Views: 0 Author: Site Editor Publish Time: 2025-07-22 Origin: Site

When I select fast medium wave infrared lamps for industry, I focus on matching lamp wavelength and characteristics to the specific material and process. The right ir heat lamps deliver rapid response and precise control, making them ideal for industrial heat applications. I always compare the spectral output of medium ir heat lamps to the absorption properties of the material. This step ensures efficient heat transfer. Fast medium wave infrared lamps for industry stand out for their ability to optimize heat, reduce energy waste, and provide reliable performance with ir heat lamps in demanding environments.

Match the lamp’s wavelength to the material’s absorption for efficient heating and energy savings.

Choose lamps with the right power rating to reach and maintain target temperatures quickly and safely.

Fast medium wave infrared lamps offer up to 96% energy efficiency, reducing costs and waste.

Check lamp lifespan and follow maintenance routines to avoid downtime and extend performance.

Always verify safety certifications and follow installation guidelines to protect people and equipment.

Use fast medium wave lamps for applications needing quick response and precise temperature control.

Consult manufacturers with detailed process data to select lamps that fit your specific industrial needs.

Avoid common mistakes like mismatched wavelengths, ignoring efficiency, and neglecting safety or maintenance.

When I evaluate fast medium wave infrared lamps for industry, I always begin by considering the application fit. Every industrial process has unique requirements. I look at the type of material, the desired temperature, and the specific heating goals. For example, some processes demand rapid heating and cooling cycles, while others require steady, uniform heat. I ask myself if the ir heat lamps can deliver the precise control needed for the application. In my experience, fast medium wave infrared lamps for industry excel in processes that need quick response times and accurate temperature management. This technology supports applications such as drying coatings, thermoforming plastics, and curing adhesives. I make sure the lamp’s design and performance align with the demands of the industrial heat processes I manage.

Matching the lamp’s wavelength to the material’s absorption characteristics is critical for efficiency. I have learned that different materials absorb infrared energy at specific wavelengths. For instance, plastics, glass, and coatings each have unique absorption peaks. If I select a lamp with a spectral output that aligns with these peaks, I achieve optimal heat transfer. This approach minimizes energy waste and maximizes process efficiency. I rely on the science behind infrared heat technology, which shows that materials with wavelength-selective absorption convert more radiation into heat. When the lamp’s emission wavelength matches the material’s absorption spectrum, the process becomes much more efficient. This principle comes from the fact that materials absorbing strongly at the lamp’s emission wavelengths will convert more radiation into heat, improving industrial heating efficiency. I always check the absorption spectrum of the material before making a final decision. This step ensures that the medium wave infrared lamp will deliver the best results for the application.

Tip: Always request absorption data from material suppliers. This information helps me select the right ir heat lamps and avoid costly mismatches.

Power and output play a major role in my selection process. I assess the required temperature and the size of the area to be heated. Fast medium wave infrared lamps for industry offer a wide range of power ratings. I have seen lamps with power ratings from as low as 200 watts up to 6000 watts, and some specialized models reach up to 10,000 watts. This flexibility allows me to choose a lamp that matches the scale and intensity of the heating task. I consider the maximum filament power density, which can reach 100 watts per inch in some designs. I always ensure the lamp can deliver enough ir energy to reach the target temperature quickly and maintain it consistently. By selecting the right power level, I prevent underheating or overheating, both of which can compromise product quality and process efficiency. Infrared heat technology gives me the control I need to fine-tune the heating process for any industrial application.

