved rehydration ability |

I have noticed that food drying with infrared systems leads to significant energy saving and better product quality. These systems also find use in textiles, pharmaceuticals, and other sectors where precise and efficient drying is critical.

From my perspective, the advantages of infrared drying systems stand out clearly:

I achieve much faster drying times compared to conventional methods, sometimes reducing the process by up to 50%.

The direct radiant heat transfer results in high energy efficiency, often between 80% and 90%, which translates to lower operational costs.

I see uniform heating across the product, which helps maintain consistent quality and prevents over-drying or burning.

Food drying with infrared systems preserves the structure, color, and nutritional value of the food, which is crucial for consumer satisfaction.

These systems can combine with other methods, such as vacuum or hot air drying, to further enhance performance and product quality.

Tip: I always monitor the power and temperature settings closely. Excessive infrared power can cause overheating and degrade the quality of food products.

While I have seen many benefits from infrared drying systems, I also recognize several important limitations that anyone considering this technology should keep in mind.

High Initial Investment

I often find that the upfront cost of installing infrared drying systems can be much higher than traditional drying equipment. The specialized heaters, reflectors, and control systems require a significant financial commitment. For small businesses or operations with limited budgets, this initial expense can be a barrier.

Product Suitability

Not every product responds well to infrared drying. I have noticed that materials with uneven thickness or low surface absorption may not dry uniformly. Some products, especially those with complex shapes or dense structures, can experience surface overheating while the interior remains moist. This makes infrared drying systems less suitable for certain agricultural or industrial goods.

Technical Complexity

Operating and maintaining infrared drying systems demands a higher level of technical expertise. I must regularly calibrate sensors and monitor temperature settings to avoid damaging sensitive products. The need for precise control means that staff training becomes essential, which adds to operational costs and complexity.

Maintenance Requirements

Although infrared systems have fewer moving parts than some conventional dryers, I still need to perform regular maintenance. Dust or residue can build up on the heating elements and reflectors, reducing efficiency and potentially causing uneven drying. I schedule frequent inspections and cleaning to keep the system running at peak performance.

Safety Concerns

Infrared radiation, if not properly managed, can pose safety risks. I always ensure that shielding and safety protocols are in place to protect workers from accidental exposure. Overheating can also lead to fire hazards, especially when drying flammable materials. I follow strict guidelines and use automated shut-off systems to minimize these risks.

Note: I recommend conducting a thorough feasibility study before investing in infrared drying systems. Consider the specific properties of your product, available budget, and technical capabilities of your team.

Despite these challenges, I believe that with proper planning and management, many of these limitations can be addressed. I always weigh the pros and cons carefully to determine if infrared drying systems are the right fit for my drying needs.

When I work with conventional drying methods, I rely on a range of established drying techniques. These methods form the backbone of many industrial drying methods and traditional drying systems. I often refer to a table to clarify the main types and their characteristics:

Drying Method | Definition / Mechanism | Advantages | Disadvantages | Applications |

|---|---|---|---|---|

Convective Drying | Uses hot air to transfer moisture from the product to the air. | Simple, low cost, easy to operate. | Long drying time, risk of oxidation and off-flavors. | Fruits, vegetables, pomace. |

Spray Drying | Atomizes liquid feed into hot air, rapidly drying droplets into powder. | Fast, produces powders. | Not suitable for heat-sensitive materials. | Liquid foods, powders. |

Freeze-Drying | Freezes product, then sublimates ice under low pressure. | Preserves quality, minimal heat damage. | High cost, slow process. | High-value, heat-sensitive foods. |

Osmotic Dehydration | Removes water by diffusion using osmotic solutions. | Low energy, preserves quality. | Slow, possible solute uptake. | Pre-treatment for fruits, vegetables. |

Microwave Drying | Uses electromagnetic waves for volumetric heating and moisture removal. | Efficient, fast. | Risk of uneven heating, possible product damage. | Fruits, vegetables, herbs. |

Transfers energy directly to product surface using infrared radiation. | Quick, energy-saving. | Limited penetration, risk of surface overheating. | Often combined with other methods. | |

Radio Frequency Drying | Heats polar molecules inside product using alternating electric fields. | Uniform, faster than hot air. | Expensive, complex control. | Horticultural products. |

Refractance Window Drying | Transfers infrared energy through a plastic film over heated water. | Low temperature, short time. | Limited to liquid/semi-liquid products. | Mango, avocado, herbs. |

Explosion Puffing Drying | Rapid pressure drop creates porous structure by expanding water vapor inside product. | Saves time, creates porous texture. | Usually combined with other methods, complex equipment. | Intermediate drying, freeze-drying alternative. |

Low-Pressure Superheated Steam Drying | Uses superheated steam under reduced pressure, no oxygen present. | Lower temperature, prevents oxidation. | Needs vacuum system, higher cost. | Sensitive products needing oxygen-free drying. |

Combined Methods | Integrates multiple techniques to reduce drawbacks and improve results. | Improved rate and quality. | Requires process optimization. | Fruits, vegetables, herbs. |

I find that each of these drying methods offers unique benefits and challenges. I choose the right technique based on the product, desired quality, and available resources.

