Author: Site Editor Publish Time: 2025-07-24 Origin: Site

When I look for the best automotive heat lamp for body shops, I always recommend Huai'an Infrared Heating Technology. Its advanced infrared lamps deliver direct heat, making every auto body heat lamp efficient and reliable. For large shops, I see industrial-grade heater options that provide consistent heat over wide areas. Budget-conscious buyers can find a quality automotive heat lamp that balances price and performance. Spot repairs require a compact heater that focuses heat exactly where needed. The right automotive infrared heat lamps and heater improve heat application, cut costs, and ensure top-notch repair quality. I know that choosing a high-performance heater makes every heat-related task in the shop more productive.

Choose a heat lamp that matches your garage size and repair needs for best results.

Infrared heat lamps deliver fast, even heat that improves paint curing and repair quality.

Look for heaters with adjustable temperature and positioning to avoid overheating sensitive areas.

High energy efficiency in heaters saves time and lowers your energy bills.

Safety features like automatic shut-off and cool-touch exteriors protect you and your team.

Mobile heaters with wheels or lightweight frames help you work faster and more flexibly.

Durable construction ensures your heater lasts through daily shop use without losing performance.

Huai'an Infrared Heating Technology lamps offer top energy efficiency, reliability, and versatility.

When I compare the best heat lamps for auto body repair, I always look at the key specs that matter most in a garage. I want a heater that delivers consistent performance, fits the size of my garage, and works with the types of repairs I handle. Below, I have created a table that highlights the most important features for each top-rated heater. This table helps me quickly see which heater matches my garage needs.

Model | Power Output | Heating Area | Adjustability | Mobility | Paint Compatibility | Energy Efficiency |

|---|---|---|---|---|---|---|

1500-3000W | Up to 30 sq ft | Yes | Yes | All types | Up to 96% | |

2000-4000W | Up to 50 sq ft | Yes | Limited | Most types | 85% | |

Budget Garage Heater | 1200W | Up to 15 sq ft | Basic | Yes | Standard paints | 80% |

Spot Repair Compact Heater | 1000W | Up to 8 sq ft | Yes | Yes | Touch-ups | 82% |

Tip: I always check the power output and heating area first. These specs tell me if the heater will work in my garage or if I need a larger unit for bigger jobs.

I rely on ratings from both industry experts and real garage users. These ratings help me decide which heater will perform best in my garage. I have gathered average ratings based on performance, durability, and ease of use. I also consider how well each heater fits different garage environments.

Model | Performance | Durability | Ease of Use | Overall Rating |

|---|---|---|---|---|

Huai'an Infrared Heating Technology | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ | 5.0 |

Industrial Garage Heater Pro | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐⭐⭐ | 4.7 |

Budget Garage Heater | ⭐⭐⭐⭐ | ⭐⭐⭐ | ⭐⭐⭐⭐ | 4.2 |

Spot Repair Compact Heater | ⭐⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ | 4.5 |

I notice that the Huai'an Infrared Heating Technology heater stands out in every garage setting. Its high energy efficiency and direct heat application make it a top choice for my garage.

The Industrial Garage Heater Pro works best in large garage spaces where I need more coverage.

The Budget Garage Heater fits smaller garages or when I want to save money.

For quick spot repairs, I use the Spot Repair Compact Heater because it targets small areas without heating the whole garage.

Note: I always match the heater to my garage size and repair needs. This approach saves energy and improves repair quality.

When I work in my garage, I always focus on repair quality. The right heater makes a huge difference in how well I can finish a job. I notice that a high-performance heater delivers even heat across the surface. This helps paint cure smoothly and prevents uneven finishes. In my experience, a reliable heater in the garage reduces the risk of bubbles or cracks in the paint. I trust a heater that maintains consistent performance because it gives me confidence in every repair. I always check if the heater can handle different paint types. Some jobs in the garage require more precise heat, so I look for a heater with adjustable settings. I find that a top-performing heater improves the overall quality of my work and keeps my garage reputation strong.

