Author: Site Editor Publish Time: 2025-07-25 Origin: Site

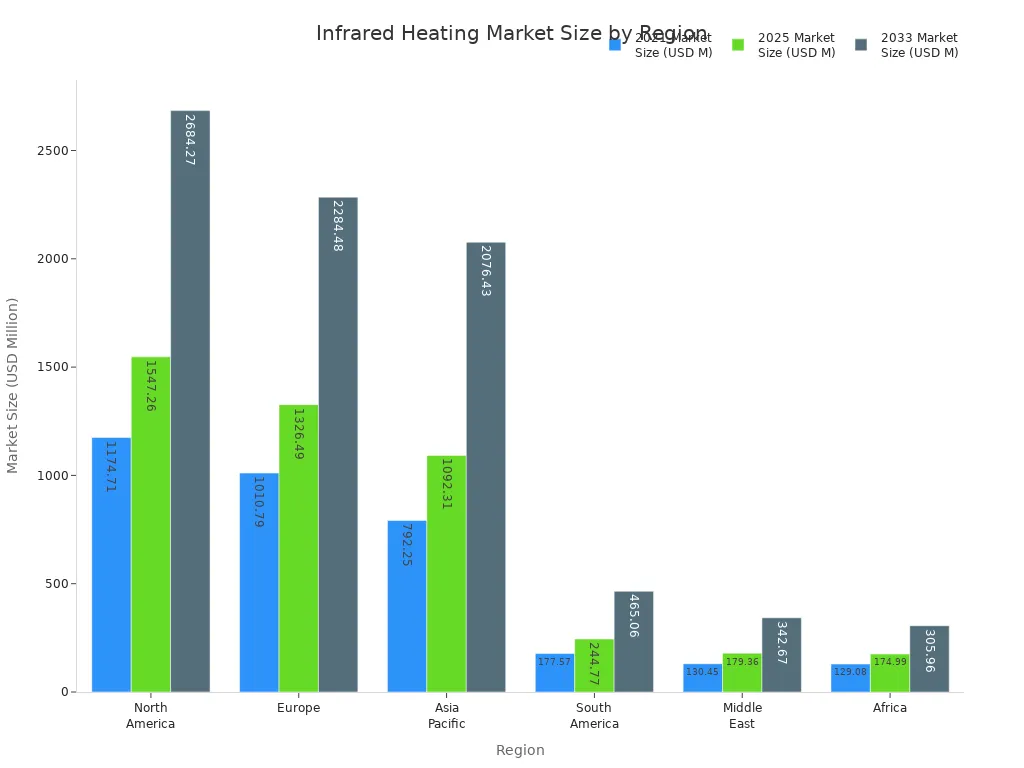

I see firsthand how infrared heating technology transforms industrial processes. I achieve higher efficiency, better product quality, and faster processing speeds while reducing operational costs and improving workplace safety. Infrared technology delivers targeted heat, which minimizes energy waste and supports sustainable manufacturing. The market for infrared heating technology continues to grow rapidly, especially in regions like North America, Asia Pacific, and Europe.

I trust brands like Huai’an Infrared Heating Technology for reliable solutions that help my business stay competitive.

Infrared heating delivers heat directly to objects, saving energy and cutting heating time drastically.

Using infrared systems can reduce energy costs by up to 50%, making operations more affordable.

Infrared heating tubes require less maintenance and last longer, lowering repair expenses and downtime.

Uniform heating from infrared technology improves product quality and reduces defects in manufacturing.

Non-contact infrared heating enhances safety and hygiene, especially in food and pharmaceutical industries.

Infrared systems heat up instantly, speeding up production and allowing quick process changes.

Infrared heating supports green manufacturing by lowering harmful emissions and meeting safety standards.

The technology adapts to many industries like agriculture, plastics, printing, and battery making, offering flexible solutions.

I see the difference that direct heat transfer makes in my operations. Infrared heating technology delivers energy straight to the surface or object that needs it, instead of wasting energy heating the surrounding air. This targeted approach means I achieve a high heat transfer rate and efficient energy transfer, which translates into real savings and improved process control.