In my experience, conventional drying methods remain vital across many industries. I see these drying techniques used extensively in the food sector, especially for preserving fruits, vegetables, and meat products. For example, hot air drying and sun drying are common for plant-based foods and agricultural by-products like coffee peel. These methods help reduce water activity, which extends shelf life by slowing down enzyme activity and microbial growth.

I also notice that traditional drying systems play a crucial role in the meat industry. In regions without reliable cold storage, salting and drying preserve meat products such as kaddid. Although these methods can be energy-intensive and may affect sensory and nutritional properties, they remain essential in developing countries with hot and humid climates.

In the agricultural sector, I often use hot air drying for by-products, but I must accept some loss of bioactive compounds and antioxidant capacity. Freeze-drying and microwave drying offer better retention of quality, but they come with higher costs. Despite these trade-offs, conventional drying methods continue to provide a cost-effective solution for many applications.

I value conventional drying methods for their simplicity and reliability. These drying techniques have stood the test of time, and I trust them for their consistent results. Some of the main strengths I observe include:

Straightforward design and operation, which makes training and maintenance easier.

Lower initial investment compared to advanced systems, making them accessible for small and medium enterprises.

Established technology with a long history of successful use in various industries.

Flexibility to handle a wide range of products, from fruits and vegetables to meat and herbs.

Economic efficiency, especially with solar-assisted drying, which reduces energy costs and improves product consistency.

Note: I always recommend conventional drying methods for projects with limited budgets or where advanced quality retention is not the top priority. These methods provide a practical balance between cost and performance.

When I rely on conventional drying methods, I always consider their drawbacks before making a final decision. Over the years, I have noticed several limitations that can impact both the process and the final product. These limitations often influence my choice of drying methods, especially when product quality and efficiency matter most.

First, I find that drying methods like hot air or sun drying require much longer processing times. The slow removal of moisture can lead to production bottlenecks, especially when I need to handle large volumes. In my experience, this extended drying period increases the risk of microbial growth and spoilage, particularly in humid environments. I have seen batches of dried fruits or vegetables lose their value because the drying process took too long.

Another major limitation involves energy efficiency. Conventional drying methods often waste a significant amount of energy. Much of the heat escapes into the surrounding air instead of reaching the product. I have tracked energy bills that rise quickly when I use these methods for extended periods. This inefficiency not only raises operational costs but also increases the environmental footprint of my facility.

Product quality can also suffer with traditional drying methods. I have observed that high temperatures and prolonged exposure to air can degrade sensitive nutrients, colors, and flavors. For example, when I use hot air drying for herbs or fruits, I sometimes notice a loss of aroma and a dulling of natural colors. These changes can make the final product less appealing to consumers.

Uniformity presents another challenge. Conventional drying methods often fail to dry products evenly. I have seen cases where the outer layers become too dry while the interior remains moist. This inconsistency can lead to texture problems and even spoilage during storage. I must monitor the process closely and sometimes rotate or mix the product to achieve better results.

Maintenance and labor requirements also add to the limitations. Many traditional drying methods need frequent cleaning and manual intervention. I spend extra time checking equipment, adjusting settings, and ensuring that the drying process runs smoothly. This hands-on approach can increase labor costs and reduce overall productivity.

Note: I always recommend evaluating the specific needs of your product and operation before choosing conventional drying methods. While these methods offer reliability and lower initial costs, their limitations can affect efficiency and product quality in the long run.

When I compare drying methods, I always look at drying time first. Infrared drying systems stand out because they reduce drying time much more than conventional drying techniques. I have seen infrared systems cut drying time by up to 60% for products like linden and by about 39% for rose flower samples when operating at 70°C. Conventional drying methods, such as hot air or convection, also show some improvement at higher temperatures, but the reduction in drying time usually stays around 40%.

I often use a table to summarize these results for different drying techniques:

Drying Method | Temperature (°C) | Drying Time Reduction (%) | Notes |

|---|---|---|---|

Infrared (IR) | 70 | Up to 60% (linden) | Rapid moisture removal, less hard layer |

Conventional (CV) | 70 | Up to 55.5% (saffron petal) | Slower, more risk of uneven drying |

Refractance Window (RW) | 70 | Up to 52% (physalis) | Fastest, but less common in industry |

I notice that increasing the temperature from 50°C to 70°C helps all drying methods work faster. However, infrared drying systems consistently deliver shorter drying times than conventional options. This speed matters when I need to process large batches or handle products that spoil quickly.

Note: Faster drying time not only boosts productivity but also helps preserve sensitive nutrients and colors in food products.

I always pay close attention to efficiency when choosing between drying techniques. Infrared drying systems use radiant energy to heat products directly, which means less heat escapes into the air. This direct approach improves energy consumption rates compared to conventional drying methods, which often lose heat to the environment.

