Views: 0 Author: Site Editor Publish Time: 2025-07-25 Origin: Site

When I consider which heater best fits your needs, I always start with the type of space you want to heat. Whether you manage a busy glass workshop, a massive warehouse, or a cozy patio, the right models can make a dramatic difference. Most industrial and commercial spaces rely on heaters for consistent, energy-efficient warmth, while residential spaces still lag in adoption. I see top brands offer a wide range of heaters, each designed to target specific space challenges. Choosing the ideal ir tube heater means matching your space and application with the right features.

Infrared tube heaters warm people and objects directly, saving energy and providing fast, even heat.

Choosing the right heater depends on your space size, insulation, and how you plan to use it.

Proper installation and regular maintenance keep heaters safe and working efficiently.

Top brands offer different features and prices, so match the heater to your budget and needs.

Infrared heaters improve air quality by not circulating dust or allergens.

Outdoor heaters need to be weather-resistant and placed to protect from wind for best comfort.

Industrial heaters often have advanced controls and durable designs for tough environments.

When I explain how an ir tube heater operates, I always start with the basics. Infrared tube heaters generate radiant energy either electrically, by passing current through a filament, or by using a gas flame to heat a tube. The heater emits infrared radiation that travels directly to the target space, warming objects and people without needing to heat the air first. This direct transfer of energy means infrared tube heaters can deliver fast, uniform, and non-contact heating. I often see these heaters use reflectors to focus the infrared rays, maximizing efficiency by directing more energy into the intended space.

Here’s a quick comparison of common infrared emitters:

IR Emitter Type | Wavelength Range | Operating Principle / Characteristics |

|---|---|---|

Shortwave Emitters | 700 to 1400 nm | Reach maximum temperature quickly; used in preheating and coating processes. |

Medium-wave Emitters | 1.4 to 3.0 μm | Operate at 850–1200 °C; emit dull orange light; require >5 kW power. |

Longwave Emitters (Tube) | Typically longer wavelengths | Emit IR radiation from heated metallic tubes; heat target by direct radiation without medium; used for uniform heating. |

The science behind infrared heating fascinates me. The heater’s source emits rays that penetrate the surface of objects in the space, causing molecular movement and a rise in temperature. The total energy output depends on the heater’s temperature and the wavelength of the infrared radiation. This principle, known as the Stefan-Boltzmann law, explains why infrared tube heaters can be so effective in both indoor and outdoor spaces.

