Views: 0 Author: Site Editor Publish Time: 2025-09-22 Origin: Site

Infrared tubes serve as advanced solutions for efficient heating and drying across industries. Huai'an Infrared Heating Technology stands out as a leader in the field, offering innovative tube designs for targeted infrared heating. Recent studies show infrared tubes provide radiant heat that directly warms objects and people, which can reduce energy consumption and support low-carbon heating. The global market for infrared radiant tube heaters reached USD 1.2 Billion in 2024 and is projected to grow rapidly:

Expected to reach USD 2.5 Billion by 2033

CAGR of 9.2% from 2026 to 2033

Short Wave, Medium Wave, and Long Wave infrared lamps each deliver unique benefits, including fast response and improved efficiency for industrial applications.

Infrared tubes provide efficient heating by directly warming objects, reducing energy waste and costs.

These tubes come in short wave, medium wave, and long wave types, each suited for specific applications.

Infrared heating systems can achieve up to 96% energy conversion efficiency, making them highly effective.

Infrared technology supports faster drying processes in industries like food and textiles, preserving product quality.

Safety features, such as protective shields and CE certification, ensure reliable operation in various environments.

Regular maintenance, including cleaning and inspections, helps extend the lifespan of infrared tube systems.

Infrared tubes are versatile, suitable for both indoor and outdoor heating applications, enhancing comfort and productivity.

Choosing the right infrared tube based on wavelength and power output is crucial for optimal performance.