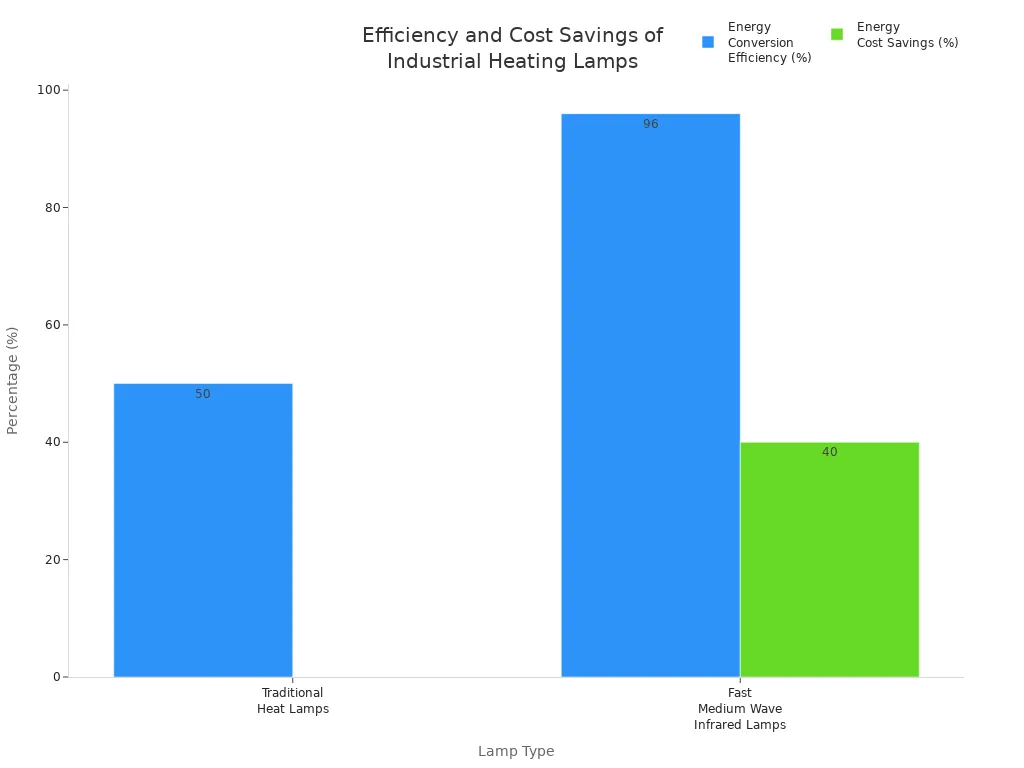

When I evaluate efficiency in fast medium wave infrared lamps, I focus on how much energy the lamp converts into usable radiant heat. High efficiency means more of the electricity I use turns directly into heat for my process, not wasted as excess air heating or lost energy. I have compared different industrial heating technologies and found that fast medium wave infrared lamps outperform traditional heat lamps in almost every aspect.

Here is a comparison that I often use when explaining the benefits to colleagues:

Aspect | Traditional Heat Lamps | Fast Medium Wave Infrared Lamps (Infrared Heating Lamps) |

|---|---|---|

Energy Conversion Efficiency | Approximately 50% | Up to 96% |

Heating Method | Heats air by convection | Directly heats objects and people |

Energy Waste | High | Low |

Energy Cost Savings | Baseline | Up to 30-50% savings |

Heat Retention After Shutdown | Heat dissipates quickly | Heat lasts longer |

Installation & Maintenance | Often requires professional help | Easy setup, minimal maintenance |

I have seen firsthand how fast medium wave infrared lamps deliver up to 96% energy conversion efficiency. This means I can achieve the same heating results with less power. The ir technology heats objects directly, so I do not waste energy heating the surrounding air. In my experience, this direct approach leads to more uniform heating and faster process times. I have also noticed significant energy cost savings—sometimes up to 50%—when switching from traditional heat lamps to fast medium wave infrared lamps. Maintenance is easier, and the lamps last longer, which reduces downtime and operating costs. For any industrial process where efficiency and cost matter, I always recommend evaluating ir heat lamps as a top choice.

Lamp lifespan is another critical factor I consider. A longer lifespan means fewer replacements, less downtime, and lower maintenance costs. Fast medium wave infrared lamps typically offer impressive durability. I have used lamps that run for thousands of hours without significant performance loss. The robust construction of these ir lamps helps them withstand frequent on-off cycles, which is common in industrial settings. I always check the manufacturer's rated lifespan before making a purchase. Some models can last up to 5,000 hours or more, depending on usage and operating conditions.

To maximize lifespan, I follow best practices for installation and operation. I avoid exposing the lamps to excessive vibration or moisture. I also ensure proper electrical connections and use recommended voltage levels. Regular cleaning of the lamp surface prevents dust buildup, which can reduce efficiency and shorten life. By following these steps, I get the most value from my investment in infrared heating technology.

Tip: Always ask suppliers for documented lifespan data and recommended maintenance schedules. This information helps me plan for replacements and avoid unexpected failures.

Safety is always at the top of my checklist when selecting ir lamps for industrial use. I look for products that meet recognized safety standards and certifications. Here are some of the key certifications I check:

Certification | Meaning | Importance |

|---|---|---|

UL | Meets global safety, health, and environmental standards | Required by many building codes and insurance companies to ensure safety |

ETL | Complies with electrical and fire safety standards | Ensures safe operation in industrial environments |

FCC | Prevents harmful electromagnetic interference | Protects other electronic equipment in the vicinity |

Energy Star | Indicates high energy efficiency and product quality | Helps reduce operational costs and supports regulatory compliance |

DLC | Verifies product quality and efficiency | Supports rebates and compliance with energy standards |

CE | Meets European safety regulations | Mandatory for products sold in the EU market |

IP Rating | Protection against water and dust ingress | Essential for lamps used in outdoor or humid industrial environments |

I always verify that the ir lamps I select have the proper certifications. Leading manufacturers often provide CE and ROHS certifications to meet European safety and environmental standards. Many also comply with ISO standards for quality management and environmental practices. These certifications give me confidence that the lamps are safe, reliable, and environmentally responsible.