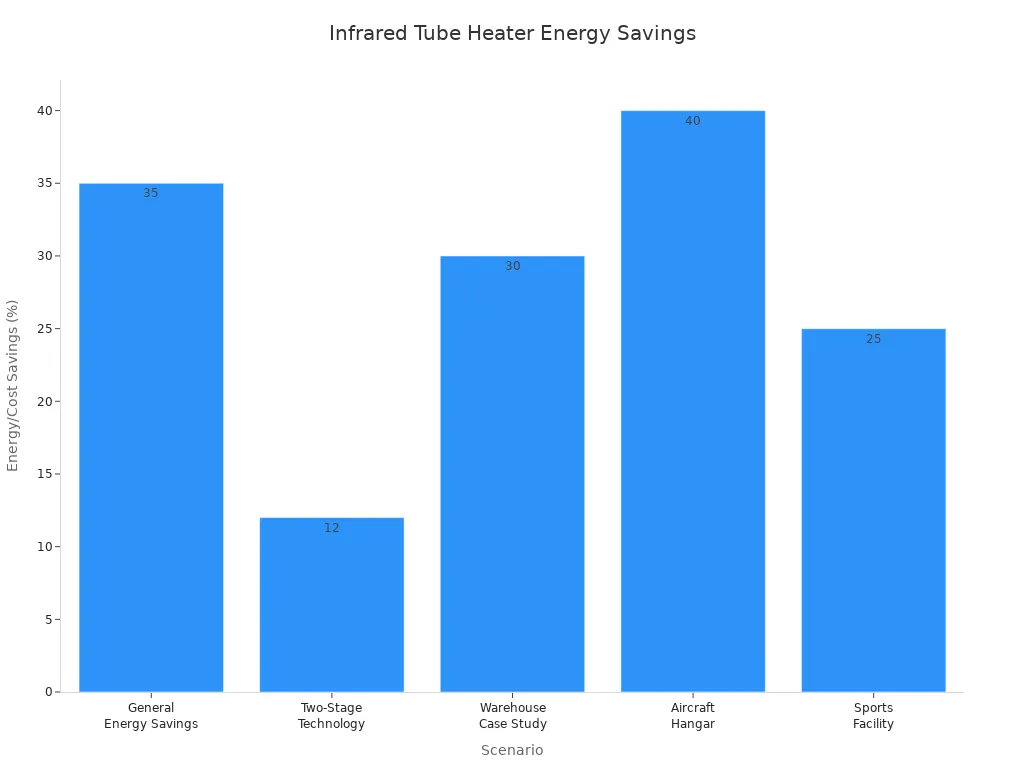

I have seen firsthand how infrared tube heaters outperform traditional convection heaters. Infrared heaters transfer energy directly to objects and people in the space, achieving nearly 100% heat absorption. This method allows facilities to save between 20% and 50% in fuel costs compared to conventional heating. I appreciate that infrared tube heaters do not circulate air, which means they avoid spreading dust and airborne pollutants in indoor spaces. The modular design of many heaters lets me target specific zones, providing personalized comfort and reducing wasted energy.

Tip: Infrared tube heaters can reduce drafts and uneven heating, making large spaces feel warmer even when the thermostat is set lower.

Here are some key advantages of infrared heating:

Direct heating of people and objects, not just air

Lower energy bills due to efficient energy transfer

Improved indoor air quality

Reduced maintenance and longer heater lifespan

Flexible installation for portable or fixed applications

I recommend infrared tube heaters for a wide range of spaces. In industrial settings, I often see these heaters used in warehouses, distribution centers, airplane hangars, and auto shops. They improve employee comfort and energy efficiency in large, open spaces. In commercial spaces, restaurants and hospitality venues use portable infrared heaters to keep patios and outdoor areas warm. For residential spaces, I find these heaters ideal for garages and outdoor heating needs.

Infrared tube heaters also play a vital role in agricultural spaces, such as poultry and swine barns, where precise heating is essential. In manufacturing, I use infrared heaters for drying, curing, welding, and embossing processes. The ability to deliver targeted, efficient heating makes them a top choice for many industries.

Note: The advantages of infrared heating extend to both permanent and portable heater models, making them suitable for nearly any space, whether indoor or outdoor.

When I select an infrared space heater, I always begin by evaluating the space and its intended application. Every space has unique requirements, whether it is an industrial warehouse, a commercial garage, or an indoor workshop. I look at the dimensions—length, width, and height—because these factors determine the heater size and output. I also consider the insulation level of the building. Well-insulated spaces need less heating capacity, while poorly insulated areas require more powerful heaters.

I pay close attention to the number and size of doors, especially in commercial and industrial spaces. Frequent door openings introduce cold air, which increases the heating load. Placement of the heater near overhead doors helps counteract cold air infiltration. I also assess the building’s shape and roof design, as these affect how radiant heat distributes throughout the space.

Here are the main factors I consider:

Space dimensions and ceiling height

Insulation R-values for walls and roof

Number and frequency of large door usage

Purpose of the space (e.g., industrial process heating, commercial space heating, indoor comfort)

Geographic location and climate

Proper sizing and placement ensure the heater delivers efficient, energy-efficient heating without oversizing or undersizing, which can impact comfort and cost.

I have found that installation and maintenance play a critical role in the performance of any infrared space heater. Ceiling-mounted tube heaters work well for most industrial and commercial spaces, providing quick, even heating. Angled installations, such as at 45 degrees, can target specific areas and improve comfort on the floor. Two-stage infrared tube heaters with ducted intake and venting offer flexibility for spaces with variable heating needs.

Installation Option | Pros | Cons |

|---|---|---|

Ceiling-mounted tube heaters | Quick, efficient heating; ideal for large spaces | Uneven heat if installed too low; thermostat placement can be tricky |

Angled installation (e.g., 45°) | Direct, intense heating; good for mid-height ceilings | Risk of overheating if oversized; may require custom length |

Two-stage with ducted intake/venting | Fast heat-up; energy efficient; staged operation | Complex setup; requires careful design |

Vent-less infrared heaters | Portable; easy to install in open spaces | Not suitable for small, tight spaces; professional specification needed |

Ceiling fans with heaters | Circulates warm air in high-ceiling spaces | Can waste electricity if not used properly |

I always recommend considering wall-mounted and wall-mounted heater options for smaller indoor spaces or where floor space is limited. Proper installation and maintenance ensure safety and maximize efficiency.