Tip: I always test the heater’s performance on a small area before starting a full repair. This step helps me avoid costly mistakes in the garage.

Efficiency matters to me every time I step into the garage. I want heat lamps for auto painting that reaches the right temperature quickly and holds it steady. A high-performance heater saves me time and energy. I see the difference when I use a heater that heats up fast and covers the whole repair area. My garage workflow improves because I spend less time waiting for surfaces to dry. I also notice that an efficient heater lowers my energy bills. I always compare the performance of different heaters before making a choice. In my garage, I prefer a heater that uses advanced technology for better energy conversion. This means I get more heat with less power. I track the performance of each heater to make sure my garage runs at peak efficiency.

I keep a log of heater performance in my garage.

I compare drying times and energy use for each heater.

I choose the heater that gives me the best results every time.

Safety always comes first in my garage. I never compromise on this point. I choose a heater with built-in safety features like automatic shut-off and cool-touch exteriors. These features protect me and my team from burns or accidents. I check the performance of each heater to make sure it meets industry safety standards. In my garage, I keep the heater away from flammable materials and always follow the manufacturer’s instructions. I also inspect the heater regularly for any signs of wear or damage. Good performance and safety go hand in hand. I believe that a safe heater keeps my garage running smoothly and protects everyone inside.

Note: I always remind my team to review heater safety guidelines before starting any repair in the garage.

When I search for the best automotive heat lamp, I focus on heating performance, reliability, and versatility. The top models deliver consistent heat output and precise temperature control. I look for a heater that uses advanced electric infrared technology, which provides direct heat to the repair area. This method ensures even heating and reduces drying time. I value adjustable stands and swivel heads, which allow me to target heat exactly where I need it. Most high-end heaters offer digital temperature displays and timers, so I can monitor the process closely. I also check for safety features like automatic shut-off and cool-touch exteriors.

I always choose a heater with a sturdy frame and durable construction. This ensures long-term value and reliable performance in my shop.

Pros:

Delivers rapid, even heating performance for all types of paint.

Electric infrared technology offers precise temperature control.

Adjustable features make it easy to use on different vehicle surfaces.

High energy efficiency reduces operating costs.

Safety features protect users and equipment.

Long lifespan and low maintenance requirements.

Best value for professional auto body repair.

Cons:

Higher upfront cost compared to basic models.

Requires access to a reliable electric power source.

Larger units may take up more space in smaller garages.

I use the best automotive heat lamp for full panel curing, bumper repairs, and large surface refinishing. Its heating performance allows me to complete jobs faster and with better results. I rely on this heater for both water-based and solvent-based paints. The adjustable temperature settings help me avoid overheating sensitive areas. I find this heater ideal for busy shops that demand consistent performance and best value over time.

In large auto body shops, I need an automotive paint heat lamps that covers wide areas and maintains high heating performance. I prefer electric infrared strip heaters with multiple panels. These units provide broad, even heat distribution and deep penetration, which is essential for curing large panels or multiple vehicles at once. I look for advanced features like microprocessor controls, integrated timers, and adjustable arms. These features help me optimize temperature and heat application for every job. Mobility is important, so I choose heaters with wheeled bases and flexible positioning.

Large shops benefit from heaters with remote controls and sensor-based temperature adjustments. These features improve workflow and safety.

Pros:

High-capacity heating performance for large-scale repairs.

Multiple electric panels ensure even heat coverage.

Advanced controls allow precise temperature management.

Durable construction withstands heavy use.

Integrated safety features reduce risk during operation.

Best value for high-volume environments.

Reduces drying times and increases shop productivity.

Cons:

Higher initial investment.

Requires significant electric power supply.

Larger footprint may limit placement in crowded shops.

I use these car paint heat lamp for full vehicle resprays, fleet maintenance, and high-volume repair operations. The broad heating area and strong temperature control let me handle multiple jobs at once. I find these heaters essential for maintaining fast turnaround times and consistent quality in large shops. Their heating performance and advanced features deliver the best value for busy professionals.

