Author: Site Editor Publish Time: 2025-08-05 Origin: Site

I have seen how infrared oven industrial turn-key solutions transform manufacturing standards. Yinfrared's Industrial Infrared Oven Heat Lamp delivers rapid, uniform, and energy-efficient processing. This technology supports precise temperature control, which helps achieve superior product quality. Custom design, seamless integration, and advanced automation fit unique production requirements. Real-world results show measurable improvements in consistency and finish.

Infrared ovens heat products directly with electromagnetic waves, providing fast, uniform, and energy-efficient processing.

Uniform temperature control reduces defects like warping and uneven curing, leading to higher product quality and fewer rejects.

Infrared ovens speed up production by heating materials faster than conventional ovens, increasing throughput and reducing bottlenecks.

These ovens improve surface finish by delivering smoother coatings and consistent color, essential for industries like automotive and food.

Infrared technology supports diverse applications including automotive paint curing, food baking, powder coating, and plastics thermoforming.

Energy savings of 15% to 35% are common due to direct heating and smart controls, helping reduce operational costs and support sustainability.

Infrared ovens require low maintenance because they have fewer moving parts and built-in filtration, ensuring reliable, long-term operation.

Advanced automation and smart controls enable precise temperature management, remote monitoring, and continuous quality improvement.

I have seen firsthand how infrared oven industrial systems use direct energy transfer to heat products. Unlike traditional ovens that heat the air, infrared ovens send electromagnetic waves straight to the product surface. This method skips the air and focuses energy exactly where it is needed. The result is a rapid and efficient heating process. I often recommend this approach for industries that require precise and consistent results.

Uniform temperature is critical for product quality. Infrared oven industrial solutions deliver even heating across the entire surface of the product. I have noticed that this uniformity reduces the risk of hot or cold spots, which can cause defects. The technology uses specialized heating elements and reflectors to maximize heat distribution. Here is a table that summarizes the fundamental principles of infrared heating technology:

Aspect | Description |

|---|---|

Fundamental Principle | Infrared heating transfers heat via electromagnetic infrared waves directly to objects, bypassing air heating. |

Heating Elements | Use of tungsten, quartz, ceramic, carbon fiber, halogen, or metal-sheathed elements that emit infrared radiation. |

Reflectors | Designed with materials like aluminum, stainless steel, ceramic, quartz, sometimes coated with gold or ruby to focus and maximize heat transmission and minimize energy loss. |

Types of Infrared Heaters | Quartz (short wavelength, high temp, intense heat), Ceramic (medium wavelength, cost-effective, reliable), Metal-sheathed (durable, high temp, industrial use). |

Wavelength Categories | Near-Infrared (0.78-1.5 microns, high temp, less absorptive), Medium-Wave (1.5-3 microns, better absorption, used in drying/curing), Far-Infrared (3-1000 microns, lower temp, high absorption by surfaces). |

Industrial Applications | Drying, curing, welding, embossing, laminating, stamping, metal pressing, plastic welding, composite curing. |

Advantages | Rapid, uniform, energy-efficient heating with precise control, reduced operational costs, and suitability for various industrial processes. |

Temperature Range | From several hundred °C up to 3600°C depending on heater type and wavelength. |

When I compare infrared oven industrial systems to conventional ovens, I see a clear difference in efficiency. Infrared ovens transfer heat directly to the product surface through electromagnetic radiation. This process uses less energy because it does not require heating the air or the oven chamber. For example, infrared ovens often operate at a lower duty cycle than convection ovens, which means lower heating costs. I have found that retrofitting infrared heating elements into existing ovens can further improve energy efficiency and reduce operational expenses.

Process speed is another area where infrared oven industrial technology excels. Infrared ovens heat objects directly, so there is minimal energy loss to the surrounding air. This direct approach leads to faster heating times and higher throughput. I have observed that infrared heating elements can be tuned to specific wavelengths, which match the material being processed. This tuning minimizes heating time and energy use. In my experience, these features allow manufacturers to increase conveyor speeds and reduce production bottlenecks.

