By the end, you will understand where quartz IR makes sense, how to size and select it, and what to watch out for when integrating infrared heating into reactors, vessels, pipes, and anti-corrosion coating lines.

Executive Summary

Chemical sector pressure: The chemical industry is a major industrial energy consumer and a significant source of CO₂ emissions, with much process heat still generated from fossil fuels. This creates strong pressure to improve efficiency and electrify heat.

Where quartz IR fits best: Quartz infrared heating lamps are particularly effective in corrosion resistant infrared heating applications where direct contact heating (steam jackets, hot oil, immersion heaters) struggles—such as lined reactors, coated vessels, chemical process equipment, and anti-corrosion coating lines.

Typical impact: Well-engineered chemical industry infrared heating solutions can shorten heat-up times, improve temperature uniformity, and reduce specific energy consumption compared with oversized steam or gas ovens, depending on process and control quality.

Key technical decisions: Success hinges on choosing the right wavelength (short vs. medium wave), power density, emitter layout, and control strategy—plus ensuring mechanical protection and materials compatibility in corrosive atmospheres.

How Huai’an Yinfrared Heating Technology helps: Huai’an Yinfrared designs and supplies short- and medium-wave quartz IR lamps, modular cassettes, panels, and complete industrial infrared heating systems for chemical plants and OEMs, from sample emitters to fully engineered retrofit projects.

Key takeaway: In corrosive chemical processes, quartz IR allows you to keep the heat close and the heaters out of the chemistry—reducing corrosion risk while improving control.

Use Cases & Buyer Scenarios

Corrosion-Resistant Heating for Chemical Reactors and Vessels

Typical process

Media: Acids, bases, solvents, or slurries that are corrosive to carbon or stainless steel.

Equipment: Glass-lined, PTFE-lined, or specialty alloy reactors and vessels.

Temperature window: Often 40–250 °C, sometimes higher for specialty reactions.

Dwell time: From batch processes (hours) to semi-continuous operations.

Pain points of conventional heating

Steam jackets and coils:

Corrosion, scaling, and fouling inside jackets reduce heat-transfer coefficients.

Leakage or under-deposit corrosion leads to costly downtime and environmental risk.

Hot oil systems:

Degradation of thermal oil at high temperatures; periodic replacement and flushing.

Fire risk, large tank and piping footprint, complex safety management.

Immersion heaters:

Direct contact with corrosive media requires expensive materials and still tends to suffer from scaling or coating buildup.

How quartz IR changes the game

Quartz infrared heating lamps can be installed externally around the reactor wall, behind a protective housing and reflectors:

Non-contact heating: Radiation passes through the reactor wall or lining and heats the contents or internal surfaces without exposing the heater to the aggressive chemistry.

Fast thermal response: Short-wave quartz IR heaters for reactors reach operating power in seconds, supporting tighter control, fast ramp-up, and improved batch cycle times.

Compact footprint: Modular cassettes follow the reactor curvature or are arranged in panels, saving space versus large steam or oil systems.

Lower corrosion risk: Heating equipment is kept in dry, insulated enclosures, reducing exposure to corrosive vapors.

Recommended Yinfrared solutions

Short-wave quartz infrared heating lamps in modular cassettes for high power density and fast control.

Medium-wave quartz IR modules when gentler heating is required or where absorption matches coatings or linings better.

Custom quartz infrared heating lamps configured in segmented zones around large vessels for uniform heating.

Infrared Curing of Anti-Corrosion Coatings on Pipes and Tanks

Typical process

Substrates: Carbon steel pipes, fittings, valves, storage tanks, and structural steel.

Coatings: Epoxy, polyurethane, phenolic, or hybrid systems designed for chemical resistance.

Thickness: Often 150–500 μm dry film, possibly in multiple layers.

Temperature window: Flash-off stages around 40–80 °C; curing stages around 80–200 °C.

Line type: Batch curing rooms, conveyorized lines, or rotating pipe systems.

Pain points of hot-air and gas-fired ovens

Uneven curing: Complex geometries and shadowed areas lead to under- or over-cure.

Long cycle times: Large air volumes require preheat time and long soak periods.

High energy cost: Convective ovens heat both air and steel; poor insulation or leakage raises fuel consumption.

