Author: Site Editor Publish Time: 2025-08-15 Origin: Site

Short-wave infrared (SWIR) heat lamps have become a key technology for fast, controllable heating in both industrial processes and comfort applications. Instead of slowly warming the surrounding air like conventional heaters, these lamps emit high-intensity infrared radiation that is absorbed directly by surfaces, coatings, and products. The result is rapid heat-up, precise control, and often a significant reduction in energy consumption.

This article explains how short-wave infrared heat lamps work, why they heat so quickly, and how to apply them effectively in real-world environments. It also compares SWIR with other infrared technologies and provides practical guidance on selection, design, and safe operation.

Infrared radiation is part of the electromagnetic spectrum, located just beyond visible red light. Short-wave infrared corresponds to the IR-A band, typically from about 0.78 to 1.4 micrometers in wavelength.

Short-wave infrared heat lamps are usually built as quartz halogen emitters:

A high-temperature tungsten filament is mounted inside a fused quartz glass tube.

An inert or halogen gas fills the tube to protect the filament and enable very high operating temperatures, often well above 2000°C.

At these temperatures, the peak emission shifts into the short-wave infrared region, which is ideal for rapid heating.

Because quartz is highly transparent to short-wave infrared and can withstand extreme temperatures, it is an excellent envelope material for the lamp.

The combination of a very hot filament and a quartz tube yields three core characteristics:

Instant response – full output in seconds, not minutes.

High power density – very high radiant power can be delivered to a relatively small target area.

Directional radiant energy – heat flows directly to the target surface rather than to the surrounding air.

Traditional convection heaters rely on heating air, which then transfers energy by contact and circulation. This method is inherently slow and inefficient, particularly in large or open spaces where warm air quickly escapes.

Short-wave infrared heating is fundamentally different:

Radiation instead of air heating

Radiant energy travels in straight lines and is absorbed by materials at the surface or just below it. Little energy is wasted on warming the air, which has relatively low absorption at many short-wave infrared wavelengths.

High filament temperature

A tungsten filament operating at very high temperature emits intense short-wave infrared radiation. This delivers a high surface heat flux so workpieces reach process temperature quickly.

Low thermal inertia

The filament and quartz tube have low mass compared with heavy metal elements or ceramic blocks. They heat up and cool down rapidly, allowing tight on/off control and power modulation without long soak times.

As a result, parts can often be heated in seconds rather than minutes. In industrial production lines, this enables shorter ovens, higher throughput, and more compact equipment. In comfort applications, people feel warmth almost immediately after switch-on.

A typical short-wave infrared heat lamp contains several engineered elements that directly influence performance, lifetime, and safety.

A high-resistance tungsten wire is wound into a coil or coiled coil.

When current flows through the filament, it generates heat and emits short-wave infrared radiation.

The filament design (pitch, diameter, coil length) determines voltage, wattage, power density, and uniformity of the emitted radiation.

Fused silica (quartz) is chosen for its excellent transmission in the short-wave infrared range and its ability to withstand extreme temperatures and thermal shock.

Tube shapes include single-tube and twin-tube designs. Twin-tube lamps enhance mechanical strength, allow longer spans, and can increase radiation density in narrow spaces.

Inert gases such as nitrogen or argon, sometimes combined with halogen gases, are used to minimize filament evaporation and maintain lamp clarity.

In halogen lamps, the halogen cycle continuously redeposits evaporated tungsten back onto the filament rather than the glass, preserving output and infrared intensity over the lamp’s life.

Gold or ceramic white coatings applied directly to the quartz act as built-in reflectors. They direct infrared energy toward the product and reduce losses to surrounding structures.

Reflector geometry (flat, parabolic, elliptical) is selected based on the required heating pattern, whether a concentrated spot, linear zone, or wide area.

Standard lamp caps or custom ceramic ends provide secure electrical contact and reliable mechanical support.

Mounting hardware ensures stable positioning, appropriate clearance, and good thermal isolation from supporting structures and surrounding equipment.

From an energy-engineering perspective, short-wave infrared lamps are attractive because they convert a high proportion of electrical power into usable radiant heat at the target.

Several factors contribute to this efficiency:

Direct radiant transfer

Energy is directed primarily into workpieces, coatings, or people, rather than into raising the air temperature. This reduces convective and ventilation losses.

High power density and short cycle times

Shorter process times reduce the overall energy consumption per part produced. Heating ovens and tunnels can be physically smaller while delivering equal or higher throughput.