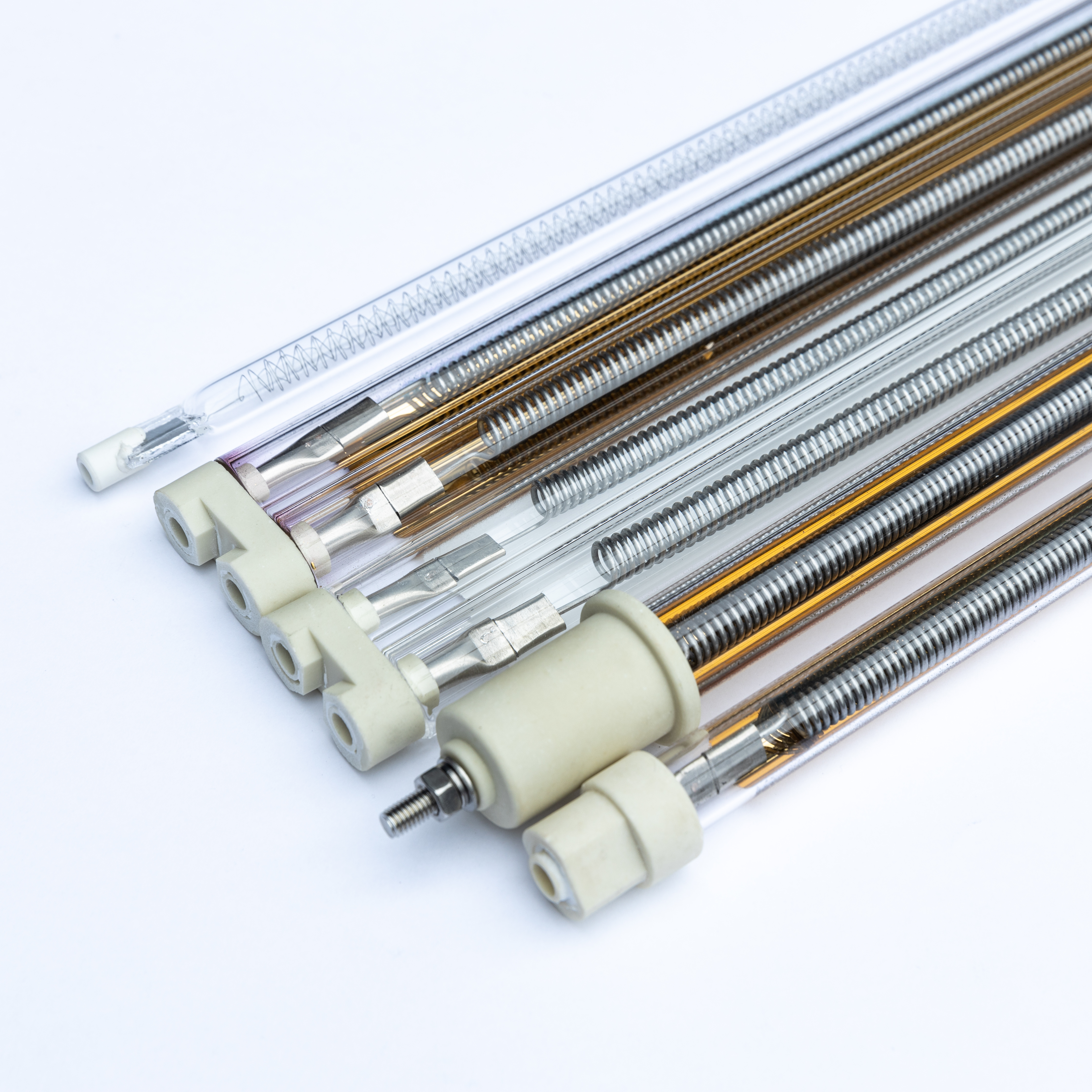

Infrared tubes represent a specialized form of radiant heating technology. Manufacturers design these tubes to emit infrared energy, which directly warms objects and surfaces without relying on air as a medium. Huai'an Infrared Heating Technology produces a wide range of infrared tubes, including short wave, medium wave, and long wave infrared lamps. Each tube contains a heating element, often made from tungsten or specialty alloys, coiled inside a quartz enclosure. This design allows for efficient energy transfer and rapid heat delivery. Quartz infrared heaters use high thermal conductivity materials to maximize durability and performance. These tubes serve as essential components in industrial and commercial heating applications, offering targeted and reliable heat output.

Infrared tubes possess several features that set them apart from conventional heaters. The following table highlights the most important characteristics:

Feature | Description |

|---|---|

Heating Element | Made from tungsten or specialty alloys, coiled to produce radiant energy. |

Reflective Surface | Maximizes heat direction and output by reflecting infrared radiation towards the target area. |

Protective Shield | Prevents accidental contact with the hot element, reducing burn or fire hazards. |

Quartz or Conductive Tube | Housed within a tube made from high thermal conductivity materials, enhancing durability and efficiency. |

Energy Efficiency | High conversion efficiency minimizes wasted energy and reduces utility bills. |

Immediate Heat Output | Provides instant heat, improving comfort and productivity. |

Uniform, Directional Heating | Delivers consistent, even heating without cold spots or drafts. |

Reduced Airborne Contaminants | Helps reduce circulation of dust and allergens, supporting a healthier indoor environment. |

Low Maintenance | Requires less maintenance than conventional HVAC systems due to fewer moving parts. |

Eco-Friendly Operation | Electric models do not produce combustion byproducts, making them safe for indoor use. |

Huai'an Infrared Heating Technology ensures product quality and safety through CE certification, TUV compliance, and trademark registration. These certifications guarantee that each tube meets strict health, safety, and environmental standards. The following table summarizes the main certifications:

Certification | Region | Implications |

|---|---|---|

CE | Europe | Ensures compliance with health, safety, and environmental protection standards |

TUV | Global | Guarantees product safety and quality through rigorous testing and certification processes |

Note: Additional certifications such as ISO 9001, ISO 14001, and RoHS further support quality management, environmental responsibility, and safe operation.

Infrared tubes are classified by their wavelength and visibility. Each type suits different applications and heating requirements. Huai'an Infrared Heating Technology offers short wave infrared heaters, medium wave, and long wave models to address a variety of needs. The table below outlines the main types:

Type of Heater | Wavelength Range (nm) | Visibility |

|---|---|---|

Shortwave Heaters | 780 - 1,400 | Visible to the naked eye |

Medium Wave Heaters | 1,400 - 3,000 | Slightly visible |

Far-infrared Heaters | Above 3,000 | Non-visible |

Short wave infrared heaters deliver rapid heat and suit high-speed industrial processes. Medium wave models provide balanced heating for applications such as digital printing and plastic molding. Far-infrared heaters, including quartz panel heaters, offer gentle, non-visible warmth ideal for comfort heating and sensitive environments. Each tube type supports specific application requirements, ensuring optimal performance and energy efficiency.