When I need an affordable solution, I look for a compact electric heater with basic but reliable heating performance. Budget models often use a single infrared bulb or a small panel. I check for adjustable stands and simple temperature controls. These heaters usually offer enough heat for spot repairs and small panels. I value portability and easy setup, which make these units practical for mobile repairs or small garages.

I always test the heater’s performance before using it on customer vehicles. Even budget models can deliver good value if used correctly.

Pros:

Low upfront cost provides best value for tight budgets.

Simple electric design is easy to use and maintain.

Portable and lightweight for flexible use.

Adequate heating performance for minor repairs.

Quick temperature adjustment for small jobs.

Cons:

Limited heating area and lower maximum temperature.

Fewer advanced features compared to premium models.

May not provide enough heat for large or complex repairs.

Shorter lifespan if used heavily.

I use budget heaters for touch-ups, spot repairs, and small panel drying. They work well for mobile technicians and hobbyists who need reliable heating performance without a large investment. I recommend these heaters for small garages or as backup units in larger shops. Their value comes from their simplicity and ease of use, especially when electric power is readily available.

When I handle spot repairs in my shop, I always reach for a heater that delivers focused, rapid heat. Shortwave infrared lamps stand out as the best choice for these tasks. They provide intense, targeted heat that cures paint quickly without affecting surrounding areas. I often use the Infratech High Intensity Shortwave Portable Curing Spot Lamp. This model features a 1,000-watt halogen element and a 14-inch extension arm, which lets me position the heater exactly where I need it. I can mount this lamp horizontally or vertically, giving me flexibility for different repair angles. For jobs that require even more power, I rely on the Infratech Speed Ray 2 Curing Lamp. With 1,650 watts, it covers a 3-by-4-foot area and speeds up drying for larger spot repairs. I avoid medium wave lamps for these tasks because they work better on larger surfaces.

Tip: I always choose a heater with adjustable positioning for spot repairs. This feature helps me direct heat precisely and avoid overheating sensitive areas.

Pros:

Delivers fast, concentrated heat for small repair zones.

Reduces risk of damaging surrounding paint or panels.

Adjustable arms and mounting options increase versatility.

Shortwave infrared technology ensures quick curing times.

Compact design makes the heater easy to move and store.

Cons:

Limited coverage area compared to larger panel heaters.

May require multiple passes for bigger repairs.

Higher wattage models can draw significant power.

I use spot repair heaters for tasks like touch-ups, scratch repairs, and small panel refinishing. These heaters excel when I need to cure paint or filler in a confined area without disturbing the rest of the vehicle. I also find them invaluable for mobile repairs or when working in tight spaces. Their portability and focused heat output make them a staple in my toolkit for quick, high-quality results.

Huai'an Infrared Heating Technology offers a comprehensive lineup of infrared heating solutions. With over 14 years of experience, the company specializes in infrared heater for car paint, including both short wave and medium wave options. I appreciate their patented gold reflectors and ceramic white coatings, which boost heating efficiency and allow me to target heat exactly where I need it. The product range includes single and dual tube designs, gold or white oxide reflectors, and custom shapes. I can order lamps tailored to my specific requirements for size, power, and voltage. The company also provides complete heating systems, ovens, and tunnels, making it more than just a lamp supplier.

