Author: Site Editor Publish Time: 2025-07-30 Origin: Site

I have seen how Golden 8 infrared emitters set a new benchmark in modern infrared heat. When I compare these emitters to traditional options, I notice a leap in efficiency and performance. The twin quartz tube layout and gold reflector deliver unmatched radiation density and directionality. I find the rapid response time and improved mechanical stability impressive, especially for demanding industrial environments.

Feature | Golden 8 Infrared Emitters | Typical Infrared Emitters |

|---|---|---|

Tube Design | Twin quartz tube | Single/round tube |

Power Density | Up to 110 kW/m² | Up to 85 kW/m² |

Heated Length | Up to 5000 mm | Up to 1500 mm |

Reflector | Gold-coated | Standard/none |

I encourage you to consider what truly sets superior infrared heating technology apart when choosing emitters for your toughest applications.

Golden 8 infrared emitters use a unique dual quartz tube and gold reflector design to deliver higher radiation density and precise heat targeting.

These emitters reach full power in as little as one second, allowing fast and accurate temperature control that saves energy and protects materials.

The gold reflector improves energy efficiency by nearly doubling infrared radiation output, reducing power consumption and lowering operating costs.

Robust construction with high-purity quartz and gold coating extends emitter lifespan and reduces maintenance needs, ensuring reliable long-term use.

Customization options let you choose wavelength, size, and filament type to match specific industrial or wellness applications for optimal results.

Golden 8 emitters integrate easily into existing systems with flexible installation and strong technical support for smooth operation.

They perform well across many industries, including manufacturing, food processing, HVAC, and FIR therapy, improving product quality and process efficiency.

Investing in Golden 8 technology offers long-term savings through energy efficiency, reduced downtime, and enhanced heating performance.

When I evaluate output, I look for consistent, high-intensity heat delivery. Golden 8 infrared emitters stand out with their unique dual-tube design. This design increases the radiation density, which means I see more energy delivered directly to the target. The gold-coated reflector plays a crucial role. It directs the infrared energy with precision, reducing losses and maximizing the usable output. In my experience, this results in a more uniform heat distribution across the entire process area. I have seen Golden 8 emitters reach power densities up to 110 kW/m², which surpasses many standard infrared emitters. This level of output is essential for demanding industrial applications, especially when I need to maintain high throughput and consistent product quality.

Speed matters in every industrial process. I have tested many infrared emitters, but the Golden 8 series impresses me with its rapid response. The shortwave and fast-response medium wave emitters can reach full output in as little as one second. This quick reaction allows me to control the heating process with precision. I can start and stop the system instantly, which reduces energy waste and improves process efficiency. The fast response also helps protect sensitive materials from overheating. In my experience, this feature is especially valuable in applications like surface treatment and FIR-based drying, where timing is critical.

Efficiency defines the value of any infrared system. I always look for emitters that convert electrical energy into usable infrared radiation with minimal loss. Golden 8 infrared emitters excel here. The gold reflector nearly doubles the radiation efficiency compared to standard models. I notice lower power consumption for the same heating effect, which translates into real savings for any operation. The high-purity quartz tubes also contribute to this efficiency by allowing more infrared energy to pass through without absorption or scattering. When I integrate these emitters into a system, I see a clear reduction in overall energy costs.

Effective heat management ensures the longevity and safety of any infrared system. The Golden 8 design addresses this with its robust dual-tube construction and advanced reflector technology. I have observed that the gold-coated reflector not only boosts output but also keeps the system cooler by directing heat away from sensitive components. This design minimizes heat buildup inside the system, which protects wiring and support structures. In my experience, this leads to fewer maintenance issues and a more stable process environment. The ability to manage heat efficiently is especially important in FIR applications, where precise temperature control is vital for product quality.

Reliability is non-negotiable in industrial settings. I rely on infrared emitters that can withstand continuous operation without frequent replacement. Golden 8 emitters use high-purity quartz and a figure-8 dual-tube design, which provide exceptional mechanical stability. Even at lengths up to 6.5 meters, I have seen these emitters maintain their structural integrity and output. The gold reflector also protects the filament from oxidation, extending the emitter’s lifespan. In my experience, this means fewer interruptions and lower replacement costs over the life of the system.

Maintenance can disrupt any process, so I prefer emitters that require minimal attention. Golden 8 infrared emitters simplify maintenance with their durable construction and efficient heat management. The gold reflector reduces dust accumulation and makes cleaning easier. I find that the robust design minimizes the risk of breakage, even in high-vibration environments. When I use these emitters in an infrared system, I spend less time on upkeep and more time focusing on production. This reliability supports continuous operation, which is essential for maintaining high-quality output in any industrial process.