When I use an infrared heating tube, I notice that the heat reaches the product almost instantly. This direct application reduces warm-up times and ensures that every part of the material receives consistent heating. For example, in my experience with aluminum billet processing, infrared heating systems can heat billets in just 20 minutes, compared to 240 minutes with conventional convection furnaces. This not only speeds up production but also boosts overall efficiency.

Switching to infrared heating has allowed me to cut down on energy consumption significantly. I have seen studies and real-world cases where gas-fired infrared heaters save up to 50% in fuel costs compared to traditional forced-air systems. In my own facility, I can set thermostats lower and still maintain comfort, which further reduces fuel use.

Here’s a quick look at how infrared heating compares to conventional methods:

Attribute | Infrared Heating System | Conventional Convection Furnace | Key Insight |

|---|---|---|---|

Heating time for aluminum billet | 20 minutes | 240 minutes | IR heating is 12 times faster |

Production throughput | 350 lbs/hr | 80 lbs/hr | IR heating increases throughput |

Energy consumption (BTU/lb) | 500 | 1500 | IR heating uses one-third energy |

Overall system efficiency (%) | ~30% | ~10% | IR heating is three times efficient |

I have also seen infrared heating tubes reduce heating costs by 40% in large spaces like aircraft hangars and warehouses. In agricultural settings, infrared heating improves growth rates and reduces energy costs by providing warmth exactly where it is needed, without adding excess humidity.

One of the biggest advantages I experience with infrared heating tube systems is their low maintenance requirements. Unlike traditional heating systems that rely on moving parts and complex air handling, infrared heating tubes have fewer components that can wear out. I spend less time and money on repairs and servicing.

Infrared heating systems often come with warranties that cover defects, and the simple design means fewer breakdowns. In my textile operations, switching to medium wave infrared heating tubes doubled line speeds and significantly reduced maintenance. I no longer have to worry about frequent part replacements or unexpected downtime.

I value equipment that lasts, and infrared heating tubes deliver on that promise. Far infrared heating tubes, especially those made from high-purity quartz, offer a long service life when I follow proper maintenance routines. I keep the tube surfaces clean, check for cracks, and ensure good ventilation. These steps help maintain high thermal efficiency and extend the lifespan of my equipment.

Here are some best practices I follow to maximize the service life of my infrared heating tubes:

I avoid bending the tubes during installation and ensure proper spacing for heat dissipation.

I use a stabilized power supply to prevent electrical damage.

I regularly inspect for signs of wear and replace damaged components promptly.

I control operation cycles to reduce thermal fatigue and set temperature thresholds to avoid overheating.

I choose high-quality quartz tubes for their purity and transparency.

By following these steps, I not only extend the life of my infrared heating tubes but also improve the overall efficiency and safety of my industrial processes. In my experience, the return on investment for infrared heating technology is rapid, often less than 18 months, thanks to energy savings and reduced maintenance costs.

I rely on infrared heating to achieve consistent results in my production lines. Uniform heating ensures that every product receives the same amount of energy, which leads to predictable and repeatable outcomes. When I use Quartz IR Emitters from Huai’an Infrared Heating Technology, I notice that the heat spreads evenly across the surface of materials. This uniformity is crucial in industries like plastics, textiles, and food processing, where even minor temperature differences can affect the final product.

Infrared heating reduces thermal stress on products, which means less damage during processing.

It improves surface finish and minimizes distortion, especially in coatings and plastics.

I maintain important attributes such as color, texture, and material properties in food and industrial goods.

Faster heating and precise temperature control ensure uniform heating batch after batch.

I see these benefits every day. For example, in my food production facility, I use far infrared heating to dry and roast nuts. The process preserves flavor and texture while reducing waste. Uniform heating also helps me maintain high standards in food safety and quality.

Uniform heating plays a key role in reducing defects. I use infrared thermographic technology to monitor temperature distribution during manufacturing. If a product has a defect, it shows up as a temperature difference. This allows me to catch issues early and improve yield.