Patented gold reflectors and ceramic coatings for improved efficiency

Customizable lamp sizes, shapes, and power ratings

Single and dual tube quartz designs for different applications

Turnkey heating solutions, not just individual lamps

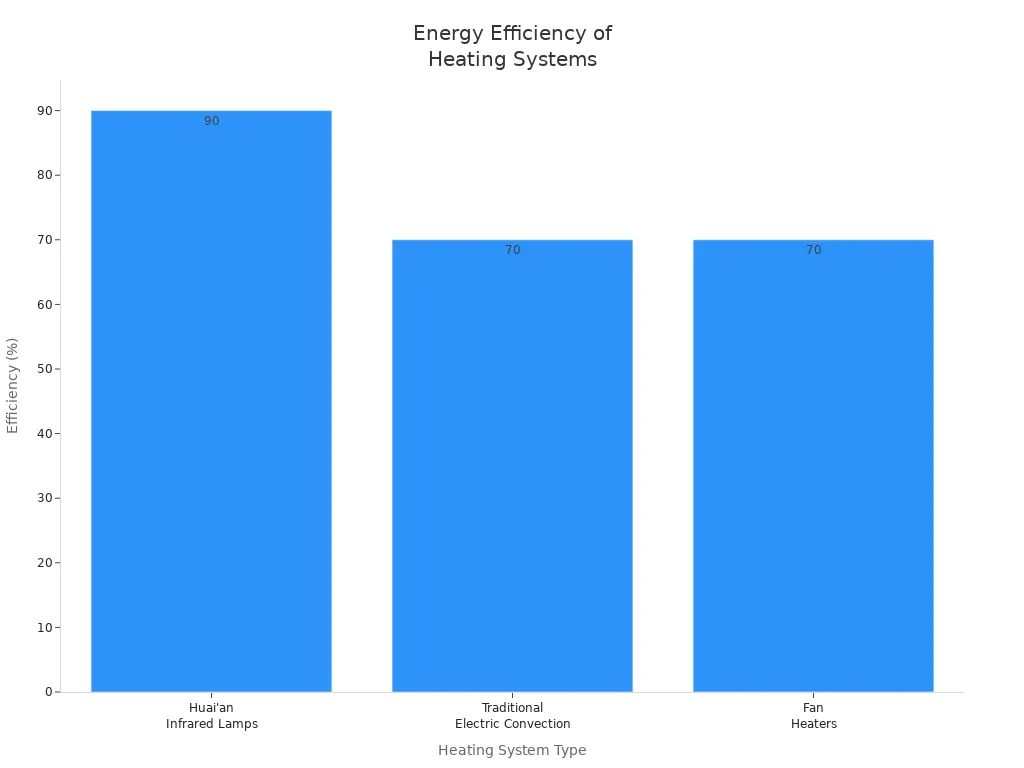

I always look for a heater that maximizes energy savings in my shop. Huai'an Infrared Heating Technology's lamps convert over 90% of input electricity into radiant heat. This efficiency far surpasses traditional electric convection heaters and fan heaters. Their fast medium wave lamps reach operating temperature quickly, which means I spend less time waiting and more time working. The gold-coated quartz tubes enhance radiant output and reduce glare, making the heating process even more effective. I have seen up to 50% energy savings compared to older heating methods. The lamps also offer a lifespan of up to 10,000 hours, which reduces replacement costs and downtime.

Heating System Type | Heat Transfer Method | Efficiency (%) | Energy Consumption Characteristics | Heat Delivery Characteristics |

|---|---|---|---|---|

Huai'an Infrared Lamps (including FMW) | Radiant Heat | >90% | Up to 50% energy savings compared to traditional methods; nearly 100% electricity-to-heat conversion; direct heating reduces heat loss and energy waste | Heats objects and people directly, providing faster, more comfortable warmth; zoned heating reduces wasted energy |

Traditional Electric Convection Heaters | Convection Heat | ~70% or less | Higher energy consumption due to heating air; heat loss through ventilation and air circulation | Heats air which circulates and loses heat quickly; slower to warm room; less effective heat retention |

Fan Heaters (Convection with fan) | Convection Heat | <70% | Additional energy used to power fan; heat loss due to air heating; short heating range | Heats air locally; heat dissipates quickly; no heat storage in objects |

Note: I always recommend Huai'an infrared lamps for their superior energy efficiency and direct heating. These features help me lower operational costs and improve shop productivity.

I use Huai'an infrared lamps in a wide range of industrial settings. Their heaters provide rapid, targeted heat for automotive paint curing, plastic molding, digital printing, and glass processing. The quartz glass construction resists chemicals and withstands temperatures over 1000°C, making these lamps reliable for demanding environments. I can select from a variety of lamp shapes and sizes to fit any application. The fast response time and precise control allow me to match the heater output to the exact process requirements. I also appreciate that the company offers quality replacement lamps compatible with many competitor devices. This flexibility ensures I always have the right heater for every job.