Tip: Infrared ovens can be integrated into automated lines to further boost process speed and consistency.

I have seen how infrared oven industrial solutions dramatically reduce warping in finished products. The direct and uniform heating method excites molecular bonds within coatings or materials, which allows for rapid and even curing. This process minimizes overheating and prevents issues such as warping or degradation. When I use these ovens, I notice that parts receive the exact amount of energy needed for optimal curing. This level of precision means that the risk of defects caused by over- or under-curing drops significantly. In my experience, this translates to less waste and more consistent product quality.

Lower reject rates stand out as one of the most tangible benefits I observe with infrared oven industrial technology. The improved process control and faster curing times lead to fewer defects and higher quality outcomes. For example, gas catalytic infrared ovens cure powder coatings without relying on heated, moving air. This reduces cross-contamination and powder blow-off, which often cause defects in traditional ovens. As a result, I see cleaner, higher quality finished parts and a noticeable reduction in rejected batches.

Note: Faster and more uniform curing not only improves quality but also boosts production efficiency by reducing the need for rework.

I have found that industrial infrared ovens deliver smoother coatings on a wide range of products. The precise and uniform heating directly targets coated surfaces, minimizing heat loss and ensuring even curing. This approach reduces common defects such as unevenness, wrinkling, or surface blemishes. Rapid heat-up times and excellent temperature control help maintain the integrity of the coating. When I work with complex shapes, features like rotating fixtures and multi-zone heating ensure that every surface receives the right amount of heat, resulting in a flawless finish.

Color consistency is critical in industries like automotive and consumer goods. I rely on infrared oven industrial systems because they provide the temperature control needed to avoid color variation. The efficient radiant heat transfer ensures that coatings cure evenly, preserving color integrity. In practical applications, such as powder coating, I have seen infrared ovens cure coated parts up to three times faster than convection ovens. This speed helps maintain consistent color application and prevents issues like fading or patchiness. The reduced air movement also minimizes contamination risks, further supporting high-quality, color-consistent finishes.

Surface Finish Benefit | How Infrared Ovens Help |

|---|---|

Smoother coatings | Uniform, direct heating; less wrinkling |

Color consistency | Precise temperature control; even curing |

Fewer blemishes | Minimal air movement; reduced dust |

Consistent curing starts with uniform drying. I have reviewed case studies from leading manufacturers, especially in auto assembly plants, that show how integrating industrial infrared drying ovens leads to faster drying times and higher product quality. These ovens use direct infrared radiation to heat materials, which results in even drying and fewer defects compared to traditional methods. Research by the American Society of Heating, Refrigerating and Air-Conditioning Engineers reports that infrared drying ovens can reduce drying time by up to 30% and energy consumption by up to 50%. This efficiency supports consistent curing and uniform drying across a variety of manufacturing applications.

Auto plants report faster drying and fewer defects.

Comparative analyses show more even drying than convection ovens.

Studies confirm up to 20% lower production costs due to improved drying uniformity.

Reliable adhesion is essential for product durability and performance. I have seen how adjustable wavelength settings and advanced temperature control systems in infrared ovens enable precise heat distribution. This precision ensures that adhesives and coatings bond properly to substrates. When I use these ovens, I notice that the risk of incomplete curing or weak adhesion drops sharply. The result is a finished product that meets strict quality standards and performs reliably in the field.

I have worked with many automotive manufacturers who rely on infrared oven industrial solutions for paint curing. These ovens deliver precise, uniform heat that ensures every vehicle part receives consistent curing. I see how this technology prevents defects like warping, uneven resin distribution, and paint flaws. The controlled environment inside the oven allows for exact temperature and humidity settings, which means the finish always meets strict industry standards. I often recommend integrating these ovens with automated conveyor systems to boost throughput and maintain quality. The automotive sector continues to adopt these ovens rapidly, driven by the need for high-quality finishes and faster production cycles.