When I consider investing in infrared heating solutions, I always weigh the initial purchase price against the long-term benefits. Golden 8 infrared emitters may require a higher upfront investment compared to standard models. However, I see this as a strategic decision. The advanced dual-tube design, gold-coated reflector, and high-purity quartz construction deliver immediate performance advantages. These features allow me to achieve higher power densities and more precise heat targeting, especially in demanding FIR applications.

Tip: I recommend evaluating not just the sticker price, but also the value added by improved process efficiency and reduced downtime.

I have found that the ability to customize wavelength, size, and filament type means I can tailor the emitter to my exact process needs. This flexibility often eliminates the need for additional equipment or retrofits. In my experience, the investment in Golden 8 technology pays off quickly, especially in industries where FIR heating is critical for product quality and throughput.

Lifecycle cost matters just as much as the initial investment. I always look at the total cost of ownership over the lifespan of the emitter. Golden 8 infrared emitters stand out here. The robust figure-8 dual-tube design and gold reflector extend operational life, even in continuous-use environments. I have seen these emitters maintain high output and mechanical stability for years, which reduces the frequency of replacements.

Lower maintenance requirements mean I spend less on service and spare parts.

The gold reflector protects the filament, which helps prevent premature failure.

High-purity quartz resists thermal shock, so I avoid costly downtime.

In FIR applications, I notice that the rapid response time and efficient heat management further reduce energy consumption. This efficiency translates into lower utility bills and a smaller environmental footprint. Over the full lifecycle, I find that Golden 8 emitters deliver significant savings compared to conventional infrared solutions.

Note: When I calculate the total cost of ownership, I always include energy savings, reduced maintenance, and increased production uptime. These factors make Golden 8 a smart choice for any operation that relies on FIR technology.

When I work with advanced infrared heating technology, I always look for features that deliver real performance gains. The figure-8 dual-tube design in Golden 8 infrared emitters stands out in every project I manage. This design gives me better stability, higher radiation density, and more power intensity than single-tube models. I see these benefits in both shortwave and medium wave applications. The dual-tube structure also allows for fast response times, reaching full power in just 1–2 seconds. I can control temperature with precision, often within ±1°C, using PLC or SCR regulators. The compact design fits into tight spaces, whether I install the system horizontally or vertically. I notice up to 50% energy savings compared to older methods. Uniform heating improves product quality, especially in processes like glass cutting, lamination, and curing.

Performance Improvement Aspect | Description |

|---|---|

Stability | Dual-tube design provides better stability for short wave, medium wave, and carbon medium wave infrared lamps. |

Radiation Density & Power Intensity | High radiation density and high power intensity enable efficient energy transfer. |

Fast Response Time | Achieves full power in 1-2 seconds, suitable for fast heating applications (50–500℃). |

Temperature Control | Accurate IR heating temperature control within ±1 ℃ using PLC or SCR regulators. |

Installation Flexibility | Small installation space, flexible for horizontal or vertical positioning. |

Energy Efficiency & Savings | Improves heating efficiency and can save up to 50% energy compared to conventional methods. |

Uniform Heating & Product Quality | Enhances uniform heating, improving product stability and quality in industrial processes like glass cutting, lamination, drying, and curing. |

Enhanced IR Radiation Focus | Special gold or ceramic reflectors coated on quartz surface improve IR radiation conveyance and focus on heated materials. |

Application Versatility | Widely used in glass treatment, drying inks, curing coatings, and plastic forming due to its performance benefits. |

I always pay close attention to how a system manages and delivers energy. The gold reflector in Golden 8 emitters changes the game for me. This technology shortens heating time by about 30% compared to traditional conduction heating. I see rapid and uniform heating, especially with thin film materials. The gold reflector focuses and reflects infrared radiation more effectively, which increases radiation density and improves energy transfer to the target. I notice better film thickness uniformity and surface flatness, often by 20%. The gold reflector also helps me achieve faster heating times and improved uniformity. I can match the infrared wavelength precisely to the material’s absorption, which optimizes energy efficiency. This approach reduces overall energy consumption and boosts the performance of my FIR applications.

The gold reflector enhances the efficiency of infrared radiation delivery.

I achieve faster heating times and improved uniformity.

The system allows precise temperature control and fast heating response.