Infrared technology relies on the emission of electromagnetic radiation to generate heat. When charged particles inside a heating element accelerate or decelerate, they release energy in the form of infrared waves. All objects above absolute zero emit this type of radiation, which falls within a wavelength range of 1 to 1000 microns. As the temperature of an object increases, it emits more infrared radiation. This process follows the laws of thermodynamics and electromagnetic radiation. Infrared tubes use this principle to deliver heat directly to surfaces and objects, making them highly effective for industrial and commercial heating.

Infrared thermography demonstrates this concept by capturing the radiation emitted from objects and converting it into visible thermal images. This non-contact method allows for precise monitoring of temperature variations, which is essential for preventive maintenance and quality control in many industries.

Radiant heat transfer sets infrared heating apart from other methods. Unlike convection, which moves heat through air currents, or conduction, which requires direct contact between materials, radiant heat travels as electromagnetic waves. These waves move outward from the source and do not need a medium to transfer energy. The sun provides a clear example of radiant heat transfer, as its energy travels through the vacuum of space to warm the Earth.

Infrared heaters emit radiation that travels until it strikes a solid object.

The object absorbs the radiation and begins to warm up.

Radiant heat transfer does not depend on air movement or physical contact, which makes it more efficient in many environments.

This direct approach ensures that energy reaches the target quickly and with minimal loss, providing uniform and consistent heating.

Infrared tubes excel in energy transfer efficiency. Shortwave infrared tubes can achieve up to 96% energy conversion efficiency, which means nearly all the electrical energy supplied transforms into usable heat. This level of efficiency surpasses most conventional heating systems, which often lose energy through air movement or heat dissipation. As a result, users benefit from lower operational costs and faster heating times.

Note: High energy transfer efficiency not only reduces fuel consumption but also supports sustainability goals by minimizing waste.

Infrared technology delivers heat directly to objects, reducing the need to warm the surrounding air. This targeted approach leads to significant improvements in both efficiency and cost savings, making infrared tubes a preferred choice for modern heating solutions.

Infrared tubes have become essential in both industrial and commercial environments. Their ability to deliver direct, efficient heating makes them a preferred choice for many sectors. Huai'an Infrared Heating Technology offers advanced solutions, such as the Twin Tube Fast Medium Wave Infrared Lamp and the IP67 ULG Ultra Low Glare Infrared Lamps, which address a wide range of heating needs.

Manufacturing facilities rely on infrared heating for precise temperature control and rapid heat delivery. Short wave infrared heaters, especially those with quartz construction, provide immediate heat for processes like plastic molding and digital printing. These heaters ensure uniform heating, which improves product quality and reduces waste. Textile manufacturers use infrared systems to dry coatings on fabrics quickly, meeting high production demands. For example, a custom-built infrared drying system helped Century Dyeing overcome specific drying challenges, increasing efficiency and reducing energy consumption.

Agriculture benefits from infrared tube heaters in livestock barns and greenhouses. These systems promote better crop yields and improve animal welfare by maintaining optimal temperatures.

Digital printing operations use quartz infrared heaters to cure inks and coatings, resulting in faster turnaround times and consistent results.

Plastic molding facilities depend on precise heating to shape materials accurately, reducing defects and improving throughput.

Warehouses often require large-scale, consistent heating. Infrared heaters, especially those with quartz tubes, deliver warmth directly to stored goods and workspaces. This approach minimizes heat loss and ensures energy efficiency. Many warehouses choose these systems for their low maintenance needs and ability to provide immediate heat, even in expansive spaces.

Commercial buildings, such as retail stores and offices, use infrared heating to create comfortable environments for employees and customers. Quartz infrared heaters offer uniform, draft-free warmth, which enhances comfort and productivity. These systems also support residential heating in schools and hospitals, where safety and reliability are critical during colder months.

Direct heating of objects leads to significant energy savings.

Consistent heating improves comfort for everyone in the space.