Based on my experience and recent studies, I see the following trends in energy consumption and efficiency:

Drying Method | Temperature (°C) | Energy Efficiency (Relative) | Energy Consumption | Notes |

|---|---|---|---|---|

Refractance Window (RW) | 70 | Highest | Lowest | Fast moisture removal, prevents hard layer formation |

Infrared (IR) | 70 | Intermediate | Lower than CV | Better than conventional, but not as efficient as RW |

Conventional (CV) | 70 | Lowest | Highest | Most energy lost to air, especially at lower temperatures |

I have found that infrared drying systems offer better efficiency than conventional drying methods, especially at higher temperatures. The energy consumption for infrared drying is lower because the system targets the product, not the surrounding air. Conventional drying methods, such as hot air drying, require more energy to heat the air and maintain temperature, which increases overall energy consumption.

Tip: I always recommend monitoring energy consumption closely. Even small improvements in efficiency can lead to significant cost savings over time.

Uniformity in drying makes a big difference in product quality. I have observed that infrared drying systems heat both the surface and the interior of materials at the same time. This approach reduces temperature gradients and leads to more uniform drying, even at lower temperatures. When I dry products like carmine radish slices, I notice that infrared drying preserves texture and hardness better than conventional methods. The moisture moves evenly through the product, which helps maintain natural color and prevents texture collapse.

In contrast, conventional drying methods rely on conduction or convection. These techniques often cause uneven heat distribution. I have seen products with dry surfaces but moist interiors, which can lead to spoilage or poor texture. This lack of uniformity also means longer drying times and more risk of losing flavor or color.

Infrared technology also improves uniformity in industrial applications beyond food. For example, when I use infrared rotary dryers in PET processing or electronics, I see fewer defects and more consistent product quality. The even heat distribution prevents clumping and blockages, which boosts reliability.

Uniform drying not only improves product quality but also reduces waste and reprocessing. I always aim for the most uniform results possible, especially for high-value or sensitive products.

When I evaluate drying methods, I always focus on how well each technique preserves nutrients. Infrared drying systems excel at retaining sensitive vitamins and antioxidants. I have observed that faster drying times and lower exposure to high temperatures help protect compounds like vitamin C and β-carotene. For example, when I use infrared drying, I see higher retention of β-carotene compared to conventional oven drying, which often results in only about 23.61% retention. Oven drying exposes products to prolonged heat, causing significant losses in both vitamin C and β-carotene.

Freeze-drying stands out for nutrient preservation. I notice that it operates at low temperatures, which minimizes thermal degradation. However, the process takes longer and costs more. In my experience, microwave and infrared drying methods strike a balance between speed and nutrient retention, making them suitable for products where both yield and quality matter.

I always recommend close monitoring of drying parameters to optimize nutrient retention and maximize yield.

Texture and color play a crucial role in consumer acceptance and product value. I have seen that conventional oven drying often leads to undesirable changes. High temperatures and long drying times cause color fading and texture loss. For instance, oven drying reduces water holding capacity, swelling capacity, and solubility. The result is a product that feels dry and brittle, with a dull appearance.

Infrared drying, on the other hand, provides more uniform heating. I find that this method preserves the natural color and texture of fruits and vegetables much better. The shorter drying time reduces the risk of color deterioration and texture collapse. When I use infrared drying for heat-sensitive products, I consistently achieve a higher yield of visually appealing and texturally pleasing products.

Oven drying:

Causes significant color loss and texture changes.

Reduces functional properties such as water holding and swelling capacity.

Infrared drying:

Retains more vibrant color and natural texture.

Produces a higher yield of quality products in less time.

Freeze-drying:

Best preserves color and texture but at a higher cost and longer processing time.

For products where appearance and mouthfeel drive market success, I always prioritize drying methods that deliver superior quality and yield.

Bioactive compounds, such as phenolics and flavonoids, contribute to both nutritional value and health benefits. I have found that the choice of drying method directly impacts the retention of these compounds. Freeze-drying preserves the highest levels of total phenolics because it avoids high temperatures and oxygen exposure. In contrast, convection oven drying activates enzymes that degrade polyphenols, leading to lower retention.

I use the following table to summarize how different drying methods affect bioactive compound retention and yield:

Drying Method | Retention of Bioactive Compounds | Impact on Yield and Quality |

|---|---|---|

Freeze-Drying | Highest | Best for sensitive compounds, high quality |

Infrared Drying | High | Good retention, efficient yield, better quality |

Oven Drying | Moderate to Low | Greater losses, lower yield, reduced quality |

Spray Drying | Moderate | Short contact time helps retain some bioactives |

I always emphasize the importance of real-time quality control and monitoring during the drying process. By tracking temperature and humidity, I can adjust conditions to protect bioactive compounds and maximize both yield and quality.

Careful monitoring ensures that I deliver products with optimal nutritional value and market appeal.