Component bonding in automotive manufacturing demands strong, reliable adhesion. I use infrared oven industrial systems to achieve this. The direct, targeted heating supports even curing of adhesives and composite materials. This process improves the mechanical properties of bonded parts, such as hardness and durability. I have seen how these ovens help manufacturers meet rigorous standards for safety and performance. Integration with robotics and process control systems further enhances consistency and traceability, which is essential for modern automotive production.

Note: Automotive manufacturers benefit from the flexibility of infrared ovens, which can handle a wide range of materials and part sizes.

In food processing, I use infrared oven industrial technology to improve baking results. These ovens transfer heat rapidly and penetrate the surface of baked goods, which shortens baking times and preserves moisture. I have noticed that bread baked with infrared ovens retains more water in the center, resulting in a softer texture and longer shelf life. The precise control over temperature and heat distribution ensures even baking, which is critical for product quality. I often combine infrared with other heating methods to achieve the best sensory qualities, such as color and texture.

Dehydration processes benefit greatly from infrared oven industrial solutions. I have observed up to 51% less energy consumption compared to traditional hot air drying. Infrared ovens heat food internally by vibrating water molecules, which drives moisture outward efficiently. This method not only reduces drying time but also preserves the texture and nutritional value of the food. I recommend these ovens for high-value, temperature-sensitive products because they maintain quality while improving efficiency. The non-contact, chemical-free process also supports food safety and sustainability.

I have seen infrared oven industrial systems revolutionize powder coating operations. These ovens cure powder coatings up to ten times faster than convection ovens. For example, one automotive parts manufacturer cut curing time in half and saved thousands of dollars each month by switching to infrared technology. The ovens provide precise temperature control, which is vital for uniform curing on parts with complex shapes. I often use programmable logic controllers to optimize heat application and ensure repeatable results. The reduced oven footprint and lower operating costs make this solution attractive for many industries.

Wood finishing requires careful control of heat to avoid damaging the material. I use infrared ovens to apply and cure finishes quickly and evenly. The direct heat minimizes airflow, which reduces contamination and improves the final appearance. I can zone and size these ovens to match specific production needs, which increases flexibility. The result is a smooth, durable finish that meets customer expectations.