On-demand operation

Because lamps reach full output within seconds, systems can be cycled or modulated closely with production flow. There is less need for “idling” heat during planned or unplanned stops.

Zoning and selective heating

Infrared modules can be divided into zones that only energize where products are present. With appropriate sensing and control, energy is targeted rather than wasted.

In many industrial environments, well-designed infrared systems can deliver significant reductions in energy consumption, especially in drying, curing, and preheating processes, while also improving process consistency.

You feel warm right away with a short wave infrared heat lamp. The lamp gets hot in one or two seconds. You do not have to wait for the air to warm up. The heat goes straight to you and nearby things. This makes you feel cozy very fast. If you use these lamps for jobs like ir paint curing lamps or powder coating with infrared lamp, you see results quickly. The heat goes deep into surfaces and helps you finish work faster. You can change the temperature easily. You get just the right amount of heat for your project.

Tip: Use shortwave infrared heating if you want to work faster or stay warm right away.

Short wave infrared heat lamps help you save energy. These lamps heat people and things directly. You do not waste energy warming the air. In places like garages or workshops, air can escape easily. Focused heating means you use less electricity and pay lower bills. Shortwave infrared heating systems get hot in seconds. You only use energy when you need it. Rooms warm up fast and stay warm longer. Surfaces keep heat even after you turn off the lamp. Regular heaters warm the air, but the air rises and leaves the room. This uses more energy. Infrared heat cuts down on energy waste and saves you money.

Infrared heat also helps the environment. These lamps do not make nitrogen oxides or carbon monoxide. They do not cause extra pollution and keep the air clean. In factories, infrared heating works better and saves time. You use less energy and make less pollution than with old heating methods.

Short wave infrared lamps are easy to use. You turn them on and get heat right away. You do not need to wait or change hard settings. Many lamps have remote controls or simple switches. They need little care because they have strong quartz tubes and good filaments. You can use them for many things, like home heating or jobs such as what is infrared quartz heater for glass or plastic molding.

Huai’an Infrared Heating Technology gives you good products. Their lamps meet strict rules and have CE certification. You get a warranty for 5,000 to 8,000 hours of use. Your lamp will last a long time. Here is a table with certifications and quality checks:

Product Type | Certification | Warranty (Operating Hours) | Quality Assurance Measures |

|---|---|---|---|

Carbon Fiber Quartz Infrared Heater | CE | 5000-8000 | Strict quality control during manufacturing |

Quartz Infrared Lamps with Reflector | CE | 5000-8000 |

You can trust your infrared heat lamp to be safe and strong. You get easy use and great performance every time.

Short-wave infrared technology is used wherever rapid, controllable heating of surfaces or thin materials is required. Typical applications include:

Paint and powder coating curing

Short-wave infrared penetrates into wet coatings, driving off solvents or water and promoting cross-linking from the inside out. This can shorten curing times and improve surface finish.

Glass processing

Pre-heating and edge-heating of glass sheets before cutting, bending, or laminating become faster and more uniform with short-wave emitters, which helps reduce thermal stress and breakage.

Plastics forming and thermoforming

Films, sheets, and preforms, such as PET bottles, often absorb short-wave infrared efficiently. Precise control of heat distribution across zones helps avoid warping, thinning, or under-heating.

Digital printing and coatings

Conveyor dryers equipped with short-wave infrared lamps accelerate drying of inks, primers, and clear coats, enabling higher print speeds and reducing the risk of smearing or offset.

Electronics and photovoltaics

Soldering, reflow, pre-baking, and cell interconnection processes benefit from fast ramp-up and localized heating. This minimizes thermal exposure of sensitive components and can improve yield.

Agricultural and food processing

Short-wave infrared heating is used to dry seeds and grains and to cure or set coatings on food products, as well as for surface decontamination steps where controlled temperatures are essential.

In many of these cases, short-wave emitters either replace or supplement hot-air and medium-wave systems to achieve shorter cycle times, higher throughput, or improved product quality.

Beyond industrial use, short-wave infrared heat lamps are widely used for spot and zone heating in:

Patios, terraces, and outdoor dining areas

Workshops and garages

Loading docks, smoking areas, and outdoor waiting zones

High-ceilinged halls, churches, and event spaces

Short-wave infrared is particularly suited to challenging environments where air is constantly replaced by wind or drafts. Instead of trying to heat the entire volume of air, the system delivers radiant energy directly to people and nearby surfaces.

