Author: Site Editor Publish Time: 2025-08-18 Origin: Site

I see the demand for short wave infrared emitters growing rapidly, with global infrared markets set to nearly double by 2032. In my experience, YFR’s short wave infrared emitters stand out for their radiant efficiency and seamless compatibility with leading brands like Ushio and Sylvania. High-performance, energy-efficient infrared solutions play a vital role in industrial heating and inspection. I always look for short-wave infrared products that deliver fast response and durability in real-world applications.

Short wave infrared (SWIR) emitters offer fast, intense heating and advanced imaging for industrial and scientific uses.

YFR’s SWIR emitters stand out for high radiant efficiency, durability, and compatibility with major brands.

Energy-efficient SWIR technologies like quantum dot LEDs and gold-reflector lamps reduce power use and save costs.

Different SWIR emitter types suit specific tasks: quartz tubes for heating, quantum dots for imaging, and lasers for precision work.

Emerging materials like colloidal quantum dots and phosphor-converted LEDs promise broader emission and better stability.

SWIR imaging improves medical diagnostics, industrial inspection, and safety by revealing hidden details and penetrating obstacles.

Choosing SWIR emitters requires balancing efficiency, lifespan, cost, and customization to fit your application needs.

Regular maintenance and selecting stable, proven emitters ensure reliable performance and long operational life.

When I evaluate short wave infrared emitters for best performance, I focus on several critical metrics. These factors help me determine which SWIR solutions deliver the highest value in demanding industrial and scientific environments.

Sensitivity

Signal-to-noise ratio

Power consumption

Cooling requirements

Beam quality

Electrical efficiency

Thermal management

Wavelength specificity

Power rating

Resolution

Imaging capabilities, such as multispectral integration

Operational reliability in harsh conditions

I have seen that cooled SWIR cameras and sensors often lead the market in sensitivity and signal-to-noise ratio. These devices excel in low-light and challenging environments, making them the top choice for high-precision applications like semiconductor inspection and medical diagnostics. For users who need portable or lightweight solutions, uncooled SWIR emitters offer lower power consumption and cost-effectiveness. I always recommend integrating multispectral imaging when possible, as it improves both resolution and spectral range for industrial and scientific tasks.

YFR’s short wave quartz replacement infrared lamps stand out in this category. Their radiant efficiency reaches up to 96%, and they maintain consistent output even under continuous operation. I have found their compatibility with major brands like Ushio, Sylvania, Dr. Fischer, GE, and Philips makes them easy to integrate into existing systems. Their robust design ensures reliable performance in both vertical and horizontal orientations, with lifespans exceeding 5,000 hours.

Energy efficiency remains a top priority for anyone selecting shortwave infrared emitters. Recent advances in SWIR technology have pushed the boundaries of what is possible. In my research, InAs-based quantum dot LEDs (QD-LEDs) have emerged as the most energy-efficient SWIR emitters available. These devices achieve external quantum efficiencies up to 20.5% at 905 nm, with nearly perfect photoluminescence quantum yield and long operational lifetimes. The use of advanced core/multishell quantum dots and optimized carrier dynamics allows these emitters to minimize energy loss and maximize output.

YFR’s Goldenrod shortwave infrared lamp also sets a benchmark for efficiency in industrial heating. Its integral gold reflector directs energy precisely where needed, boosting energy savings by about 23.5% compared to standard lamps. I appreciate how this design not only improves efficiency but also keeps surrounding equipment cooler, which is crucial in high watt density applications.

In my experience, certain SWIR emitters have become industry standards due to their reliability and versatility. Indium Gallium Arsenide (InGaAs) emitters dominate sectors like semiconductor inspection, food processing, and medical imaging. Their high spectral response from 900 to 1700 nm and excellent performance in low-light conditions make them indispensable for detecting moisture, chemical composition, and subtle defects.

I have noticed a growing trend toward CMOS-based SWIR sensors, especially in manufacturing and semiconductor industries. These sensors offer a cost-effective alternative to traditional InGaAs devices, expanding access to SWIR imaging for more companies. The 850 nm to 950 nm spectral range remains the most popular for SWIR LEDs, striking the right balance between penetration depth and resolution. This range supports clear imaging through fog, smoke, and other obstacles, making it ideal for industrial inspection and medical diagnostics.

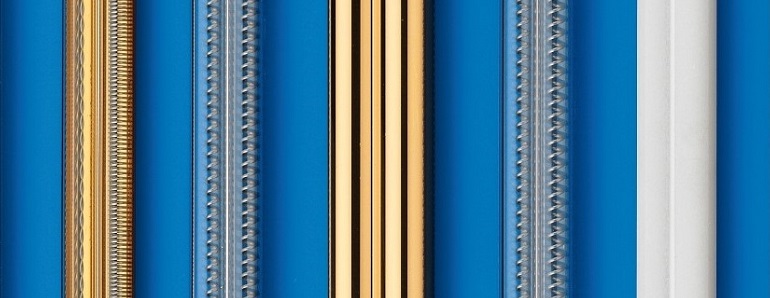

YFR’s short wave infrared emitters continue to be a favorite among industrial users. Their broad compatibility, high radiant efficiency, and customizable options make them a reliable choice for a wide range of applications, from curing and drying to precision heating.

