Views: 0 Author: Site Editor Publish Time: 2025-07-17 Origin: Site

I see infrared lamps for heating as a modern solution that uses radiant energy to deliver heat directly to objects and surfaces. These systems provide impressive energy efficiency, with up to 96% energy conversion, and help lower fuel costs by 20% to 50% compared to traditional warm air systems. I often recommend them for their ability to improve comfort and air quality, thanks to targeted heating and minimal air movement.

The global market for these lamps continues to expand, driven by demand for energy-efficient and reliable heating in many industries.

Attribute | Value |

|---|---|

Market Size (2024) | |

Projected Market Size | |

CAGR | 6.3% – 8.9% |

Key Applications | Industrial, Medical, Food, Household |

Huai’an Infrared Heating Technology stands out in this field. With expertise in quartz IR emitters and advanced industrial solutions, I trust their products for durability, precision, and versatile heating performance.

Infrared lamps heat objects directly by emitting radiant energy, making them highly energy efficient and cost-saving.

These lamps warm surfaces and people quickly without heating the air, providing instant and targeted comfort.

Different types of infrared lamps suit various needs, from fast industrial heating to gentle comfort warming.

Infrared heating reduces energy waste by focusing heat where it is needed, lowering fuel and electricity costs.

Proper installation and maintenance are essential to ensure safety, durability, and optimal performance.

Infrared lamps are versatile, used in industries, homes, medical therapy, and outdoor spaces for effective heating.

Safety certifications and following guidelines help prevent risks from infrared radiation and electrical hazards.

Choosing the right lamp type and wattage depends on the space, application, and environmental conditions.

When I look at the science behind infrared lamps for heating, I see a fascinating process rooted in physics. These lamps generate heat by passing electricity through a tungsten filament or a special electric element inside a quartz or halogen tube. As the filament heats up, it emits energy in the form of infrared radiation. This radiation falls within the electromagnetic spectrum, specifically in the wavelength range of about 0.78 to 1000 micrometers. The exact wavelength depends on the temperature of the filament. Higher temperatures produce shorter wavelengths and more intense radiation.

Explanation | |

|---|---|

Infrared Radiation Origin | Emitted by hot objects; wavelength and energy depend on temperature (Planck's Law). |

Temperature Effect | Higher temperature → shorter wavelength, higher energy, more intense radiation. |

Emission Spectrum | Objects at room temperature emit longer wavelengths; as temperature rises, visible light appears (red to white glow). |

Inverse Square Law | Intensity of radiation decreases with the square of the distance from the source. |

Lambert’s Cosine Law | Intensity depends on the angle of incidence; applies to small sources over distance. |

Types of Emitters | Ceramic (longwave, 3-10 μm), Quartz cassette (medium wave), Quartz tungsten and halogen (short wave). |

Planck’s Law | Describes energy distribution and peak wavelength shift with temperature increase. |

Heat Generation Mechanism | Infrared radiation absorbed by materials causes molecular vibrations, generating heat. |

I find it remarkable that when this infrared radiation strikes a surface, the energy gets absorbed and causes the molecules in the material to vibrate. This vibration generates heat directly within the object or surface, rather than heating the air around it. That is why infrared lamps for heating deliver such efficient and targeted warmth.

I often explain to clients that infrared heating works differently from traditional methods like conduction or convection. Infrared energy travels as electromagnetic waves, so it does not need a medium like air or water to transfer heat. When these waves reach an object, they penetrate a few millimeters below the surface, especially if the material contains water molecules. This direct absorption causes the molecules to vibrate, producing heat from within.

Infrared heating transfers energy through electromagnetic radiation, not requiring a medium.

The radiation penetrates the surface, causing molecular vibrations and internal heating.

Conduction and convection heat the surface first, then transfer heat inward by particle collisions or fluid movement.

Infrared heating provides rapid warmth, high energy efficiency, and minimal heating of the surrounding air.

The depth and efficiency of heating depend on the wavelength, material thickness, and composition.

I notice that this process allows for much faster and more precise heating. Infrared lamps for heating can warm up objects and people directly, without wasting energy on heating the air. This makes them ideal for environments where quick, focused heat is necessary.