Energy efficiency remains a top priority for me when choosing a space heater. Infrared tube heaters deliver high efficiency by directing radiant heat to people and objects, not just the air. Radiant tube heaters typically achieve around 60% downward radiant efficiency, resulting in up to 20.8% energy savings compared to traditional heaters. High-end models can reach up to 93% efficiency, making them ideal for both commercial and industrial process heating.

I always match the heater’s wavelength to the material being heated for maximum efficiency. For example, medium-wave infrared heaters work best for materials like glass or polypropylene, where absorption is nearly complete. Integrating heaters with HVAC systems can reduce overall energy demand by up to 61%.

Tip: Always consult with a heating expert to tailor the heater layout and ensure optimal energy-efficient heating for your specific space.

When I evaluate any heater, I always put safety at the top of my checklist. Infrared tube heaters have evolved to include a range of advanced safety features that protect both people and property. I look for models that carry certifications from recognized organizations. Most leading heaters display the CSA seal, which means they meet or exceed the American National Standard Z83.20 for infrared heaters. This certification gives me confidence that the heater has passed rigorous testing.

I also check for UL-listed electrical components. These parts, such as draft inducer motors, come with thermal protectors approved by both CSA and UL. This ensures that the heater will shut down safely if it detects a fault. Many heaters use a pull-through combustion system. This design pulls combustion products through the chamber, increasing both radiant efficiency and safety. I appreciate that draft inducer motors are permanently lubricated, totally enclosed, and fan-cooled. Heavy-duty ball bearings minimize maintenance and reduce the risk of failure.

Here are some standard safety features I always look for:

100% gas shut-off safety control to prevent leaks

Direct spark ignition for reliable and safe startup

Vacuum system with a fully enclosed combustion chamber

Diagnostic monitoring lights for quick troubleshooting

Factory-assembled units to ensure safety compliance

Tip-over protection and overheating protection in portable models

I always recommend that installation and servicing be performed by licensed contractors. Following local codes and manufacturer instructions is essential for safety. I never compromise on these steps because a properly installed heater will operate safely for years.

Tip: Always check for visible safety certifications and ask your installer about the heater’s built-in protection systems.

Budget plays a major role when I choose a heater for any space. I always balance upfront costs with long-term operating expenses. Some heaters may cost more initially, but their energy efficiency and low maintenance can save money over time. I compare the price of the heater, installation fees, and expected energy consumption. High-quality heaters often come with longer warranties and better support, which adds value.

I also consider the specific needs of the space. For example, a small workshop may only need a basic model, while a large industrial facility might require a more advanced heater with extra features. I look for models that offer the best combination of performance and price. Sometimes, investing in a premium heater with advanced safety features and higher efficiency pays off in the long run.

I always advise buyers to factor in the total cost of ownership. This includes not just the purchase price, but also installation, maintenance, and energy use. By taking a comprehensive approach, I ensure that the heater I select delivers reliable performance and fits within the budget.

When I evaluate the landscape of infrared tube heaters, I see a diverse field of brands, each with its own strengths and specialties. Over the years, I have worked with many of these heaters in industrial, commercial, and even residential settings. Some brands focus on innovation and precision, while others build their reputation on reliability and energy efficiency. I always recommend starting with a broad view of the market before narrowing down your options.

Here is a quick overview of some of the most recognized brands and their reputations in the infrared heaters industry:

Brand | Reputation Highlights |

|---|---|

Known for advanced, application-specific solutions, especially in glass cutting and industrial heating. | |

Reznor | Trusted for robust, energy-efficient heaters for commercial and industrial spaces. |

Roberts Gordon | Specializes in high-intensity electric infrared heaters with a strong industry presence. |

Detroit Radiant | Offers a wide range of infrared tube heaters, valued for durability and performance. |

Space-Ray | Recognized for energy-efficient radiant heating and CSA-certified agricultural heaters. |

Superior Radiant Products | Delivers reliable, high-performance heaters for large-scale applications. |

Modine | Focuses on versatile, easy-to-install heaters for commercial and industrial use. |