Outdoor areas, including patios and entryways, benefit from specialized infrared heaters like the IP67 ULG Ultra Low Glare Infrared Lamps. These heaters withstand harsh weather and provide reliable warmth without producing glare. Car wash facilities use infrared tube heaters to prevent ice formation on brushes and entry points, ensuring safety for vehicles and staff. Features such as corrosion-resistant materials and quick heating response make these systems ideal for challenging environments.

Versatility allows use in warehouses, retail spaces, and outdoor venues.

Quick heating and low maintenance reduce operational costs.

Tip: Selecting the right quartz infrared heaters for each application ensures optimal performance and long-term savings.

Infrared tubes play a vital role in industrial drying processes, offering efficient solutions for a wide range of applications. Manufacturers rely on quartz infrared heaters to deliver rapid heating and precise control, which is essential for drying water-based paints, coatings, inks, plastics, and films. These heaters transmit heat without contact, allowing for short response times and consistent results.

Paint and coating industries benefit from infrared drying due to its ability to accelerate process speed and improve product quality. Infrared heaters provide direct heating to surfaces, ensuring uniform drying and reducing the risk of defects. Operators can adjust emitter systems to match the specific requirements of each product, which leads to energy savings and optimized performance.

Increased process speed supports higher production rates.

Improved quality of dried coatings reduces rework and waste.

Energy savings result from precisely adjusted infrared emitter systems.

Infrared dryers are commonly used in textile and paper industries, where they help dry coatings quickly and efficiently. The contactless nature of quartz infrared heaters minimizes contamination and supports a cleaner working environment.

Plastic and film manufacturers use infrared tubes for drying applications that demand accuracy and speed. Infrared heaters deliver targeted heat, which prevents warping and ensures consistent moisture removal. The rapid heating capability of quartz infrared heaters allows for faster turnaround times and better control over product quality.

Infrared dryers provide precise control in the drying process.

Short response times enhance process speed and product consistency.

Optimized emitter systems contribute to significant energy savings.

Infrared technology has transformed drying applications in food and agriculture, offering advantages over traditional methods. Infrared tubes deliver direct heating, which preserves flavor, texture, and nutritional value in crops and processed foods.

Farmers use infrared tubes to dry crops such as grains, fruits, and vegetables. The direct transfer of infrared radiation enables lower operating temperatures, which helps retain nutrients and maintain product quality. Infrared drying prevents common issues like dull color and flavor loss, making it ideal for high-quality agricultural products.

Benefit/Feature | Infrared Drying | Traditional Drying |

|---|---|---|

Energy Efficiency | High energy conversion efficiency | Higher heat loss in air |

Heating Method | Direct transfer of infrared radiation | Indirect heating via hot air |

Drying Rate | Higher heating rates | Slower drying rates |

Operating Temperature | Lower temperatures | Higher temperatures |

Nutritional Retention | Better retention of nutrients | Common nutrient loss |

Quality Preservation | Preserves flavor and texture | Risk of dull color and flavor loss |

Control Over Moisture Content | Precise control, avoids over-drying | Less control, risk of over-drying |

Infrared drying effectively controls the drying process of instant cereals, preserving their flavor and texture. This method supports better retention of nutrients and quality compared to conventional techniques.

Food processors utilize quartz infrared heaters for drying applications such as dehydrating fruits, vegetables, and ready-to-eat meals. Infrared heaters offer rapid heating and precise moisture control, which prevents over-drying and maintains the integrity of food products.

Infrared drying preserves flavor and texture in grain-based products.

Operators achieve better control over moisture content, reducing waste.

The process supports high-quality results with minimal nutrient loss.

Tip: Infrared tubes provide rapid response and contactless heating, making them ideal for sensitive drying applications in both industrial and agricultural settings.

Infrared tube systems deliver remarkable efficiency in modern heating and drying applications. Advanced designs have raised efficiency levels from 45% to as high as 75% in industrial settings. This improvement means that more of the energy supplied to the system converts directly into usable heat. Huai'an Infrared Heating Technology’s products can achieve up to 96% energy conversion, setting a new standard for operational performance. Properly designed radiant tube systems also reduce energy consumption by 15% to 30%. These gains translate into lower utility bills and a smaller environmental footprint. Many industries now choose infrared solutions to meet strict energy targets and sustainability goals. The high efficiency of these systems supports both productivity and responsible resource management.