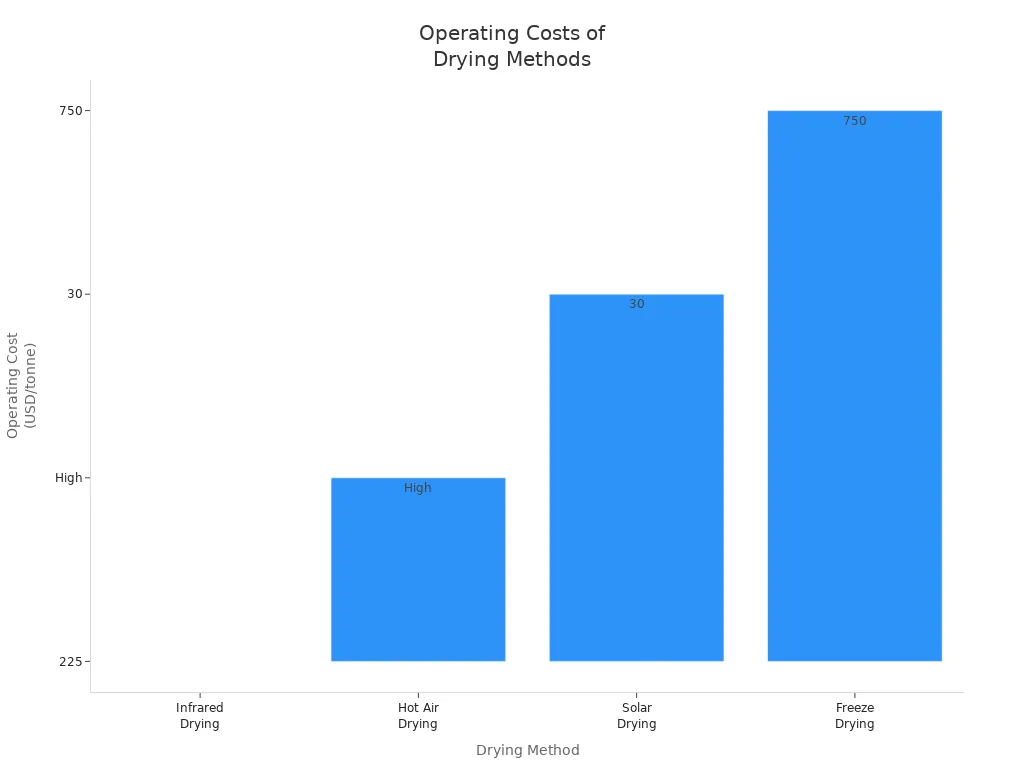

When I evaluate drying systems, I always start by comparing the costs. Infrared drying systems require a higher initial investment than most conventional methods. This upfront cost includes not only the equipment but also integration, staff training, and ongoing technical support. For small businesses, this can be a significant hurdle. However, I have found that the operating cost per tonne is moderate, usually between $150 and $300, thanks to faster drying and improved energy efficiency. In contrast, hot air drying systems cost less to install but have higher operating costs due to greater energy consumption and longer drying times. Solar drying offers low operating costs but depends on weather conditions, while freeze drying is the most expensive in both setup and operation.

Here’s a table that summarizes these cost differences:

Drying Method | Initial Investment Cost | Operating Cost (USD/tonne) | Key Notes on Costs and Operation |

|---|---|---|---|

Infrared Drying | High (equipment, integration, training, maintenance) | Moderate (approx. 150–300) | Faster drying, higher energy efficiency, skilled operators needed |

Hot Air Drying | Lower initial equipment cost | Higher (due to high energy consumption) | Longer drying times, uneven heating |

Solar Drying | Medium to High (system sophistication) | Low (approx. 10–50) | Weather-dependent, eco-friendly |

Freeze Drying | Very High | Very High (approx. 500–1000) | Long processing time, high energy use |

Tip: I always consider long-term savings from lower energy consumption and faster throughput when justifying the higher upfront cost of infrared systems.

