Views: 0 Author: Site Editor Publish Time: 2025-11-28 Origin: Site

Drying PET slices and chips efficiently is critical for PET resin producers, film and sheet extruders, fiber manufacturers, and preform plants. If moisture is not removed properly, hydrolysis in the extruder reduces intrinsic viscosity (IV), causes yellowing, and leads to brittle products. Quartz infrared heating lamps give plant engineers, OEM/ODM dryer builders, and system integrators a compact, controllable way to crystallize and dry PET slices faster, often with lower specific energy consumption than large hot-air dryers.

This article explains where quartz infrared heaters fit best in PET slice and chip drying, how to select the right wavelength and power density, and what to watch out for during integration with existing crystallizers and hoppers.

Main opportunity: Conventional hot-air PET chip dryers and large drying towers are energy-intensive and slow to start up. They often require long residence times to reach very low moisture levels, increasing footprint and operating cost.

Where IR fits best: Quartz infrared heating lamps are well suited to PET slices, flakes, and pellets in pre-crystallization and final drying stages, typically upstream of extrusion, spinning, or preform injection. IR can combine heating, crystallization, and drying in one step in rotary drums or moving-bed systems.

Impact on energy and throughput: Well-designed PET IR dryers can reduce drying and crystallization times from several hours to tens of minutes, with significantly lower specific energy use compared with conventional hot-air dryers, depending on the baseline system and operating conditions.

Key technical decisions: Success depends on wavelength (short vs fast medium wave), installed power density, residence time, agitation/mixing, and control strategy (temperature and moisture feedback).

How Huai’an Yinfrared helps: Huai’an Yinfrared Heating Technology provides short-wave and fast medium-wave quartz infrared heating lamps, modular IR heating modules, and PET slice IR dryer concepts for OEM/ODM partners, including support for retrofitting hot-air PET dryers with infrared heaters.

Key takeaway: Infrared PET drying works best when you design the dryer around material flow, residence time, and moisture targets—not just “add more heat.”

Process overview

Many PET resin and packaging plants use hot-air or desiccant dryers on PET chips or pellets before extrusion. Typical conditions include:

Initial moisture: roughly 0.2–0.5% or higher for amorphous chips.

Target moisture: typically below about 0.005% for bottle-grade PET.

Dryer temperature window: 140–180 °C, depending on grade and IV.

Throughput: from a few hundred to several thousand kg/h.

Pain points of conventional hot-air drying

Long warm-up and residence times to reach low moisture levels.

Large dryer footprints (tall towers or multiple hoppers).

High energy consumption due to continuous heating of air and vessels.

Risk of local overheating and IV degradation if airflow is not uniform.

How quartz infrared heaters for PET chip drying change the game

By installing quartz infrared heaters for PET chip drying as a pre-heating section or hybrid IR+air zone, plants can:

Raise chip temperature rapidly and more uniformly before they enter the main desiccant dryer.

Shorten overall drying time or reduce the size of the hot-air section.

Improve responsiveness to throughput changes; IR power can be modulated quickly.

Reduce specific energy use in many cases by transferring energy directly into the chips rather than into large volumes of air.

This kind of infrared drying solution for PET resin pellets is particularly attractive where existing hot-air systems are bottlenecks or where energy prices are high.

Suitable Huai’an Yinfrared solutions

Short-wave quartz infrared heating lamps arranged around a moving bed, chute, or rotary drum.

Modular quartz infrared heating modules that can be mounted around existing hoppers or integrated into hot-air ducts.

Control packages that link IR power to throughput, inlet moisture, or dryer outlet dew-point.

Process overview

PET slices and flakes are widely used as feedstock for bottle-grade and film-grade resins, including recycled PET (rPET). The process typically includes:

Preheating amorphous PET slices.

Crystallization to prevent sticking and agglomeration at higher temperatures.

Final drying to achieve very low residual moisture before extrusion or solid-state polycondensation.

Quality requirements are strict: IV must be retained, and color shifts or yellowing must be avoided.

Problems with conventional crystallizers

Traditional fluidized beds or agitated towers rely on long residence times and indirect convective heat transfer. This can lead to:

Non-uniform temperature within the bed.

Agglomeration or sticking, especially for amorphous flakes.

Long start-up times and slow response to grade or throughput changes.

High energy consumption per kilogram dried and crystallized.