Uniform temperature distribution means fewer defects and higher quality.

I detect problems in photovoltaic modules and electronics before they reach customers.

Non-contact, high-speed inspection covers large areas quickly, making quality control efficient.

With Quartz IR Emitters, I achieve rapid warm-up and cool-down times. This flexibility lets me adjust processes quickly, reducing downtime and minimizing the risk of defects.

Non-contact processing is essential in food and pharmaceutical industries. I avoid direct contact between heating elements and products, which reduces contamination risks. Infrared and UV technologies allow me to disinfect and process food without chemicals, preserving nutrients and extending shelf life.

I use non-contact methods like pulse light and infrared heating to ensure food safety. These techniques inactivate microbes while maintaining nutritional quality and sensory appeal.

Safety is always a top priority in my operations. Non-contact infrared heating minimizes the risk of burns and cross-contamination. I process packaged food and sensitive materials without exposing them to open flames or hot surfaces.

Ohmic and infrared heating methods provide safe, efficient, and consumer-friendly solutions.

High-pressure and UV processing further enhance safety by inactivating pathogens without thermal damage.

Huai’an Infrared Heating Technology’s products, such as Quartz IR Emitters, meet strict quality assurance standards. Their IP65-rated heaters resist dust and water, making them reliable in demanding environments. The use of quartz glass and advanced filaments ensures durability and consistent performance. Certifications like TUV and ISO 9000 give me confidence in their safety and reliability.

I value the immediate heat that infrared heating provides in my facility. When I switch on the system, I see a rapid temperature rise, which means I do not have to wait for long warm-up periods. This instant response allows me to start production tasks right away. In automotive manufacturing, for example, I have seen how custom-designed quartz tungsten tube infrared heaters reach operating temperature almost instantly. This capability minimizes downtime and keeps my production line moving. I do not lose valuable time waiting for equipment to heat up, so I can focus on delivering results.

Fast response times lead to quick turnaround in my daily operations. I notice that when I use infrared heating, I can complete heat treatment processes much faster than with traditional methods. Scientific research shows that medium-wave infrared heaters with short reaction times reduce curing cycle times and improve energy efficiency. I finish jobs sooner and move on to the next task without delay. This efficiency helps me increase throughput and meet tight deadlines. In my experience, the ability to eliminate lengthy warm-up times directly supports higher productivity and better use of resources.

Tip: I always schedule maintenance during natural breaks in production, knowing that my infrared heating system will be ready to go as soon as I need it.

Precision control is essential in my work. Infrared heating gives me the ability to set and maintain accurate temperatures throughout the process. I rely on this control to ensure that every product meets strict quality standards. Uniform heating across molds or surfaces eliminates temperature gradients, which can cause uneven curing or defects. I see consistent results, batch after batch, because the system delivers heat exactly where it is needed.

I appreciate the customization options that come with advanced infrared heating systems. I can adjust power levels, wavelengths, and heating zones to match the specific requirements of each application. This flexibility allows me to optimize processes for different materials, shapes, and sizes. For example, in food processing, I use precise temperature control to preserve flavor and nutrients while ensuring safety. The direct transfer of heat minimizes losses and supports rapid, even heating, which improves both operational efficiency and product consistency.

Here is a summary of how precision control benefits my manufacturing outcomes:

Aspect | Benefit |

|---|---|

Uniform Heat Distribution | Consistent product quality, fewer defects |

Rapid Heating and Cooling | Faster production cycles, less downtime |

Energy Efficiency | Lower power consumption, reduced costs |

Mold Longevity | Less thermal stress, longer equipment life |

Precision Temperature | Reliable results in sensitive applications like plastic injection molding |

I trust infrared heating to deliver the speed and control I need to stay competitive in today’s fast-paced industrial environment.

I have seen how the infrared heating tube transforms printing operations. In my experience, these tubes deliver rapid, uniform heat that dries inks and coatings efficiently. I rely on YFR Quartz IR Emitters for their instant response and precise temperature control. This technology works especially well with water-based inks, which require consistent drying to prevent smudging and ensure vibrant colors. I can adjust the emitter’s wavelength and power to match the specific needs of each print job, whether I am working with textiles, packaging, or specialty papers. The result is a flawless finish and faster production cycles.