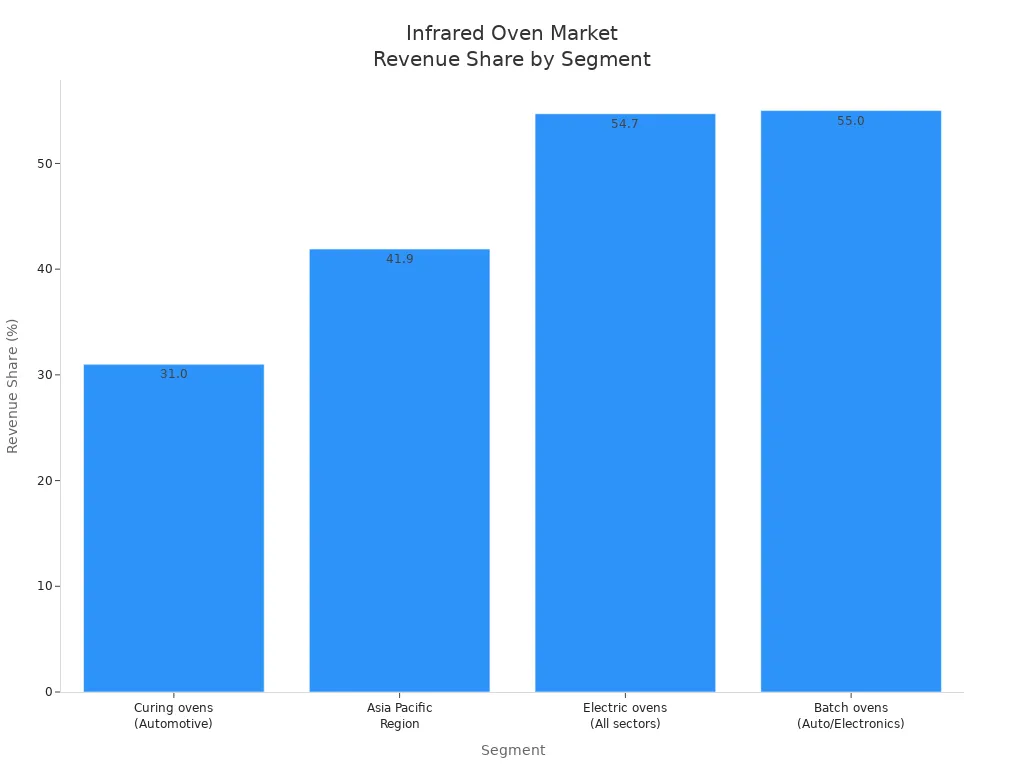

The chart above highlights the strong market presence of curing ovens in automotive and other sectors, reflecting the widespread adoption of infrared oven industrial solutions.

I have worked with many manufacturers who rely on advanced heating solutions for plastics processing. Thermoforming requires precise and rapid heating of plastic sheets before shaping them into final products. I often recommend integrating infrared ovens for this step. These ovens deliver targeted heat directly to the material, which allows for fast and uniform temperature rise. This approach reduces cycle times and improves the consistency of the formed parts.

In my experience, automation plays a crucial role in modern thermoforming lines. For example, I have seen how KraussMaffei's FiberForm process uses an industrial infrared oven to preheat composite sheets. This step is essential before over-molding or back-molding operations. The automated system ensures each sheet reaches the ideal temperature, which leads to better material flow and fewer defects. I have noticed that this method supports high-rate production, especially in automotive and aerospace applications where quality cannot be compromised.

I also value the flexibility of infrared ovens. I can adjust the heating zones to match different sheet sizes and thicknesses. This feature helps me maintain tight process control, even when switching between product types. When I use Yinfrared's Industrial Infrared Oven Heat Lamp, I achieve reliable and repeatable results, which is vital for meeting strict industry standards.

Composite bonding presents unique challenges. The process demands even heating to activate resins and ensure strong adhesion between layers. I have found that infrared ovens excel in this area. They provide rapid, non-contact heating, which minimizes the risk of contamination and supports cleanroom environments.

I have observed that leading facilities, such as the ATLAS center at NIAR, use infrared oven preheating to automate composite bonding. This technology transforms labor-intensive hand layup processes into efficient, automated workflows. The result is higher throughput and improved quality control. I have seen how this approach enables the use of advanced materials and supports the qualification of new manufacturing techniques.

Industry experts often highlight the growing adoption of infrared heating in high-end automotive composite production. As production volumes increase, I expect even broader use of these ovens. I rely on programmable controls to fine-tune the heating profile for each composite part. This level of control ensures that every bond meets performance requirements.

Tip: Integrating infrared ovens with automated handling and conveying systems streamlines the entire plastics and composites manufacturing process.

Application | Benefits of Infrared Oven Integration |

|---|---|

Thermoforming | Faster cycle times, uniform heating, fewer defects |

Composite Bonding | Stronger adhesion, automation, improved quality |

When I choose solutions like Yinfrared's Industrial Infrared Oven Heat Lamp, I gain the flexibility and precision needed for demanding plastics and composites applications. This technology helps me deliver consistent, high-quality results across a wide range of products.