Infrared radiation, especially in the near-infrared range, can pose health risks such as eye damage or skin effects. Medium wave infrared lamps operate at longer wavelengths and lower filament temperatures, so the risk is lower, but I still follow all manufacturer guidelines. I use proper shielding and personal protective equipment when necessary. Safe installation practices help prevent burns and electrical hazards. By prioritizing safety, I protect both my team and my equipment.

When I evaluate fast medium wave infrared lamps for industry, I always consider the total cost of ownership, not just the purchase price. The initial investment for these lamps can be high. I have seen units priced between £600 and £1,500, depending on the model and power rating. For example, a Herschel Advantage IRP4 (2.6kW) costs around £1,000, while some NexGen Rafts reach up to £1,500 per unit. This upfront expense often surprises new buyers.

However, I look beyond the sticker price. The real value of fast medium wave infrared lamps comes from their operational savings. These lamps use energy far more efficiently than traditional convector heaters. In one case study, I found that infrared heaters operated at just 26.8% of the power required by comparable convector heaters. This efficiency translates into lower electricity bills and reduced energy waste. For instance, running a 2.6kW heater at 25p per kWh costs about £5.20 per day, or £156 per month. Over time, these savings add up.

I also factor in maintenance and installation costs. Fast medium wave infrared lamps have no moving parts and require minimal upkeep. I rarely need to schedule repairs or replacements, which keeps my maintenance budget low. Flexible installation options allow me to adapt the system to different spaces without major construction work.

Here is a summary of the key cost factors I consider:

Aspect | Details |

|---|---|

Initial Cost | £600–£1,500 per unit, depending on model and power |

Operational Cost | ~£5.20/day or £156/month for a 2.6kW heater at 25p/kWh |

Energy Efficiency | Uses only 26.8% of the power of comparable convector heaters |

Maintenance | Minimal; no moving parts; long lifespan |

Installation | Flexible options; often less disruptive than traditional systems |

Overall Value | High upfront cost offset by significant long-term savings |

Tip: I always calculate the payback period before making a purchase. In many cases, the energy savings cover the initial investment within a few years, making these lamps a smart long-term choice.

The demand for energy-efficient heating continues to grow in industry. I find that the operational savings and low maintenance requirements make fast medium wave infrared lamps an economically sound investment, even when the upfront cost is higher than conventional alternatives. By focusing on total cost of ownership, I ensure my heating solutions deliver value year after year.

When I select fast medium wave infrared lamps for industry, I look for specific technical features that set them apart from other heat lamps. These lamps use a tungsten coil sealed inside a quartz tube, which allows for rapid heating and cooling. The design gives them a low thermal inertia, so they reach operating temperature within seconds. I rely on these lamps when I need a fast response in my industrial processes. The filament temperature can reach up to 1,500 °C, which shifts the peak wavelength to around 1.6 μm. This wavelength falls within the medium wave infrared range, making these lamps ideal for materials that absorb energy efficiently in this band. The construction and performance details help me match the right lamp to each application.

Characteristic | Details |

|---|---|

Filament Temperature | Up to 1,500 °C (2,730 °F) for medium wave; around 2,500 K (2,230 °C) for quartz tungsten |

Peak Wavelength | Approximately 1.6 μm for medium wave infrared |

Response Time | Reaches operating temperature within seconds |

Wavelength Range | Medium wave infrared typically 1.5–8 μm |

Construction | Quartz tube with tungsten coil |

Thermal Inertia | Low thermal inertia due to tungsten coil design |

I have found that the fast response time and precise control make these infrared lamps a top choice for demanding heat lamp uses in industry.

I use infrared heat technology because it delivers energy directly to the surface of materials. When the heated element emits infrared waves, these waves travel through space and strike the material. The energy causes the molecules in the material to vibrate, which produces heat. This process does not require heating the surrounding air, so I achieve rapid and efficient heating. The effectiveness of this technology depends on the wavelength of the infrared radiation and the absorption properties of the material. I always check that the wavelength matches the absorption peak of the material to maximize efficiency. Infrared heat technology allows me to control temperature precisely, which is essential for many industrial applications. I see the benefits in processes like drying, curing, and surface treatment, where fast and uniform heating improves product quality.

Note: Infrared heating works best when the wavelength matches the molecular vibration frequency of the material. This match ensures the energy is absorbed quickly and efficiently.