Schwank | Known for innovative, efficient infrared heaters for both indoor and outdoor environments. |

Bromic | Excels in stylish, high-performance heaters for hospitality and outdoor spaces. |

Infratech | Specializes in electric infrared heaters for architectural and residential projects. |

Dr. Infrared | Popular for portable, user-friendly heaters for home and small business use. |

EdenPURE | Offers safe, efficient heaters with a focus on residential comfort. |

Duraflame | Known for affordable, easy-to-use heaters for home and office settings. |

I have also encountered other reputable manufacturers in the field. For example, Aitken Products, Inc. engineers efficient, reliable infrared heating systems that help reduce operational costs. Glenro Inc. stands out for precision and consistency in industrial process heating. Solaronics, Inc. optimizes comfort and energy savings with high-performance solutions. Space Ray, in particular, has earned recognition for its CSA-certified poultry and swine heaters, which maintain uniform tube temperatures for agricultural needs.

Applebee-Church, Inc. serves both industrial and commercial sectors with electrical heating systems. Fannon Products, LLC manufactures infrared systems for printing, automotive, and custom heating applications. All Sensors provides electric infrared heaters with a focus on quality and innovation. Cambridge Air Solutions has built a reputation for reliability since 1963, especially in radiant tube heaters. Infra-Red Radiant, Inc. also offers electric infrared heaters known for quality and innovation.

I always advise clients to consider both the brand’s reputation and the specific features of their heaters. The right choice often depends on your unique application, whether you need industrial-grade performance, energy efficiency, or specialized solutions for processes like glass cutting.

With so many options, I find that reviewing each brand’s product focus and customer feedback helps me match the best infrared tube heaters to each project’s requirements.

When I evaluate the Yinfrared FMW Twin Tube IR Emitter, I notice several standout features that set it apart from other infrared tube heaters. The twin tube design ensures uniform heat distribution and allows for flexible installation in various industrial settings. I appreciate the gold reflector, which reflects about 90% of the infrared radiation. This design not only improves energy efficiency but also enables precise, localized heating. The medium wave performance, operating in the 1.4 to 2.0 micrometer range, matches the absorption characteristics of glass and other materials, resulting in fast and even heating. The robust construction supports reliable operation under continuous industrial use, making it a dependable choice for demanding environments.

Twin tube design for even heat distribution

Gold reflector for enhanced energy efficiency

Medium wave infrared output for rapid, uniform heating

Durable build for 24/7 industrial operation

I have seen firsthand how the technology behind this emitter delivers high-performance infrared heating. The lamp uses fast medium wave infrared, which glass absorbs three times faster than shortwave IR. This results in rapid, controlled heating with minimal thermal stress. The adjustable power range from 500W to 2000W allows me to tailor the output to different glass thicknesses and types.

Here is a summary of key performance metrics:

Performance Metric | Reported Value / Description |

|---|---|

Cutting Speed | 55% faster than CO₂ lasers |

Edge Quality | Zero rejection rate; flawless edges |

Return on Investment | Achieved within 3 months |

Heating Time | 3 to 15 seconds for glass thickness 3–8 mm |

Power Range | Adjustable between 500W and 2000W |

Energy Efficiency | Consumes 40% less power than halogen IR lamps |

Lamp Lifespan | Minimum of 10,000 hours |

Operating Cost | Rated highest compared to halogen IR and CO₂ lasers |

Maximum Glass Thickness Support | Up to 12 mm |

I spoke with a German auto glass supplier who reported a 55% increase in cutting speed after switching to this emitter from a CO₂ laser system. The edge quality improved dramatically, with zero rejection rate due to edge defects. The lamp heats glass quickly, enabling cuts of 3 to 8 mm thickness in just 3 to 15 seconds. The energy consumption dropped by 40% compared to halogen IR lamps, which reduced operating costs and allowed the company to achieve a return on investment within three months.

I recommend the Yinfrared FMW Twin Tube IR Emitter for a wide range of industrial and manufacturing processes. Its rapid response time of 1–2 seconds and precise temperature control (±1°C) make it ideal for applications that demand both speed and accuracy. The compact size and flexible installation options allow me to replace traditional air heating systems and other high energy consumption electric heaters with ease.