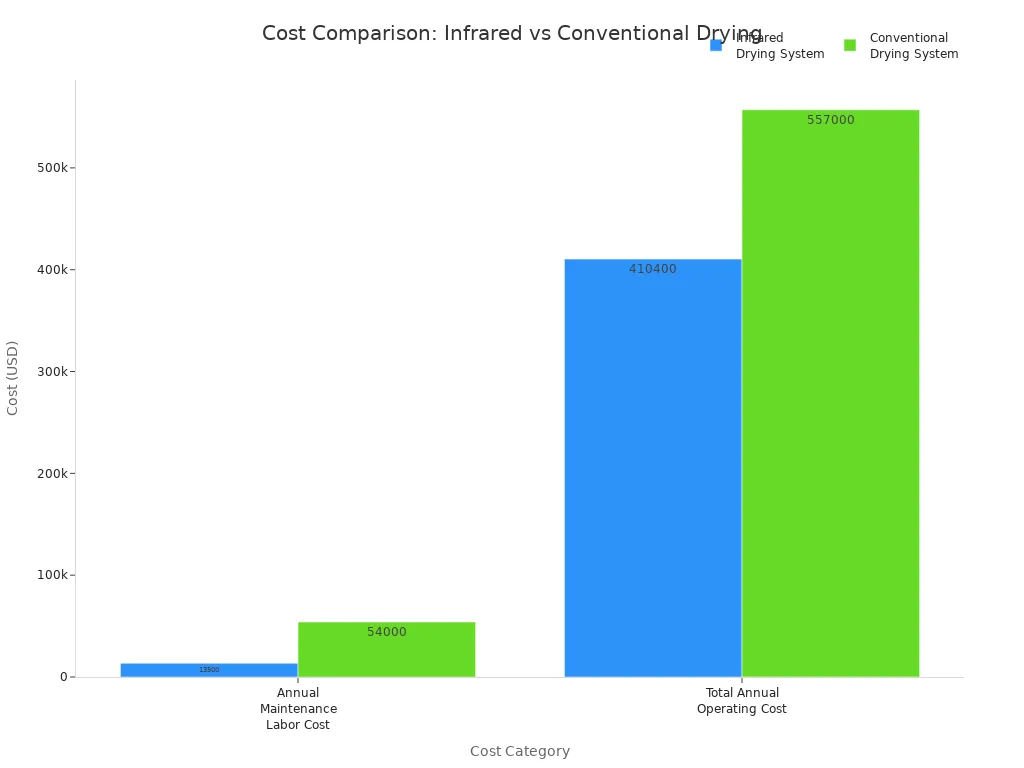

Maintenance plays a big role in my decision-making process. Infrared drying systems need less maintenance than conventional dryers. I usually only perform routine cleaning, check connections, and replace worn parts. This simplicity reduces downtime and keeps repair costs low. Infrared heaters last over 20 years, which is longer than the 10–15 years I see with traditional systems. In my experience, annual maintenance labor costs for infrared systems are much lower—about $13,500 compared to $54,000 for conventional dryers. This difference adds up over time and makes infrared systems a reliable choice for demanding environments.

Aspect | Infrared Drying System | Conventional Drying System |

|---|---|---|

Annual Maintenance Labor Cost | Significantly lower (~$13,500) | Much higher (~$54,000) |

Maintenance Requirements | Minimal (routine cleaning, checks) | Higher labor and associated costs |

System Lifespan | Longer | Shorter |

Total Annual Operating Cost | Lower (~$410,400) | Higher (~$557,000) |

Note: I always schedule regular inspections to maximize system lifespan and minimize unexpected repairs.

Scalability matters when I plan for growth or handle large product volumes. Infrared drying systems scale well for industrial use, especially with tray or conveyor belt setups. I have seen near-infrared drying reduce processing time by over three times compared to conventional oven drying at 140°C. This speed, combined with direct and uniform heating, lowers energy consumption and boosts throughput. However, scaling up brings challenges. Uniform irradiation and efficient energy use across large batches require careful engineering. I always look for validated drying models and pilot studies before committing to full-scale implementation. Despite these challenges, the cost–benefit ratio remains favorable for infrared systems due to lower energy consumption and faster processing.

I recommend further research and pilot testing to optimize large-scale operations and ensure consistent results.

When I evaluate drying systems, I always put safety at the top of my checklist. Both infrared and conventional drying methods come with unique safety considerations. I have learned that understanding these risks helps me protect my team, my facility, and my products.

Infrared Drying Systems: Key Safety Points

Infrared drying systems use radiant energy, which means I must manage both heat and electromagnetic radiation. I always install proper shielding around infrared heaters. This prevents accidental exposure to high-intensity infrared rays, which can cause burns or eye injuries. I also make sure that all operators receive training on safe distances and correct procedures.

Fire risk is another concern. Infrared systems reach high temperatures quickly. If I dry flammable materials or allow dust to accumulate, the risk of ignition increases. I always keep the area clean and use automatic shut-off features. These systems detect overheating and stop the process before a fire can start.

Electrical safety matters, too. Infrared dryers require high-voltage connections. I schedule regular inspections for wiring and control panels. I also ground all equipment to prevent electrical shocks.

Conventional Drying Methods: Key Safety Points

Conventional dryers, such as hot air or convection systems, present different hazards. I often deal with hot surfaces and moving parts. Burns and mechanical injuries can happen if someone ignores safety guards or wears loose clothing. I always enforce strict safety protocols and provide personal protective equipment (PPE).

Some conventional dryers use open flames or gas burners. This introduces risks of gas leaks and carbon monoxide buildup. I install gas detectors and ensure proper ventilation. I also train staff to recognize warning signs and respond quickly.

Dust explosions can occur in both systems, but I find them more common in conventional dryers that handle powders or fine particles. I use dust extraction systems and avoid letting dust build up inside the dryer or ductwork.

Safety Comparison Table

Safety Aspect | Infrared Drying Systems | Conventional Drying Methods |

|---|---|---|

Radiation Exposure | Requires shielding and training | Not applicable |

Fire Hazard | High (if overheating) | Moderate (depends on heat source) |

Electrical Safety | High voltage, needs inspection | Varies (often lower voltage) |

Mechanical Hazards | Minimal | Higher (moving parts, hot surfaces) |

Gas/CO Risk | None (electric) | Possible (if gas-fired) |

Dust Explosion Risk | Present (if dusty) | Present (often higher) |

Tip: I always review local safety regulations and industry standards before installing or operating any drying system. Compliance not only protects my team but also avoids costly fines and shutdowns.

