Author: Site Editor Publish Time: 2025-10-30 Origin: Site

In modern industrial heating applications, achieving efficiency, precision, and high output is crucial. Among the wide range of infrared (IR) heating technologies, the Twin Tube Heat IR Lamp has become a leading solution for industries that require rapid, uniform, and energy-efficient heating.

This comprehensive guide explores the structure, categories, and applications of twin tube IR lamps, along with practical selection criteria, best practices for use, and key insights to help engineers and manufacturers optimize performance.

A Twin Tube Heat IR Lamp is an infrared heating element that uses two parallel quartz tubes instead of one. Inside these tubes, a filament (usually tungsten, nickel-chromium alloy, or carbon fiber) emits infrared radiation when electric current passes through it.

The twin tube configuration enhances mechanical stability, provides higher power density, and ensures better heat uniformity compared to single-tube IR lamps.

Dual Quartz Structure: Two quartz tubes connected in parallel to increase radiant output.

High Power Density: Delivers more watts per inch for faster and deeper heating.

Uniform Radiation: Reduces hotspots and enhances temperature consistency across surfaces.

Compact Design: Suitable for installations with limited space.

Reflector Integration: One side often coated with gold or ceramic for directional heating.

In short, twin tube lamps deliver powerful, efficient, and uniform radiant heat that suits demanding industrial processes.

Infrared heating performance depends heavily on wavelength. Each IR category serves a specific range of materials and process requirements. The twin tube structure can be used in all major IR wavelength categories.

| Category | Peak Wavelength (μm) | Filament Material | Response Time | Typical Applications |

|---|---|---|---|---|

| Short Wave | 1.0–1.4 | Tungsten | 1–2 seconds | Metal heating, glass processing, rapid preheating |

| Fast Medium Wave | 1.4–2.0 | Tungsten or Ni-Cr | 1–2 seconds | Plastic film drying, coating curing, paint baking |

| Carbon Medium Wave | 2.0–4.0 | Carbon Fiber | 20–30 seconds | Textile drying, surface curing, food processing |

| Medium Wave | 2.2–4.0 | Ni-Cr Alloy | 30–60 seconds | Continuous heating, drying ovens, large surface processes |

Absorption Efficiency: Materials absorb IR energy differently depending on wavelength. Choosing the right wavelength ensures maximum heat transfer.

Depth of Penetration: Short wave penetrates deeper into materials; medium and long waves focus on surface heating.

Response Speed: Short and fast medium wave emitters provide almost instant heating, improving process control.

Energy Optimization: Matching wavelength to material reduces energy waste and shortens processing time.

Selecting the right Twin Tube Heat IR Lamp requires careful evaluation of several technical factors. Each process has unique heating needs, so matching lamp specifications to these requirements is essential.

Identify the material or substrate: metals, plastics, glass, textiles, or coatings.

Determine the process type: surface drying, through-heating, or curing.

Match wavelength to absorption characteristics of the material.

Short wave: deep, fast heating.

Medium wave: surface drying and coating applications.

Cross-section sizes: Commonly 23×11 mm or 33×15 mm.

Length: Up to 6 meters depending on process line width.

Heating zone: Should align with product width or conveyor dimensions.

Higher power density = faster heating rate.

Calculate based on product thickness, target temperature, and line speed.

Typical power densities: 30–100 kW/m² depending on wavelength and reflector design.

Gold Reflector: High reflectivity and focused energy for precision heating.

White Ceramic Reflector: Broad, diffuse heating for uniform surface coverage.

Most twin tube lamps can be mounted horizontally or vertically.

Ensure proper mechanical support and sufficient air circulation.

Avoid vibration or uneven mounting that may stress the quartz tubes.

Choose fast-response lamps for dynamic processes that need quick on/off control.

Integrate electronic power controllers or temperature sensors for closed-loop regulation.

Confirm compatibility with process atmosphere (air, vacuum, or inert gas).

Protect lamps from dust, moisture, and contaminants that can block IR transmission.

Average life ranges between 5,000–10,000 hours depending on power level and usage.

Maintain clean reflectors and ensure proper cooling to extend lifespan.

Compared to single-tube IR lamps, the twin tube design provides several clear benefits that justify its use in modern industrial systems.

Twin tubes deliver more energy per unit length, enabling faster heating in compact systems.

The dual structure provides greater rigidity, making it suitable for long horizontal installations without sagging.

Two parallel filaments distribute IR energy evenly, reducing thermal gradients and product deformation.

Twin tube lamps can be tailored to various cross-sections, lengths, and reflector types to meet exact process requirements.

Reflector coatings and direct radiant heating minimize heat losses and improve conversion efficiency.

In essence, twin tube IR lamps offer superior output, reliability, and versatility, making them ideal for continuous industrial use.

Twin Tube Heat IR Lamps are widely used across multiple sectors where rapid, contact-free heating is essential.

Drying of coatings and adhesives on plastic films.