How short wave infrared lamps for PET crystallization and drying help

Short-wave IR penetrates PET particles and heats them volumetrically. In rotary drums or moving beds equipped with short wave infrared lamps for PET crystallization and drying:

Slices heat and crystallize quickly, often in tens of minutes rather than hours.

Combined crystallization and drying in a single IR drum or tower becomes feasible.

Agitation and tumbling in the drum prevent clumping and improve uniformity.

IR power can be controlled to keep PET temperature safely below degradation thresholds, preserving IV and color.

Suitable Huai’an Yinfrared solutions

High-power short-wave quartz IR lamps with optimized reflectors for drum or tower applications.

Fast medium-wave quartz IR lamps where gentler surface heating is desired.

PET slice crystallizer infrared dryers that integrate lamps, mixing elements, and exhaust systems into one modular unit.

Process overview

Smaller compounding plants, masterbatch producers, and specialty film lines often process multiple PET grades, colors, or blends. Their requirements include:

Frequent product changeover.

Limited floor space for large dryers.

Desire to minimize energy waste when lines are stopped.

Pain points with legacy equipment

Oversized hot-air dryers originally designed for larger plants.

Long warm-up times and poor part-load efficiency.

Difficulty in maintaining consistent outlet moisture during frequent stops and starts.

Benefits of an energy efficient PET slice drying system

A modular energy efficient PET slice drying system based on quartz IR can:

Fit into a much smaller footprint than tall drying towers.

Reach operating temperature quickly, supporting stop/start and partial-load operation.

Use zoned IR modules to match power input to actual throughput, avoiding over-drying and wasted energy.

Suitable Huai’an Yinfrared solutions

Modular quartz infrared heating modules integrated with compact hoppers or sliding-bed dryers.

IR cabinets where PET slices move on vibrating trays or screw conveyors under IR lamps.

OEM integration kits (emitters, reflectors, control components) that machine builders can adapt into their own dryer designs.

Pro tip for plant engineers: When you evaluate IR-based PET dryers, look at kWh per kilogram of dried PET and total residence time at temperature—not only installed kW.

Definition

Infrared wavelength band describes the main emission range:

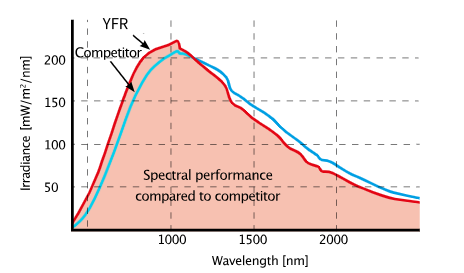

Short-wave: approximately 0.8–1.5 µm

Fast medium-wave: approximately 1.4–2.0 µm

Standard medium-wave: approximately 2–3 µm

Why it matters

PET absorbs IR in parts of the near and mid-infrared spectrum; water within chips also has strong absorption bands.

Short-wave IR penetrates PET granules and heats them volumetrically, beneficial for rapid crystallization and drying.

Fast medium-wave IR can give slightly gentler heating of surfaces and near-surface moisture.

Typical choices for PET drying

Short-wave quartz IR lamps: preferred for high-throughput PET slice preheating, crystallization, and drying.

Fast medium-wave quartz IR: used when PET grades or additives are sensitive to very rapid surface heating or when deeper moisture migration is needed.

Definition

Power: total electrical rating of lamps or modules feeding a zone.

Power density: installed IR power per unit area of PET bed or drum wall (kW/m²).

Why it matters

Determines how quickly PET slices reach drying temperature.

Oversizing power density without control can cause local overheating or IV degradation.

Too low power density leads to long residence times and bulky equipment.

Typical ranges for PET slice drying

Roughly 30–80 kW/m² for intensive pre-crystallization and drying zones in rotary IR drums or cascading trays.

Roughly 15–40 kW/m² for hybrid IR+hot-air retrofits where IR supports, but does not replace, existing dryers.

Short-wave quartz tube lamp

Tungsten filament in a quartz glass envelope, often with gold or ceramic reflector coating. Very fast response (seconds); well suited to start/stop operation and power modulation.

Fast medium-wave quartz IR lamp

Modified filament and envelope design to emit in the fast medium-wave band. Slightly slower response than short-wave but still fast enough for PET dryers.

Carbon/standard medium-wave IR heater

Carbon filaments or other emitters tuned to classic medium-wave spectrum. Lower power density and slower response; usually for low-temperature preheating stages.