I have used fast medium wave infrared lamps for industry in a wide range of applications. These lamps excel in processes that require fast response times and accurate temperature control. In printing and textiles, I use them to dry inks and coatings rapidly. The fast response time—often just 1-2 seconds—lets me maintain tight control over the process. In powder coating and film laminating, I rely on the precise temperature range of 50-500℃ and the ability to adjust power output using PLC or SCR regulators. For moisture drying, the wavelength of these ir heat lamps matches the vibration frequency of water molecules, which leads to rapid evaporation and energy savings.

In food processing, I use infrared lamps for pre-heating and drying without direct contact. The flexible installation options—horizontal or vertical—make them easy to integrate into existing lines. In photovoltaic and semiconductor manufacturing, I depend on the fast response and accurate temperature control for delicate processes like wafer soldering and thin-film curing. Glass cutting and BOPET film production also benefit from the high power density and uniform heating these heat lamps provide. I have seen energy savings of up to 50% compared to traditional heat lamps, which makes this technology a smart investment for many industrial applications.

When I start selecting heat lamps for my facility, I always begin by assessing the process requirements. This step ensures I choose the right solution for my specific needs. I gather all technical data related to the machines and production lines. I look at the brand and model of the equipment, oven dimensions, preform size and thickness, and the speed at which I need to run industrial processes. I also check if the system is compatible with near-infrared or medium wave infrared lamps.

I follow these steps to accurately assess what my process demands:

Collect technical data: machine brand, model, oven size, preform thickness, and production speed.

Identify the heating requirements: target temperature, uniformity, and cycle times.

Evaluate material properties: absorption characteristics, reflectivity, and thickness.

Determine compatibility: check if the equipment supports medium wave infrared heat lamps.

Consider customization: assess if the process needs special lamp shapes, power levels, or heating zones.

Review durability and maintenance: estimate lamp lifespan, reflector condition, and ease of replacement.

Plan for validation: schedule testing to confirm the lamp meets process goals.

Tip: I always share detailed machine and process information with suppliers. This helps them recommend the best heat lamps for my application.

After I understand the process requirements, I match them with the right lamp specifications. I know that every industrial process has unique needs, so I focus on the most critical features that affect performance and efficiency. I use a table to compare the key specifications and their importance:

Lamp Specification | Description and Importance |

|---|---|

Lighting Levels | I ensure the lamp provides the right illumination for the task, following industry standards. |

Operating Temperature | I check that the lamp can handle the temperatures required by my processes. |

Color Temperature | I select lamps with color temperatures that suit the visual needs of the process. |

Luminous Efficacy | I look for high efficiency to reduce energy costs. |

Spectral Output | I match the lamp’s spectral output to the material’s absorption peak for optimal heating. |

Lamp Base Design | I verify the base fits my equipment and supports proper heat management. |

Electrode Configuration | I choose configurations that ensure stable operation and long lamp life. |

Fill Components | I review the fill gases and metals to ensure reliable ignition and color quality. |

Internal Pressure | I confirm the lamp operates safely under the required pressure conditions. |

Geometric Tolerances | I select lamps with precise manufacturing for consistent results. |

Reflector Design & Positioning | I make sure the reflector directs heat efficiently to the target area. |

I always pay special attention to the emission wavelength. For example, when I work with PET materials, I look for lamps with a peak wavelength between 2.7 and 3.2 micrometers. This range matches the absorption characteristics of PET, which leads to efficient heating. I also consider the lamp’s response time, durability, and whether it can be customized for my process.

Once I have matched the process requirements and lamp specifications, I reach out to manufacturers for expert advice. I provide them with all the technical details I have gathered. I request datasheets, technical documentation, and information about customization options. I ask about the wavelength range of their medium wave infrared lamps, which typically falls between 2.2 and 4.0 micrometers. I also inquire about the heating filament temperature, which usually ranges from 1200 to 1800℃, and the application heating range, which is often 50–500℃.

I make sure to discuss the following points with manufacturers:

Response time: I need lamps that reach full power in 1–2 seconds.

Temperature control: I look for accuracy within ±1℃.

Installation flexibility: I prefer lamps that fit small spaces and can be mounted horizontally or vertically.

Customization: I ask about adjustable filament design, lamp shape, heating length, and output power.

Application suitability: I confirm the lamp works for fast heating of surfaces, drying food, paints, plastics, or solvents.

Advantages: I want to know how their heat lamps compare to traditional heating in terms of energy savings and efficiency.

Note: I always request information about lamp lifespan, maintenance needs, and reflector quality. This helps me plan for long-term reliability and performance.

By following these steps, I ensure I select the best heat lamps for my industrial processes. I rely on a thorough assessment, careful specification matching, and open communication with manufacturers to achieve optimal results with infrared heating technology.

When I install fast medium wave infrared lamps in industrial settings, I always prioritize safety and operational efficiency. Proper installation not only extends lamp lifespan but also protects my team and equipment. Over the years, I have developed a checklist that helps me avoid common pitfalls and ensures reliable performance.