In my experience, both systems can operate safely with the right precautions. I never skip safety training or routine inspections. I also document all incidents and near-misses to improve my protocols. By staying proactive, I create a safer workplace and ensure reliable production.

When I evaluate infrared drying systems, I see several clear advantages and a few important drawbacks. Here is how I summarize my experience:

I achieve faster and more even drying, which helps preserve product quality.

The direct heat transfer reduces energy use and operational costs over time.

I notice less heat damage, so nutrients, color, and texture remain intact.

These systems offer adjustable settings, which allow me to tailor the process for different products.

I find maintenance requirements are lower, and the equipment lasts longer.

However, I must consider the higher initial investment and the need for skilled operators.

Some products may not respond well to infrared drying, especially if they have uneven thickness.

I always monitor for potential safety concerns, such as overheating or electromagnetic exposure, though I have not encountered documented harmful effects.

I recommend infrared drying systems for operations that prioritize efficiency, product quality, and long-term savings.

Conventional drying methods remain a staple in many industries. I rely on these methods for their reliability and simplicity, but I also recognize their limitations:

I appreciate the mature technology and widespread acceptance in the industry.

These methods are easy to operate and scale, making them suitable for a variety of products.

I use them to effectively remove moisture and control microbes, which extends shelf life.

The initial investment is usually lower, which helps when budgets are tight.

On the downside, I see higher energy consumption and increased operational costs.

I often deal with longer drying times and uneven results, which can affect product quality.

Heat exposure sometimes leads to nutrient loss, texture changes, and flavor degradation.

Environmental concerns, such as a larger carbon footprint, are becoming more important in my decision-making.

I suggest conventional drying methods for projects where cost and simplicity outweigh the need for advanced quality retention.

To help you compare both options at a glance, I created this table:

Feature/Aspect | Infrared Drying Systems | Conventional Drying Methods |

|---|---|---|

Drying Speed | Much faster, more uniform | Slower, often uneven |

Energy Efficiency | High, less heat loss | Lower, more energy wasted |

Product Quality | Better retention of nutrients, color, texture | More risk of quality loss |

Initial Investment | Higher | Lower |

Operating Cost | Lower over time | Higher due to energy use |

Maintenance | Minimal, longer lifespan | More frequent, higher costs |

Scalability | Good, but requires careful design | Excellent, well-established |

Safety | Needs shielding, training | Standard precautions |

Environmental Impact | Lower carbon footprint | Higher carbon footprint |

Suitability | Best for sensitive, high-value products | Good for bulk, less sensitive items |

I always match the drying methods to the specific needs of my product and operation. The right choice depends on your priorities—speed, quality, cost, or simplicity.

I have seen firsthand how infrared drying systems have transformed food drying in commercial settings. In my work with grain processing, I noticed that infrared heating delivers higher heat fluxes than conventional methods. This results in rapid temperature increases and much shorter thermal processing times. Over the past twenty years, researchers have improved emitter designs and deepened our understanding of how infrared interacts with food components. These advances have made food drying more energy efficient and have helped preserve product quality. For example, I have used infrared drying in combination with hot-air drying to process fruits and vegetables. This approach consistently produces better texture and color while reducing drying time. I rely on real-time monitoring to ensure that every batch meets strict quality standards. The food industry now recognizes the versatility and commercial potential of these systems.

Outside the food sector, I have applied infrared drying to textiles, pharmaceuticals, and even electronics. In textile manufacturing, I use infrared systems to dry fabrics quickly and evenly, which prevents shrinkage and color fading. Pharmaceutical companies benefit from precise temperature control, which protects sensitive compounds during drying. I have also seen infrared drying used in the production of electronic components, where uniform moisture removal is critical. In each case, I depend on continuous monitoring to maintain product integrity and safety. Conventional drying methods still play a role in these industries, especially when budgets are tight or when processing less sensitive materials. However, I find that the demand for higher efficiency and better quality often pushes companies toward infrared and smart drying solutions.

Recently, I have worked with hybrid drying systems that combine infrared with hot air, solar, or biomass energy. These systems deliver significant improvements in drying efficiency and energy use. For instance, I tested a hybrid infrared-hot air dryer on garlic slices. By increasing air temperature and infrared intensity, I reduced drying time to a minimum. I also integrated AI and machine learning models, such as artificial neural networks, to predict drying time, energy consumption, and thermal efficiency. This allowed me to optimize the process in real time. AI now plays a central role in smart drying by enabling real-time monitoring, predictive control, and intelligent energy management. I use AI to dynamically adjust parameters based on product type, drying stage, and even weather conditions. These advances have made food drying more sustainable and climate-resilient. I have also seen hybrid solar-wind drying systems enhanced with AI tools, which enable adaptive control and predictive maintenance. Although challenges remain, such as data standardization and sensor costs, I believe that ongoing research in edge AI and IoT will further improve smart drying solutions. My experience shows that combining hybrid systems with AI leads to better product quality, lower energy consumption, and more reliable operations.