I have watched the landscape of swir technology evolve rapidly over the past few years. New materials and device architectures now drive a wave of innovation, pushing the boundaries of what swir emitters can achieve. These advances open up new possibilities for industrial, scientific, and imaging applications.

One of the most exciting developments involves solid-state thin-film emitters based on colloidal quantum dots (CQDs). These solution-processed devices deliver broadband swir emission with a full-width-half-maximum of 400 nm and high quantum efficiency. I see these emitters enabling compact, CMOS-compatible, and cost-effective swir light sources. Their integration into on-chip spectrometers makes portable swir spectroscopy a reality, overcoming the bulk and inefficiency of traditional infrared emitters.

Another breakthrough comes from phosphor-converted LEDs using Cr3+ and Yb3+ co-doping. These phosphors emit intense swir light in the 900–1200 nm range when excited by blue LEDs. I have found that co-doping with Yb3+ enhances the emission intensity through energy transfer from Cr3+, achieving internal quantum yields close to 30%. These phosphor-converted LEDs offer a practical solution for broadband swir sources in spectroscopy and imaging, combining high performance with cost-effectiveness.

Note: The NaScP2O7:Cr3+,Yb3+ phosphor stands out for its broad emission from 700 to 1200 nm and its successful integration with blue LED chips. This innovation brings swir light sources closer to mainstream adoption in industrial and scientific settings.

PbS CQD-based swir down-conversion films represent another leap forward. I have seen these films achieve a maximum output power density of 0.54 mW/mm² and a power conversion efficiency of about 15%. Compared to traditional QLEDs and phosphor emitters, PbS CQD films show less efficiency roll-off under high excitation, maintaining stable performance even in demanding environments. Their scalable fabrication and tunable emission wavelengths give them a clear edge for applications that require efficient, stable, and customizable swir light sources.

In practical demonstrations, I have used lab-built swir torches with PbS CQD films to illuminate scenes obscured by smoke. Swir light penetrates smoke far better than visible or near-infrared light. In one test, a note hidden by smoke became clearly visible under swir illumination, while it remained unreadable with other light sources. This superior penetration and contrast highlight the unique advantages of emerging swir emitters for imaging in challenging conditions.

When I compare these emerging swir technologies to established emitters, I notice several key advantages:

Higher efficiency: CQD-based emitters and Cr3+–Yb3+ phosphors deliver greater quantum yields and power conversion efficiency.

Broader emission bandwidth: Solid-state thin-film and phosphor-converted LEDs provide broadband swir output, ideal for spectroscopy.

Enhanced stability: PbS CQD films maintain performance with minimal efficiency loss, even at high power densities.

Scalability and integration: Solution-processed emitters and CMOS-compatible designs simplify manufacturing and system integration.

I believe these advances will shape the future of swir emitters. They promise to expand the reach of swir imaging, sensing, and industrial heating. As these technologies mature, I expect to see even more efficient, robust, and versatile swir solutions entering the market.

When I discuss swir, I refer to shortwave infrared radiation. This region sits between visible light and mid-infrared on the electromagnetic spectrum. I often see swir described as a powerful tool for both industrial and scientific applications. The unique properties of swir allow it to penetrate materials that visible light cannot. I rely on swir for its ability to reveal hidden features, support rapid heating, and enable advanced imaging. In my experience, short-wave infrared stands out for its high intensity and fast response, making it essential for demanding environments.

I always pay close attention to the spectrum range when selecting swir emitters. The wavelength range defines the performance and suitability for different applications. Here is a summary of the key features:

Feature | Short Wave Infrared (SWIR) | Description and Impact on Application Suitability |

|---|---|---|

Wavelength Range | 0.7 to 1.5 micrometers | Defines the short wave infrared spectrum, enabling very high heat intensity and deep penetration. |

Heat Intensity | Very high | Suitable for rapid, intense heating in industrial settings. |

Visible Light | Bright red/orange | Emits bright visible light, which can be uncomfortable for prolonged exposure, limiting use in comfort heating. |

Comfort Level | Low for long use | Not ideal for comfort heating due to intense radiation and brightness. |

Best Applications | Industrial heating, on-demand heating (e.g., loading docks, outdoor events, construction sites) | Quick response time and near-instant heat output make swir ideal for applications requiring immediate heat rather than sustained comfort. |

I have found that shortwave infrared emitters operating in the 0.7 to 1.5 micrometer range deliver exceptional heat intensity and deep penetration. This makes them perfect for rapid, on-demand heating in industrial settings. However, the bright visible light and intense radiation mean I avoid using them for comfort heating over long periods.

I see swir technology used across a wide range of industries. Its versatility and performance make it a top choice for many critical tasks. Here are some of the main applications I encounter:

I use shortwave infrared emitters for paint drying, pre-heating foils, and thermoforming textiles, leather, and synthetic materials.

In the furniture and automotive industries, swir supports high-speed production lines and quality control.

I rely on twin tube emitters for extreme heat tests in aerospace and for processes that demand rapid, uniform heating.