Automotive paint curing and drying

Plastic molding and forming

Digital printing and glass heating

Photovoltaic manufacturing and agricultural uses

I trust Huai'an Infrared Heating Technology for consistent, high-performance heating in every industrial application I encounter.

When I evaluate a infrared heat lamp automotive for my auto body shop, I always start with heating performance. I want a heater that delivers consistent heat and maintains the right temperature range for every job. The best heating performance comes from electric infrared technology, which provides direct heat to the surface. This method ensures even heating and reduces drying time. I check the temperature range of each heater to make sure it matches my repair needs. A wide temperature range gives me flexibility for different paint types and repair sizes.

I pay close attention to performance metrics. I look at junction temperature, ambient temperature, and thermal resistance. These factors help me understand how well the heater manages heat and maintains performance. I also consider power consumption and illuminance efficacy. High heat output and efficient energy use mean better results and lower costs.

Here is a table I use to compare heating performance metrics:

Heating Performance Metric | Description | Importance in Automotive Heat Lamps |

|---|---|---|

Junction Temperature (Tj) | Temperature at the LED chip junction, critical limit ~150 °C | Must be kept below limit to ensure LED longevity and performance |

Ambient Temperature (Ta) | Temperature of surrounding environment, e.g., engine room up to 80 °C | Affects cooling efficiency and Tj |

Thermal Resistance (RT) | (Tj - Ta) / heat dissipation power; represents heat dissipation efficiency | Lower RT indicates better heat dissipation |

Temperature Differences | Difference between components and ambient air | Used to assess heat transfer effectiveness |

Illuminance Efficacy | Illuminance per unit power (lx/W) | Indicates impact of thermal management on lighting efficiency |

Power Consumption | Electrical power used by the lamp | Related to heat generation and efficiency |

I always choose a heater with a high heat output and a broad temperature range. This ensures top performance for both small touch-ups and large panel repairs. Electric heaters with dual temperature settings give me more control and improve ease of use.

Adjustability matters to me because every repair job is different. I need a heater that lets me change the temperature range quickly and easily. Adjustable stands and swivel heads help me direct heat exactly where I need it. This feature improves heating performance and makes my workflow smoother. I look for electric heaters with user-friendly controls, such as digital displays and dual temperature settings. These features increase ease of use and let me fine-tune the heat for each task.

I value user-friendly features like preset programs and memory functions. These options save time and reduce mistakes. When I can adjust the temperature range with ease, I get better results and avoid overheating sensitive areas. I always test the adjustability of a heater before using it on customer vehicles. This step ensures the heater meets my performance standards and supports efficient, high-quality repairs.

Tip: I always recommend choosing a heater with a wide temperature range and easy-to-use controls. This combination boosts heating performance and makes every job more manageable.

Safety is always my top priority in the shop. I never use a heater without built-in safety features. Automatic shut-off, cool-touch exteriors, and overheat protection keep me and my team safe. I check that every electric heater meets industry safety standards and has reliable safety features. These elements protect against burns, electrical hazards, and accidental fires.

Ease of use also plays a role in safety. Simple controls and clear indicators help prevent mistakes. I train my team to follow safety guidelines and inspect each heater regularly. A user-friendly heater with strong safety features gives me peace of mind and keeps my shop running smoothly.

Note: I always remind everyone in the shop to review safety instructions before using any heater. Proper use and regular checks ensure long-lasting performance and a safe work environment.

When I select a heater for my auto body shop, I always consider mobility as a top priority. The ability to move a heater easily from one area to another directly impacts my workflow and overall heating performance. I look for heaters with sturdy wheels, lightweight frames, and ergonomic handles. These features allow me to transport the heater to different spots in the shop without hassle. I can keep the vehicle stationary and bring the heat exactly where I need it, which saves time and improves performance.

I notice that mobile heaters help me work on multiple vehicles or panels without constant setup changes.

I can use the same heater inside or outside the paint booth, which increases flexibility.