Tip: I always recommend investing in real-time monitoring and AI-driven optimization for any large-scale food drying operation. These tools help maintain consistent quality and reduce costs over time.

When I help companies select drying methods, I always start by looking at their industry requirements. Food processors often need to preserve nutrients and color, so I recommend modern drying methods like infrared or hybrid systems. Textile manufacturers value speed and uniformity, which makes infrared and radio frequency dryers a strong choice. Pharmaceutical companies require precise temperature control and gentle handling, so I suggest vacuum or freeze-drying. For bulk agricultural products, I find that conventional drying methods still offer a cost-effective solution, especially when budgets are tight. I always match the drying method to the scale of production, energy costs, and the need for automation or integration with ai-driven controls.

Every product has unique characteristics that influence which drying methods work best. I use the following checklist to guide my decisions:

Moisture content

Heat sensitivity

Oxidation susceptibility

Bioactive compound preservation

Color retention

Structural integrity

For products sensitive to heat or oxidation, I choose vacuum or microwave vacuum drying. These modern drying methods operate at lower temperatures and protect both appearance and quality. When I work with high-moisture foods, I often use far infrared drying because it heats the surface efficiently. If I need to preserve active ingredients, I rely on rotary microwave vacuum drying, which improves uniformity and avoids local overheating. Hot air drying remains popular for its simplicity, but I see it degrade color and bioactive compounds more than other options. I always consider the product’s structure and desired shelf life before making a final recommendation.

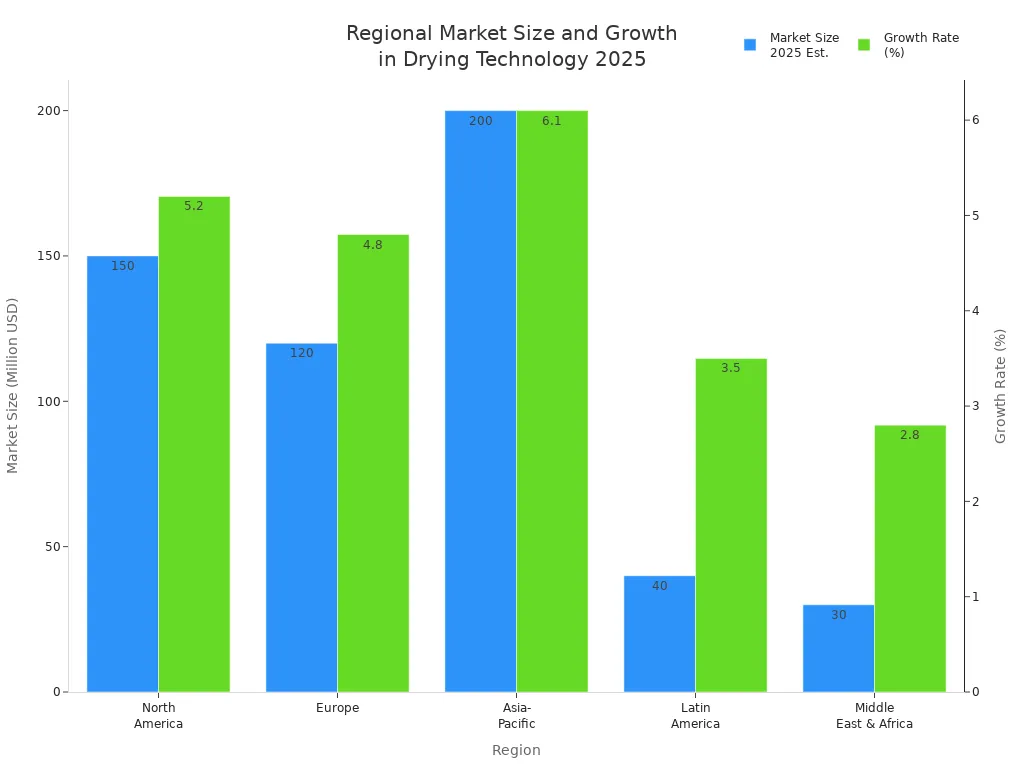

I see the future of drying methods moving toward greater efficiency, sustainability, and intelligence. Smart drying is becoming the norm, with real-time monitoring and predictive maintenance powered by ai. These innovations can cut energy use by up to 50%. I also notice that advanced materials, like nanotechnology coatings, are making modern drying methods more durable and energy efficient. Regulatory changes in Europe and new export controls are pushing manufacturers to adopt eco-friendly solutions. The market for industrial dryers and dehumidifiers continues to grow, especially in food, pharmaceutical, and electronics sectors.

Region | Market Size (2025 Est.) | Growth Rate (%) | Key Applications | Innovative Features |

|---|---|---|---|---|

North America | $150 Million | 5.2% | Textile, Food Processing | Energy Efficiency, Automation |

Europe | $120 Million | 4.8% | Pharmaceutical, Chemical | Compact Design, Sustainability |

Asia-Pacific | $200 Million | 6.1% | Electronics, Dairy | IoT Integration, High Throughput |

Latin America | $40 Million | 3.5% | Agriculture, Mining | Low Maintenance, Modular Systems |

Middle East & Africa | $30 Million | 2.8% | Energy, Petrochemical | Advanced Control Systems, Durability |

I expect modern drying methods to keep evolving, with ai and emerging smart drying techniques setting new standards for operational excellence. I always encourage companies to invest in flexible, scalable systems that can adapt to future market and regulatory demands.