I replace higher energy consumption heating elements, reducing total energy use.

The gold reflector increases mechanical stability and radiation density.

Every industrial process I manage has unique requirements. Golden 8 infrared emitters give me the flexibility to select the right wavelength for each application. I can choose from shortwave, mediumwave, and fast mediumwave options. This flexibility lets me optimize the system for different materials and processes. For example, shortwave radiation penetrates deeper, which is perfect for uniform heating of solids. Mediumwave options heat surfaces efficiently, making them ideal for glass, plastics, and water-based materials. I can tune the emission spectrum to match specific industrial needs, such as gas detection or surface treatment. The ability to select the right wavelength improves process efficiency and product quality.

Aspect | Description | Impact on Performance |

|---|---|---|

Metamaterial Geometry | Circle-shaped and ring-shaped patterns with tunable deformation ratios (n) | Enables precise tuning of emission wavelengths across a broad IR spectrum (2.16 µm to 5.83 µm) |

Wavelength Tuning Range | Circle-shaped: 2.13 µm (2.16 to 4.29 µm); Ring-shaped: 3.22 µm (2.61 to 5.83 µm) | Larger tuning range in ring-shaped metamaterials allows better matching to target gas absorption lines |

Transmission Intensity | Circle-shaped increases from 75% to 85%; Ring-shaped stable around 74-76% | Stable or enhanced transmission intensity improves radiated power and emitter efficiency |

Resonance Quality | Ring-shaped metamaterials reduce lower-order resonances and interference | Narrower full-width at half-maximum (FWHM) leads to higher wavelength selectivity and sensitivity |

Material | Gold (Au)-based microheaters | High thermal conduction and uniform temperature improve electrothermal conversion efficiency and radiated power |

Application Example | Emission at 2.44 µm matches CO2 absorption at 2.369 µm | Enhances gas sensing sensitivity and efficiency in industrial applications |

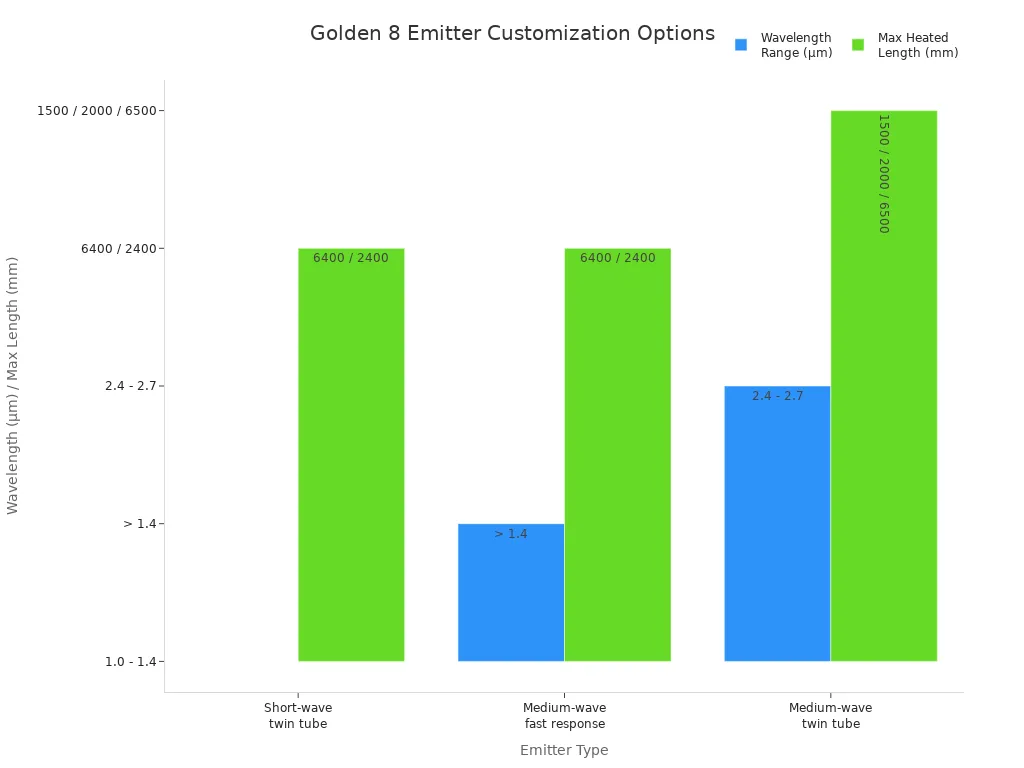

I often need emitters that fit specific spaces or deliver targeted heating. Golden 8 infrared heating technology offers a wide range of customization options. I can select the emitter type, wavelength range, maximum heated length, and cross-section dimensions. The system supports special filament configurations and unique geometries, such as omega-shaped or bent designs. This flexibility allows me to meet the exact requirements of each project, whether I need a long heated length or a compact emitter for a tight space.