Speed remains a defining advantage of infrared tube heating. These systems provide immediate heat output, allowing processes to start quickly and maintain consistent temperatures. Operators in manufacturing, food processing, and digital printing benefit from rapid response times. Infrared tubes do not rely on warming the surrounding air, so they deliver heat directly to objects and surfaces. This direct transfer shortens process cycles and increases throughput. In environments where time is critical, such as automotive paint drying or plastic molding, fast heating ensures that production schedules stay on track. The ability to reach target temperatures quickly also reduces downtime and supports continuous operation.

Tip: Fast response times from infrared tubes help businesses adapt to changing production demands and seasonal shifts.

Cost savings represent a major benefit for companies that adopt infrared tube systems. By reducing energy consumption, these systems lower operational costs significantly. Studies show that implementing advanced control strategies with infrared technology can lead to cost savings of up to 5.8%. In facilities with flexible occupancy and optimized temperature settings, energy consumption reductions of over 25% and cost savings of nearly 34% have been reported. The payback period for upgrading to efficient infrared systems often falls under two years, making it a smart investment for many businesses. Lower fuel costs, reduced maintenance needs, and improved process efficiency all contribute to a stronger bottom line. Companies that switch to infrared heating gain a competitive edge through better resource management and long-term savings.

Infrared tubes play a crucial role in improving product quality across many industries. Manufacturers rely on precise heat delivery to achieve consistent results. Huai'an Infrared Heating Technology designs infrared lamps that provide targeted heating, which helps maintain the integrity of materials and finished goods.

Food processors benefit from infrared heating systems in several ways. The technology allows operators to control temperature with accuracy. This control prevents overcooking and preserves the natural flavor and texture of food products. For example, infrared tubes can brown breadcrumb coatings evenly, creating a visually appealing product without sacrificing taste. The ability to apply heat directly to the surface ensures that food retains its moisture and nutritional value.

Industrial applications also see significant improvements in product quality. Infrared tubes deliver uniform heat, which reduces the risk of defects in plastics, films, and coatings. Consistent heating helps manufacturers avoid warping, uneven drying, or discoloration. Textile producers use infrared lamps to cure dyes and coatings, resulting in vibrant colors and durable finishes. Digital printing operations depend on infrared technology to set inks quickly, producing sharp images and long-lasting prints.

Huai'an Infrared Heating Technology’s products support high standards in manufacturing and food processing. Their infrared lamps extend shelf life by reducing germ formation. Pumpkin seeds and baked bread treated with infrared heat can last three to four days longer than those processed with conventional methods. This advantage helps companies reduce waste and deliver fresher products to customers.

Operators appreciate the following benefits of infrared tube heating:

Precise heat delivery maintains food quality and prevents overcooking.

Enhanced appearance makes products more appealing, such as evenly browned coatings.

Extended shelf life results from reduced germ formation, supporting freshness.

Uniform heating reduces defects in plastics, films, and coatings.

Consistent results improve customer satisfaction and brand reputation.

Note: Infrared tubes from Huai'an Infrared Heating Technology offer reliable performance and help businesses achieve superior product quality. Their commitment to innovation ensures that each lamp meets the demands of modern production environments.

Manufacturers and food processors who invest in advanced infrared heating solutions gain a competitive edge. They produce goods that look better, last longer, and meet the highest standards for quality and safety.

Proper installation of infrared tubes ensures reliable performance and safety in any environment. Technicians must follow specific steps to maximize efficiency and longevity. They place turbulator baffles in the farthest tube from the burner. This step helps distribute heat evenly and prevents hotspots. Most reflector joints need to be secured, but leaving one expansion joint unsecured allows for thermal expansion. For higher output models, installers position certain tubes immediately downstream of the burner. This placement boosts heat transfer and system responsiveness.

Clamps play a critical role in maintaining tube integrity. Installers center clamps on tube seams and apply the correct torque to prevent separation during operation. Flexible gas lines should be arranged in a 'C' shape. This configuration accommodates expansion and contraction, reducing stress on connections. Quartz accessories, such as protective shields and reflectors, enhance durability and heat distribution. Power controls allow operators to adjust output for different applications, supporting both safety and energy savings.