SWIR imaging plays a vital role in safety and surveillance, especially in firefighting and rescue operations where it penetrates smoke and ash.

Security teams use swir to detect hidden objects and people in low-visibility conditions.

In manufacturing, swir imaging reveals defects invisible to the naked eye, such as bruises on fruit or flaws in electronics.

Medical professionals use swir for non-invasive diagnostics, monitoring tissue health, and analyzing water and lipid concentrations.

I have seen advances in swir camera technology, like InGaAs sensors, improve machine vision, laser profiling, and medical research.

I consider swir an essential part of modern industrial and scientific workflows. Its ability to deliver fast, high-intensity infrared heating and advanced imaging continues to drive innovation in many fields.

When I assess the performance of swir emitters, quantum yield stands out as a primary metric. Quantum yield measures how efficiently a material converts absorbed photons into emitted photons. In the context of swir and near-infrared emitters, I rely on photoluminescence quantum yield (PLQY) as the standard. The most accurate way to measure PLQY involves integrating sphere spectroscopy. This method captures both the incident and emitted light, allowing me to directly calculate the quantum yield. I often use commercial integrating sphere instruments that can detect photons up to 1650 nm, which covers the swir range.

However, I have found that many organic fluorophores designed for swir applications exhibit very low PLQYs, often below 1%. This low efficiency results from the energy gap law, which increases nonradiative decay and reduces the number of emitted photons. Measuring such low quantum yields requires sensitive equipment and careful calibration. While alternative methods like photoacoustic spectroscopy exist, I trust integrating sphere setups for their accuracy, even though they require significant investment and expertise.

Stability is another critical metric I consider when selecting swir emitters for industrial or scientific use. In real-world applications, swir emitters face several challenges that can impact their operational lifetime and reliability. For example, swir phosphor-converted LEDs often struggle with low stability, which limits their ability to deliver broadband and high-efficiency emission. I have seen that swir LED chips require complex processing and can be costly to produce. Organic and perovskite LEDs tend to show poor device performance and low external quantum efficiency, especially at wavelengths above 950 nm.

Quantum dot LEDs present their own set of challenges. Achieving high and stable power output remains difficult, and efficiency roll-off—where external quantum efficiency degrades at higher power—can be a significant issue. I always look for swir emitters that avoid toxic elements, as these can further impact stability and limit their use in sensitive environments. Extending the operational lifetime of swir emitters remains a top priority for manufacturers and end users alike.

Tip: When choosing swir emitters for demanding environments, I recommend prioritizing products with proven stability and a track record of reliable performance under continuous operation.

Biocompatibility becomes essential when I use swir emitters in medical and biological imaging. I assess biocompatibility by examining both the material composition and the surface chemistry of the emitter. Rare-earth doped nanoprobes encapsulated with FDA-approved albumin have become a preferred choice for swir imaging in biological systems. This encapsulation improves bioactivity and tumor targeting while reducing toxicity compared to quantum dots that may contain lead, mercury, or arsenic.

To evaluate biocompatibility, I look at in vivo imaging studies that demonstrate safe and effective use of swir emitters. Albumin encapsulation not only reduces toxicity but also provides functional groups for targeting specific biomarkers or delivering drugs. This comprehensive approach ensures that swir emitters can be safely used for real-time imaging of anatomical structures and diseased tissues. In my experience, careful material selection and surface modification are key to achieving both high performance and safety in swir-based medical applications.

When I evaluate swir emitters, I always pay close attention to power use. Efficient power consumption is essential for both industrial and scientific applications. I have seen that the best short wave infrared emitters deliver high output with minimal energy waste. This efficiency translates directly into lower operating costs and reduced environmental impact.

I often compare different types of swir emitters by looking at their wattage ratings and radiant efficiency. For example, YFR’s replacement quartz infrared tubes can operate at wattages ranging from 1000 to 6000 watts. These infrared heating elements achieve up to 96% radiant efficiency, which means almost all the electrical energy converts into usable infrared radiation. In my experience, this level of efficiency is rare among fast response infrared emitters.

Tip: Always check the radiant efficiency and watt density when selecting swir emitters for your application. High efficiency means less wasted energy and better performance.

I also consider the response time. Fast response infrared emitters reach their full output almost instantly. This feature reduces warm-up periods and saves energy during start-stop operations. I have found that instant ON/OFF capability is especially valuable in automated production lines and quality control systems.

Here is a quick comparison of power use factors for different swir emitter types:

Emitter Type | Typical Power Range | Radiant Efficiency | Response Time |

|---|---|---|---|

Quartz Infrared Tubes | 1000–6000 W | Up to 96% | Instant |

Solid-State Thin-Film Emitters | 1–100 W | 60–80% | Instant |

Phosphor-Converted LEDs | 1–50 W | 30–50% | Fast |

InGaAs Emitters | 10–1000 W | 40–70% | Fast |

I always recommend matching the power rating and efficiency to the specific needs of your process. For high intensity infrared emitters in industrial heating, higher wattage and efficiency are crucial. For imaging or sensing, lower power and precise control matter more.