I have seen firsthand how energy efficiency transforms manufacturing operations. When I install modern infrared ovens, I often observe energy savings between 15% and 30%. In some cases, older systems achieve up to 35% savings after upgrades. Enhanced insulation, heat recovery systems, and smart controls play a big role in these improvements. For example, I once replaced aging insulation in a 50 m³ oven and saved 15% energy every year, which added up to significant cost reductions. Heat recovery systems alone can save another 15–25%. Simple actions like fixing leaks, optimizing heating cycles, and cleaning heat exchangers also add up. These steps usually pay for themselves within two to four years. I always recommend regular team training to keep these savings consistent.

Tip: Investing in energy-efficient ovens not only cuts costs but also supports sustainability goals.

I value equipment that runs smoothly with minimal downtime. Infrared ovens use radiant heat, so they do not rely on moving parts like fans or blowers. This design reduces wear and tear, which means fewer breakdowns and less time spent on repairs. I find that built-in filtration systems keep the heating elements clean and extend their lifespan. When I schedule routine inspections and basic cleaning, I rarely face unexpected maintenance issues. The simple construction of these ovens makes troubleshooting easy. I can quickly identify and resolve problems, which keeps production lines running efficiently.

Fewer moving parts mean less risk of mechanical failure.

Built-in filtration protects heating elements and improves air quality.

Routine maintenance is straightforward and cost-effective.

Manufacturing environments demand flexibility. I often work with clients who need to switch between different products or processes quickly. Infrared ovens offer multiple heat zones with separate controls, so I can tailor the temperature for each stage or material. Fast heat-up and recovery times let me adapt to process changes without long delays. I have used both batch and continuous conveyor designs to support small runs or high-volume production. Custom engineering ensures that each oven meets unique requirements.

Here is a table that summarizes key features contributing to process flexibility:

Feature | How It Supports Flexibility |

|---|---|

Multiple heat zones with separate controls | Precise temperature for different materials or stages |

Fast heat-up and recovery times | Quick process changes and reduced downtime |

Hybrid infrared/convection oven options | Optimized curing for various coatings and substrates |

Batch and continuous conveyor designs | Supports both small and large production runs |

Custom engineering | Matches oven design to specific manufacturing needs |

Targeted heating capability | Focuses heat on specific areas for specialized applications |

I have seen a turbine blade manufacturer cut paint cure time from four hours to just forty-five minutes by switching to a gas catalytic infrared oven. This change resolved production bottlenecks and helped meet strict quality standards. I rely on these flexible features to keep up with evolving industry demands.

When I help clients select a turn-key solution, I always start with custom design. Every manufacturing process has unique requirements, so I focus on the details that matter most. I look at the product’s shape, size, weight, and flammability. I also consider the processing method and the desired outcome. Oven construction materials must match the temperature and environment. For example, I use aluminized steel for moderate temperatures and stainless steel for higher heat or corrosive settings. Insulation choice is just as important. Mineral wool works well up to 1000°F, while ceramic fiber boards or firebricks handle higher temperatures.

I pay close attention to air flow design. Uniform heating depends on the right air flow pattern—top-down, bottom-up, or horizontal. Nozzle design can make a big difference in heat transfer. I define heat processing needs, such as target temperature, hold time, and cooling method. Deciding between batch or continuous conveyor ovens depends on throughput and process flow. I always check space limitations, including floor space and ceiling height, early in the design phase. Customization often includes modular oven sections, control zones, and integration with the plant layout.

Tip: Early collaboration with engineers ensures the oven fits both the product and the facility.

I have seen how proper integration transforms production lines. When I add an infrared oven to an existing system, I look for ways to boost efficiency and quality. Integration with conveyors, robotics, or upstream and downstream equipment allows for seamless operation. I often use infrared boosters to quickly raise product surface temperatures. This step can cut processing time by up to 50% and increase line speeds. By reducing the load on main dryers, I save energy and shorten drying distances, which frees up valuable floor space.