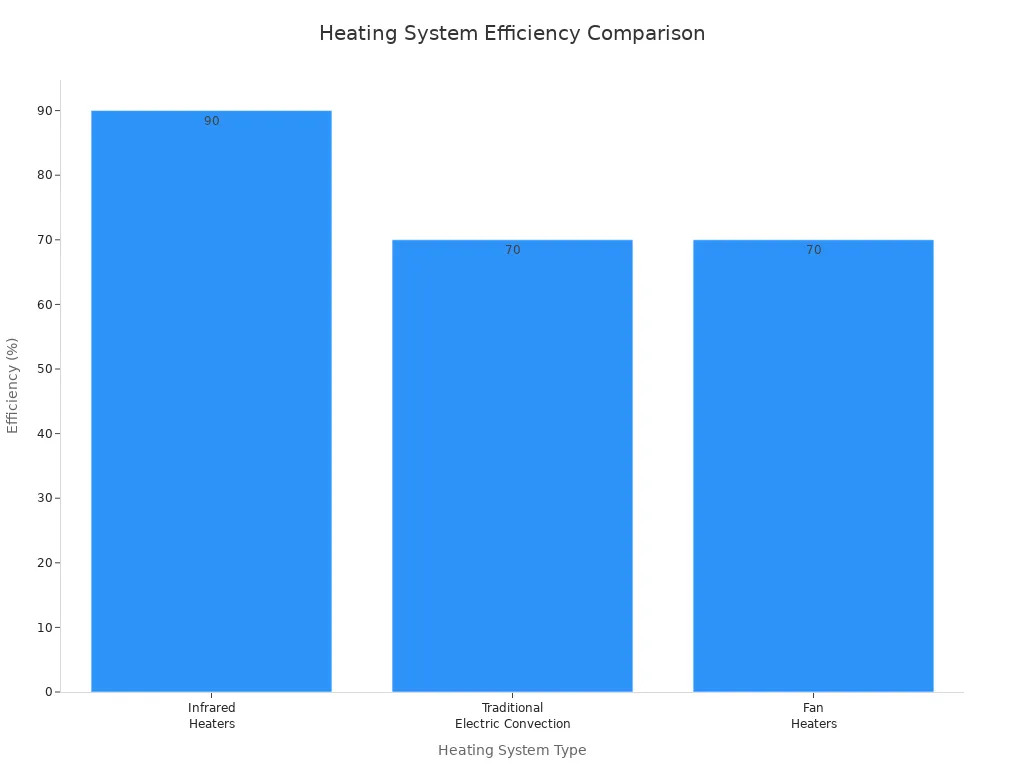

When I compare infrared heating to conventional systems, the differences become clear. Traditional heaters, such as electric convection units or fan heaters, work by warming the air. This heated air then circulates around the room, gradually raising the temperature. However, much of this heat can escape through ventilation or drafts, leading to energy loss and uneven warmth.

Infrared heaters, on the other hand, convert over 90% of their electrical energy into radiant heat. They deliver warmth directly to objects, surfaces, and people, which means less energy is wasted. I have seen that this direct approach results in faster comfort and better heat retention, especially in spaces with poor insulation or high ceilings.

Heating System Type | Heat Transfer Method | Efficiency (%) | Energy Consumption Characteristics | Heat Delivery Characteristics |

|---|---|---|---|---|

Radiant Heat | >90% | Lower energy consumption due to direct heating of objects; zone heating possible; reduced heat loss from air circulation | Heats objects and surfaces directly, stores heat in room elements, provides faster and more comfortable warmth | |

Traditional Electric Convection Heaters | Convection Heat | ~70% or less | Higher energy consumption due to heating air; heat loss through ventilation and air circulation; no heat storage in objects | Heats air which circulates and loses heat quickly; slower to warm room; less effective heat retention |

Fan Heaters (Convection with fan) | Convection Heat | <70% (due to fan energy use) | Additional energy used to power fan; heat loss due to air heating; short heating range | Heats air locally; heat dissipates quickly; no heat storage in objects |

For example, a 2.5 kW infrared heater with 90% efficiency delivers 2.25 kW of radiant heat, while a 3.0 kW traditional heater at 70% efficiency only provides 2.1 kW. This means I can achieve better heating performance with less energy input. I also appreciate the ability to use zone heating, which lets me target specific areas and further reduce energy consumption.

In my experience, infrared lamps for heating offer a smarter, more efficient way to deliver warmth exactly where it is needed, making them a superior choice for many applications.

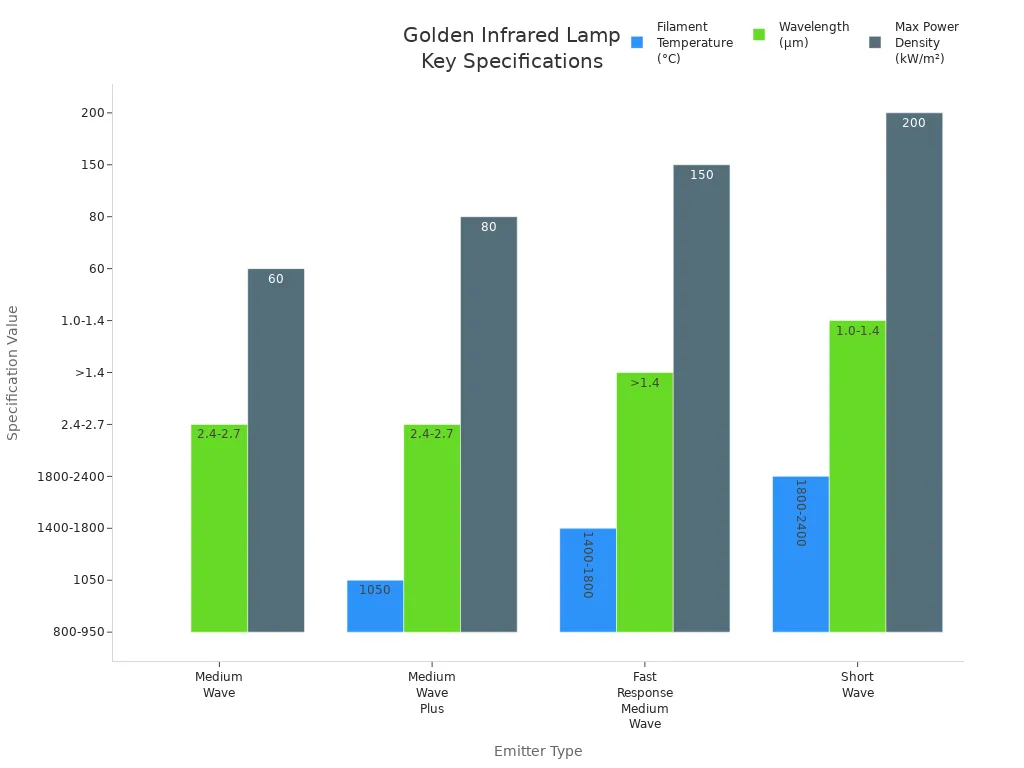

When I evaluate golden infrared lamps, I see them as a premium choice for many industrial and commercial heating applications. These lamps use a special gold coating on the quartz tube, which acts as a reflector to maximize radiant output and direct heat precisely where it is needed. The gold reflector not only increases efficiency but also reduces glare, making these lamps suitable for environments where visual comfort matters.