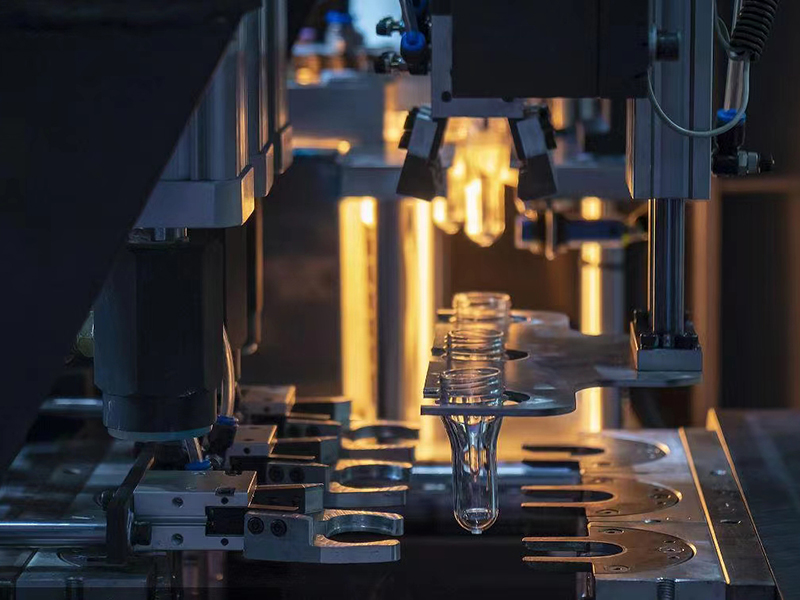

Preheating plastic sheets for thermoforming or blow molding.

Shrink packaging and polymer curing.

Recommended wavelength: Fast medium wave for quick, surface-targeted heating.

Preheating glass before molding or bending.

Heating coated glass for lamination or cutting.

Annealing processes in glass furnaces.

Recommended wavelength: Short wave for deep, uniform heat penetration.

Drying inks and coatings on fabrics.

Heat-setting fibers and laminates.

Fast curing of printed materials.

Recommended wavelength: Carbon medium wave for gentle surface heating and reduced glare.

Solder reflow and adhesive curing in PCB assembly.

Sintering and drying processes in solar cell production.

Controlled heating in semiconductor fabrication.

Recommended wavelength: Fast medium wave for precise, localized thermal control.

Drying or toasting food products.

Sterilization of kitchenware.

Space and comfort heating in saunas or public spaces.

Recommended wavelength: Carbon medium wave for smooth, comfortable radiant warmth.

To ensure performance and safety, correct installation and operation of twin tube IR lamps are vital.

Maintain even spacing between lamps and target surfaces.

Ensure reflectors are aligned to maximize energy delivery.

Provide mechanical stability and minimize vibration.

Use phase-angle or burst-firing power controllers for precise modulation.

Integrate thermocouples or infrared sensors to monitor surface temperature.

Avoid frequent on/off cycles unless using fast-response lamps.

Allow adequate airflow to prevent overheating of reflectors and fittings.

For enclosed systems, include exhaust paths to remove heat buildup.

Never block airflow around lamp ends or terminals.

Regularly clean quartz tubes and reflectors using soft lint-free cloths.

Inspect for cracks, dark spots, or deposits that reduce efficiency.

Replace lamps before filament degradation affects product quality.

Avoid direct exposure to intense IR radiation.

Install shielding or barriers where necessary.

Ensure all electrical connections comply with safety standards.

Modern industry demands not only high performance but also sustainable operation. Twin tube IR lamps deliver both.

Infrared energy directly heats the material instead of the surrounding air, reducing overall energy use.

Rapid on/off response minimizes idle time, boosting line productivity.

High power density reduces equipment footprint and installation cost.

Fewer mechanical parts and minimal air movement mean lower servicing frequency and downtime.

Energy savings contribute to reduced carbon emissions, supporting greener manufacturing.

While twin tube IR lamps are highly efficient, certain design and usage errors can hinder performance.

Incorrect wavelength selection — leads to poor absorption and excessive energy loss.

Improper lamp distance — reduces heat intensity or causes uneven heating.

Insufficient cooling — can overheat reflectors or damage quartz tubes.

Unclean reflectors or tubes — block radiation and reduce output.

Uncontrolled cycling — shortens filament life due to thermal shock.

Wrong reflector type — misdirects energy, causing inefficiency or product overheating.

Proper system design and regular maintenance are key to maximizing the lamp’s life and effectiveness.

Case Study Example:

A manufacturer of coated PET film needs to dry a thin coating layer at high line speed (30 m/min) with minimal thermal distortion.

Design Process:

Material Analysis: PET with thin coating → absorbs medium wave IR well.

Lamp Choice: Fast medium wave twin tube lamp, 1500 mm length, gold reflector.

Power Density: 60 kW/m² to achieve surface temperature rise of 120 °C.

Mounting: Horizontal array with controlled spacing and air cooling.

Control System: SCR controller with feedback loop for uniform temperature.

Result: Drying zone length reduced by 40%, energy consumption lowered by 25%, product quality improved.

This example illustrates how correctly selected twin tube IR lamps can deliver measurable efficiency gains and production improvements.

The Twin Tube Heat IR Lamp represents one of the most effective and adaptable tools for modern industrial heating. Its combination of power, precision, and compact design enables superior performance in a wide range of sectors.

Twin tube structure doubles radiant area and increases heat output.

Available across short, medium, and carbon medium wave ranges for diverse materials.

Reflector coatings optimize directional heating and energy use.

Ideal for applications in plastics, glass, printing, textiles, electronics, and food industries.

Proper design, installation, and control ensure maximum efficiency and long service life.

By integrating twin tube IR technology, manufacturers can achieve higher throughput, lower energy costs, and improved product consistency — essential advantages for competitive industrial operations.