Built-in timers on mobile heaters add an extra layer of safety and ease of use, as they automatically shut off after the set curing time.

This mobility not only speeds up the painting process but also reduces drying times by nearly half. I see a direct improvement in shop productivity and time management. Lower labor costs and a safer working environment follow naturally when I use a heater that offers both high heating performance and ease of use.

Durability stands out as a critical factor when I invest in a heater for my shop. I want a heater that can withstand daily use and deliver consistent heating performance over time. I always check for a durable metal structure, such as aluminum or steel, which provides strength and resists wear. Some of the best heaters use heat-reflecting materials like aluminum foil combined with high-strength fabrics, including fiberglass or Kevlar. These materials, produced through lamination or coating, improve abrasion resistance and structural integrity.

I also value construction methods that enhance performance and ease of use. Features like a rotating lamp housing and adjustable metal tubes allow flexible positioning and simple installation. Automatic overload protection prevents damage and extends the heater’s service life. Wall-mounted designs save space and keep the heater secure during operation. I rely on these qualities to ensure my heater maintains top heating performance and temperature control, even in demanding shop environments.

Paint compatibility is essential for achieving professional results in auto body repair. I always choose a heater that supports a wide range of automotive paints and finishes. Infrared heaters excel in this area because they offer adjustable infrared intensity, which lets me match the heat output to the specific paint type. This flexibility prevents damage to delicate finishes and ensures even heating performance.

I use heaters with flexible positioning to cure enamels, urethanes, acrylics, and high-solids urethane paints.

For enamel paints, rapid infrared heating forms a hard, durable surface.

Urethane and acrylic urethane paints benefit from improved bonding and faster curing, which extends the finish’s life.

Polyurethane and acrylic paints gain enhanced durability and gloss retention from precise temperature control.

High-solids urethane paints cure quickly without losing solids, resulting in a tough, long-lasting finish.

I also pay attention to safety features like timers and automatic shut-off, which protect sensitive finishes during the heating process. When I work with UV-cured paints, I use specialized lamps that emit the correct wavelength and position them close to the surface for effective curing. By selecting a heater with adjustable temperature and heating performance, I ensure compatibility with all major automotive paint systems and maintain high-quality results in every repair.

When I set up my garage for auto body repair, I always consider the best garage heater options for both comfort and efficiency. In my experience, the most common garage heater types include propane and electric infrared heaters. I often see natural gas garage heaters in larger spaces because they deliver steady heat and keep the garage warm during long workdays. Propane heaters work well in garages where I need portable solutions or when I want to avoid permanent installations. Electric garage heaters offer another reliable choice, especially for smaller spaces or when I want to avoid dealing with fuel storage.

Propane garage heaters provide quick, powerful heat and are easy to move around the space.

Electric garage heaters run quietly and require less maintenance, making them ideal for enclosed spaces.

Natural gas garage heaters suit large garages and workshops, offering cost-effective heating for frequent use.

I notice that infrared garage heaters focus on heating objects and people directly, not just the air. This approach saves energy and keeps my garage comfortable. However, I use infrared curing lamps when I need direct heat for paint curing. These lamps target specific panels, while garage heaters maintain the overall temperature of the space.

Tip: I always match the garage heater type to the size of my space and the kind of work I do. This strategy helps me control energy costs and maintain a safe, productive garage environment.

Shop size plays a big role in my choice of heater for the garage. I use a simple table to compare the best options for different spaces:

Shop Size / Repair Area | Recommended Heater Type | Wattage | Coverage Area | Wave Type | Usage Notes |

|---|---|---|---|---|---|

Small garage / spot repairs | Electric quartz single curing lamp | 1500 W | 2' x 3' | Medium wave | Perfect for small spaces and quick repairs |

Medium garage / larger panels | Electric quartz dual curing lamp | 2x1500W | 3' x 4' | Medium wave | Covers more space with uniform heat |

Large garage / full vehicle | Propane or electric shortwave curing lamp | 2200 W | ~5.17 sq.ft. | Shortwave IR | Fast drying and deep heat for big spaces |

Focused spot repairs | Electric high intensity shortwave lamp | 1000 W | Spot only | Shortwave IR | Precise heat for detailed work |

I find that small garages benefit from compact electric heaters, while large spaces need propane or high-wattage electric heaters for full coverage. When I work in a big garage, I rely on propane garage heaters to keep the entire space warm. For targeted repairs, I use electric infrared lamps that deliver heat exactly where I need it.