I often recommend golden infrared lamps for processes that demand rapid, uniform heating. Their fast response time—sometimes as quick as one second—means I can achieve instant heat without waiting for a warm-up period. The unique twin-tube design enhances mechanical stability and allows for high radiation capacity, which is essential in demanding production lines.

Here’s a quick overview of their technical specifications:

Specification Category | Medium Wave | Medium Wave Plus | Fast Response Medium Wave | Short Wave |

|---|---|---|---|---|

Power (W/cm) | 18 / 20 / 25 | 35 to 50 | 80 | <200 |

Heated Length (mm) | 1500/2000/6500 | 1000* | 2400-6400 | 2400-6400 |

Filament Temp (°C) | 800-950 | 1050 | 1400-1800 | 1800-2400 |

Wavelength (µm) | 2.4-2.7 | 2.4–2.7 | >1.4 | 1.0-1.4 |

Max Power Density (kW/m²) | 60 | 80 | 150 | 200 |

Response Time (s) | 60-240 | 60–240 | 1-2 | 1 |

*Potential expansion possible, contact for details.

I have seen golden infrared lamps excel in applications such as curing inks and coatings, welding plastics, preheating metals, and even food processing. The ability to customize wavelength, size, and filament type means I can tailor these lamps to very specific requirements. The gold reflector ensures that nearly all the generated energy is directed toward the target, which boosts efficiency and reduces energy costs.

Tip: I always consider golden infrared lamps when I need high-intensity, focused heat with minimal energy loss and glare.

Fast Medium Wave (FMW) infrared lamps stand out for their rapid response and precise temperature control. I often choose these lamps for processes that require fast surface heating and accurate thermal management. The wavelength range of 1.4 to 2.0 micrometers allows these lamps to deliver energy efficiently to thin layers and surfaces, making them ideal for drying inks, coatings, and adhesives.

What impresses me most is their ability to reach operating temperatures between 1200°C and 1800°C within just a couple of seconds. This quick response time means I can start and stop heating cycles almost instantly, which is crucial for high-speed production lines. FMW lamps also offer up to 50% energy savings compared to traditional heating methods, thanks to their direct radiation approach.

Here’s how FMW lamps compare to other types:

Attribute | Fast Medium Wave (FMW) Infrared Lamps | Short Wave Infrared Lamps | Carbon/Medium Wave Infrared Lamps |

|---|---|---|---|

Wavelength Range | 1.4 - 2.0 μm | 0.9 - 1.4 μm | 2.0 - 4.0 μm |

Response Time | 1 - 2 seconds | 1 - 2 seconds | Slower |

Heating Filament Temp | 1200 - 1800 ℃ | High | Lower |

Typical Heating Temp | 50 - 500 ℃ | Deeper penetration | Deeper, slower heating |

Efficiency | Up to 50% energy savings | Similar | Less efficient |

Application Suitability | Fast surface/thin layer heating | Fast response, deep heat | Slower, more penetration |

I have used FMW lamps in industries like glass cutting, digital printing, and paint drying. Their compact size and flexible installation options make them easy to integrate into existing systems. The YINFRARED FMW lamps from Huai’an Infrared Heating Technology, for example, provide high precision and durability, with a lifespan reaching up to 10,000 hours. I find these lamps particularly effective when I need to minimize edge defects and energy consumption in glass processing.

Medium wave infrared lamps offer a balance between deep penetration and surface heating. I rely on these lamps for applications that involve moisture-rich materials or require gentle, even heating. The wavelength range of 2.0 to 4.0 micrometers matches the absorption characteristics of water and many organic materials, making these lamps perfect for drying water-based coatings, heating plastic films, and processing glass.

Medium wave lamps emit a bright orange glow and operate at lower filament temperatures than short wave or FMW lamps. This results in a slightly slower heat-up time, but it also extends the lamp’s lifespan and provides consistent, reliable performance. I appreciate their mechanical ruggedness and high moisture resistance, which are essential for demanding industrial environments.

Some key performance characteristics include:

Performance Characteristic | Medium Wave Quartz Tubes | Flat Panel Emitters (F-Series) | Flat Panel Emitters (V-Series) |

|---|---|---|---|

Heat-up/Cool-down Time | Medium | Not specified | Fast (low mass elements) |

Moisture Resistance | High | Not specified | Not specified |

Mechanical Ruggedness | Good | Durable quartz composite face | Not specified |

Color Temperature | 1800°F (orange glow) | Not specified | Not specified |

Radiant Efficiency | ~60% | 80% | 80% |

Watt Density | 450 - 5200 Watts | Max 25 watts/in⊃2; | Max 100 watts/in⊃2; |

Voltage Range | 120 - 480 Volts | Flexible | Not specified |

Life Expectancy | Not specified | ~25,000 hours | ~12,000 hours |

Special Features | Nickel-chrome element, porcelain ends | Flexible sizes, replaceable thermocouple, fans, multi-zone heaters, stainless steel housing | Low thermal mass insulation, tight process control |

I have seen medium wave infrared lamps used in glass bending, textile drying, and heat-setting processes. Their ability to handle moisture and provide tight process control makes them a reliable choice for many industrial tasks. When I need a solution that balances power, durability, and efficiency, I often turn to medium wave infrared lamps.