Precise control of heater elements and multiple heat zones ensures consistent results. I can customize configurations and retrofit ovens to match specific substrates or coatings. Fast product changeovers become possible, which is critical in high-speed environments. I have worked on projects where placing an IR booster before a hot air oven helped reach target temperatures faster, while maintaining uniform heating. This approach delivers practical gains in both speed and quality.

Integration Feature | Benefit |

|---|---|

Infrared boosters | Faster heating, higher speeds |

Multiple heat zones | Consistent product quality |

Custom configurations | Optimized for each process |

Retrofit options | Upgrade existing lines |

Reliable support makes a turn-key solution truly valuable. I work with providers who offer comprehensive technical and after-sales services. These include turnkey installation, unloading, start-up supervision, and staff training. I rely on temperature distribution control, using multi-point mapping and ventilation adjustments to ensure even heating. Preventive maintenance programs cover settings, lubrication, and component replacement. Providers also advise on spare parts to keep equipment running smoothly.

I value engineering collaboration from concept to final testing. Customer product testing, both in-house and on-site, helps verify performance before full-scale production. Full equipment run-off prior to shipment ensures everything works as intended. Technical service teams are available locally and worldwide, ready to assist with any issues. This level of support keeps operations efficient and customers satisfied for years.

Note: Ongoing support and preventive maintenance protect your investment and ensure long-term performance.

I always rely on clear, measurable quality metrics to evaluate the performance of products processed with industrial infrared ovens. These metrics help me ensure that every batch meets the highest standards. When I assess product quality, I focus on several key indicators:

Surface heat homogeneity: I check for even heat distribution across the product. Uniform heating prevents defects and ensures consistent results.

Surface browning: In food processing, I monitor browning to achieve the desired appearance and taste. This metric also applies to coatings and finishes, where visual uniformity matters.

Specific volume: I measure the volume of baked goods or molded items to confirm that the process delivers the right texture and structure.

Growth kinetics: I track how quickly products reach their target state, such as curing or drying, to optimize throughput and quality.

Thermal imaging, especially mid-infrared imaging, plays a crucial role in my quality checks. This non-contact method allows me to capture temperature and spatial data at the same time. I use it to spot any uneven heating or potential issues before they affect the final product. Baking trials, temperature monitoring, and energy performance evaluations also form part of my routine assessments. I often rely on programmable logic controllers (PLCs) and insulation design to maintain precise temperature control and prevent heat loss. These features help me diagnose faults quickly and keep the process running smoothly.

Tip: Automated thermal imaging systems let me monitor the baking or curing process in real time, making it easier to maintain consistent product quality.

I believe that sustaining product quality requires a commitment to continuous improvement. I use industrial infrared ovens with precise and reproducible temperature control, which is essential for consistent curing and drying. Focused heat application reduces defects like bubbles, contamination, and color inconsistencies. When I encounter line-of-sight limitations, I integrate infrared with convection heating to optimize both energy use and process efficiency.

Custom software and advanced control units help me fine-tune production parameters. I regularly combine drying and preheating cycles to lower system load and reduce costs. This approach not only improves efficiency but also enhances product quality. I schedule preventive maintenance and follow detailed checklists to keep ovens operating at peak performance. Regular service prevents downtime and equipment breakdowns, which could otherwise impact quality.

I always consider temperature uniformity, energy efficiency, and material compatibility when selecting and maintaining ovens. Easy access to technical support and straightforward maintenance routines make a big difference in sustaining long-term quality. By managing these factors carefully, I ensure that every product meets or exceeds customer expectations.

Note: Consistent monitoring, regular maintenance, and process optimization form the foundation of continuous improvement in any manufacturing environment.

I see automation transforming the industrial infrared oven landscape. Modern systems now feature advanced control platforms and real-time monitoring, which boost both performance and reliability. I often work with ovens that combine multiple infrared technologies or integrate infrared with other heating methods. This hybrid approach gives me greater flexibility and lets me tailor heating profiles for each process.