Quality issues: Blistering, pinholes, or solvent entrapment when heat-up is too slow or non-uniform.

How quartz IR improves coating curing

Using infrared coating curing for corrosion protection with quartz IR lamps:

Direct radiant heating: IR energy is absorbed by the coating and steel surface, increasing temperature rapidly and uniformly.

Better film formation: Controlled ramp rates help drive off solvents while avoiding skinning or blistering.

Zoned heating: You can apply higher intensity to thick or cold spots and lower intensity elsewhere.

Retrofit-friendly: IR tunnels can be added before, after, or instead of part of an existing oven to debottleneck lines.

Recommended Yinfrared solutions

Medium-wave quartz IR panels for uniform curing of coatings on tanks and large fabrications.

Short-wave quartz IR lamp tunnels for fast, high-throughput pipe coating lines.

Custom infrared heating for chemical process equipment like skids and modules, integrated with conveyors or rotation devices.

Pro tip for plant engineers: Start by retrofitting a short IR zone into your existing coating line to relieve a bottleneck or reduce gas usage, then scale up once you have proven recipes.

Spot Heating and Drying for Chemical Equipment Maintenance

Typical process

Local repair of corrosion-resistant linings or coatings on flanges, nozzles, and manways.

Drying after high-pressure water cleaning or hydro-testing.

Softening gaskets or adhesives for removal in maintenance operations.

Pain points of flames and hot air

Safety risks: Open flames are rarely acceptable in chemical areas; hot air guns can still pose ignition or surface damage risk.

Poor control: Difficult to maintain consistent temperature; risk of overheating nearby seals or linings.

Slow drying: Thick sections, confined spaces, or low ambient temperatures extend maintenance windows.

Benefits of compact quartz IR modules

Targeted heat: Small quartz IR emitters can be aimed at a defined area, minimizing impact on adjacent components.

Rapid on/off: Fast response supports short maintenance windows and safer operation.

Non-contact: No risk of mechanical damage to delicate linings or seals.

Recommended Yinfrared solutions

Portable frames with short-wave quartz IR modules for on-site repair work.

Compact IR panels designed for maintenance shops that handle small equipment.

Spec & Selection Guide (the heart)

To design robust chemical industry infrared heating solutions, you need to understand key IR parameters and how they affect process performance.

Wavelength Band (Short-, Medium-, Long-Wave)

Definition: The spectral range in which the IR emitter radiates most of its energy:

Short-wave: ~0.8–1.5 μm

Medium-wave: ~1.5–3 μm

Long-wave: >3 μm

Why it matters: Different materials (metals, coatings, polymers, glass linings) absorb IR differently. Matching the wavelength to the absorption characteristics improves efficiency.

Typical trade-offs:

Short-wave: Highest power density, very fast response, good for metals and thin coatings, more penetrating.

Medium-wave: Better absorption in many organic coatings and plastics, still relatively fast, less glare.

Long-wave: Gentler, slower heating, suitable for low-temperature drying and non-metallic parts.

For glass-lined or coated metal vessels and pipes, short- and medium-wave quartz infrared heating lamps are common choices because they balance absorption, controllability, and compact size.

Power and Power Density

Definition: Total power (kW) and power per unit area (kW/m²) delivered at the product surface.

Why it matters: Determines heating rate, achievable line speed, and risk of overheating.

Typical ranges:

Light-duty drying: 5–15 kW/m²

Coating curing: 15–40 kW/m²

High-intensity spot heating or small reactors: 40–80+ kW/m² (with careful control)

Higher power densities shorten cycles but demand precise control and good understanding of coating or lining limits.