Paint drying is another area where I see the infrared heating tube excel. I use these tubes to cure water-based paints and coatings on automotive parts, metal panels, and industrial equipment. The focused, non-contact heat reduces drying times by up to 60%, which keeps my production line moving. I appreciate that the tubes emit heat directly to the coated surface, minimizing energy waste and avoiding air turbulence that can disturb the finish. The versatility of YFR Quartz IR Emitters allows me to handle a wide range of paint types, including water-based and solvent-based formulations. I achieve a smooth, durable surface every time.

Note: I often choose twin tube infrared emitters for high-speed paint drying because they provide homogeneous radiation and higher power density, which is ideal for demanding industrial environments.

I have witnessed the impact of infrared drying technology in battery manufacturing. When I use an infrared heating tube for electrode drying, I see production speeds increase by up to 80%. The technology ensures even drying of water-based slurries, which improves electrode conductivity and durability. I avoid issues like cracking and uneven moisture, which can compromise battery performance. Carbon infrared radiators help me bake and roll electrodes without creases or foil deformation. This process results in higher quality batteries with longer life cycles.

Photovoltaic manufacturing also benefits from the versatility of the infrared heating tube. I use these tubes to dry and cure water-based coatings on solar cells and modules. The rapid, uniform heating improves cross-linking and reduces residual moisture, which enhances the efficiency and reliability of the final product. I can customize the emitter’s size and shape to fit different production lines, ensuring optimal heat transfer for each application. The technology supports green energy goals by reducing energy consumption and emissions.

Here is a table summarizing some of the most common industrial applications and their effectiveness:

Industrial Sector | Application Examples | Effectiveness Highlights |

|---|---|---|

Factories & Warehouses | Space heating | Energy-efficient, suitable for large spaces |

Printing | Ink and coating drying (water-based) | Fast, uniform drying, improved print quality |

Paint Drying | Automotive, metal, industrial coatings | Up to 60% faster drying, flawless finish |

Battery Manufacturing | Electrode drying (water-based slurries) | 80% faster, improved conductivity and durability |

Photovoltaic | Solar cell/module coating and drying | Enhanced efficiency, reduced moisture, green manufacturing |

I choose Huai’an Infrared Heating Technology because their product lineup covers every need I encounter. From short-wave lamps for rapid heating to carbon infrared heaters for delicate processes, I find a tailored solution for each sector. Their systems integrate easily with my existing controls, and I can rely on their durability and performance in demanding environments.

I use infrared heating tubes in food processing, plastics, agriculture, and even outdoor heating.

The technology is widely used because it adapts to different materials and processes.

I appreciate the environmental benefits, such as low emissions and improved air quality, especially when working with water-based products.

I rely on infrared radiation heating to improve the drying process in my food production lines. This technology delivers high thermal radiation efficiency and strong penetration, which means I can dry food quickly and evenly. The infrared drying method allows me to process thermosensitive substances without causing chemical decomposition. I see a clear advantage in drying speed compared to traditional methods. For example, when I use the infrared drying method for fruits or vegetables, I notice that the food retains its color and texture. The process locks in moisture where needed and prevents over-drying.

Application Area | Evidence of Effectiveness |

|---|---|

Infrared Dehydration & Drying | High thermal radiation efficiency, strong penetration, fast heating speed, uniform absorption, high heating efficiency, minimal chemical decomposition, suitable for thermosensitive substances. |

Infrared Baking | Direct radiation heats food faster, reduces waiting time, allows precise temperature control. |

I use the infrared drying method for baking as well. The direct radiation heats food faster and gives me precise control over temperature. This results in food that is perfectly baked, with a crisp exterior and a tender interior.

Sterilization is a critical step in food processing. I trust infrared radiation heating to achieve effective sterilization and mold killing. Infrared sterilization works by delivering energy directly to the surface and interior of food, eliminating bacteria and pathogens without the need for a heat medium. I have seen studies where infrared radiation heating successfully sterilizes nuts, grains, and powders. The process avoids contamination and maintains food quality.