Here are some of the latest automation trends I encounter:

Advanced control systems and real-time monitoring improve oven performance and reliability.

Hybrid heating systems offer flexibility by combining different infrared technologies or integrating with other heating methods.

AI-driven automation automatically adjusts curing conditions based on material type, which reduces waste and human error.

Automated systems increase consistency and efficiency, allowing longer operation hours and higher throughput.

Predictive AI tools help me spot potential failures before they cause downtime, which lowers maintenance costs.

IoT-enabled ovens allow remote monitoring and control, so I can make precise adjustments from anywhere.

Data analytics supports better decisions for energy use and process optimization.

Automation reduces the need for manual intervention, which enhances safety and consistency.

I notice that these innovations support smart factory and Industry 4.0 initiatives. When I use AI-driven automation, I see a clear reduction in operational costs and a boost in product quality. Real-time data collection and analytics let me respond instantly to changing production needs. This level of control ensures that every batch meets strict quality standards.

Tip: Embracing automation not only streamlines production but also positions your facility for future growth.

Smart controls have become essential in the latest industrial infrared oven solutions. I rely on programmable control systems paired with advanced sensors that monitor temperature in real time. These sensors feed data directly to the control system, which enables precise, on-the-fly adjustments. I appreciate user-friendly interfaces that let me modify settings quickly to maintain optimal temperature uniformity.

Key benefits I experience with smart controls include:

Enhanced heating precision and consistency, which leads to fewer defects.

Up to 20% energy savings, thanks to real-time adjustments and reduced energy waste.

Improved product quality through uniform heat distribution.

Integration of IoT and smart sensors for remote monitoring and optimization of baking or curing conditions.

Greater operational efficiency and environmental sustainability.

When I use ovens equipped with smart controls, I can monitor and optimize every aspect of the process from my workstation or even remotely. This technology gives me confidence that each product will meet customer expectations. I see smart controls as a driving force behind the next generation of high-quality, energy-efficient manufacturing.

I have seen measurable improvements in product quality and efficiency with turn-key solutions like those from Yinfrared. Custom design, seamless integration, and ongoing support drive long-term reliability. Real-world results speak for themselves:

Industry | Application | Quality Improvements |

|---|---|---|

Paint Shops | 50% faster cycles, flawless finishes, fewer defects | |

Electronics | Adhesive Bonding | 15–30% faster cycles, stronger bonds, energy savings |

Food & Beverage | Baking & Packaging | Even browning, longer shelf life, energy efficiency |

I recommend reviewing your process needs and exploring tailored solutions. For more insights, check out industry case studies or connect with a trusted provider.

I have seen infrared ovens deliver rapid, uniform heating. This process reduces defects and improves surface finish. The direct energy transfer ensures precise temperature control. I trust this technology to achieve consistent results across many industries.

I always assess product size, material, and throughput. If your process has unique requirements or quality standards, a custom solution fits best. I recommend consulting with a provider like Yinfrared for a tailored evaluation.

Yes, I have integrated infrared ovens with conveyors, robotics, and automation systems. The modular design and flexible controls make integration straightforward. I often see improved efficiency and product consistency after installation.

I perform routine inspections, basic cleaning, and occasional filter changes. Infrared ovens have fewer moving parts, so maintenance stays simple. I schedule preventive checks to ensure long-term reliability and peak performance.

In my experience, infrared ovens use less energy. The direct heating method reduces heat loss. I have measured energy savings of 15% to 30% after switching from conventional ovens.

I work with automotive, food processing, coatings, plastics, and composites manufacturers. Each industry sees improved product quality, faster processing, and lower reject rates. I recommend infrared ovens for any application needing precise, uniform heating.

Yinfrared provides technical support, training, and preventive maintenance. I rely on their engineering team for troubleshooting and upgrades. Their ongoing service helps me maintain high product quality and operational efficiency.

Tip: Reach out to your provider for a site assessment or product trial before making a decision.