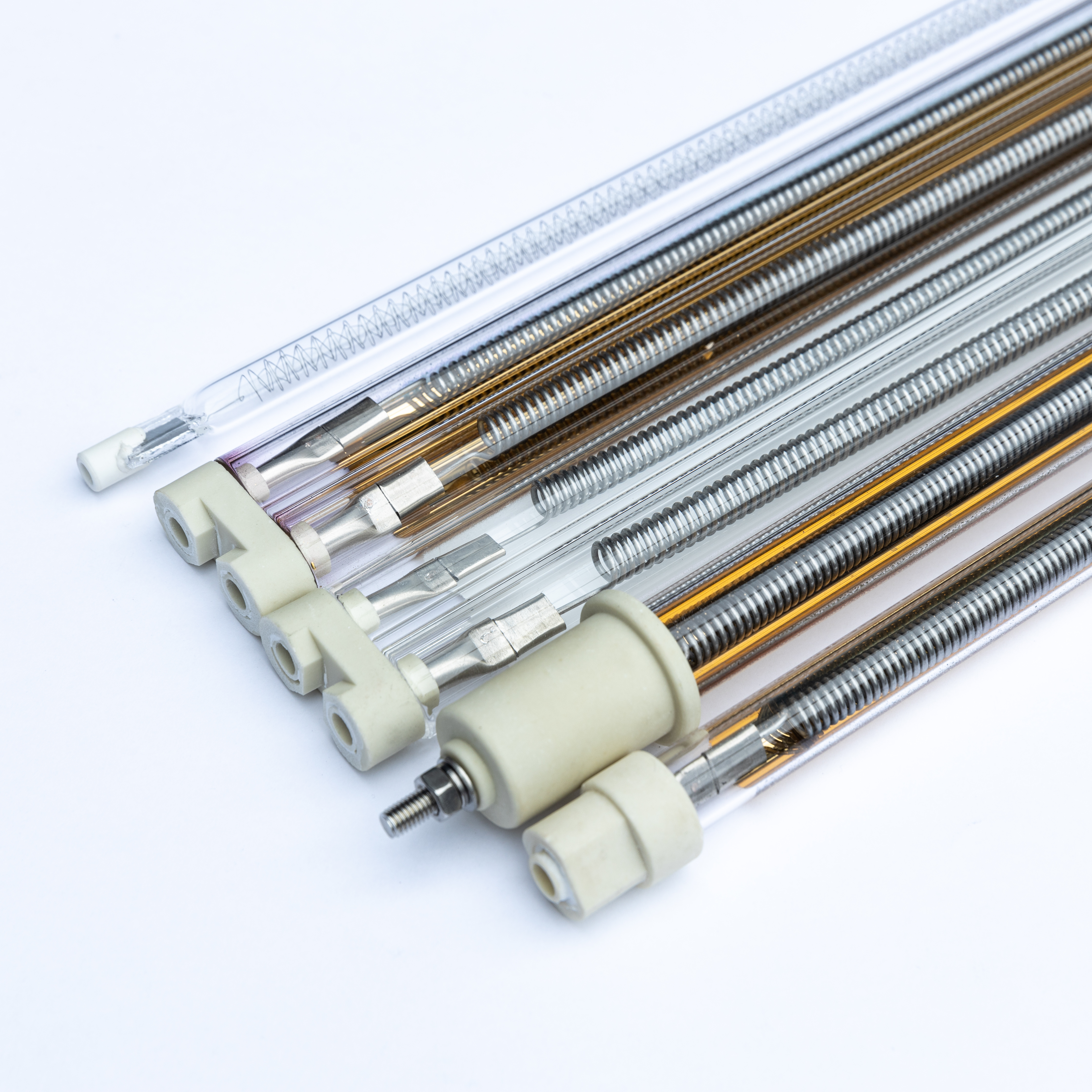

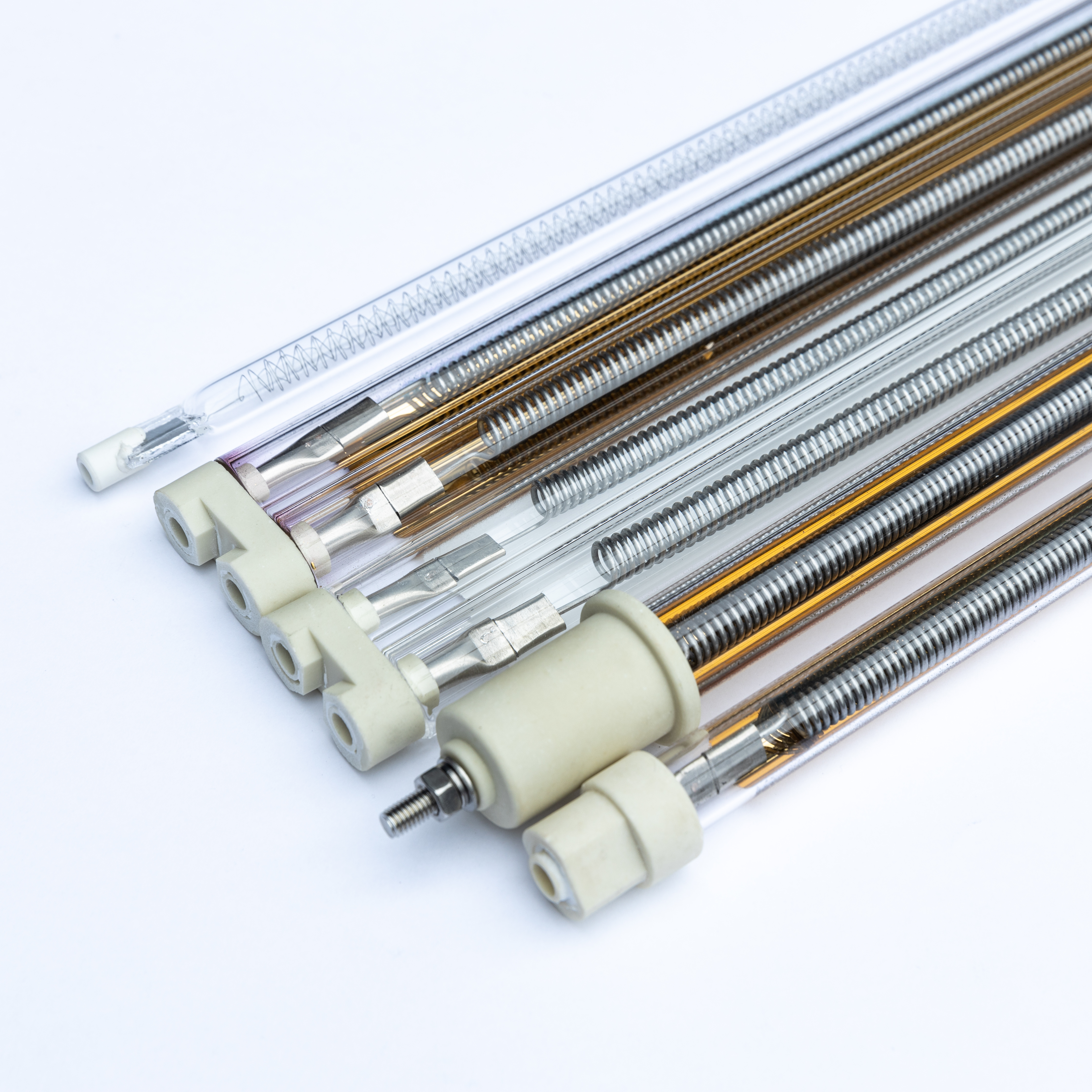

Heater / Emitter Type

Quartz tube (short- or medium-wave):

High power density, fast response, compact form factor.

Often used in modules with reflectors for focused heating.

Ceramic IR heaters (long-wave):

Robust, lower surface temperature, slower response, good for low-temperature drying.

Metal foil / panel emitters:

Medium power density, can be built into large flat panels for tanks or room heating.

Cassette modules:

Pre-engineered assemblies with multiple quartz lamps, reflectors, and wiring, simplifying installation.

Emitter Length / Panel Size and Zoning

Longer lamps and larger panels cover more area but may reduce fine control.

Zoning (splitting the heater area into independently controlled zones) improves uniformity and allows process tuning.

Surface Temperature and Response Time

Quartz IR emitters typically operate at filament temperatures of several thousand °C, translating to very fast IR output response.

For process design, what matters is:

Time to reach steady-state product surface temperature.

Ability to modulate power to follow recipes and avoid overshoot.

Working Distance and Layout Constraints

Radiant intensity decreases with distance; typical working distances are 100–500 mm depending on power and footprint.

In chemical plants, you must consider:

Space constraints around reactors, pipes, and tanks.

Access for maintenance and cleaning.

Shielding from corrosive vapors and mechanical impacts.

Control Options

On/Off control: Simple but coarse; suitable for non-critical drying.