Cost remains a major factor when I select swir emitters for any project. I look at both the initial purchase price and the total cost of ownership. The cost of infrared emitters for industrial use can vary widely based on technology, efficiency, and customization.

In my experience, quartz-based short wave infrared emitters offer the best balance of price and performance. These emitters provide long lifespans, high efficiency, and compatibility with existing systems. Replacement quartz infrared tubes from YFR, for example, reduce downtime and maintenance costs because they fit directly into standard fixtures.

Solid-state swir emitters, such as thin-film or quantum dot devices, often have higher upfront costs. However, they may offer savings over time due to lower power consumption and longer operational life. I always factor in installation, maintenance, and energy costs when comparing options.

Note: Custom solutions may have higher initial costs but can deliver significant savings through improved efficiency and process optimization.

I suggest creating a cost-benefit analysis before making a decision. Consider not just the price tag, but also the expected lifespan, energy use, and maintenance requirements. This approach ensures you select the most cost-effective swir solution for your application.

I often use organic dyes as short wave infrared emitters in applications that demand flexibility and tunable emission. These dyes, such as polymethine compounds, operate through a process called photoluminescence. When I excite the dye molecules with light, they absorb photons and then release energy in the swir region. The emission wavelength depends on the molecular structure and the environment surrounding the dye. I have found that the efficiency of these dyes is highly sensitive to solvent polarity. In polar solvents, non-radiative decay increases due to trans-cis isomerization, which reduces quantum yield and overall brightness.

Encapsulation strategies have transformed the performance of organic dyes. By embedding hydrophobic dyes into water-soluble polymer nanoparticles, I can create a microenvironment that protects the dye and boosts quantum yield. This approach also enhances photostability, making the dyes suitable for real-time biological imaging. I have seen encapsulated dyes maintain their fluorescence and stability across a wide pH range, which is essential for medical diagnostics and swir imaging.

Organic dye-based swir emitters typically consist of polymethine dyes like IR-26, IR-1048, and IR-1061. These molecules feature extended conjugated systems that allow for absorption and emission in the swir region. I often select dyes based on their hydrophobicity and compatibility with encapsulation materials. The most effective compositions involve embedding the dye in polymeric or silica nanoparticles. This structure creates a hydrophobic cavity that shields the dye from water and other polar solvents.

I have worked with dye nanoparticles that exhibit up to 50-fold increased brightness compared to pure dyes. These nanoparticles disperse easily in water and maintain their size and fluorescence stability for nearly two months. Such improvements enable efficient in vitro and in vivo imaging with low toxicity. Although organic dyes have lower intrinsic efficiency and stability than inorganic emitters, engineering approaches like encapsulation make them viable for advanced swir applications.

Tip: For biological imaging, I recommend using encapsulated organic dyes to achieve higher brightness and stability. This strategy supports long-term imaging and reduces toxicity.

I rely on carbon nanotubes for swir emission in applications that require high intensity and fast response. Carbon nanotubes emit infrared light through bandgap transitions. When I excite these nanotubes with a suitable energy source, electrons move between energy bands and release photons in the swir region. The emission properties depend on the nanotube’s chirality and diameter. Single-walled carbon nanotubes (SWCNTs) are especially effective for swir emission due to their well-defined electronic structure.

I have used carbon nanotubes in optical communication systems because they offer rapid modulation and strong emission in the swir range. Their unique electronic properties support high-speed data transmission and advanced sensing. In my experience, carbon nanotubes deliver stable performance even under continuous operation, making them ideal for industrial heating elements and fast response infrared emitters.

Carbon nanotubes consist of rolled-up sheets of graphene that form cylindrical structures. I work with both single-walled and multi-walled nanotubes, but SWCNTs provide the best swir emission. The diameter and chirality of the nanotube determine the bandgap and, consequently, the emission wavelength. I often select nanotubes with diameters between 0.7 and 2 nanometers for optimal swir output.

The structure of carbon nanotubes allows for efficient heat dissipation and mechanical durability. I have integrated these nanotubes into composite materials to enhance the performance of replacement quartz infrared tubes and high intensity infrared emitters. Their robust design supports long-term use in industrial environments and optical communication networks.

Note: Carbon nanotubes combine high efficiency with mechanical strength, making them suitable for demanding swir applications.

I use lanthanide nanoparticles as swir emitters in applications that require precise control over emission wavelength and intensity. These nanoparticles achieve swir emission through energy transfer processes involving lanthanide ions such as Tm3+, Er3+, Nd3+, and Yb3+. When I excite the nanoparticles at specific wavelengths, energy transfers between the dopant ions, resulting in upconversion or downconversion luminescence. This process produces strong emission in the swir and near-infrared regions.

I have observed that the emission characteristics depend on the type and concentration of dopants, as well as the host matrix structure. For example, 4% Tm3+-doped nanocrystals can emit around 800 nm through two-photon processes. These nanoparticles enable deep tissue imaging with sub-50 nm optical resolution. I have used photon-avalanche nanoparticles doped with 8% Tm3+ for super-resolution imaging at low power densities, which supports advanced swir imaging and optical communication.