Modular quartz infrared heating module

One or more lamps plus reflectors, insulation, housing, and electrical terminations. Simplifies design and maintenance compared to mounting bare lamps.

Emitter length / panel size

Common emitter lengths range from about 0.5–2.0 m. Modules can be assembled to follow the geometry of drums, conical hoppers, or flat-bed dryers.

Zoning

Divide the dryer into multiple axial and circumferential zones.

Apply higher power in wet-inlet zones and lower power in dry-outlet zones.

Enable partial-load operation by switching off unused zones.

Surface temperature

Lamp surface temperature can exceed 1,000 °C, but PET material typically remains in the 140–180 °C range. Careful tuning ensures PET does not exceed temperature limits that cause IV loss or yellowing.

Response time

Short-wave IR lamps reach useful output in seconds, letting the dryer follow throughput changes quickly. Compared with hot-air systems that may take tens of minutes to stabilize, IR dryers can respond in minutes.

Working distance

Distance from lamp to PET bed or drum wall is often 150–400 mm. Closer distances increase intensity but require more careful design to avoid hot spots.

Layout

In rotary drums, PET is tumbled through the IR field; in hoppers, it may cascade or flow in a moving bed. Lamp orientation and reflector design must account for material movement so all particles see sufficient radiation.

On/off control

Basic; suitable for small pilot rigs or simple batch dryers.

SSR/SCR phase-angle or burst-firing control

Provides smooth power modulation from 0–100% per zone. Common in continuous IR PET dryers.

PID, PLC, and fieldbus integration

PID loops can use temperature or moisture feedback to stabilize the process. PLC recipes link IR power setpoints to PET grade, throughput, and target moisture. Line integration supports data logging and alarms.

Enclosure

IR modules are typically housed in insulated steel enclosures around drums, hoppers, or channels. Dust, fines, and off-gas management must be considered in design.

Insulation

Proper insulation minimizes heat losses and keeps outer-surface temperatures safe for operators.

Ingress protection

Electrical components exposed to dust-laden air may require enhanced ingress protection and sealed junction boxes.

| Infrared Solution Type | Wavelength Band | Typical Power Density | Response Time | Recommended PET Applications | Control Options |

|---|---|---|---|---|---|

| Short-wave quartz IR lamp | Short-wave | High | Very fast | High-throughput PET slice preheating/drying | On/off, SSR, SCR, PLC |

| Fast medium-wave quartz IR lamp | Fast medium-wave | Medium–high | Fast | PET crystallization, gentle chip drying | On/off, SSR, SCR, PLC |

| Modular quartz infrared heating module | Short/medium | Medium–high | Fast | Retrofitting hot air PET dryers with IR sections | On/off, SSR, SCR, PLC |

| Carbon/standard medium-wave IR heater | Medium-wave | Low–medium | Medium | Low-temperature PET preheating or mixing stages | On/off, PID, PLC |

If/then rules

If you need to minimize drying time and have high throughput (for example, ≥1,000 kg/h), use short-wave quartz IR lamps as the primary heating source.

If your PET grades are sensitive to very rapid heating or you prioritize gentle crystallization, consider fast medium-wave quartz IR lamps or mixed short-/fast-medium zones.

If you want to retrofit existing hot-air PET dryers, choose modular quartz infrared heating modules that can be installed in front-end preheating sections or in recirculation ducts.

If your application is mainly preheating or conditioning at lower temperatures, medium-wave or carbon IR heaters can be sufficient.

Mini decision flow (simplified)

Start: PET slice/chip drying requirement

Yes → modular quartz IR sections integrated with existing dryers

No → design new IR-dominant PET slice drying system

Yes → short-wave quartz IR primary + optional fast medium-wave zones

No →

Yes → compact IR drum or IR hopper with short-wave lamps

No → hybrid IR + hot-air solution

Floor space limited?

Throughput ≥ 1,000 kg/h?

Is retrofitting hot air PET dryers with infrared heaters a priority?

Mains voltage and phase

PET plants often operate at 380–480 V three-phase. Confirm available capacity and short-circuit levels early. Distribute IR loads evenly across phases and sections to avoid unbalance and transformer issues.

Wiring, load balancing, and protections

Use high-temperature cable and glands near hot zones. Provide separate breakers or fuses per lamp string or module, plus main isolation switches for each dryer.