Note: I always match the lamp’s wavelength and power density to the material and process requirements for optimal results with infrared lamps for heating.

When I work with carbon infrared heaters, I notice their unique construction and performance. These heaters use a carbon fiber filament encased in a quartz tube. The carbon element emits medium to long wave infrared radiation, which provides gentle and even heating. I often choose carbon infrared heaters for applications that require comfortable warmth without intense glare or rapid temperature spikes.

I appreciate the soft, reddish glow these heaters produce. The heat feels natural and pleasant, making them ideal for spaces where people spend extended periods. Carbon infrared heaters excel in environments like offices, restaurants, and residential patios. Their medium wave output matches the absorption characteristics of water and organic materials, so they efficiently warm people and objects.

Some advantages I have observed include:

Quick heat-up and cool-down times, which allow for responsive temperature control.

Lower surface temperatures compared to short wave heaters, reducing the risk of accidental burns.

Long lifespan and stable performance, thanks to the durability of carbon fiber filaments.

Minimal light emission, which enhances comfort in visually sensitive areas.

I often recommend carbon infrared heaters for both indoor and outdoor comfort heating. Their energy efficiency and gentle warmth make them a popular choice for hospitality venues and wellness centers. When I need a solution that balances comfort, safety, and efficiency, carbon infrared heaters consistently deliver.

Short wave infrared lamps stand out for their ability to deliver rapid, targeted heat. I rely on these lamps when I need to heat surfaces quickly and efficiently. The short wave spectrum allows these lamps to transfer energy directly to objects, minimizing heat loss to the surrounding air.

Here are some key benefits and considerations I have found:

Convert electrical energy into radiant heat, directly warming objects rather than air. This makes them highly efficient for industrial applications.

Provide rapid, even, and uniform heat, which is ideal for processes like drying paints and curing products. This improves productivity and reduces energy costs.

Increase safety by eliminating sparks and flames. I find them suitable for poorly ventilated or sensitive environments.

Direct heat at specific objects, preventing overheating of people or animals nearby.

Offer precise temperature control and fast heat-up times, which are essential in industrial processes.

Present some challenges, such as achieving uniform heat distribution and the need for careful temperature management.

The coils reach very high temperatures, so I always ensure proper safety measures during installation and operation.

High initial costs can be a barrier, but the long-term energy savings often justify the investment.

I use short wave infrared lamps in industries like automotive, printing, and food processing. Their ability to deliver instant, focused heat makes them indispensable for high-speed production lines and demanding environments.

Tip: I always select short wave infrared lamps when I need fast, surface-level heating with maximum energy efficiency and safety.

Special infrared heaters address niche applications that standard models cannot serve. I often encounter situations where unique heating requirements demand specialized solutions. These heaters come in various forms, each tailored for specific industries and processes.

The table below summarizes some specialized infrared heater types and their typical applications:

Specialized Infrared Heater Types | Niche Applications | Industries Served |

|---|---|---|

Ceramic Heating Elements | Composite forming, drying ovens, thermoforming, comfort heating | Aerospace, automotive, agriculture, food, medical |

Quartz Heating Elements | Conveyor ovens, furnace ovens, lab testing, drape forming | Aerospace, automotive, manufacturing |

Quartz Tungsten / Halogen Elements | Infrared curing of carbon composites, high-temp thermoplastics | Aerospace, automotive, advanced composites |

Heating Components (Reflectors, etc.) | Custom infrared ovens, specialized heating setups | Multiple industries |

Indoor/Outdoor Comfort Infrared Heaters | Comfort heating in indoor and outdoor environments | Residential, commercial, recreational |

Custom and Standard Infrared Ovens | Testing services, automation, specialized heating processes | R&D, manufacturing, industrial processing |

I have used ceramic heating elements for composite molding in aerospace projects. Quartz heating elements perform well in conveyor ovens and laboratory testing. For advanced composites, quartz tungsten or halogen elements provide the high temperatures needed for curing carbon fiber materials.

I also see a growing demand for custom infrared ovens and modular heating components. These solutions allow me to tailor heating systems for unique production lines or research environments. Indoor and outdoor comfort heaters, including wall-mounted and freestanding models, offer flexible options for commercial and recreational spaces.

Note: When I face a challenging heating scenario, I consult with manufacturers like Huai’an Infrared Heating Technology. Their expertise in custom and special infrared heaters ensures I find the right solution for any application.

When I assess heating technologies, I always look for solutions that maximize energy use. Infrared heating stands out because it delivers heat directly to people and objects, not the air. This direct transfer means I can feel warmer with less energy input. The human body absorbs infrared radiation efficiently, so I notice a comfortable warmth almost immediately.

Infrared panels convert nearly all the electricity they use into heat. I find this level of efficiency unmatched by most traditional systems. Zoned heating lets me target only the areas I need, which reduces wasted energy. I also appreciate that these systems avoid the uneven temperatures I often see with convection heaters. Maintenance needs are minimal, and the panels last for years, which helps me keep operational costs low.

Directly heats objects and people, not air, for minimal heat loss.

Converts almost 100% of electricity into usable heat.

Allows for zoned heating, so I only warm occupied spaces.

Reduces energy waste and operational expenses.