Tip: Always consult manufacturer guidelines and certified professionals when installing infrared tube systems. Proper installation reduces maintenance needs and extends the life of quartz infrared heaters.

Safety remains a top priority when working with infrared tube systems. Huai'an Infrared Heating Technology designs products that meet strict safety standards. CE certification and TUV compliance guarantee that each system passes rigorous testing for electrical and mechanical safety. Quartz tubes provide an extra layer of protection, resisting high temperatures and minimizing the risk of breakage.

Operators must ensure that all safety shields and guards are in place before activating the system. Regular inspections help identify wear or damage early, preventing accidents. Power controls should be accessible and clearly labeled to avoid confusion during emergencies. Proper ventilation in the installation area prevents overheating and supports safe operation.

Note: Certified quartz infrared tubes offer reliable performance and peace of mind in demanding environments.

Selecting the right infrared tube for a specific application requires careful consideration of several factors. The following table outlines key elements that determine suitability:

Factor | Description |

|---|---|

Wavelength | The specific wavelength of infrared radiation affects how well it heats materials. |

Heating Power | The power output of the infrared tube must match the heating requirements of the application. |

Material Properties | Different materials absorb infrared radiation differently, impacting heating efficiency. |

Application Requirements | Specific needs such as temperature control and drying efficiency must be considered for optimal results. |

Quartz infrared tubes excel in applications that demand precise temperature control and rapid response. Their versatility makes them suitable for manufacturing, food processing, and agricultural drying. Operators should evaluate the environment, material type, and desired outcome before choosing a system.

Tip: Matching the wavelength and power of quartz infrared tubes to the application ensures optimal performance and energy efficiency.

Infrared tubes from Huai'an Infrared Heating Technology offer a straightforward maintenance routine that supports long-term reliability and performance. Operators find these systems easier to care for than traditional heating technologies. The design of infrared tubes eliminates many moving parts, which reduces the risk of mechanical failure and lowers the need for frequent repairs.

Routine maintenance tasks help preserve efficiency and safety. Technicians should focus on several key areas:

Cleaning reflectors and burners: Dust and debris can accumulate on reflectors and burners over time. Regular cleaning ensures that the system maintains optimal heat output and energy conversion. A clean reflector directs infrared energy more effectively, which supports consistent heating.

Inspecting gas connections: For models that use gas, periodic inspection of connections prevents leaks and ensures safe operation. Technicians should check for signs of wear or corrosion and address any issues immediately.

Checking mounts and brackets: Secure mounting is essential for safe operation. Technicians should examine all mounts and brackets to confirm that the tubes remain stable during use. Loose or damaged hardware can lead to misalignment or safety hazards.

Replacing worn components: Over time, certain parts may show signs of wear. Replacing these components before they fail helps avoid larger problems and costly downtime. Quartz glass accessories, such as shields and reflectors, should be inspected for cracks or discoloration.

Professional servicing: Scheduling regular professional inspections allows experts to identify potential issues early. Certified technicians can verify that the system meets CE and TUV standards, ensuring continued compliance and safety.

Tip: Establishing a maintenance schedule helps operators catch minor issues before they become major problems. Consistent care extends the lifespan of infrared tubes and maintains high performance.

Infrared heating systems require less maintenance than forced-air heaters. Traditional systems rely on fans, filters, and ducts, which need frequent cleaning and replacement. These moving parts are prone to wear and often have a shorter lifespan. Infrared tubes, by contrast, operate with fewer components and experience less mechanical stress.

Operators appreciate the simplicity of maintaining infrared tubes. The absence of complex machinery means fewer interruptions and lower maintenance costs. Quartz glass accessories add durability and resist high temperatures, further reducing the need for repairs. Power controls allow users to adjust output easily, which minimizes strain on the system and supports efficient operation.

Huai'an Infrared Heating Technology designs products with maintenance in mind. Their infrared tubes feature robust construction and high-quality materials. CE certification and TUV compliance guarantee that each system meets strict safety and reliability standards. With proper care, these heating solutions deliver consistent performance year after year.

Note: Investing in regular maintenance not only protects equipment but also ensures energy efficiency and safety. Well-maintained infrared tubes help businesses avoid unexpected downtime and maintain a competitive edge.