In the human body, infrared in the IR-A band can penetrate several millimeters into the skin, reaching the dermis and subcutaneous layers. This deeper penetration explains the strong sensation of warmth even when ambient air remains relatively cool.

However, comfort design must balance intensity and reflection:

At very high intensities, a portion of short-wave radiation is reflected from the skin surface.

To ensure comfort and avoid glare, lamps are often used with diffusers, low-glare coatings, or carefully calculated distances and angles.

System designers should consider mounting height, seating positions, and ambient conditions to achieve even, comfortable heating.

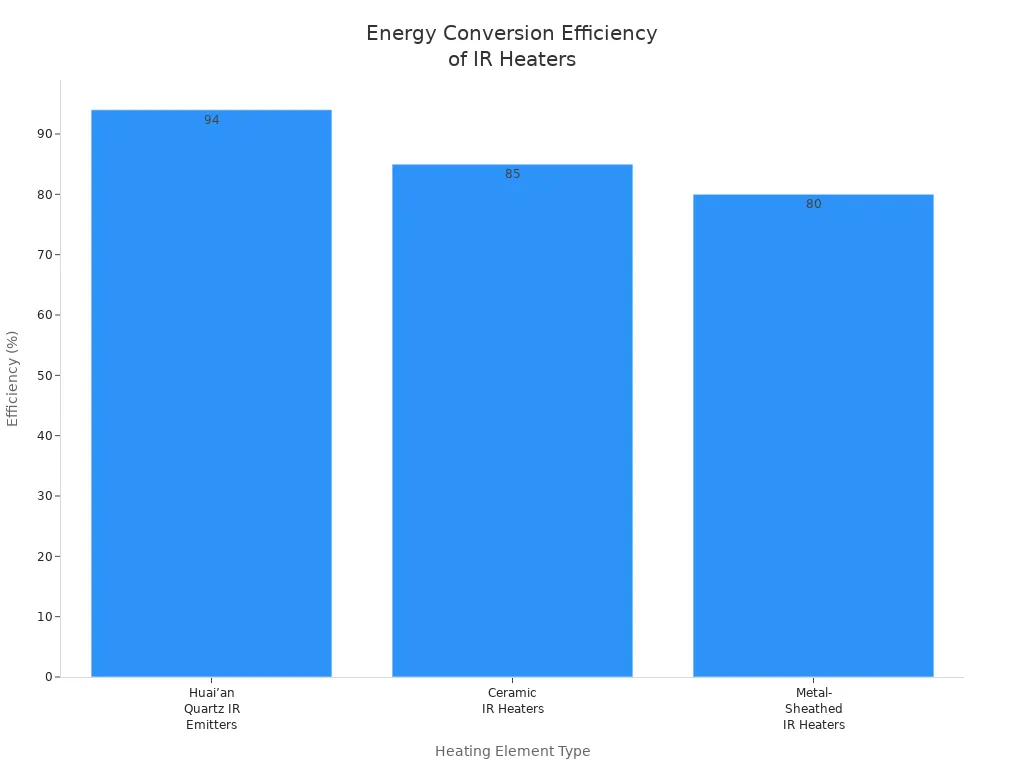

Infrared heaters are generally categorized into three bands, each with specific strengths and typical applications.

Short-wave infrared (IR-A, approximately 0.78–1.4 micrometers)

Very high filament temperatures

Deep penetration into many materials and into human skin

Best for rapid heating, high power density, and compact equipment

Medium-wave infrared (IR-B, approximately 1.4–3 micrometers)

Lower surface temperatures and gentler heat

Often better matched to water-based coatings and some plastics that absorb strongly in this band

Widely used for drying, plastics processing, and many comfort heating applications

Long-wave infrared (IR-C, above approximately 3 micrometers)

Typically generated by ceramic or metal-sheathed elements at lower temperatures

Heats mainly surfaces and nearby air

Common in space heating, low-intensity comfort heaters, and some industrial ovens

For many high-speed industrial processes and demanding outdoor installations, short-wave infrared is the preferred option because it delivers the deepest, fastest heating in the smallest footprint. Medium-wave and long-wave systems remain valuable where slower, gentler, or bulk air heating is required.

To fully realize the benefits of short-wave infrared heating, engineers and specifiers should carefully consider several design parameters.