Requires little maintenance and offers a long service life.

I have seen that, compared to incandescent bulbs, infrared lamps for heating operate at lower filament temperatures. This design choice boosts efficiency and extends the lamp’s lifespan. I always recommend these systems for anyone seeking to lower their energy bills and improve heating performance.

One of the features I value most is the ability to deliver heat exactly where I need it. Infrared technology lets me focus warmth on specific zones, surfaces, or even individual workstations. I can avoid heating empty spaces, which saves energy and increases comfort.

The instant response time impresses me. When I switch on an infrared heater, I feel the warmth within seconds. There is no long wait for the system to reach operating temperature. This rapid heat-up is especially useful in industrial settings, where production lines cannot afford delays. In my experience, targeted and instant heat improves both efficiency and user satisfaction.

Tip: I always use infrared heaters in areas where quick, focused warmth is essential, such as workshops, patios, or assembly lines.

Durability is a top priority for me when choosing heating equipment. Advances in filament materials and reflector designs have made modern infrared lamps extremely robust. Manufacturers now use improved filaments that resist wear and tear, which means I replace lamps less often and save on costs.

Technological innovations, such as optimized filament structures and enhanced reflectors, further extend lamp life. I have noticed that high-quality manufacturing and adherence to safety standards also play a big role in durability. Maintenance requirements remain low, so I spend less time and money on upkeep.

Durable filaments reduce replacement frequency.

Enhanced reflector systems contribute to longer lamp life.

Quality manufacturing and safety standards ensure reliability.

Minimal maintenance keeps operational costs down.

When I invest in infrared heating, I know I am choosing a solution built to last. This reliability gives me peace of mind and a strong return on investment.

When I work with advanced heating systems, I always look for precise control and consistent results. Infrared heating technology gives me both. These systems use electrical power, so I can adjust the heater output instantly by changing the electrical input. This rapid response lets me fine-tune the temperature and maintain uniform heat across the entire process. I see this as a major advantage in industries where product quality depends on tight temperature control.

Infrared heaters allow me to select specific wavelengths that match the absorption peak of the material I want to heat. This means I can optimize energy use and avoid overheating or underheating. For example, in plastics forming or glass manufacturing, I can tune the system to deliver just the right amount of energy. This level of control leads to better product consistency and fewer defects.

I have seen how direct energy transfer from the heater to the target reduces energy waste. The system responds quickly to changes, so I can start or stop heating almost immediately. This is especially useful in fast-paced production lines, such as paint drying or textile processing. In one case, I optimized polypropylene web heating by using infrared technology, which improved both process control and product quality.

Wavelength tuning matches material needs for maximum efficiency.

Direct energy transfer reduces waste and speeds up response.

Consistent heating improves product quality and reduces defects.

I always recommend infrared heating when I need precise, reliable, and efficient process control in demanding industrial environments.

Quality and safety matter to me when I choose heating solutions. I trust manufacturers who meet strict international standards. Leading companies in this field, like Huai’an Infrared Heating Technology, hold certifications that prove their commitment to quality, safety, and environmental responsibility.

Most top manufacturers obtain CE certification and comply with ROHS standards. These certifications show that the products meet European safety and environmental requirements. I also look for ISO certifications, which cover quality management, environmental practices, and industry-specific needs. Some companies go further, meeting standards like FDA registration or Good Manufacturing Practices (GMP).

Here is a table of common certifications and what they mean:

Certification Type | Examples / Specific Standards |

|---|---|

ISO Standards | ISO/IEC 17025, ISO 13485, IATF 16949, ISO 14001, ISO 14644 series, ISO 22000 |

Industry-Specific Standards | AS9100, IRIS (International Railway Industry Standard) |

Regulatory Certifications | CE, ROHS, FDA registration, GSAGSA approval |

Quality & Safety Systems | GMP, IPC/WHMA-A-620, ITAR registration |

Management Systems | Lean Manufacturing, OHSAS 18001 |

Huai’an Infrared Heating Technology certifies its products to international industry standards. This gives me confidence that their lamps are safe, reliable, and built to last. I know I can rely on their products for demanding applications, knowing they meet or exceed global benchmarks.

I always check for these certifications before making a purchase. They help me ensure that I am investing in quality and safety for my projects.

When I evaluate infrared heating lamps, I always prioritize safety. Infrared radiation, especially in the Near Infrared (Near IR) spectrum, can pose health risks in certain environments. In industrial settings like glass blowing, arc welding, or blast furnaces, high-intensity Near IR exposure can penetrate the cornea and increase the risk of cataracts. Prolonged exposure may also accelerate skin aging and raise the potential for cancer. Scientific reviews and guidelines from organizations such as the International Commission on Nonionizing Radiation Protection (ICNIRP) highlight these concerns. I always recommend using proper shielding and personal protective equipment in environments with high Near IR levels. For typical heating applications, especially those using Far Infrared (Far IR), the risk remains minimal at standard dosages. Still, I advise users to follow manufacturer guidelines and ensure safe installation to prevent accidental burns or electrical hazards.

Note: Always consult safety standards and use protective measures when working in environments with intense infrared radiation.

I often find that cost plays a significant role in the decision to adopt infrared heating technology. Several factors contribute to the overall expense:

High initial purchase costs due to advanced materials and sophisticated manufacturing processes.

Skilled labor required for installation and ongoing maintenance.

Specialized expertise needed for setup and servicing, which can be a barrier in areas with limited trained personnel.