Infrared sterilization penetrates the surface and reaches the interior.

I achieve rapid and uniform sterilization, which is essential for food safety.

The method is environmentally friendly and does not introduce harmful residues.

Maintaining flavor is a top priority for me. Infrared radiation heating helps preserve the natural taste and aroma of food. The technology locks in moisture and prevents the loss of volatile compounds that contribute to flavor. I have read studies showing that infrared heating can sanitize raw milk while retaining its flavor profile. When I use this method for baking, I notice that the food develops a rich color and aroma, which appeals to consumers.

Hygiene is non-negotiable in my facility. I use infrared radiation heating to reduce microbial contamination and ensure food quality and safety. Research demonstrates that this method eliminates bacteria such as Listeria monocytogenes on hotdogs and reduces microbial load on eggshell surfaces. Far-infrared heating also decontaminates onions and other produce while maintaining their quality. I trust this approach because it provides effective sterilization and mold killing without compromising food safety.

Study / Food Matrix | Microbial Impact (Hygiene) | Quality Impact (Flavor, Volatiles) | Key Findings |

|---|---|---|---|

Krishnamurthy et al., 2008 (Raw Milk) | Significant reduction of Staphylococcus aureus and other bacteria | Changes in volatile organic compounds affecting milk flavor profile | Demonstrated IR as a viable milk sanitization method with microbial inactivation and flavor retention |

Coskun et al., 2021 (Onions) | Surface decontamination via far-infrared heating | Maintained quality attributes of onions | FIR effective for microbial reduction while preserving quality |

Tip: I always monitor the placement of IR sources and system geometry to maximize efficiency and ensure uniform results in my food processing operations.

I always prioritize the well-being of my team when choosing industrial heating solutions. Infrared heating technology creates a safer workspace because it does not rely on combustion or open flames. I do not have to worry about carbon monoxide leaks or airborne particulates that can harm operators. The absence of moving air also means less dust circulation, which helps maintain clean air quality on the production floor. I notice that my staff feels more comfortable and confident working near infrared systems, knowing that the risk of exposure to hazardous gases is minimal.