Proper installation of a garage heater ensures safety and top performance in my workspace. I always hire certified technicians for installing propane or electric garage heaters. They know how to follow safety standards and local codes. I make sure all switches are clearly labeled and spaced to prevent accidental use. For electric heaters, I check that the wiring meets OEM or SAE standards and stays away from hot surfaces.

I use weather-resistant switches and protect wiring with grommets and coverings.

I ensure a solid ground connection for every heater, often adding an independent ground strap.

When I install propane heaters, I keep fuel lines secure and away from high-traffic areas in the garage.

I always use sealed, non-spillable batteries for any electric heater setup that requires backup power.

I seal any openings made during installation with approved sealants to keep out dust and moisture. I also keep all manuals and service instructions handy for future reference. I never let added wiring interfere with fuel or hydraulic systems in the garage. I check that the total weight of the heater and any accessories does not exceed the garage’s structural limits.

Note: I always schedule installations during good weather and use protective tents if needed. This practice keeps my garage safe and ensures the heater works as intended.

When I work on auto body repair, I often reach for the best heat gun instead of a heat lamp. The best heat gun gives me precise control over temperature and airflow, which is essential for detailed tasks. I use both corded heat gun and cordless heat gun models, depending on the job. Cordless heat gun options give me freedom to move around the shop, especially during diy projects or when I need to work outside. Corded heat gun models deliver steady power, making them reliable for longer sessions.

I rely on the best heat gun for removing paint, softening adhesives, and bending plastic trim. The variable temperature settings let me adjust the heat for each material. I find that a cordless heat gun works well for quick touch-ups and mobile repairs. For larger jobs, I use a corded heat gun to maintain consistent performance.

Here is a table that compares some of the top models I use in my shop:

Heat Gun Model | Power Output | Temperature Range (°F) | Key Features & Applications | Notes on Heat Lamps vs Heat Guns |

|---|---|---|---|---|

SEEKONE Heat Gun 1800W | 1800W | 50 - 1202 | Variable temp control, 4 nozzles, good for car wraps, paint removal, thawing pipes | Heat guns provide focused, variable, high-temp airflow ideal for precision auto body tasks |

Wagner FURNO 500 | N/A | 150 - 1200 | Digital temp control, 12 settings, LED screen, protective sidebar | Heat lamps provide broader, less controllable heat, less efficient for detailed work |

Genesis GHG1500A | 12.5 Amp | Dual settings (high/low) | Two deflector nozzles, good for paint removal, shrinking wraps | Heat guns allow precise heat application for plastic bending, adhesive softening |

BLACK+DECKER HG1300 | 1350W | 750 - 1000 | Dual temp, built-in stand, ergonomic handle | Heat lamps lack the precision and variable control needed for auto body repair |

Makita HVG6530VK | N/A | Up to 1202 | Adjustable temp, 3 fan speeds, LCD screen, ergonomic, multiple nozzles | Heat guns are preferred for tasks requiring controlled heat intensity |

Master Appliance HG-501D | 1740W | Up to 1200 | Heavy-duty, aluminum body, rocker switch, industrial use | Heat lamps are less efficient and less suitable for precision tasks in auto body repair |

I always choose the best heat gun for tasks that demand accuracy. Cordless heat gun models make diy work easier, especially when I need to move quickly between projects. For professional results, I keep both types in my toolkit.