Fluctuating raw material prices, especially for quartz and ceramics, can make budgeting unpredictable.

Regulatory compliance costs related to meeting safety and environmental standards.

Competition from alternative heating technologies, such as electric and gas-based systems, can influence pricing and market dynamics.

Cost Factor | Impact on Infrared Heating Projects |

|---|---|

Initial Purchase Price | Higher due to advanced materials |

Installation Labor | Requires skilled technicians |

Maintenance | Needs specialized expertise |

Raw Material Fluctuations | Affects long-term cost management |

Regulatory Compliance | Adds to upfront and ongoing expenses |

Market Competition | May affect pricing and adoption rates |

I always encourage clients to consider not just the upfront investment but also the long-term savings from energy efficiency and reduced maintenance.

In my experience, infrared heating lamps do not suit every environment equally. Certain industrial settings, such as those involving blast furnaces or arc welding, expose workers to high levels of Near IR radiation. Scientific studies confirm that this type of exposure can cause eye damage, including cataracts, and increase the risk of skin aging or cancer. Near infrared saunas, which emit high power Near IR over a broad spectrum, also present safety concerns for habitual use. The inability to precisely control skin exposure in these environments makes it difficult to guarantee user safety. On the other hand, Far Infrared (Far IR) heating panels, commonly used for comfort heating, have not shown negative health impacts at standard dosages. I always assess the spectral output and intensity of the infrared lamps before recommending them for a specific application. This careful evaluation ensures that the chosen heating technology matches the safety requirements and operational needs of the environment.

I advise facility managers to review their workspace conditions and consult with experts before installing infrared heating systems, especially in high-risk industrial settings.

In my experience, industrial environments demand reliable and efficient heating solutions. I often turn to infrared lamps for heating because they deliver rapid, targeted energy directly to products and materials. I have seen these lamps used in automotive paint drying, glass manufacturing, digital printing, and plastic molding. The direct radiant energy heats objects without relying on air as a medium, which results in faster response times and significant energy savings.

I remember a project in an aluminum forging plant where we replaced a conventional batch-type gas-fired furnace with a continuous-belt hybrid rapid IR furnace. The results impressed me. The billet heating time dropped from 240 minutes to just 20 minutes. Throughput increased from 80 lbs/hr to 350 lbs/hr. Energy consumption per pound fell by two-thirds, and overall system efficiency tripled. These improvements not only boosted productivity but also reduced operational costs.

Application Area | Benefit of IR Heating |

|---|---|

Industrial space heating | 40-50% more energy-efficient |

Paint drying (automotive) | Faster drying, improved finish |

Glass and plastic processing | Precise, rapid heating |

Food processing | Rapid, uniform heating |

Liquid heating (metal-sheathed) | Handles corrosive/acidic solutions |

Metal forming | Higher throughput, lower energy usage |

I always recommend matching the type of infrared heater—quartz, ceramic, or metal-sheathed—to the specific process. This approach ensures optimal performance and energy efficiency.

I have noticed a growing trend in the use of infrared lamps for heating in commercial spaces like offices, retail stores, and restaurants. These heaters provide rapid warmth and help reduce energy costs, which appeals to business owners. I often see them integrated with smart building systems, allowing for precise control and improved energy management.

In residential settings, homeowners appreciate the comfort and efficiency these heaters offer. I have installed them in living rooms, bathrooms, and patios. Many clients tell me they enjoy lower energy bills and a more comfortable indoor environment. The compatibility with smart home systems adds convenience, letting users adjust settings remotely or automate heating schedules.

Tip: I always advise clients to consider infrared heating if they want a solution that is both energy-efficient and environmentally friendly.

I have worked with healthcare professionals who use infrared lamps for heating in clinical and therapeutic settings. Far-infrared therapy has shown benefits in improving blood flow and vascular function. For example, studies have found that this therapy can enhance access blood flow in hemodialysis patients and increase nitric oxide production, which supports cardiovascular health. Other research shows improved skin microcirculation in animal models.

I have seen infrared therapy used to:

Alleviate pain and reduce inflammation in muscle strains, joint pain, and arthritis.

Promote healing in sports injuries.

Support dermatology treatments for conditions like acne and eczema.

Assist in physiotherapy and pain management.

Provide therapeutic heat in veterinary medicine.

Regulatory bodies require rigorous testing and approval for medical devices. I always follow safety guidelines to ensure effective and safe use. When used properly, infrared therapy offers a non-invasive and generally safe option for many patients.

I have seen infrared heating technology transform outdoor comfort in ways that traditional systems cannot match. Outdoor environments present unique challenges—open air, wind, and fluctuating temperatures often make it difficult to maintain warmth. Infrared heaters solve this by delivering direct, radiant energy to people and surfaces, regardless of air movement. I often recommend these systems for patios, terraces, and open-air venues where conventional heaters fall short.

A wide range of sectors now rely on infrared heating for outdoor spaces. I have summarized some of the most common specialized applications in the table below:

Description | |

|---|---|

Residential | Heaters warm patios, decks, and gardens, allowing families to enjoy outdoor living year-round. |

Hotel | Outdoor hotel lounges and pool areas use infrared heaters to enhance guest comfort in all seasons. |

Restaurant | Outdoor dining spaces stay inviting for patrons, even on chilly evenings. |

Superyacht & Cruise | Luxury vessels install infrared heaters on decks to provide warmth during sea voyages. |

I have worked with restaurant owners who wanted to extend their outdoor dining season. By installing wall-mounted or freestanding infrared heaters, they created comfortable spaces for guests, even in cooler months. Hotel managers often choose these systems for rooftop bars and poolside lounges, ensuring guests remain cozy without bulky equipment or intrusive noise.