Solid-State Relay (SSR) control: Time-proportioning for basic power modulation.

Silicon-Controlled Rectifier (SCR) control: Phase-angle or zero-cross, enabling fine, fast control of power for sensitive processes.

Closed-loop PID: Using thermocouples or IR sensors to regulate product or surface temperature.

PLC/fieldbus integration: Linking IR power to plant DCS, recipe management, and safety interlocks.

Enclosure, Insulation, and IP Rating

Enclosures protect emitters from dust, drips, and corrosive vapors.

Insulation improves efficiency and protects nearby structures.

IP ratings and appropriate materials (stainless steel, coated metals) are essential in washdown or corrosive atmospheres.

Comparison Table of Typical Infrared Solutions

| Infrared Solution Type | Wavelength Band | Typical Power Density | Response Time | Recommended Applications | Control Options |

|---|---|---|---|---|---|

| Short-wave quartz IR lamp module | Short-wave | High | Very fast | Fast heating of metal vessels, pipes, high-speed coating lines | On/Off, SSR, SCR, PID |

| Medium-wave quartz IR panel | Medium-wave | Medium | Fast | Coating curing on tanks, composite linings, gentle drying | On/Off, SSR, SCR, PID |

| Long-wave ceramic IR heater | Long-wave | Low–medium | Slower | Low-temperature drying, non-metallic equipment components | On/Off, SSR, basic PID |

| Custom IR oven for chemical equipment | Mixed band | Adjustable | Engineered | Integrated corrosion-resistant heating for equipment and skid systems | PLC/fieldbus, multi-zone PID |

Practical Selection Logic

If/then rules

If you need very fast heat-up on metal surfaces or high line speed → choose short-wave quartz IR lamp modules.

If your focus is coating curing on tanks, pipes, or composite linings with moderate line speed → choose medium-wave quartz IR panels.

If you only need low-temperature drying of non-metallic parts → consider long-wave ceramic heaters.

If you require equipment-level integration (reactor, skid, or package unit) → consider a custom infrared heating solution with mixed wavelengths and zoning.

Mini decision flow (ASCII)

What is your target surface/film temperature?

≤120 °C → consider long-wave or low-power medium-wave.

120–220 °C → medium-wave or moderate short-wave.

-

220 °C or very fast ramp → short-wave.

What is your substrate?

Mostly metals → short- or medium-wave quartz.

Mostly coatings or composites → medium-wave often preferred.

How critical is cycle time?

Very critical / high throughput → higher power density + SCR/PID control.

Moderate → medium power density + SSR control.

Low → simple on/off or basic PID.

Integration & Engineering Notes

Power & Control

Mains voltage & phase: Chemical plants often use 3-phase 380–480 V supplies. Quartz IR systems can be designed to match common plant voltages and distribution schemes.

Wiring & load balancing:

Distribute IR lamp loads evenly across phases.

Use appropriately rated cables, busbars, and terminations.

Provide separate circuits and protection for each zone to simplify troubleshooting.

Protection & safety:

Circuit breakers or fuses sized for inrush and steady-state current.

Residual current devices (where appropriate) and robust grounding.

Over-temperature protection on enclosures and critical structures.

Control strategies:

On/off control via contactors for simple zones.

SSR or SCR control for precise power modulation.

PID temperature controllers or PLC-stored recipes controlling heating profiles.

Control cabinet layout:

Segregate power and signal wiring.

Provide adequate ventilation or cooling.

Include clear terminal markings, wiring diagrams, and maintenance labels.

Mechanics & Installation

Mounting options:

Frames around reactors or tanks.

Cassettes bolted to structural members.

Panels integrated into tunnel ovens or booths.

Working distance:

Typically 150–300 mm from heater face to product surface for high power density systems.

Adjust for uniformity, accessibility, and safety.

Line speed & dwell time:

For conveyorized lines, required power is strongly influenced by line speed and target ΔT.

For batch vessels, dwell time is governed by batch size, mixing quality, and heat loss.

Reflectors & shielding:

Highly polished metal reflectors focus IR toward the product and improve efficiency.

Shields protect operators from glare and reduce stray heating of nearby components.

Maintenance & access:

Design for easy lamp replacement without full disassembly.