Application Areas | Description / Examples |

|---|---|

Plastic Forming | Industrial shaping of plastics |

Bottle Blowing | PET bottle manufacturing |

Paint Drying | Automotive paint curing, printing ink fusing |

Food Processing | Food catering and processing |

Pre-heating of PET Performs | Preparation step in PET bottle manufacturing |

Paper Mill Drying | Drying processes in paper production |

Plastics Thermoforming | Heating plastics for shaping |

Semiconductor Manufacturing | Silicon wafer processing |

Textile Printing and Dyeing | Printing and dyeing textiles |

Laminated Glass Cutting | Glass cutting applications |

The emitter excels in fast heating industrial applications requiring temperatures from 50 to 500°C. I use it for laminated glass cutting, plastics thermoforming, and even semiconductor manufacturing. Its high efficiency and clean, electric heat source make it a preferred choice in industries where energy savings and environmental considerations matter. The ability to deliver high-performance infrared heating in a compact, reliable package sets this emitter apart from other infrared tube heaters.

When I assess the Yinfrared FMW Twin Tube IR Emitter, I see a product engineered for maximum energy efficiency and workplace safety. The twin tube quartz infrared lamps deliver fast, even heating with precise temperature control. I notice that these lamps direct radiation energy straight to the object, eliminating the need for an intermediate medium. This direct approach improves energy utilization and reduces waste.

The wavelength of the emitted infrared radiation can be matched to the absorption characteristics of the material being heated. I find this feature especially valuable in glass cutting, where optimal absorption leads to faster, more uniform heating. Compared to traditional heating sources—such as hot air, ceramic, gas, or metal heaters—these lamps achieve higher energy efficiency and much quicker heating cycles.

The gold or ceramic reflectors, coated directly on the quartz tube, reflect up to 90% of the infrared radiation back to the target. This design minimizes energy loss and shortens heating times, which translates to lower electricity costs and improved sustainability.

I appreciate the fast response time of just 1–2 seconds. The lamp reaches operating temperature almost instantly, which means I can start or stop the heating process with minimal delay. The precise temperature control (±1°C) ensures consistent results and prevents overheating, which is critical in sensitive industrial processes.

Here is a simplified comparison of energy efficiency and annual savings:

Lamp Model | Energy Efficiency | Estimated Annual Savings |

|---|---|---|

Standard IR Lamp | Moderate | $500 |

YFR Semi-White IR | High | $1,200 |

While the Yinfrared FMW Twin Tube IR Emitter already outperforms standard IR lamps, the company’s advanced models like the YFR Semi-White IR push efficiency even further. I see that efficient lamps also produce less excess heat, which protects surrounding equipment and enhances workplace safety.

Safety remains a top priority in my evaluations. The Yinfrared FMW Twin Tube IR Emitter includes several built-in safety features. The lamp automatically shuts off at 300°C to prevent glass deformation or accidental overheating. The IP65 rating ensures dust and water resistance, making it suitable for harsh industrial environments. EMI shielding prevents electromagnetic interference, which is essential in electronics workshops.

I always recommend this emitter for facilities that demand both energy savings and robust safety. The combination of rapid, targeted heating and advanced protection systems makes it a reliable choice for modern industrial applications.

When I assess Reznor’s offerings, I see a comprehensive selection designed for both industrial and commercial environments. Reznor’s product range stands out for its flexibility and adaptability. The VZ Low-Intensity Radiant Tube Heater serves occupied spaces such as warehouses, loading docks, and aircraft hangars. This line offers burner sizes from 40,000 to 200,000 BTUh and tube lengths ranging from 10 to 60 feet. I can choose from straight, U-tube, or L-tube configurations, which allows me to tailor the system to the specific layout of a facility. The VZ line supports both natural gas and LPG propane, making it suitable for various fuel preferences.

For harsher environments, I rely on the VZH Harsh Environment Radiant Tube Heater. This model works well in locations like car washes and parking ramps, where exposure to moisture and chemicals is common. The VZH line features burner sizes from 40,000 to 175,000 BTUh and the same flexible tube lengths and configurations as the VZ series. Stainless-steel burners and enclosed burner boxes provide extra durability. I appreciate the LED status indicator and the five-year warranty, which add peace of mind for long-term operation.