Control strategies

Combine on/off control for enabling zones with analog power control using SCR drives. Link power setpoints to throughput and inlet moisture or dew-point where possible. Implement safe power-down sequences in case of fan failure or conveying stops.

Control cabinet layout hints

Separate power electronics (SCRs, contactors) from PLC/control areas with appropriate cooling and dust protection. Include clear labeling, lamp-fault indication, and local/off/remote mode selection.

Mounting options

Lamps in removable cassettes on the shell of rotary drums.

Modules forming “rings” around cylindrical hoppers or cones.

Flat modules above/below trays or channels in cascading systems.

Distance from heater to PET bed

Keep within a design window (for example 150–250 mm) to balance intensity and uniformity. Use mixing paddles, screws, or drum flights so particles do not stay permanently in hot spots.

Flow patterns and residence time

Residence time is a key design variable; it depends on drum speed, fill level, and chip size. IR power sizing and zoning should be calculated from required residence time to achieve target moisture at allowed temperature.

Reflectors, shielding, and insulation

High-reflectivity surfaces behind lamps direct IR into the product and improve efficiency. Shields protect bearings, seals, and sensors from direct radiation. Insulation thickness is chosen to keep outer surfaces below plant safety limits.

Maintenance and access

Design hinged doors, removable cassettes, or lamp drawers for quick replacement. Allow access for cleaning quartz tubes and reflectors to remove dust and PET fines.

Defining the drying profile

Inputs: initial moisture, target moisture, allowed maximum PET temperature, desired IV retention. Outputs: residence time, IR power per zone, mixing/agitation strategy.

Sensors and feedback

Use thermocouples or RTDs in the PET bed and exhaust gas. Use infrared pyrometers for surface temperature monitoring where line-of-sight is available. Complement with online or periodic moisture measurements at dryer outlet.

From trial-and-error to structured testing

Start with conservative power and gradually increase until outlet moisture is within specification. Characterize drying curves versus power density and residence time for each key PET grade. Create standard recipes in the control system and protect them with appropriate access levels.

Tuning examples

If IV loss is observed, lower peak PET temperature by reducing power in final zones and increasing residence time slightly.

If moisture specifications are not met, increase power in early zones and verify mixing uniformity before extending dryer length.

If yellowing appears, check exhaust conditions and ensure efficient removal of degradation products and fines.

Lab tests

Small batch tests with IR lamp rigs to study heating and drying kinetics. Measure moisture versus time and temperature, IV retention, and color changes.

Pilot line validation

Use a pilot-scale IR dryer in front of existing extrusion or preform lines. Validate that finished products meet mechanical and optical specifications.

Full-scale acceptance criteria

Throughput: kg/h at specified moisture and IV targets.

Temperature uniformity: acceptable spread across bed or drum at steady state.

Specific energy consumption: kWh per kg dried PET compared to baseline hot-air system.

Product quality metrics: moisture content, IV retention, color (for example b*), and any downstream performance tests.

Standards and directives (examples)

Industrial IR PET dryers may fall under general electrical and machinery safety frameworks, depending on region. Additional norms may apply to food-contact PET or packaging lines, but IR heaters themselves are usually part of the broader machine.

Thermal and mechanical safety

Provide guards and barriers to prevent contact with hot surfaces. Use interlocks on inspection doors so IR power is removed before access is possible.

Fire and dust explosion prevention

PET dust and fines can be combustible; manage accumulation with appropriate housekeeping and extraction. Use over-temperature protection and link IR power to fan operation to avoid hot, stagnant conditions.

Electrical safety

Ensure proper grounding, short-circuit, and earth-fault protection. Provide lockout/tagout provisions for maintenance and follow local electrical codes.

Huai’an Yinfrared can provide technical documentation to support your overall conformity assessment and help OEMs integrate IR modules into compliant machine designs.

Engagement models

Supply of standard quartz IR lamps and modules for PET applications.

Custom emitters and modules designed around specific drums, hoppers, or dryers.

Complete IR PET slice drying systems or hybrid IR+hot-air retrofit packages.

MOQ and sample policies

Reasonable MOQs for standard lamps to support stocking and replacement, plus sample lamps and pilot modules to support lab and pilot testing before large orders.

Lead times (indicative)

Standard lamps: shorter lead times, based on existing designs.

Custom modules and systems: additional weeks for engineering, modeling, and documentation.