Here are the key installation considerations I follow:

I always monitor the temperature around the lamp. I adjust the distance to prevent surfaces from exceeding 400°F. For sensitive parts, I keep the lamp about 6 inches away.

I maintain a minimum clearance of 25 feet from any flammable materials or vapors. This step reduces the risk of fire hazards in my workspace.

I never block the front of the lamp. Unobstructed airflow allows for proper heat dissipation and prevents overheating.

I mount the lamp securely on a stable stand. I avoid placing it on uneven surfaces, tables, or floors. If needed, I add weight to the stand for extra stability.

I use only grounded electrical outlets. For extension cords, I select a 14-gauge or heavier cord for up to 25 feet, and a 12-gauge or heavier cord for 26 to 50 feet. This practice prevents electrical hazards and voltage drops.

I handle quartz elements with care during installation or replacement. I never force components into place, which helps me avoid breakage.

I avoid looking directly at the infrared elements. I also make sure not to touch them while they are hot or before they have fully cooled.

I keep unauthorized personnel away from the installation area. Infrared coils reach very high temperatures and can cause burns or other injuries.

I never operate the lamp near powder spraying or flammable vapors. I also avoid leaving the lamp unattended during use.

I clean the lamp elements only when they are cool and unplugged. I use a soft rag and alcohol to remove dust or residue.

I adjust the angle and height of the lamp using the stand’s locking mechanisms. Secure positioning ensures even heating and prevents accidental movement.

I remove any conventional paint, gaskets, or plastics near the curing surface. This step prevents unwanted melting or damage during operation.

I always wear protective goggles to shield my eyes from intense infrared radiation. Prolonged exposure can cause eye damage, so I never skip this step.

I minimize direct skin exposure during loading and unloading. Intense infrared radiation can cause skin and tissue damage, so I follow proper handling procedures.

Tip: I always review the manufacturer’s installation manual before starting. Following these guidelines helps me achieve safe, effective, and long-lasting operation of my infrared heating system.

When I choose between fast medium wave and short wave IR heat lamps, I always start by looking at their core differences. Short wave IR heat lamps operate at higher temperatures and deliver intense, direct heat. They reach full power almost instantly, which makes them ideal for processes that need rapid, high-temperature heating. Fast medium wave IR heat lamps, on the other hand, provide more gentle and uniform surface heating. They work best for applications where I need stable, controlled heat.

Here is a table that helps me compare these two types:

Aspect | Short Wave Infrared Lamps (NIR) | Fast Medium Wave Infrared Lamps (MFIR) |

|---|---|---|

Wavelength Range | 0.75-1.4 micrometers | 3-20 micrometers |

Penetration Depth | Strong penetration, deeper into materials | Shallower penetration, mainly surface or shallow layers |

Heating Speed | Fast heating due to high energy density | Slower heating speed |

Energy Efficiency | Higher energy consumption | Higher energy efficiency, suitable for stable heating |

Heating Characteristics | Rapid, high-temperature heating, instant response | Uniform, gentle, and stable surface heating |

Applications | Plastic processing, metal heating, rapid drying/curing | Food processing, textile/paper drying, indoor heating |

I have seen that short wave IR heat lamps reach up to 2200 °C and offer about 80% radiating efficiency. They provide intense heat with little energy waste. Fast medium wave IR heat lamps take under 30 seconds to start and operate at lower temperatures, around 900 °C. They lose more heat to the air, so I avoid using them in windy environments. For deep heating or metal processing, I pick short wave. For surface drying or food processing, I rely on fast medium wave.

When I compare fast medium wave IR heat lamps to long wave types, I focus on response time and lifespan. Fast medium wave IR heat lamps reach full power in just 1–2 seconds. This quick response helps me when I need fast on/off cycles or precise temperature control. Long wave IR heat lamps take much longer—sometimes up to four minutes—to reach operating temperature. They suit processes that run continuously and do not need rapid changes.

Here is a table I use to highlight the main differences:

Feature | Fast Medium Wave Infrared Lamps | Long Wave (Medium Wave) Infrared Lamps |

|---|---|---|

Response Time | Very fast, about 1-2 seconds to full power | Longer, approximately 1-4 minutes |

Lifespan | Shorter lifespan due to higher filament temperatures and fast cycling | Longer working life, more economical for continuous use |

Operating Temperature | High filament temperature (1200-1800°C) | Lower filament temperature |

IR Radiation Wavelength | 1.4-2.0 μm | 2.2-4.0 μm |

Typical Applications | Rapid heating of surfaces and thin layers, fast heating from 50 to 500°C | Continuous heating, long-duration processes, drying ovens |

Heating Efficiency | Fast heating, adjustable output heat power, suitable for quick on/off cycling | Uniform heating energy when stable running |

I use fast medium wave IR heat lamps for quick heating tasks, like surface curing or rapid drying. For long, steady processes, such as drying ovens or continuous production lines, I prefer long wave IR heat lamps. Long wave types last longer and cost less to maintain over time.