Here’s a quick comparison of Reznor’s main product lines:

Product Line | Environment/Application | Burner Size Range (BTUh) | Tube Length Range (feet) | Configurations | Fuel Types | Key Features |

|---|---|---|---|---|---|---|

VZ Low-Intensity Radiant Tube Heater | Warehouses, loading docks, aircraft hangars | 40,000–200,000 | 10–60 | Straight, U-tube, L-tube | Natural gas, LPG propane | Powder-coated burner, hinged door, aluminum reflectors, CSA certified |

VZH Harsh Environment Radiant Tube Heater | Car washes, parking ramps, harsh indoor/outdoor spaces | 40,000–175,000 | 10–60 | Straight, U-tube, L-tube | Natural gas, LPG propane | Stainless-steel burner, enclosed box, LED indicator, 5-year warranty, CSA certified |

Reznor integrates advanced technology into its infrared tube heaters to maximize efficiency and reliability. I notice that the powder-coated burners and aluminum reflectors in the VZ line help direct radiant energy precisely where it is needed. The hinged door access simplifies maintenance, which reduces downtime. In the VZH series, stainless-steel burners and enclosed burner boxes protect internal components from harsh conditions. The LED status indicator provides real-time feedback, making troubleshooting straightforward. Both product lines carry CSA certification, which assures me of their safety and compliance with industry standards.

In my experience, Reznor’s infrared tube heaters deliver consistent and efficient heating across a wide range of applications. The broad burner size range allows me to match the heater output to the specific needs of each space. I have installed these systems in large warehouses and smaller commercial garages, and they always provide uniform warmth without excessive energy use. The flexible configurations let me optimize coverage, even in irregularly shaped areas. The robust construction of the VZH line ensures reliable performance in environments with high humidity or chemical exposure. I trust Reznor heaters to maintain comfort and efficiency, even during continuous operation.

When I evaluate Reznor infrared tube heaters, I notice that their pricing reflects the brand’s reputation for quality and durability. The initial investment for a Reznor system often sits in the mid-to-high range compared to other commercial and industrial infrared heaters. I have seen basic models start around $1,000 for smaller units, while larger, high-output systems can exceed $3,000, especially when custom configurations or harsh environment features are required.

I always remind clients that the total cost includes more than just the heater itself. Installation expenses can vary based on the complexity of the system, the need for venting, and the layout of the facility. For example, a straightforward ceiling-mounted installation in a standard warehouse may cost less than a custom setup in a car wash or a facility with unique ventilation needs. I recommend budgeting an additional $500 to $1,500 for professional installation, depending on the project scope.

Operating costs for Reznor heaters remain competitive due to their energy efficiency. Many models use advanced reflectors and combustion technology to maximize radiant output and minimize fuel consumption. Over time, I have observed that these heaters can deliver significant savings on utility bills, especially in large spaces where traditional forced-air systems would waste energy.

Tip: Always consider the long-term value. While the upfront price may seem higher, the reliability and efficiency of Reznor heaters often result in lower maintenance and operating costs over the lifespan of the system.

I have reviewed feedback from many users who rely on Reznor infrared tube heaters in demanding environments. Their experiences highlight several recurring themes:

Many users praise the long-term reliability of Reznor heaters. I often hear stories of units running for years with minimal repairs, sometimes only requiring an igniter replacement after extended use.

Maintenance emerges as a key topic. In dusty workshop environments, users report that dust can accumulate inside the heater. Regular and thorough cleaning becomes essential to maintain performance and safety.

Professional installers frequently advise using outside air for combustion. This practice helps prevent dust and contaminants from entering the heater, which can extend its lifespan and reduce maintenance needs.

Some users mention that certain models, such as the V3, can be finicky in rough service environments. I recommend discussing your specific application with a professional to ensure the right model selection.

There is a strong recommendation against filtering the combustion air inlet. Filters can cause flame instability, which may compromise both performance and safety.

Most feedback centers on practical considerations like installation and ongoing maintenance rather than on specific ratings or scores. I find that users who follow recommended maintenance schedules and installation guidelines report the best long-term results. When I advise clients, I always stress the importance of proper setup and regular servicing to maximize the benefits of a Reznor infrared tube heater.