Doping is the key to tuning the emission properties of lanthanide nanoparticles. I introduce lanthanide ions into host nanocrystals to control the energy transfer and emission wavelength. The choice of dopant and its concentration determine the efficiency and stability of the swir emission. I often use host matrices like NaYF4 or NaGdF4 to support high dopant concentrations without quenching the emission.

I have found that careful doping enables strong emission and photostability, which are essential for industrial heating elements and swir imaging. The ability to operate at low power densities with high nonlinearity makes these nanoparticles ideal for optical communication and biological imaging. Although direct efficiency values are scarce, experimental studies confirm that lanthanide-doped nanoparticles deliver reliable swir emission for advanced applications.

Tip: For high-resolution imaging and optical communication, I recommend using lanthanide nanoparticles with optimized doping levels. This approach ensures strong emission and long-term stability.

I rely on quantum dots as one of the most advanced swir emitters available today. These nanocrystals operate through quantum confinement, which allows me to tune their emission wavelength by adjusting their size and composition. When I excite quantum dots with light or electrical energy, they emit photons in the swir region. This process delivers high fluorescence quantum yields, often between 10% and 30%. I find this efficiency far superior to other swir probes and carbon nanotubes, especially for sensitive imaging applications.

Quantum dots offer narrow and tunable emission spectra, covering wavelengths from 900 nm to 1600 nm. This feature enables multiplexed imaging, where I can use multiple colors to track different biological processes simultaneously. The photostability of quantum dots stands out in my experience. InAs-based core/shell and core/shell/shell structures maintain their optical quality over time, even under continuous illumination. I have seen monodispersity rates around 8-10%, which ensures consistent performance across batches.

Surface functionalization expands the versatility of quantum dots. I use phospholipid micelles, lipoprotein coatings, and composite particles to make quantum dots biocompatible. These modifications allow me to perform metabolic imaging, angiography, and blood flow tracking in living organisms. Fast photoluminescence lifetimes, typically around 100 nanoseconds, support high-flux applications such as confocal microscopy and swir imaging in real time.

Tip: For biological imaging, I recommend quantum dots with biocompatible coatings. These emitters maintain high quantum yields and emission properties after phase transfer into physiological buffers, ensuring reliable performance in medical environments.

The size of quantum dots plays a critical role in their swir emission properties. I select quantum dots with diameters ranging from 2 to 10 nanometers, depending on the desired wavelength. Smaller dots emit at shorter wavelengths, while larger dots shift emission toward the longer swir region. This tunability allows me to customize infrared emitters for specific imaging and sensing tasks.

Miniaturization has reached impressive levels. I have worked with sub-2-μm pixel pitch arrays, which enable compact and high-resolution swir imaging sensors. Monolithic integration of quantum dots into device arrays supports high throughput manufacturing and broad deployment in imaging systems. These advances make quantum dots ideal for portable swir imagers and industrial inspection tools.

Thermal stability and broad absorption are essential for swir applications in physiological conditions. Slow crystal growth synthesis methods enhance the durability of quantum dots, allowing them to maintain high quantum yields even in challenging environments. I have observed external quantum efficiencies above 40% at 1450 nm, which indicates exceptional device sensitivity.

Here is a summary of the unique properties that influence the adoption of quantum dot-based swir emitters in imaging and sensing:

High fluorescence quantum yields (10-30%) for sensitive and fast swir imaging.

Tunable and narrow emission spectra (900–1600 nm) for multiplexed imaging.

Photostability and improved optical quality due to advanced core/shell structures.

Biocompatible surface functionalizations for diverse biological applications.

Fast photoluminescence lifetimes (~100 ns) for high-flux swir imaging.

Miniaturization capability with sub-2-μm pixel pitch arrays.

Thermal stability and broad absorption for use in physiological conditions.

External quantum efficiencies above 40% at 1450 nm for high device sensitivity.

I use quantum dots in swir imaging, sensing, and optical communication. Their combination of efficiency, stability, and tunability makes them indispensable for modern infrared heating elements and high intensity infrared emitters.

I have seen fiber lasers become a cornerstone in swir technology. These lasers use doped optical fibers as the gain medium, which allows for efficient light amplification in the swir region. Fiber lasers deliver output powers ranging from milliwatts to tens of watts, making them suitable for both laboratory and industrial environments. I appreciate their narrow linewidth and long coherence length, which enable precision applications such as lidar, 3D scanning, and optical communication.

Fiber-coupled swir lasers offer broad versatility. I can select single-mode or multimode configurations to match the needs of my system. Ruggedized designs withstand harsh industrial conditions, and customizable platforms allow me to tailor pulse widths, repetition rates, and wavelengths. I rely on fiber lasers for high-resolution imaging, defense, and telecommunications. Their reliability and adaptability make them a preferred choice for demanding swir applications.

Note: Fiber lasers support continuous wave and pulsed operation, giving me flexibility for both steady-state and time-resolved swir measurements.

Semiconductor swir lasers provide another powerful option for infrared emission. These devices use semiconductor materials such as InGaAs or GeSn to generate swir light through electrical excitation. I have used laser diodes and diode-pumped solid-state (DPSS) lasers for applications requiring compact form factors and high output power.