Keep viewing windows or inspection ports where possible.

Plan cleaning intervals if dust or condensation is expected.

Thermal Process & Tuning

Defining a heating profile:

Identify target temperature, maximum allowable ramp rate, and any soak periods.

For coatings, respect manufacturer curing curves and maximum substrate temperature.

Instrumentation:

Use thermocouples on the substrate, not just in the air.

IR pyrometers can monitor moving products or hot surfaces without contact.

From trial-and-error to structured testing:

Start with conservative power levels.

Incrementally increase power or reduce dwell time.

Record temperature curves and product quality for each setting.

Examples of tuning:

If blistering occurs in anti-corrosion coatings, reduce initial power density or increase flash-off time.

If cure is incomplete at edges, add higher-power edge zones or adjust reflector geometry.

Testing & Validation (Lab → Pilot → Full-Scale)

Lab tests on samples

Flat coupons of coated steel or lining materials.

Measure heating curves and energy input vs. achieved temperature.

Pilot line or test zone

Small tunnel or test rig equipped with representative quartz IR lamps.

Validate line speed, uniformity, and coating performance.

Full-scale acceptance criteria

Throughput (e.g., m/min of coated pipe or m²/h of tank surface).

Temperature uniformity (e.g., ±5–10 °C across surfaces).

Specific energy consumption (kWh per m² or kg) under realistic operating conditions.

Product quality (adhesion tests, cure tests, corrosion-resistance trials).

Compliance, Safety & Certifications

Applicable standards (examples):

Electrical safety and performance can be designed to align with CE-related directives such as the Low Voltage and EMC Directives in the EU.

For North America, systems can be engineered with UL/CSA requirements in mind.

RoHS/REACH considerations for materials, especially in lamp housings and wiring.

Safety in chemical environments:

High surface temperatures require guards and clear marking.

Maintain adequate clearances from combustible materials.

Use over-temperature sensors and interlocks to shut down on fault.

Electrical safety:

Robust grounding and bonding.

Appropriately rated switching devices and cables.

Attention to hazardous area zoning where flammable atmospheres may exist; place IR equipment outside hazardous zones when possible.

A dedicated compliance and application support approach from Huai’an Yinfrared can provide up-to-date guidance and example documentation for your region.

Business Model, MOQ & Lead Time (OEM/ODM)

Engagement Models

Standard catalog products

Off-the-shelf quartz IR lamps, modules, and panels in standard lengths and powers.

Suitable for simple retrofits and OEM designs where dimensions align with catalog sizes.

Customized emitters and panels

Tailored wattage, length, voltage, and connector styles.

Custom reflectors and mounting frames for specific reactors or coating lines.

Complete systems

Turnkey industrial infrared heating systems including emitters, frames, controls, and thermal design support.

Engineered to integrate with existing plant utilities and automation systems.

MOQ, Samples, and Lead Times

Typical MOQ:

Low MOQ for standard lamps and modules to facilitate trials.

Higher MOQ for fully custom lamps or complex assemblies.

Lead times (indicative, not guaranteed):

Samples of standard lamps: often a few weeks depending on stock.

Custom lamp designs: additional engineering time plus manufacturing.

Full systems: project-based timelines aligned with plant shutdowns and CAPEX cycles.

Private Label / Co-Branding

For OEMs and system integrators, private label options may be available:

Laser marking or labeling of lamps and modules.

Co-branded documentation and nameplates.

Documentation & Support

2D and 3D CAD models for integration into OEM designs.

Wiring diagrams, load lists, and recommended protection devices.

Application notes covering corrosion resistant infrared heating and optimization of curing or heating recipes.

Example ROI Model: Conventional vs Quartz IR

Assumptions (illustrative only, results depend on real data):

Existing process: gas-fired hot-air oven curing anti-corrosion coating on pipes.

Proposed process: quartz IR tunnel oven.

Operating hours: 6,000 h/year.

Gas and electricity prices based on local market assumptions.

Maintenance: higher for combustion systems due to burners and flues.

| Item | Gas-Fired Hot-Air Oven | Quartz IR Tunnel |

|---|---|---|

| Specific energy use (relative) | 100% | ~70–85% |

| Annual energy cost (index) | 100 | 70–85 |

| Typical maintenance effort (index) | 100 | 60–80 |

| Typical cycle time | 100% | ~70–90% |

| Estimated simple payback | — | Often 2–5 years* |

*Payback depends on energy prices, baseline efficiency, production volume, and capital costs. Real calculations should use measured data from your line.