I always match the IR heat lamps to the specific needs of my process. I consider several factors before making a decision:

Wavelength compatibility: I check if the emission spectrum of the IR heat lamps matches the absorption peak of the material.

Power density: I select IR heat lamps with enough power to achieve the desired heating, drying, or curing.

Application-specific needs: I look at whether I need fast on/off cycling, uniform heating, or precise temperature control.

Lamp type characteristics: I compare the advantages of quartz halogen, tungsten filament, or even IR LEDs for my application.

Tip: I always test a sample IR heat lamp in my process before making a large purchase. This step helps me confirm that the lamp delivers the right performance and efficiency.

By understanding the differences between fast medium wave, short wave, and long wave IR heat lamps, I can choose the best option for any industrial heating challenge. The right choice improves efficiency, saves energy, and ensures reliable results.

In my experience, fast medium wave heat lamps have transformed glass processing. I rely on these lamps for cutting, shaping, and recycling glass in industrial settings. The wavelength of these heat lamps matches the absorption characteristics of glass, which allows for rapid and even heating along the cut line. This results in clean breaks with almost no chips or micro-cracks. I often use them for automotive glass, laminated windshields, and specialty display panels. The technology supports automated production lines, which increases throughput and reduces labor costs. I have seen a significant improvement in edge quality and a reduction in waste.

Here is a summary of how I use fast medium wave heat lamps in glass processing:

Use Case Category | Description |

|---|---|

Industrial Glass Cutting | Fast, precise heating for chip-free breaks in automotive and laminated glass. |

Specialty & Display Glass | Controlled low-power heating for thin, fragile panels like smartphone and display glass. |

Laminated Glass Processing | Heats polymer interlayers without damaging outer layers, enabling fast separation. |

Glass Recycling | Efficient, contactless cutting in automated lines, increasing throughput and reducing labor. |

I have measured cutting speeds up to 55% faster than traditional CO₂ lasers. The edge quality is flawless, and I rarely see rejected parts. These heat lamps consume less energy than halogen lamps, which lowers my operating costs. I can adjust the power to suit different glass types and thicknesses, and I maintain precise temperature control for consistent results.

When I work with plastics and thermoforming, I always choose fast medium wave heat lamps for their efficiency and reliability. The wavelength of these lamps aligns with the absorption spectrum of most plastics, which means I get rapid and uniform heating. I notice that the lamps heat thermoplastics within 1-2 seconds, which reduces energy waste and improves process control. Even heat distribution helps me avoid defects and ensures product uniformity.

Some key benefits I have observed include:

Consistent heating that reduces defects and maintains product quality.

Energy efficiency by focusing heat only where needed.

Faster cycle times, which increase production throughput.

Longer lamp lifespan, resulting in less downtime and lower maintenance costs.

I often add reflectors to further improve heating efficiency. These heat lamps are compatible with OEM systems, so I can customize them for different industrial needs. The result is a smoother workflow and higher-quality plastic products.

I have found that fast medium wave heat lamps offer major advantages for curing paint and coatings. These lamps penetrate the paint surface and heat the substrate first, which prevents surface defects like craters from solvent popping. I get uniform heat distribution, making it easy to dry and cure large areas. The technology works well with both solvent-based and waterborne paints, which helps me avoid slow drying issues.

Here are the main advantages I see in my work:

Curing times are reduced by 50-90% compared to air drying.

The finish quality improves, with less orange peel, better adhesion, and higher gloss.

Energy costs drop because I can target heat only where needed.

The work environment is safer and cleaner, with no toxic gases or airflow required.

The risk of airborne particle contamination is minimized, since no airflow is needed during curing.

I rely on these heat lamps to deliver consistent, high-quality results in my paint and coatings processes. The technology supports faster production and a better finish, which keeps my clients satisfied.

In my work with food processing, I have seen how fast medium wave infrared lamps transform production lines. These lamps deliver rapid, uniform heating that targets food products directly. I do not need to heat the surrounding air, which means I achieve faster results and save energy. This direct approach allows me to accelerate drying and heating steps, which boosts throughput and keeps production schedules on track.

Medium wave infrared lamps give me precise control over the heating process. I can adjust the intensity and duration to suit different foods, whether I am drying fruits, baking snacks, or roasting coffee beans. The non-contact nature of infrared heating means I avoid contamination risks and maintain a clean processing environment. I have noticed that products retain their color, aroma, and crispiness better when I use these lamps compared to traditional methods.