Semiconductor swir lasers offer output powers from milliwatts up to tens of watts. I can choose free-space or fiber-coupled options, depending on integration needs. Advanced configurations include wavelength-stabilized and tunable lasers, which enhance application flexibility. I have deployed these lasers in night vision, industrial inspection, and optical communication systems.

The precision and reliability of swir lasers set them apart from other infrared emitters. I value their ability to deliver high output power with narrow linewidths, supporting a wide spectrum of industrial and scientific uses. MIL-Spec ruggedization ensures performance in defense and harsh environments. With nearly 30 years of proven deployment, swir lasers continue to drive innovation in infrared heating elements and fast response infrared emitters.

Here is a table comparing fiber and semiconductor swir lasers:

Feature | Fiber SWIR Lasers | Semiconductor SWIR Lasers |

|---|---|---|

Output Power | mW to tens of watts | mW to tens of watts |

Linewidth | Narrow | Narrow |

Coherence Length | Long | Moderate to long |

Integration | Fiber-coupled, ruggedized | Free-space, fiber-coupled |

Application Versatility | High | High |

Customization | Pulse width, wavelength | Wavelength, stabilization |

Reliability | Excellent | Excellent |

I use swir lasers for precision tasks in lidar, 3D scanning, defense, and optical communication. Their combination of output power, versatility, and reliability makes them essential for modern swir imaging and industrial heating systems.

When I select quartz lamps for industrial swir applications, I focus on radiant efficiency, durability, and flexibility. YFR’s quartz lamps consistently outperform standard infrared heating elements. Their radiant efficiency reaches up to 98.4% when equipped with a gold-plated coating. I have seen these lamps warm up in just 2.3 seconds, which supports fast response infrared emitters in high-speed production lines. The lifespan exceeds 12,000 hours, and the failure rate remains below 0.3%. In packaging applications, I have observed a reduction in reject rates from 3.2% to 0.4%, and a 22% decrease in cycle time. These improvements translate directly into higher productivity and lower operational costs.

Metric | Value / Description |

|---|---|

Radiation Efficiency | Up to 98.4% with gold-plated coating |

Warm-up Time | Approximately 2.3 seconds |

Lifespan | Over 12,000 hours with failure rate below 0.3% |

Reject Rate Reduction | Reduced from 3.2% to 0.4% in packaging applications |

Cycle Time Reduction | 22% decrease in cycle time |

Certifications | TUV, Certificate of Conformity, License Verified Report, Trademark Registration Certificate |

YFR’s dual-tube design allows me to tune the wavelength for targeted heating. This feature improves product quality and reduces defects. The certifications further assure me of their reliability and safety in demanding swir environments.

Directional lamps play a crucial role in swir systems where energy savings and application precision matter. I rely on YFR’s Goldenrod lamp, which features an integral gold reflector. This design directs infrared energy exactly where I need it, eliminating the need for a secondary reflector. I have measured energy savings of about 23.5% compared to standard lamps. The gold reflector also helps keep surrounding equipment cooler, which is essential in high watt density applications.

I use directional bar lights and ring lights to maintain brightness and uniformity in high-speed scenarios. These lamps provide high-contrast image capture, which is vital for machine vision and inspection. Their energy efficiency and long service life reduce maintenance costs and improve uptime. By combining bar lights with ring and dome lights, I create a versatile lighting ecosystem that enhances precision in complex inspection environments. Directional lamps focus light where needed, reducing waste and improving energy savings while delivering stable, well-directed illumination for precise swir industrial applications.

Every industrial process has unique requirements, so I often turn to custom swir emitter solutions. YFR offers a wide range of customization options that allow me to optimize performance for specific tasks. I can select emission materials with precise wavelengths, choose chip mounting techniques like wire bonding or die attach, and pick from various packaging types such as SMD, COB, or TO-can. Multi-chip assemblies enable higher output power, which is useful for applications like night vision or medical monitoring.

Custom drive currents and beam profiles let me tailor the emitter to my process. Ruggedized packaging ensures reliability in harsh environments. I have seen multi-chip arrays provide two to four times the light output of older generations, which boosts sensitivity in food sorting, moisture sensing, and telecommunications. Testing and binning processes guarantee consistent quality and performance.

Tip: Custom swir emitters allow me to match electrical, optical, and thermal characteristics to my application, improving efficiency and extending the lifetime of my infrared emitters.

I have seen swir technology transform the field of biomedical imaging. When I use short wave infrared emitters for deep tissue imaging, I achieve much greater penetration—up to 6 mm—compared to visible or near-infrared light. This deeper reach allows me to visualize biological structures with higher resolution and less scattering. I often rely on swir for in vivo imaging, where I need to see blood vessels, organs, or tumors beneath the surface. During surgeries, swir helps me guide procedures by clearly outlining tumors, detecting metastases, and even visualizing nerves in real time.