Key takeaway: Even modest reductions in energy use and maintenance, combined with throughput gains, can support a strong business case for quartz IR in chemical coating lines.

Pitfalls, Benchmarks & QA

Common Mistakes to Avoid

Wrong wavelength selection

Using long-wave heaters for processes that would benefit from short- or medium-wave, leading to slow heat-up and poor cure.Under-sizing power

Not allowing enough power density for peak production rates; results in bottlenecks and incomplete curing during high load periods.Neglecting insulation and shielding

Wasted energy and unwanted heating of surrounding equipment.Poor mounting and alignment

Uneven distances and misaligned reflectors cause hot spots and cold zones.Missing safety layers

No over-temperature protection, no interlocks, or inadequate guarding.Ignoring corrosive vapors

Using unsuitable enclosure materials in atmospheres with acids, solvents, or salts.

Practical Benchmarks

Heat-up time targets:

Small parts and thin coatings: typically seconds to a few minutes.

Large tanks or vessels: tens of minutes, depending on wall thickness and insulation.

Temperature uniformity:

±5–10 °C across critical surfaces is a reasonable target in many coating applications.

Specific energy consumption:

For IR-enhanced systems, engineers often aim for noticeable reductions vs. legacy systems, recognizing that exact values will depend on design and operation.

QA Philosophy at Huai’an Yinfrared Heating Technology

Rigorous incoming inspection of quartz tubes, filaments, and key components.

Electrical and functional testing of assembled lamps and modules.

Burn-in tests for selected products or batches to ensure stability.

Traceable labeling and documentation to support long-term spares and maintenance.

FAQs

1. How do I size quartz infrared heating lamps for my chemical reactor?

Start with the required heat duty (kW) based on batch size, target temperature rise, and heat losses. Then choose a practical power density and available install area to determine how many lamps or modules you need. Providing reactor dimensions, insulation details, and process conditions helps Huai’an Yinfrared propose a suitable design.

2. What energy savings can I expect vs. steam or gas ovens?

In many cases, IR-based systems can reduce energy use by a noticeable margin because they heat the product more directly and allow better control. Exact savings depend on baseline efficiency, insulation, operating conditions, and control quality, so they must be evaluated case by case.

3. How long do quartz IR emitters last in corrosive environments?

Emitter life depends on operating temperature, on/off cycling, and air quality. When properly enclosed and protected from direct chemical exposure, quartz IR lamps can provide long, predictable service life. Periodic inspection and cleaning of reflectors and covers is important.

4. Can you provide custom quartz IR designs for my OEM equipment?

Yes, OEM/ODM cooperation typically includes custom lamp lengths, powers, connectors, mounting hardware, and sometimes private labeling. Providing 3D models of your equipment and process requirements enables optimal integration.

5. What information do you need to design a system for my coating line?

Key inputs include substrate material and thickness, coating type and target cure, line speed or batch time, available footprint, existing heating system details, and local utilities (voltage, available power).

6. Do you offer support outside of China or Asia?

Huai’an Yinfrared works with integrators and distributors globally, providing remote engineering support, documentation, and cooperation with local partners for installation and service.

7. How does quartz IR support decarbonization goals?

Quartz IR is an electric heating technology that can be powered by low-carbon electricity. Process heat electrification is widely recognized as a key lever for industrial decarbonization, including in chemicals, as clean electricity becomes more available.

Call-to-Action (CTA)

If you are evaluating quartz infrared heating for reactors, tanks, pipes, or anti-corrosion coating lines, Huai’an Yinfrared Heating Technology can help you quickly assess feasibility and approximate sizing.

Share your basic process data—materials, chemical media, target temperatures, line speed or batch cycle, and current heating method—and our engineers can outline a practical concept using quartz infrared heating lamps and modular IR systems. Contact Huai’an Yinfrared Heating Technology or your local channel partner to start a structured discussion on design options, ROI, and implementation timing.

Last modified: 2025-11-28