In residential settings, I have helped homeowners transform patios and gardens into year-round retreats. The instant, targeted heat means families can host gatherings or relax outdoors, regardless of the weather. On superyachts and cruise ships, I have seen infrared heaters integrated into deck designs, providing discreet yet effective warmth for luxury travelers.

Tip: I always advise clients to select IP-rated infrared heaters for outdoor use. These models withstand rain, dust, and humidity, ensuring reliable performance in any weather.

Specialized applications go beyond hospitality and leisure. I have seen infrared heating used in agriculture to protect crops from frost and in animal care facilities to maintain optimal temperatures for livestock and pets. In commercial settings, multi-use buildings benefit from customized infrared solutions that address diverse heating needs, including semi-outdoor spaces like covered walkways or event venues.

Marley Engineered Products highlights real-world cases where infrared heating addresses outdoor and semi-outdoor challenges.

Multi-use buildings and hospitality venues often require tailored solutions for patios, terraces, and entryways.

Outdoor heating improves comfort, extends usable space, and supports business growth in competitive markets.

I always consider the specific demands of each environment before recommending a solution. The versatility and efficiency of infrared heating make it my top choice for outdoor and specialized applications.

When I help clients select the right infrared lamp, I always start by evaluating their specific requirements. I look at the size and layout of the space. Large, open areas may need higher wattage or multiple units, while smaller rooms can use compact models. I consider the primary application—whether it is for industrial processing, commercial comfort, or residential use. Each scenario demands a different approach.

I also assess environmental factors. Outdoor spaces require weather-resistant models, such as IP-rated heaters. For indoor environments, I check for ventilation, ceiling height, and the presence of sensitive equipment or materials. I always ask about the desired heating speed and whether instant or gradual warmth is preferred. These factors guide my recommendations and ensure the chosen solution matches the user’s expectations.

Tip: I recommend making a checklist of your space dimensions, usage patterns, and any special requirements before shopping for infrared lamps for heating.

I find that comparing lamp types helps narrow down the best option for each application. Performance, cost, and suitability vary widely among available technologies. Here is a table I use to guide my clients:

Type of IR Lamp | Performance Characteristics | Cost Considerations | Suitability for Applications |

|---|---|---|---|

Incandescent IR | Instant on/off, high heat, short lifespan | Low upfront, frequent replacements | Medical, security, basic heating |

Halogen IR | Efficient, bright, longer life, fragile | Higher cost, careful handling | Outdoor, automotive, industrial |

LED IR | Energy-efficient, durable, lower brightness | High initial, long-term savings | Greenhouses, security, specialty |

CFL IR | Efficient, compact, contains mercury | Moderate, disposal concerns | Residential, commercial lighting |

Infrared Heat Lamps | Quick, efficient, long life, safety needed | Moderate, safety precautions | Bathrooms, saunas, industrial, culinary |

I also match lamp wavelength to the application. Shortwave lamps (1.0-1.4 μm) deliver fast, deep heating—ideal for rapid industrial processes. Fast medium wave lamps (1.4-2.0 μm) excel at drying inks and coatings. Carbon medium wave lamps (2.0-4.0 μm) provide gentle, even heat for moisture-rich materials. Specialized lamps address unique needs in glass cutting, plastic forming, and photovoltaics. I always consider the absorption characteristics of the target material and the required heating speed.

Energy efficiency and cost play a major role in my recommendations. Infrared lamps for heating transfer energy directly to objects, not the surrounding air. This approach improves efficiency but means the heat dissipates quickly when the lamp turns off. I always factor in the initial investment, installation, and ongoing maintenance costs. Some models require skilled labor for setup and periodic servicing, which can add to the total expense.

I pay close attention to the operating environment. Agricultural and animal husbandry applications often justify higher upfront costs due to the need for reliable, consistent warmth. Technological advancements continue to improve efficiency and capacity, which can offset higher purchase prices over time. I advise clients to weigh long-term energy savings against initial costs and to consider the durability and lifespan of each lamp type.

Direct energy transfer reduces wasted heat.

Some models have higher installation and maintenance costs.

Technological improvements can lead to better efficiency and lower operational expenses.

Application-specific needs, such as outdoor use or industrial processing, may require a larger initial investment.

Note: I always recommend consulting with a trusted manufacturer like Huai’an Infrared Heating Technology. Their expertise and product range help ensure the best fit for any application.

When I help clients choose heating solutions, I always stress the importance of safety and certification. These factors protect both people and property. I never overlook them, especially when dealing with electrical devices that generate heat.

I always check for recognized safety certifications before recommending any product. UL certification stands out as a global standard. It shows that a lamp meets strict safety, environmental, and health criteria. Many building codes and insurance companies require UL-listed products. ETL certification offers similar assurance. It confirms that the lamp complies with electrical and fire safety standards. I also look for FCC certification. This ensures the device will not cause harmful electromagnetic interference, which can affect other electronics in the area.

Energy efficiency matters to me as well. I look for Energy Star and DLC certifications. These labels indicate that the lamp meets high standards for energy use and product quality. They also help with regulatory compliance and can lower operational costs over time.

Before I purchase or install a lamp, I always verify these certifications. I check product pages, installation manuals, spec sheets, and packaging. This step gives me confidence that the product is safe and reliable.