Some of the most common bioimaging applications I use include:

Deep tissue imaging for live animal studies and human diagnostics

Intraoperative guidance to improve surgical precision

Real-time monitoring of drug distribution in blood vessels

Detection of specific conditions, such as middle ear infections, with high accuracy

For these tasks, I focus on performance metrics like image resolution, imaging depth, and signal-to-noise ratio. High photostability and photothermal conversion efficiency are also essential, especially when I use advanced techniques like surface-enhanced resonance Raman scattering. Machine learning tools now help me enhance image quality and detection accuracy, making swir a powerful alternative to traditional imaging methods. I appreciate that swir imaging provides real-time results without exposing patients to ionizing radiation.

Tip: For deep tissue imaging, I always look for swir emitters with high specificity and sensitivity. This ensures I get clear, reliable images for diagnosis and treatment.

In my experience, short wave infrared emitters have become indispensable in industrial inspection. I use them for rapid heating, quality control, and process monitoring. The instant heat and strong penetration of swir allow me to work with thick materials and achieve uniform results. I often choose fast response infrared emitters for applications like plastic molding, metal heat treatment, and rapid drying.

Here is a table summarizing the key benefits I observe:

Feature | Description |

|---|---|

Rapid Heating | Provides instant heat for processes like molding and metal treatment |

Strong Penetration | Delivers energy deep into materials for efficient heating |

Energy Efficiency | Gold reflector technology boosts conversion efficiency up to 95% |

Fast Response Times | Reduces downtime and increases productivity |

Precise Temperature Control | Maintains consistent product quality with advanced sensors |

Cost Savings | Lowers energy and maintenance costs, saving thousands annually |

Environmental Benefits | Reduces carbon emissions and supports sustainability |

Industrial Applications | Used in molding, heat treatment, drying, curing, and reflow soldering |

I have seen manufacturers reduce energy costs by over €10,000 per year by switching to short wave infrared emitters. In powder coating, I can cut preheating times by up to two hours, which boosts throughput and lowers expenses. The long lifespan and low maintenance of these infrared heating elements make them a smart investment for any production line.

I rely on swir sensors for a wide range of scientific and industrial tasks. These sensors, often based on InGaAs technology, cover a broad spectral range from 350 to 1700 nm. With high resolution and fast frame rates, I can capture detailed images even in low-light conditions. The peak quantum efficiency reaches up to 90% at 1200 nm, which gives me excellent sensitivity for deep tissue imaging and material analysis.

Some of the main applications I use include:

Industrial inspection and material analysis

Environmental monitoring and scientific research

Laser industry, LiDAR, and range finding

Machine vision, printing, and semiconductor equipment

Clinical diagnostics, dentistry, endoscopy, and medical devices

Ophthalmology, radiography, and molecular imaging

Surgery, thermometry, safety, and security systems

Astronomy, biology, and physics research

The versatility of short wave infrared emitters and sensors allows me to address challenges in both industrial and biomedical imaging. I value their ability to deliver high-quality results across so many fields.

When I compare short wave infrared emitters, I always focus on the metrics that matter most in real-world applications. I look at radiant efficiency, response time, operational lifespan, and compatibility. These factors help me decide which IR emitters fit my needs best. Below, I have created a table that summarizes the key metrics for the most common types of infrared heating elements:

Emitter Type | Radiant Efficiency | Response Time | Lifespan (hours) | Customization | Compatibility |

|---|---|---|---|---|---|

Replacement Quartz Infrared Tubes | Up to 96% | Instant | 5,000+ | High | Ushio, Sylvania, GE, Philips, Dr. Fischer |

Goldenrod Directional Lamps | ~96% + 23.5% energy savings | Instant | 5,000+ | Medium | Major industrial brands |

Solid-State Thin-Film Emitters | 60–80% | Instant | 10,000+ | High | Custom integration |

Quantum Dot SWIR Emitters | 30–40% | Fast | 10,000+ | High | Imaging systems |

Phosphor-Converted LEDs | 30–50% | Fast | 8,000+ | Medium | Spectroscopy, imaging |

Tip: I always check radiant efficiency and response time first. These two metrics have the biggest impact on energy savings and process speed.

I match each type of fast response infrared emitter to its ideal application. My experience shows that the right choice depends on the process requirements, environment, and budget. Here is how I break down the suitability:

Replacement Quartz Infrared Tubes: I use these for industrial heating, drying, and curing. Their high efficiency and compatibility make them my go-to for retrofits and upgrades.

Goldenrod Directional Lamps: I choose these for high intensity infrared emitter needs, especially when I want to focus heat and save energy in targeted zones.

Solid-State Thin-Film Emitters: I recommend these for compact systems and applications that need precise control, such as semiconductor processing or lab equipment.

Quantum Dot SWIR Emitters: I rely on these for advanced imaging, medical diagnostics, and research where tunable wavelengths and high sensitivity matter.

Phosphor-Converted LEDs: I use these in spectroscopy and portable sensing devices, where broad emission and moderate efficiency are acceptable.

Note: I always consider the cost of infrared emitters for industrial use when planning large-scale projects. Custom solutions can deliver big savings over time.

Every infrared heating element comes with trade-offs. I weigh these carefully before making a decision:

Efficiency vs. Cost: High efficiency often means a higher upfront cost. I find that replacement quartz infrared tubes offer the best balance for most industrial users.