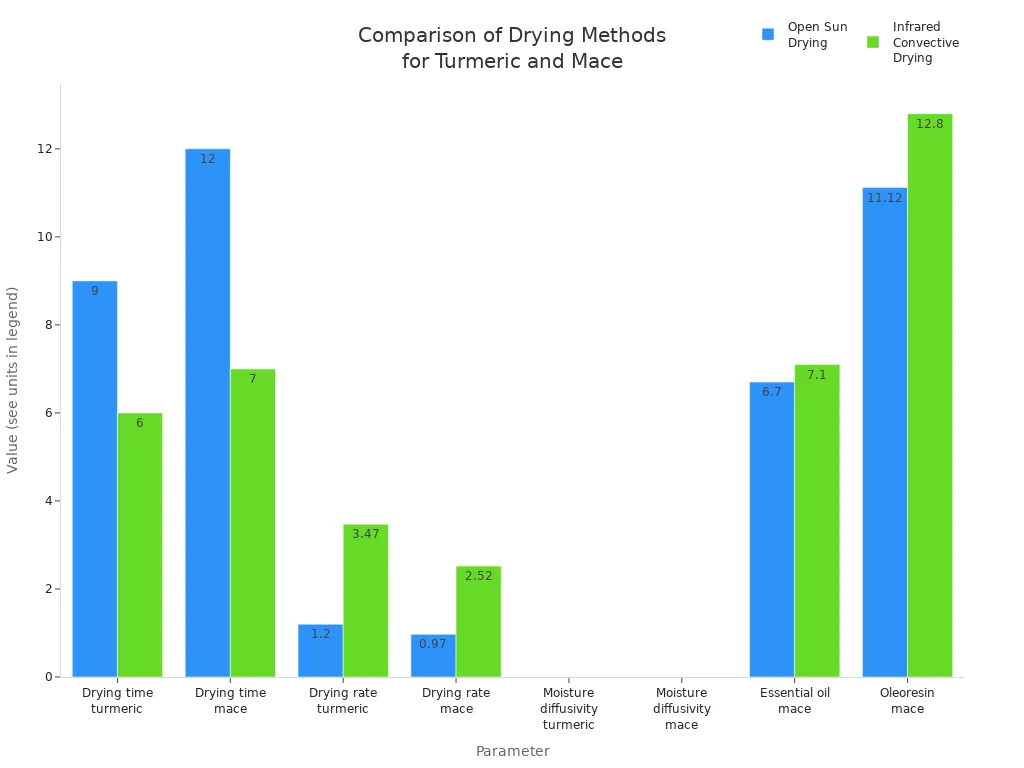

I see that infrared drying systems deliver faster drying, higher rates, and better moisture removal than conventional methods. The chart below shows how infrared convective drying outperforms open sun drying for turmeric and mace:

When I help clients choose a drying method, I recommend the following:

Match oven type to your product’s shape and heat needs.

Use infrared for fast, targeted drying; choose convection for uniform results with irregular shapes.

Always check temperature requirements and production scale.

Consult specialists and ensure compliance with safety standards.

I always advise reviewing your product’s unique needs and future goals before making a final decision. Emerging smart and hybrid systems will keep changing the landscape, so stay informed and flexible.

I see the best results with heat-sensitive foods, pharmaceuticals, and textiles. Infrared drying preserves nutrients, color, and texture. I recommend it for fruits, vegetables, herbs, and specialty chemicals that require gentle, uniform drying.

I always assess product type, desired quality, budget, and production scale. Infrared works well for high-value, sensitive items. Conventional methods suit bulk, less sensitive products. I suggest consulting with a drying specialist for complex decisions.

Yes, I find them safe when I follow proper protocols. I install shielding, train staff, and use automatic shut-offs. Regular inspections help prevent overheating and electrical hazards. I always prioritize safety in every installation.

In many cases, I can retrofit infrared modules onto existing conveyor or tray dryers. I evaluate compatibility, space, and power requirements first. I recommend consulting equipment suppliers for a feasibility assessment.

I perform routine cleaning, check electrical connections, and replace worn parts as needed. Infrared heaters last longer than conventional elements. I schedule regular inspections to ensure peak performance and safety.

I notice that infrared drying often preserves natural flavors and aromas better than hot air drying. The shorter drying time and lower temperatures help maintain sensory qualities. I recommend monitoring temperature closely for optimal results.

Infrared systems use less energy because they heat the product directly. I see lower utility bills and reduced carbon footprint. Conventional dryers waste more energy heating the air, which increases operating costs.

I recognize higher upfront costs, technical complexity, and product suitability as key limitations. Not all products dry evenly with infrared. I always conduct pilot tests before full-scale adoption.

Tip: I recommend starting with a small-scale trial to evaluate performance and suitability for your specific product.