Selecting the right infrared tube system requires careful attention to technical and operational details. The following table highlights the most important factors to consider for different applications:

Factor | Description |

|---|---|

Voltage Selection | Choose a 110V power supply to reduce electric field strength and minimize arcing risks. |

Lead Configuration | Decide between single-ended or double-ended leads. Double-ended leads support higher power density and easier wiring. |

Temperature Control | Use forced cooling for cold-end sections when operating above 300°C. Water cooling increases efficiency and reliability. |

Quartz tubes play a key role in these systems. They provide durability and withstand high temperatures, making them ideal for demanding environments. Operators should match the tube’s wavelength and power output to the specific heating requirements of their process.

Infrared tubes offer several advantages over traditional heating technologies. The table below compares key aspects:

Aspect | Infrared Heating | Traditional Heating |

|---|---|---|

Efficiency | Directly warms objects, reducing energy waste | Heats surrounding air, often inefficient in large spaces |

Cost | Substantial savings on energy expenses | Higher energy input required for similar comfort levels |

Application Range | Suitable for zonal heating in large areas | Less effective in large, open environments |

Maintenance | Minimal, no moving parts | Requires regular servicing and ductwork |

Environmental Impact | Lower carbon footprint, can use renewable energy | Higher fossil fuel consumption |

Quartz infrared heaters from Huai'an Infrared Heating Technology stand out for their high efficiency and low maintenance needs. These systems excel in industrial, commercial, and agricultural applications, providing reliable performance and energy savings.

To maximize the performance and lifespan of your quartz infrared tube system, consider the following best practices:

Choose quality heaters from reputable brands like Huai'an Infrared Heating Technology.

Work with certified installers to ensure proper mounting and safe gas connections.

Clean reflectors and burners regularly to maintain radiant efficiency.

Inspect gas connections and check mounts or brackets for security.

Replace worn components such as gaskets or ignition elements before failure occurs.

Use modulating controllers to adjust output and reduce strain on the system.

Schedule annual professional inspections to catch issues early and ensure peak performance.

Tip: Consistent maintenance and proper installation help quartz infrared tubes deliver reliable heating for years.

Infrared tubes deliver efficient heating and drying for industrial and commercial applications. Huai'an Infrared Heating Technology provides advanced solutions that improve energy conversion and reduce operational costs. Recent studies highlight the advantages of infrared drying, including better preservation of product quality and nutrients.

Key Findings | Description |

|---|---|

Effectiveness of Far-IR Drying | Minimizes color changes and preserves bioactive compounds in dried products. |

Vitamin C Preservation | Short drying times at lower temperatures help retain vitamin C content. |

Structural Integrity | Far-IR drying maintains the quality and structure of sensitive materials. |

Professionals seeking reliable, fast, and energy-efficient heating should consider infrared solutions for superior results.

Huai'an Infrared Heating Technology offers short wave, medium wave, and long wave infrared tubes. Each type suits different heating and drying needs in industrial, commercial, and agricultural applications.

Infrared tubes convert up to 96% of supplied energy into usable heat. This direct heating reduces energy waste and lowers operational costs for businesses.

Yes. Infrared tubes from Huai'an Infrared Heating Technology meet CE and TUV safety standards. Quartz glass shields and protective features ensure safe operation in indoor environments.

Industries such as manufacturing, agriculture, digital printing, and food processing gain significant advantages. Infrared tubes deliver fast, uniform heating and support high-quality production.

Operators should clean reflectors and inspect mounts monthly. Annual professional servicing helps maintain peak performance and ensures compliance with safety standards.

Yes. Products like the IP67 ULG Ultra Low Glare Infrared Lamps provide reliable outdoor heating. These lamps resist weather and deliver consistent warmth for patios, warehouses, and entryways.

Power controls, quartz glass shields, and reflectors improve efficiency and safety. These accessories help operators adjust output and protect heating elements.

Tip: Always select certified accessories to ensure compatibility and maximize system lifespan.

Users should consider wavelength, power output, and application requirements. Consulting with Huai'an Infrared Heating Technology’s experts ensures optimal selection for specific heating or drying tasks.