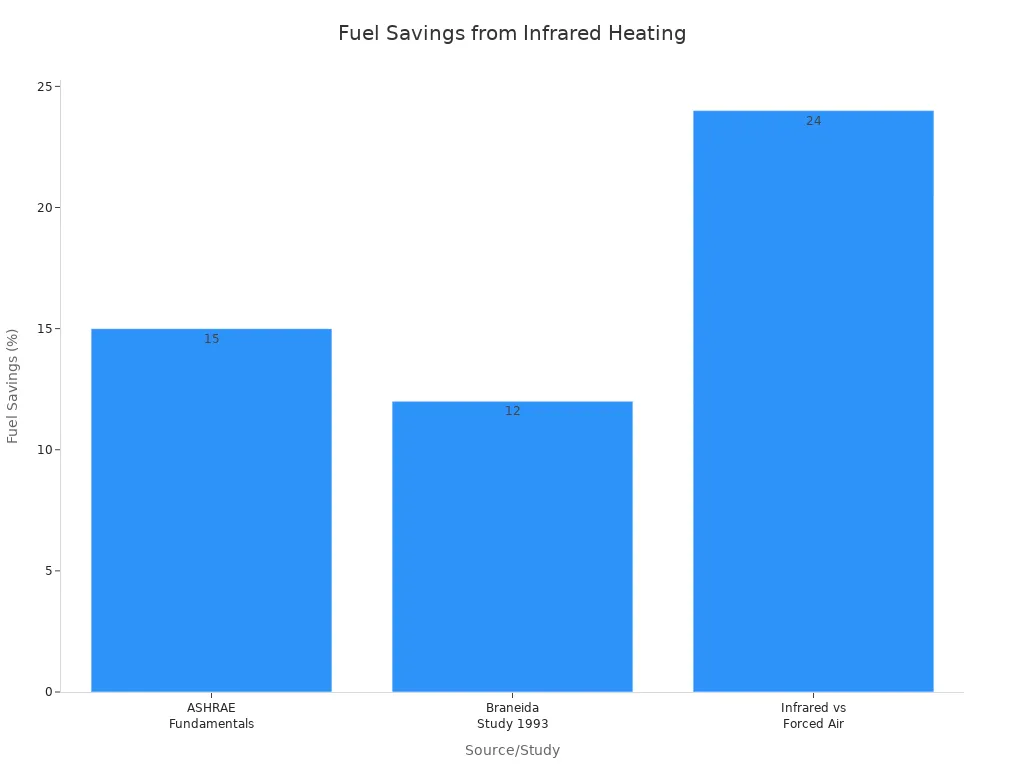

I see a clear environmental advantage when I switch to infrared heating. The technology uses energy more efficiently, which directly reduces fuel consumption and harmful emissions. Scientific studies confirm that hybrid infrared dryers emit less CO2, NOx, and SO2 compared to conventional hot-air dryers. This reduction in greenhouse gases supports my company’s sustainability goals and helps me comply with stricter environmental regulations.

Here’s a quick comparison of fuel savings from several studies:

Source/Study | Description | Fuel Savings (%) |

|---|---|---|

ASHRAE Fundamentals Book | Perimeter mounting infrared heaters | 15 |

Braneida Study (1993) | Two-stage infrared heaters vs single-stage | 12 |

Infrared vs Forced Air Study (ASHRAE Paper #4643) | Two-stage infrared vs forced air system | 24 |

New York State Report (ASHRAE Handbook) | Annual fuel savings reported | Up to 50 |

Emerging Technologies (ASHRAE Journal) | Infrared heaters vs unit heaters | 33-50 |

These numbers show that I can cut fuel use by up to half, which means fewer emissions released into the environment.

I always check for certifications before installing new equipment. Infrared heating panels and emitters meet strict standards for health, environmental protection, and electrical safety. I look for CE and UKCA marks, which show compliance with European and UK regulations. These products are also RoHS compliant, so I know they contain no hazardous substances. In the US, I trust UL 508 certification for safe operation under different conditions. Many panels and heaters use recyclable materials, which supports my commitment to responsible sourcing and waste reduction.

Certification/Standard | Region | Description/Focus |

|---|---|---|

CE Mark | EU | Health, safety, and environmental protection |

UKCA Mark | UK | Conformity assessment and technical documentation |

EcoDesign Directive (EU 2015/1188) | EU | Energy efficiency and environmental requirements |

BS EN 60335 | UK/EU | Electrical safety |

BS EN 55014-1:2017 / 55014-2:2015 | UK/EU | Electromagnetic compatibility (EMC) |

BS EN 61000-3-2:2019 / 61000-3-3:2013/A1:2019 | UK/EU | Voltage and harmonics |

BS EN 50581:2012 / EN IEC 63000:2018 | UK/EU | Restriction of hazardous substances (RoHS) |

BS EN 32321-8:2017 | UK/EU | Control efficiency |

UL 508 | US | Safety certification for infrared heaters |

I want my operations to support green manufacturing. Infrared heating systems convert nearly all electrical input into usable heat, especially when powered by renewable energy. I reduce my carbon footprint and meet environmental targets. The recyclable design of many infrared panels and lamps means I can recycle them at the end of their service life. I also appreciate features like overheat protection, timers, and cool-to-touch surfaces, which help me operate safely and efficiently while staying compliant with regulations.

Tip: I always review product documentation for certifications and recycling options before making a purchase. This practice helps me maintain high standards for both safety and environmental responsibility.

I see infrared heating technology making a real difference in agriculture. I use it to dry crops, sterilize seeds, and control greenhouse climates. The direct heat transfer helps me process water-based agricultural products quickly and evenly. I can dry fruits and vegetables without damaging their nutrients or color. In my greenhouse, I rely on infrared panels to maintain optimal temperatures for plant growth. This approach reduces humidity and prevents mold, which keeps my crops healthy. I notice that many farms now use infrared systems to improve efficiency and product quality.