Emitter Type | Wavelength Range (µm) | Max Heated Length (mm) | Cross-Section Dimensions (mm) |

|---|---|---|---|

Short-wave twin tube emitter | 1.0 - 1.4 | Up to 6400 / 2400 | 34 x 14 / 23 x 11 |

Medium-wave fast response | > 1.4 | Up to 6400 / 2400 | 34 x 14 / 23 x 11 |

Medium-wave twin tube emitter | 2.4 - 2.7 | Up to 1500 / 2000 / 6500 | 18 x 8 / 22 x 10 / 33 x 15 |

I value solutions that integrate smoothly into existing systems. Golden 8 infrared emitters make this process easy for me. The compact dual-tube design fits into both new and retrofit installations. I can position the emitters horizontally or vertically, which gives me flexibility during setup. The fast response time and precise temperature control allow me to synchronize the emitters with automated production lines. I see fewer disruptions and smoother operation in every FIR application I manage.

Reliable support makes a big difference in my daily work. When I use Golden 8 infrared heating technology, I know I can count on expert guidance and responsive service. The manufacturer provides detailed technical documentation, training, and troubleshooting assistance. I get help with system integration, maintenance planning, and process optimization. This level of support ensures that my infrared system runs efficiently and delivers consistent results. I spend less time solving problems and more time focusing on production goals.

Tip: I always recommend working with suppliers who offer strong technical support and customization options. This approach helps me maximize the value of my FIR investment and keeps my operations running smoothly.

I have spoken with several industry experts about the rapid adoption of fir technology. Many specialists in thermal processing highlight the unique advantages of Golden 8 emitters for fir therapy and industrial heating. They point out that the dual-tube design and gold reflector set a new standard for efficiency. Experts in medical applications of fir emphasize the importance of precise wavelength control. They say that this feature supports both industrial and health-related uses, including fir saunas and advanced fir therapy systems.

One analyst told me,

"The biological effects of fir are well-documented. Golden 8’s ability to deliver targeted fir wavelengths opens new doors for both manufacturing and fir therapy."

I have noticed that researchers in the field of infrared heating often reference the stability and output of Golden 8 emitters. They see these as essential for applications where the biological effects of fir play a role, such as in fir saunas and specialized fir therapy equipment.

I have received feedback from customers in a wide range of industries. Many users praise the consistent performance of Golden 8 emitters in fir therapy rooms and fir saunas. They mention that the rapid response time and uniform heat distribution improve both comfort and process results. Customers in the wellness sector report that fir saunas equipped with Golden 8 technology provide a more effective and enjoyable experience. Manufacturing clients tell me that the emitters support fir-based drying and curing, which leads to higher product quality.

Customers often say, "We trust Golden 8 for all our fir therapy and fir sauna needs. The technology delivers reliable results every time."

I have observed a clear trend toward fir solutions in both industrial and wellness markets. The demand for fir therapy continues to grow, especially as more people learn about the health benefits. Fir saunas have become a staple in spas and fitness centers. I see manufacturers investing in fir-based systems to improve energy efficiency and product quality. The market for infrared heating, especially fir, is expanding as companies seek advanced solutions for both production and fir therapy.

Market Segment | Growth Driver | Golden 8 Role |

|---|---|---|

Industrial | Energy savings, efficiency | High-output fir emitters |

Wellness | Health, relaxation | Fir saunas, fir therapy tech |

Medical | Biological effects of fir | Specialized fir equipment |

Golden 8 emitters have influenced competitors to rethink their approach to fir and infrared heating. I see more companies adopting fir therapy systems and integrating fir saunas into their offerings. The proven biological effects of fir drive innovation in both wellness and industrial sectors. Golden 8’s leadership in fir technology has raised the bar for performance and reliability. I believe this impact will continue as more industries recognize the value of fir, fir therapy, and the unique benefits of advanced infrared solutions.