Note: I often combine infrared heating with other drying techniques, such as convective or vacuum drying. This hybrid approach reduces drying times by nearly half and cuts energy consumption by more than 60%. I have seen studies where combining these methods led to a 48% reduction in drying time and a 63% drop in energy use.

Uniformity is another major advantage. Infrared lamps heat every piece of food evenly, which means I get consistent product quality from batch to batch. I no longer worry about undercooked or over-dried sections. This consistency helps me meet strict quality standards and reduces waste.

Here are some ways I use fast medium wave infrared lamps in food processing:

Drying fruits, vegetables, and herbs quickly and evenly

Roasting coffee beans and nuts with precise temperature control

Baking snacks and ready-to-eat foods with improved texture and color

Pre-heating or pasteurizing products without direct contact

Enhancing the crispiness and aroma of baked goods

I value the flexibility these lamps offer. I can integrate them into existing lines or use them in new installations. Their fast response time lets me adjust to changes in production demand without delay. The energy savings and improved product consistency make fast medium wave infrared lamps a smart investment for any food processing facility. I have seen firsthand how this technology helps me deliver high-quality products efficiently and reliably.

I have seen many projects fail because the lamp wavelength did not match the material’s absorption characteristics. This mistake wastes energy and leads to poor heating results. I always check the absorption spectrum of the material before I select a lamp. If I skip this step, I risk choosing a lamp that delivers most of its energy at wavelengths the material cannot absorb. The result is slow heating, uneven temperatures, and sometimes even product defects.

Tip: I always ask suppliers for detailed spectral data. I compare this data with the material’s absorption curve. This simple check helps me avoid costly mismatches.

Here is a quick reference table I use:

Material Type | Best Absorption Wavelength (μm) | Recommended IR Lamp Type |

|---|---|---|

Plastics | 2.5 – 3.5 | Fast Medium Wave |

Glass | 1.0 – 3.0 | Short or Fast Medium Wave |

Water-based | 2.7 – 3.0 | Fast Medium Wave |

Metals | < 1.5 | Short Wave |

If I ignore this match, I often see higher energy bills and lower product quality. I always make wavelength compatibility my first checkpoint.

I have learned that efficiency is not just about saving money. It also affects process speed and product consistency. Some teams focus only on the lamp’s power rating and ignore how much of that power turns into usable heat. I always look for lamps with high energy conversion rates. If I overlook efficiency, I end up with longer cycle times and higher operating costs.

I check the manufacturer’s efficiency ratings.

I compare the lamp’s radiant output to its electrical input.

I look for lamps with up to 96% efficiency for the best results.

Note: Efficient lamps reduce the load on my facility’s electrical system. This means fewer outages and less wear on other equipment.

I also monitor the system for heat loss. Poorly placed lamps or missing reflectors can waste a lot of energy. I always optimize lamp placement and use quality reflectors to direct heat where I need it most.

Safety mistakes can lead to injuries, equipment damage, or even fires. I never compromise on safety when I install or operate infrared lamps. I always check for certifications like UL, CE, or ETL. These marks show that the lamp meets strict safety standards.

Here are some safety steps I follow:

I keep flammable materials far from the lamp.

I use proper electrical connections and grounded outlets.

I wear protective goggles and gloves during installation and maintenance.

I train my team on safe handling and emergency procedures.

Alert: Never operate infrared lamps near flammable vapors or unattended. Always follow the manufacturer’s safety guidelines.

I also inspect lamps regularly for cracks, loose wires, or dust buildup. A small issue can become a big hazard if I ignore it. By making safety a habit, I protect my team and my investment.

I have seen many teams overlook the importance of regular maintenance for fast medium wave infrared lamps. This mistake often leads to unexpected downtime, reduced efficiency, and higher operating costs. I always remind myself that even the most advanced infrared heating systems need consistent care to perform at their best.

When I first started working with these lamps, I assumed their robust design meant they required little attention. I quickly learned that dust, debris, and even minor misalignments can impact performance. Over time, I developed a maintenance routine that helps me avoid costly surprises.

Here are some common maintenance oversights I have encountered:

Skipping regular cleaning of lamp surfaces and reflectors

Ignoring signs of wear, such as dark spots or flickering

Failing to check electrical connections for corrosion or looseness

Overlooking the need to replace aging reflectors or damaged quartz tubes

Not monitoring lamp hours or following the manufacturer’s recommended replacement schedule

Neglecting these tasks can cause several problems. Dust buildup reduces the lamp’s radiant output and can lead to overheating. Loose connections may result in intermittent operation or even electrical hazards. Worn-out reflectors scatter heat, making the process less efficient and increasing energy consumption. I have seen production lines come to a halt because a single lamp failed unexpectedly.