In plastics manufacturing, I depend on infrared heating for forming, welding, and drying. The technology allows me to heat plastic sheets and molds with precision. I can process water-based coatings on plastic parts, ensuring a smooth and durable finish. I select heaters tuned to the peak absorption wavelength of each material, which maximizes energy efficiency. I appreciate that I can adjust the power and coverage area to match the size and shape of my products. This flexibility helps me reduce waste and improve throughput.

I have seen infrared heating used in many sectors, from healthcare to manufacturing. Applications range from home heating and saunas to industrial drying and curing. The technology’s energy efficiency and eco-friendliness support its adoption worldwide.

Here is a table showing the broad adoption of infrared heating panels:

Industry Sector | Applications / Settings |

|---|---|

Industrial / Commercial | Warehouses, Factories, Workshops, Others |

I value the range of accessories available for infrared heating systems. I can choose from different reflectors, mounting brackets, and protective covers. For example, I use aluminum or ceramic reflectors to focus heat where I need it most. I select covers made from copper or steel to protect heating elements in demanding environments. I also rely on advanced temperature controllers, from simple setpoint devices to programmable PLCs. These accessories help me customize my system for water-based processes, powder coating, or composite bonding.

I can select heating elements such as carbon fiber, halogen, or quartz tube heaters.

I choose wattage, mounting options, and safety certifications to fit my application.

I integrate smart controls for automation and process monitoring.

System integration is essential for my operations. I connect infrared heating systems with building automation and smart controls. This integration gives me precise temperature management and process repeatability. I have seen case studies where companies reduced energy bills by 30% after switching to integrated infrared systems. Installation is quick, and the plug-and-play design saves time and money. I appreciate the reliability, with warranties that ensure long-term performance. The consistent, comfortable warmth eliminates cold spots and drafts, which improves working conditions.

I trust manufacturers who offer custom design and system integration. Their expertise helps me optimize performance for specific industrial applications, from water-based paint drying to plastics forming.

I see infrared heating technology deliver unmatched efficiency, product quality, and processing speed in my operations. The compact equipment, low emissions, and precise control support safer, greener manufacturing. Here’s a quick overview:

Benefit | Key Impact |

|---|---|

Heating Speed | Faster processing, reduced downtime |

Energy Efficiency | Up to 50% lower energy use |

Uniform Heating | Consistent results, fewer defects |

Compact Design | Saves valuable floor space |

Environmental Impact | Lower emissions, improved workplace safety |

I recommend evaluating your current heating systems and consulting with experts. In my experience, tailored solutions from Huai’an Infrared Heating Technology can transform productivity and reduce costs.

I see the biggest impact in manufacturing, food processing, agriculture, plastics, and automotive sectors. I use infrared heating for drying, curing, sterilizing, and forming. The technology adapts well to many industrial processes.

I consider the material, required temperature, and process speed. I consult with experts from Huai’an Infrared Heating Technology. They help me select the right wavelength, power, and emitter type for my needs.

I trust infrared systems because they do not use open flames or combustion. I see fewer risks of burns or gas leaks. I always check for safety certifications and proper installation to ensure a safe workspace.

Yes, I have reduced my energy bills by up to 50% after switching. Infrared heating delivers heat directly to the target, which minimizes waste. I notice faster warm-up times and lower overall consumption.

I clean the tubes regularly, avoid bending them, and use a stable power supply. I inspect for cracks and replace damaged parts promptly. I follow the manufacturer’s guidelines to maximize efficiency and lifespan.

I rely on their high-purity quartz, advanced filaments, and strict quality control. Their products hold certifications like TUV and ISO 9000. I see consistent performance and durability in demanding industrial environments.

Yes, I connect infrared heaters to building automation and smart controls. I use programmable controllers for precise temperature management. Integration helps me optimize energy use and improve process consistency.

Absolutely. I use infrared heating to lower emissions and energy use. The systems convert nearly all input energy into usable heat. I meet environmental targets and support sustainable production practices.