I have worked with many manufacturing lines that demand precise and efficient heating. Golden 8 infrared emitters deliver the performance I need for plastics, metals, glass, and textiles. I rely on their rapid response and high radiation density to speed up the curing process for adhesives and coatings. In powder coating curing, I see consistent results and improved product quality. The ability to select the right wavelength—shortwave for deep penetration or mediumwave for surface heating—lets me match the emitter to each material. This flexibility ensures that every process, from drying to welding, runs smoothly and efficiently.

In processing environments, I often face challenges with throughput and energy use. Golden 8 infrared technology helps me overcome these obstacles. I use these emitters for preheating films, laminating, and embossing. The twin quartz tube design provides mechanical stability, even in long installations. I notice that the gold reflector directs energy exactly where I need it, reducing waste. When I manage processes like plastic molding or glass heating, I see faster cycle times and lower maintenance needs. The short response time of the carbon filament allows me to control temperature changes instantly, which is critical for sensitive materials.

I have installed Golden 8 infrared emitters in commercial HVAC systems to improve comfort and efficiency. The emitters provide targeted heating, which reduces energy consumption and creates a more pleasant environment. I can integrate them into existing systems without major modifications. The fast response and precise control make them ideal for spaces that require quick temperature adjustments. I find that the gold reflector and high-quality quartz glass ensure stable operation, even with frequent cycling.

In the food industry, I use infrared heating for drying, sterilization, and surface treatment. Golden 8 emitters help me achieve uniform results in baking, roasting, and pasteurization. The ability to choose the correct wavelength is essential. For example, mediumwave infrared works well for surface drying, while shortwave penetrates deeper for thorough heating. I have seen energy savings and improved product consistency in every process. The robust design of the emitters stands up to the demands of continuous food production.

Surface treatment applications benefit greatly from Golden 8 technology. I rely on the twin quartz tube design for higher radiation density and stability. The gold reflector increases energy efficiency by focusing the radiation on the target. I use these emitters to dry water-based coatings and paints, often using about 30% less energy than traditional shortwave infrared systems. The rapid response of the carbon filament allows me to start and stop the process quickly, which is vital for high-speed production lines. The ceramic lamp base and high-quality quartz glass provide durability and thermal stability, reducing downtime.

Key advantages I observe:

High radiation density for efficient drying and curing

Fast response time for rapid process control

Durable construction for long-term reliability

Energy savings in water-based coating applications

I have applied Golden 8 emitters in specialty tasks such as FIR therapy, FIR saunas, and advanced medical equipment. The precise wavelength control supports both industrial and wellness uses. In FIR therapy rooms, I see improved comfort and therapeutic effects. For industrial specialty tasks, such as gas detection or specialty curing, the ability to customize the emitter’s size and wavelength is invaluable. I can optimize each process for maximum efficiency and product quality.

Tip: Always match the infrared wavelength to the material and application. This approach maximizes efficiency and ensures the best results for every process, from curing to FIR therapy.

I have seen Golden 8 infrared emitters deliver unmatched efficiency, durability, and advanced technology in every project. These features make them a top choice for industrial users who need reliable, high-performance heating. I recommend considering Golden 8 for your next system upgrade or procurement. For those interested in deeper technical details, I often refer to application notes, case studies, expert tips, selection guides, technical articles, handling instructions, and webinars. Detailed datasheets and industry publications also provide valuable insights.

I notice the dual-tube design and gold reflector set Golden 8 apart. These features boost radiation density and efficiency. I see more precise heat targeting and longer operational life compared to typical single-tube emitters.

Yes, I can select wavelength, size, and filament type to match specific needs. This flexibility lets me optimize heating for different materials and processes, whether I work in manufacturing, food, or specialty applications.

I have measured response times as fast as one second for shortwave models. This rapid start allows me to control heating processes with precision and minimize energy waste during production.

Absolutely. I see lower power consumption due to the gold reflector and high-purity quartz. These components maximize infrared output, so I achieve the same heating effect with less energy.

I spend less time on maintenance because of the robust construction and efficient heat management. The gold reflector reduces dust buildup, and the quartz tubes resist thermal shock, which keeps the system running smoothly.

I use Golden 8 emitters in plastics, glass, metal, textiles, food, and wellness sectors. Their versatility and efficiency make them ideal for drying, curing, welding, surface treatment, and even FIR therapy applications.

I always match the wavelength to the material. Shortwave penetrates deeper for uniform heating of solids. Mediumwave works best for surface heating, especially with glass, plastics, or water-based products.

Tip: If you need help selecting the right model, I recommend consulting with a technical expert or requesting a product demo.