To keep my infrared heating system running smoothly, I follow a simple maintenance checklist:

Clean lamp surfaces and reflectors every month using a soft, lint-free cloth and isopropyl alcohol.

Inspect lamps for cracks, discoloration, or other signs of damage.

Check all electrical connections and tighten them if necessary.

Replace reflectors and quartz tubes as soon as I notice reduced performance.

Track lamp operating hours and schedule replacements before the end of their rated lifespan.

Tip: I always keep spare lamps and key components in stock. This practice allows me to replace faulty parts quickly and avoid extended downtime.

By treating maintenance as a priority, I extend the life of my lamps and maintain consistent heating quality. I also reduce the risk of safety incidents and keep my operating costs under control. Regular attention to these details ensures my infrared heating system delivers reliable performance year after year.

Before I finalize my choice of a fast medium wave infrared lamp, I always ask myself a series of essential questions. These questions help me avoid costly mistakes and ensure the lamp fits my industrial process perfectly:

What is the infrared absorption spectrum of the material I need to heat? I check which wavelengths the material absorbs best.

How thick is the material? I consider how thickness affects the optimal heating wavelength.

What are the required operating temperature and power output for the heater? I know these factors influence both performance and lamp lifespan.

Are there environmental challenges, such as dust, debris, or contamination, that could reduce the lamp’s effectiveness?

Do I need air circulation to prevent overheating or to keep the material temperature uniform?

Which type of reflector—internal or external—works best in my production environment?

How quickly must the lamp reach operating temperature and cool down to match my process speed?

Have I slightly overdesigned the system to avoid running the lamp at maximum capacity, which can extend its lifespan?

Tip: I always write down my answers to these questions. This habit helps me compare different lamp options and spot any gaps in my planning.

I never skip a thorough documentation review before making my final selection. I request and examine all technical datasheets, installation manuals, and safety certifications from the manufacturer. I look for clear information on:

Emission wavelength range and peak output

Power ratings and recommended operating conditions

Lamp lifespan and maintenance schedules

Safety certifications (UL, CE, ETL, etc.)

Installation requirements and compatibility with my existing equipment

I use a simple table to track the most important documentation:

Document Type | What I Check For |

|---|---|

Datasheet | Wavelength, power, lifespan, efficiency |

Installation Manual | Mounting, electrical, safety instructions |

Certification Report | Compliance with safety and quality standards |

Maintenance Guide | Cleaning, replacement, troubleshooting |

I always confirm that the documentation matches my process needs and local regulations.

When I reach the final decision stage, I focus on a few critical checks. I verify that the lamp’s spectral output aligns with my material’s absorption peak. I confirm the lamp can deliver the required power without operating at its maximum limit. I double-check that all safety certifications are current and relevant for my region.

I also test a sample lamp in my process whenever possible. This step gives me confidence that the lamp will perform as expected. I review my answers to the key questions and ensure the documentation supports my choice.

✅ If everything checks out, I proceed with the purchase, knowing I have minimized risks and optimized my heating process.

I always follow a clear process when I select fast medium wave infrared lamps for industry. I assess my process needs, match lamp specifications, and review safety and efficiency. I focus on the material’s absorption spectrum and the lamp’s power output. I consult with suppliers and use my checklist before making a decision.

For best results, I recommend reviewing your process requirements and speaking with trusted suppliers. Use the checklist to ensure you choose the right lamp for your application.

Takeaway: The right lamp choice improves efficiency, safety, and product quality. Start your selection with confidence today.

I choose fast medium wave infrared lamps for their rapid response and precise control. These lamps heat up and cool down quickly. They work best for processes that need accurate temperature management and energy efficiency.

I always check the absorption spectrum of the material. If the lamp’s emission wavelength aligns with the material’s absorption peak, I get efficient heating. I ask suppliers for data or use reference tables for guidance.

I install lamps with a high IP rating for protection against dust and moisture. I also follow manufacturer guidelines for cleaning and maintenance. This approach keeps my lamps running safely and efficiently.

I track lamp operating hours and follow the manufacturer’s recommended replacement schedule. Most fast medium wave infrared lamps last between 3,000 and 5,000 hours. Regular inspections help me avoid unexpected failures.

I always use proper shielding and follow safety guidelines. These lamps emit strong infrared radiation, which can cause burns or eye damage. I train my team and use protective equipment when necessary.

I check the power supply, inspect for visible damage, and review electrical connections. If I cannot find the issue, I consult the manufacturer’s troubleshooting guide or contact technical support for help.

I often retrofit existing systems by matching lamp size, power, and voltage. I consult with manufacturers to ensure compatibility. Sometimes, I need to upgrade reflectors or controls for optimal performance.

Tip: Always review technical documentation before making changes to your system.