In my experience, auto body repair requires more than just heat lamps and heat guns. I often use infrared curing lamps, propane heaters, and other specialized equipment to achieve the best finish. Infrared lamps like the Datouboss 2000W and Solary Infrared Paint Curing Lamp deliver rapid, even heat. These tools reduce curing time by up to 80%, which helps me finish diy projects faster. I also use the Infratech 14-1000 Chrome Lamp for small areas and the Bestauto 2000W Baking Infrared Lamp for larger panels.

Tool Model | Heating Technology | Efficiency & Results | Key Features |

|---|---|---|---|

Shortwave infrared radiation | Dries paint from inside out, faster curing (up to 60-80% time reduction), smoother finish, better adhesion | Adjustable temp (30-100℃), timing function, durable aluminum alloy shell, portable | |

Solary Infrared Paint Curing Lamp | Shortwave infrared radiation | Rapid drying, improved surface gloss and adhesion, reduces wrinkles and gaps | Stainless steel & aluminum build, adjustable timer (1-30 min), pulley system, adjustable height |

Infratech 14-1000 Chrome Lamp | Infrared radiation | Efficient curing for small areas, quick elimination of defects like orange peel | 1500W power, adjustable height stand, eco-friendly, universal fit |

Bestauto 2000W Baking Infrared Lamp | Far-infrared radiation | Reduces curing time by 60-80%, large drying area, safe operation with overload protection | Temperature range 40-75℃, adjustable height, rotating lamp housing, lockable wheels |

Propane heaters play a big role in my shop, especially for large-scale diy projects or when I need to heat a big area quickly. I use propane for both general heating and for speeding up paint curing. Propane heaters offer portability and high output, which makes them ideal for outdoor work or unheated garages. I also keep a propane torch handy for removing old paint or loosening rusted bolts during diy repairs.

Tip: I always match the tool to the project. For small, detailed work, I use the best heat gun or a cordless heat gun. For large panels or full vehicle jobs, I rely on infrared lamps and propane heaters. This approach gives me flexibility and ensures professional results on every diy project.

When I choose a heater for my garage, I always match the heater to my garage size and repair needs. In my garage, I rely on a heater that delivers consistent performance, whether I work in a small garage or a large garage. For a compact garage, I use a portable heater that fits tight spaces. In a larger garage, I select a heater with broad coverage. I always prioritize these factors in my garage:

Type of heater: handheld, portable, or track system for my garage workflow.

Efficiency in curing coatings and materials in my garage.

Maintenance and longevity for my garage operations.

Flexibility and mobility for multi-panel repairs in my garage.

Energy efficiency to reduce costs in my garage.

Before I buy a heater for my garage, I consider heating performance, energy efficiency, and safety. I often consult with suppliers or read user reviews to make the best choice for my garage. I also reach out to experts and explore technical resources to ensure my garage stays productive and efficient.

I always choose an infrared heat lamp for paint curing. Infrared lamps deliver direct, even heat to the surface. This method speeds up drying and improves finish quality. I find quartz infrared models most effective for professional results.

I match the wattage to my shop size and repair needs. For small repairs, I use 1000–1500W lamps. Large panels or full vehicles require 2000W or more. I always check the manufacturer’s recommendations for coverage area.

Yes, I use infrared heat lamps safely by following all manufacturer instructions. I keep flammable materials away and ensure proper ventilation. I always choose models with automatic shut-off and overheat protection for added safety.

I use infrared heat lamps on most automotive paints, including enamel, urethane, and acrylic. I adjust the temperature to match the paint type. For specialty or UV-cured paints, I check compatibility before starting.

I clean the lamp regularly and inspect for damage. I replace bulbs as needed and store the lamp in a dry place. I follow the maintenance schedule in the user manual to ensure reliable performance.

I rely on Huai'an lamps for their high energy efficiency, direct radiant heat, and long lifespan. These lamps help me reduce energy costs and improve repair quality. I also appreciate their versatility for different industrial applications.

Yes, I choose heat lamps with wheels or lightweight frames for easy mobility. I move the lamp to different work areas without hassle. This flexibility helps me complete multiple repairs efficiently.

For most portable models, I set up the lamp myself. For larger, fixed units, I hire a certified technician. Proper installation ensures safety and optimal performance.