Here are some key certifications and what they mean:

Certification | What It Means | Why It Matters |

|---|---|---|

UL | Meets global safety, health, and environmental standards | Required by many codes and insurers |

ETL | Complies with electrical and fire safety standards | Ensures safe operation |

FCC | No harmful electromagnetic interference | Protects other electronics |

Energy Star | High energy efficiency and quality | Reduces energy costs |

DLC | Verified product quality and efficiency | Supports rebates and compliance |

CE | Meets European safety regulations | Required for EU markets |

IP Rating | Protection against water and dust | Essential for outdoor use |

I also pay attention to international standards. For example, CE certification is necessary for products sold in Europe. IP ratings, such as IP X4, show that a lamp can withstand water splashes. This is vital for outdoor or humid environments.

I always advise clients to choose products from trusted manufacturers. Companies like Huai’an Infrared Heating Technology provide lamps with verified certifications. This commitment to safety and quality gives me peace of mind and ensures long-term reliability.

Tip: Always verify certifications before making a purchase. This simple step can prevent accidents and protect your investment.

When I install infrared heating lamps, I always follow a precise process to ensure safety and optimal performance. Proper installation not only extends the life of the lamp but also maximizes energy efficiency and heating effectiveness. Here is the step-by-step method I use, based on manufacturer guidelines:

I handle each lamp gently, avoiding vibrations or squeezing that could cause breakage.

I never pinch the quartz tube ends with one hand, as this can damage the lamp.

I wear soft gloves during handling to prevent contamination and protect my hands from injury.

I avoid rigidly fixing the quartz body or ceramic base. Instead, I use recommended mounting accessories and allow a 3-5mm axial gap for thermal expansion.

I always orient the lamp so the reflective layer faces away from the heated material, ensuring efficient heat transfer.

I take care to prevent collisions or scratches, especially on reflective surfaces.

I avoid looking directly at lamps with strong visible light unless I wear protective glasses.

I never touch the lamp until it has fully cooled, which prevents burns.

I place the lamp ends in low-temperature areas (below 300℃) to extend lamp life.

I install lamps horizontally unless the manufacturer specifies otherwise.

I use extra insulated sleeves on cables to prevent electrical leakage.

I always use professional lamp accessories recommended by the manufacturer to reduce installation issues.

Tip: Careful installation reduces the risk of damage and ensures your infrared heating system operates at peak efficiency.

Operating infrared heating lamps safely is essential in any environment. I always monitor the temperature and adjust the lamp’s distance from the workpiece to prevent overheating. I keep the temperature below 400°F to avoid damaging materials or the lamp itself. I never look directly at high-intensity lamps without eye protection, and I make sure the area around the lamp remains clear of flammable materials.

I also check that all electrical connections are secure and that cables have proper insulation. If I notice any unusual sounds, smells, or flickering, I turn off the system and inspect it before continuing use. I always follow the manufacturer’s safety instructions and encourage others to do the same.

Regular maintenance keeps infrared heating lamps running efficiently and safely. I schedule routine inspections to check the condition of the emitters and replace any malfunctioning parts promptly. I clean reflectors, emitter covers, and air filtration components frequently to prevent performance loss from dust or debris.

When replacing elements, I unplug the unit and place it on a stable surface. I remove end covers and grills with the right tools, loosen mounting nuts gently, and handle the ceramic ends to avoid damaging the quartz glass. I dispose of used elements safely, inspect new ones for damage, and install them carefully without forcing parts. After reassembly, I clean the elements with a soft rag and alcohol to remove fingerprints or contaminants.

I address issues like clogged burner orifices, defective emitters, or dirty reflectors immediately.

I always use original packaging for disposal and recommended accessories for replacements.

Regular maintenance not only extends the lifespan of your infrared heating lamps but also ensures consistent, safe, and energy-efficient operation.

I see infrared lamps for heating as a smart choice for efficient, targeted warmth in many settings. These systems offer energy savings, rapid response, and precise control. I always remind readers to weigh both the benefits and limitations before making a decision. For expert advice and reliable products, I trust Huai’an Infrared Heating Technology. I suggest reaching out for tailored recommendations or further research to ensure the best fit for your needs.

I see infrared lamps for heating as highly efficient because they transfer heat directly to objects and people. This method reduces energy loss. I often notice lower utility bills and faster heating times compared to conventional systems.

Yes, I often install IP-rated infrared lamps for heating in patios, gardens, and terraces. These models withstand rain and dust. I recommend choosing products designed for outdoor use to ensure safety and durability.

From my experience, high-quality quartz infrared lamps can last up to 10,000 hours. I always check the manufacturer’s specifications. Regular maintenance helps extend the lifespan and ensures consistent performance.

I consider infrared lamps safe for homes when installed and operated correctly. I always follow manufacturer guidelines and use certified products. Proper placement and regular inspection help prevent accidents.

I have seen industries like automotive, glass manufacturing, digital printing, agriculture, and food processing benefit greatly. Infrared lamps for heating provide precise, rapid, and energy-efficient solutions for these demanding environments.

I assess the space size, heating needs, and environment. I compare lamp types—short wave, medium wave, carbon, or special heaters. I consult with experts at Huai’an Infrared Heating Technology for tailored recommendations.

I perform routine inspections, clean reflectors, and replace worn parts as needed. I always use original accessories and follow the manufacturer’s maintenance schedule. This approach keeps the system efficient and safe.

Absolutely. I have seen significant cost reductions in warehouses and factories. Infrared lamps for heating target specific zones, minimizing wasted energy and lowering overall expenses.