Private label / co-branding

Options for machine builders to integrate Huai’an Yinfrared modules under their own nameplate while leveraging proven IR components.

Documentation and support

3D CAD models, wiring diagrams, thermal layout proposals, and application notes specific to PET drying, plus remote engineering support for sizing, layout, and commissioning.

Assumptions:

Conventional hot-air PET dryer uses 0.25 kWh/kg of dried PET.

IR-assisted dryer uses 0.15 kWh/kg at the same throughput.

Throughput: 4,000 kg/h.

Operating hours: 6,000 h/year.

Energy cost: 0.12 USD/kWh.

Additional investment in IR hardware: 250,000 USD.

| Item | Conventional Hot Air Dryer | IR-Assisted PET Slice Dryer |

|---|---|---|

| Specific energy use (kWh/kg, assumed) | 0.25 | 0.15 |

| Annual energy use (kWh/year) | 6,000,000 | 3,600,000 |

| Annual energy cost (USD/year) | 720,000 | 432,000 |

| Estimated annual energy cost saving | – | 288,000 |

| Simple payback on additional IR (years) | – | < 1 |

Actual performance will depend on your existing dryer efficiency, operating profile, and how aggressively IR is used (for example, warm-up, partial load, and stop/start strategies).

Common pitfalls in PET slice drying with IR

Wrong wavelength selection, reducing absorption efficiency for PET and moisture.

Under-sizing IR power, failing to achieve target moisture at rated throughput.

Neglecting mixing and residence time, assuming more power alone will compensate for poor material flow.

Insufficient process control, running only on lamp power percentage without stable temperature or moisture feedback.

Ignoring dust and fines, not designing for cleaning and extraction of PET dust around lamps and reflectors.

Missing safety interlocks between IR power, fans, and conveying equipment.

Practical benchmarks

Heat-up time

IR PET dryers often bring chips from ambient to drying temperature in minutes rather than tens of minutes or hours.

Temperature uniformity

Aim for a narrow temperature band in the PET bed to avoid both under-drying and local overheating.

Specific energy consumption

Track kWh per kilogram of dried PET at the plant scale; this is the key KPI for justifying IR investments.

Huai’an Yinfrared QA philosophy

Huai’an Yinfrared Heating Technology emphasizes:

Controlled sourcing and inspection of quartz tubes, filaments, and reflector materials.

Functional testing of lamp assemblies and modules before shipment.

Burn-in and thermal cycling on representative products.

Documentation and traceability that support OEMs’ own QA and validation procedures.

Start from your throughput (kg/h), inlet and outlet moisture targets, and allowable PET temperature. Use lab or pilot tests to determine how much energy is required per kilogram. From that, calculate installed power and zone power density, typically in the 30–80 kW/m² range for intensive IR zones.

In some cases, yes; in others, a hybrid IR+hot-air configuration is more practical. For retrofits, IR is often used as a preheating and partial-drying step that reduces load on existing dryers and increases throughput without adding tower height.

Many infrared rotary dryers and IR-assisted systems show significantly lower specific energy consumption than conventional hot-air dryers, sometimes by tens of percent, but actual savings depend on your baseline system, load factor, and control strategy.

If the process is properly designed and controlled, IR drying and crystallization can maintain IV and color within specification. As with any heating method, excessive temperature or residence time can cause degradation, so power, mixing, and monitoring must be engineered carefully.

Typically: PET grade and initial moisture, target outlet moisture, throughput, preferred operating temperature range, available footprint, current dryer type (if any), and local mains voltage and power capacity.

Lamp life depends on filament loading, switching frequency, and cleanliness of the environment. With correct design and maintenance, lamps provide long service life; PET dust and fines should be managed to keep lamp surfaces and reflectors clean.

Yes. Huai’an Yinfrared can provide customized lamp and module designs, thermal layout support, and documentation packages that OEMs can incorporate into their own PET dryers, with options for private labeling.

If you run PET drying, crystallization, or recycling lines and are exploring quartz infrared heating lamps for PET slice drying, the most direct next step is a data-based feasibility assessment. Share your PET grade, throughput, moisture targets, and current dryer configuration with Huai’an Yinfrared Heating Technology, and we can outline an initial IR sizing and integration concept.

From there, we can help plan lab or pilot tests, refine the IR system design, and estimate potential energy and throughput benefits before you commit to a full-scale retrofit or new line.

Last modified: 2025-11-28