Lifespan vs. Performance: Some fast response infrared emitters deliver instant heat but may have shorter lifespans if pushed to maximum output.

Customization vs. Lead Time: Custom emitters meet unique needs but may require longer delivery times and higher initial investment.

Integration vs. Compatibility: Advanced emitters like quantum dots or thin-film devices offer superior performance but may need specialized integration.

I always recommend evaluating your process needs, budget, and long-term goals. The right short wave infrared emitter can boost productivity, cut energy costs, and improve product quality.

I often encounter efficiency challenges when working with short wave infrared emitters. High cost and complexity remain major obstacles, especially for SWIR lasers. Many traditional lasers rely on expensive compound semiconductors, which limits scalability and increases the cost of infrared emitters for industrial use. I have seen research teams develop colloidal quantum dot lasers using PbS quantum dots. These new lasers cover broad SWIR wavelengths and work seamlessly with silicon CMOS platforms. This innovation enables low-cost, scalable, and compact lasers, making fast response infrared emitters more accessible for industrial and scientific applications.

Another issue I face involves the high optical gain threshold. Conventional SWIR lasers often require bulky femtosecond amplifiers for excitation. Recent advances in quantum dot technology, such as using larger PbS quantum dots, increase the absorption cross-section. This allows nanosecond excitation, dramatically reducing the optical gain threshold and paving the way for practical, miniaturized laser devices. Integration with silicon photonics also presents challenges. CQD lasers compatible with silicon CMOS technology now make it possible to create miniaturized SWIR photonic circuits, which I find essential for next-generation imaging and sensing systems.

Thermal stability is critical for high intensity infrared emitters and replacement quartz infrared tubes. I have observed that lattice mismatch during fabrication can cause defects and strain, leading to reduced stability and performance. To address this, researchers use metamorphic lattice relaxation layers that gradually adjust lattice constants between the substrate and active layers. This approach reduces lattice strain and defects, resulting in high material quality and flexible bandgap tuning.

Intrinsic material limitations also affect thermal stability. Traditional InGaAs materials have a limited detection range and higher noise, which impacts the reliability of fast response infrared emitters in harsh environments. The development of new materials, such as indium arsenide phosphide (InAsP) grown on InP substrates, expands the detection range from 1.7 μm to 2.8 μm and lowers noise-to-signal ratios. I have seen charge carrier leakage and efficiency droop become problematic at high temperatures and current densities. The introduction of InAsPSb multiple quantum wells with stronger electron and hole confinement minimizes charge leakage, ensuring stable light emission and reduced efficiency droop.

Material innovations continue to drive progress in short wave infrared emitters. I have followed research into nanoribbons and thin-film emitters, which offer new possibilities for infrared heating elements and industrial applications. Refinement of metamorphic lattice relaxation growth techniques suppresses threading dislocations, enabling defect-free, high-quality LEDs with smooth surfaces. This advancement improves the performance and lifespan of high intensity infrared emitters.

The shift toward colloidal quantum dot lasers using PbS quantum dots stands out as a cost-effective and scalable solution. These lasers reduce the optical gain threshold and enable nanosecond excitation, making them ideal for integration into silicon CMOS platforms. I see these innovations expanding the capabilities of replacement quartz infrared tubes and fast response infrared emitters, supporting applications in imaging, sensing, and industrial heating.

I believe ongoing research and material breakthroughs will continue to enhance the efficiency, stability, and versatility of short wave infrared emitters. These advances help me deliver reliable solutions for demanding industrial and scientific environments.

When I choose short wave infrared emitters, I match each type to the task. For industrial heating, I rely on high intensity infrared emitters and replacement quartz infrared tubes. YFR’s fast response infrared emitters stand out for their radiant efficiency and custom options. I see new materials and solid-state designs shaping the future.

Tip: Always compare the cost of infrared emitters for industrial use and check for compatibility. Stay updated on SWIR advances to get the best results.

I see short wave infrared emitters deliver rapid, uniform heating. They reduce energy costs and improve process speed. Their fast response makes them ideal for drying, curing, and precision heating in manufacturing.

Fast response infrared emitters reach full output almost instantly. I use them to minimize warm-up times and reduce downtime. This quick activation supports automated lines and boosts overall productivity.

Yes, I have replaced many standard IR emitters with YFR’s replacement quartz infrared tubes. They fit most major brands and offer high radiant efficiency. Installation is straightforward, and I see immediate performance improvements.

I consider wattage, efficiency, customization, and lifespan. High intensity infrared emitters with advanced features may cost more upfront, but they save money over time through lower energy use and maintenance.

I trust high intensity infrared emitters from reputable brands like YFR for continuous use. Their robust design, thermal management, and quality materials ensure safe, reliable operation in demanding environments.

I select directional lamps, like the Goldenrod, when I need focused heat and energy savings. Standard infrared heating elements work best for broad, uniform heating. Application needs determine my choice.

I perform regular inspections for dust and debris. I check connections and replace lamps at end-of-life. YFR’s emitters require minimal maintenance due to their durable construction and long lifespan.

Yes, I often request custom wattages, lengths, and reflector options. YFR offers tailored solutions for specialized processes, ensuring optimal performance and integration.