Different materials absorb infrared energy more effectively at specific wavelengths. Matching the emitter’s spectrum to the absorption characteristics of the product improves efficiency and process control.

Although short-wave lamps are relatively broadband within the IR-A band, their peak around the near-infrared region aligns well with many metals, glass, and certain plastics. For highly water-rich or solvent-rich coatings, combinations with medium-wave emitters may be optimal.

Select lamp wattage and length based on required heat flux and target area.

Adjust mounting distance and angle to achieve uniform coverage and avoid hot spots.

Use twin-tube emitters or modular arrays to scale up power and tailor heating profiles to the product geometry.

Short-wave lamps respond quickly, which makes them ideal for advanced control strategies:

Phase-angle or burst-firing control with solid-state relays

Closed-loop control using pyrometers, thermocouples, or infrared cameras

Zoned control along conveyors or forming lines, synchronized with line speed and product location

Sophisticated control enables precise temperature ramps, hold times, and cool-down profiles, which are essential for high-quality curing and forming.

Evaluate dust, humidity, vibration, and chemical exposure when selecting fixtures and housings.

For outdoor or wash-down environments, use appropriately rated enclosures and ingress-protection levels.

Ensure that fixtures include mechanical guards, shields, or glass panels to protect both lamps and personnel from accidental contact.

Short-wave infrared lamps deliver very high surface temperatures and must be handled with care. Good practice includes:

Handling and installation

Avoid touching quartz with bare hands; fingerprints can create hot spots and stress. Use clean gloves or a soft cloth.

Ensure firm, vibration-resistant mounting to prevent shock damage.

Maintain recommended clearances from combustible materials and from personnel.

Cleaning and maintenance

Periodically wipe quartz surfaces with a lint-free cloth and a suitable cleaning agent to remove dust and contaminants.

Inspect electrical connections for discoloration, corrosion, or looseness.

Replace lamps at the end of their rated service life or if visible damage, darkening, or significant output reduction occurs.

Thermal and electrical safety

Incorporate over-temperature protection for enclosures and surrounding structures.

Use appropriate fusing, grounding, and wiring sized for high currents and elevated ambient temperatures.

Provide interlocks or emergency-off circuits where required by local codes and standards.

Worker protection

Avoid direct staring into operating lamps at close distance.

In high-intensity or close-range installations, consider eye protection and shielding against glare.

Provide clear operating procedures and warning labels consistent with safety regulations.

Following these guidelines helps maintain both safety and long-term lamp performance in demanding industrial and commercial environments.

When electrical current passes through a tungsten filament inside a quartz envelope, the filament quickly reaches a very high temperature. At this temperature it emits intense short-wave infrared radiation. The quartz glass transmits this radiation while containing the gas fill and protecting the filament. The radiant energy travels directly to nearby surfaces, which absorb it and convert it into heat almost instantly.

Most short-wave quartz halogen emitters reach operating temperature within a few seconds. Because of their low thermal mass, they can also cool rapidly when switched off, making them well suited for on-demand and modulated heating.

Service life depends on design, operating temperature, switching cycles, and environmental conditions. Many industrial short-wave lamps are designed for several thousand operating hours under nominal conditions, provided they are installed correctly, cooled appropriately, and kept clean.

When applied correctly, short-wave infrared heaters are safe and widely used in commercial and public spaces. As with any high-intensity radiant source, exposure should be managed:

Maintain recommended distances and avoid excessively high intensities.

Minimize direct staring into lamps.

Use shields or diffusers to reduce glare where people are very close to the source.

System design should always consider exposure time and intensity, particularly for installations in close proximity to occupants, and follow applicable safety guidelines.

Yes. Short-wave infrared technology is used in residential and light-commercial heaters, particularly for patios, balconies, and workshops. When choosing a heater for home use, it is important to select products that comply with relevant electrical and safety standards, provide adequate protection for outdoor use, and include clear installation and operating instructions.

Short-wave infrared heat lamps combine very high filament temperature, quartz-based construction, and targeted radiant transfer to deliver exceptionally fast and efficient heating. When specified and applied correctly, they can:

Reduce energy consumption by focusing heat where it is needed

Shorten process times and increase line throughput

Provide reliable heating in challenging industrial and outdoor environments

Deliver immediate comfort in open or drafty spaces

By understanding the underlying physics, carefully matching wavelength and power density to the material, and applying sound engineering and safety practices, designers and operators can take full advantage of short-wave infrared technology to make heating easier, faster, and more sustainable.