When I evaluate Roberts Gordon, I see a brand that offers one of the most comprehensive product portfolios in the industry. The company specializes in low-intensity and high-intensity infrared tube heaters for commercial and industrial applications. I often recommend their CORAYVAC® line for large, open spaces like warehouses, aircraft hangars, and manufacturing plants. This system uses a continuous radiant tube design, which allows for custom layouts that fit unique building shapes. The VANTAGE® series provides flexible solutions for smaller commercial spaces, garages, and workshops. I also see the Blackheat® line used in environments that require robust, reliable heating with minimal maintenance.

Here is a quick overview of their main product lines:

Product Line | Application Area | Key Features |

|---|---|---|

CORAYVAC® | Large industrial spaces | Continuous tube, custom layouts |

VANTAGE® | Commercial, light industrial | Versatile, modular, easy to install |

Blackheat® | Harsh environments | Durable, low maintenance |

I find that Roberts Gordon designs their systems to scale easily. Whether I need to heat a small auto shop or a massive distribution center, I can select a model that matches the space requirements.

Roberts Gordon invests heavily in technology to improve efficiency and performance. I notice that their CORAYVAC® system uses a vacuum-assisted design. This technology pulls combustion gases through the entire length of the radiant tube, which maximizes heat transfer and ensures even temperature distribution. The system supports condensing operation, which increases energy efficiency by extracting more heat from exhaust gases.

The VANTAGE® series features advanced burner controls and high-reflectivity aluminum reflectors. These components direct radiant energy precisely where it is needed. I appreciate the use of direct spark ignition and fully enclosed combustion chambers, which enhance both safety and reliability. Many models offer two-stage operation, allowing me to adjust output based on heating demand.

Note: Roberts Gordon heaters often include diagnostic LEDs and modular components. These features simplify troubleshooting and reduce downtime during maintenance.

In my experience, Roberts Gordon infrared tube heaters deliver consistent and reliable performance in demanding environments. The CORAYVAC® system excels in large, open spaces where uniform heating is critical. I have seen these systems maintain comfortable temperatures even in facilities with high ceilings and frequent air changes. The vacuum-assisted design ensures that every section of the tube emits heat evenly, eliminating cold spots.

The VANTAGE® and Blackheat® models provide rapid heat-up times and precise zone control. I can target specific work areas without wasting energy on unoccupied zones. The high-reflectivity reflectors and efficient burners translate to lower operating costs and reduced energy consumption.

I trust Roberts Gordon products for their durability and long service life. Many installations I have managed continue to operate efficiently after years of continuous use. When I need a solution that combines flexibility, advanced technology, and proven performance, I often turn to Roberts Gordon for infrared tube heaters.

When I evaluate Roberts Gordon infrared tube heaters, I always consider both the initial investment and the long-term value. Roberts Gordon positions its products in the mid-to-high price range within the commercial and industrial heating market. I have seen basic models start at approximately $1,200, while more advanced or custom systems can exceed $4,000. The final price depends on several factors, including the length of the radiant tube, the number of burners, and the complexity of the installation.

I often advise clients to factor in the following cost elements:

Heater Model and Size: Larger or more powerful units cost more.

Configuration: Custom layouts, such as continuous tube systems, increase the price.

Installation: Professional installation is essential. Labor and materials can add $800 to $2,000.

Accessories: Options like advanced controls, reflectors, or venting kits add to the total.

Tip: Always request a detailed quote that includes both equipment and installation. This helps avoid surprises during the project.

Here is a quick comparison table for reference:

Model/Series | Typical Price Range | Installation Cost | Notable Features |

|---|---|---|---|

VANTAGE® | $1,200–$2,500 | $800–$1,500 | Modular, easy to install |

CORAYVAC® | $2,500–$4,000+ | $1,500–$2,000 | Custom layouts, large spaces |

Blackheat® | $1,500–$3,000 | $1,000–$1,800 | Durable, harsh environments |

I find that Roberts Gordon heaters deliver strong value over time. Their energy efficiency and durability often offset the higher upfront cost. Many clients report lower utility bills and reduced maintenance expenses, which improves the total cost of ownership.

I have reviewed feedback from facility managers, installers, and end users who rely on Roberts Gordon infrared tube heaters. Most customers praise the consistent performance and reliability of these systems. I often hear that the heaters maintain even temperatures in large or challenging spaces, such as warehouses and airplane hangars.

Here are some common themes I notice in customer reviews:

Durability: Many users report that their Roberts Gordon systems run for years with minimal issues. The robust construction stands up to demanding environments.

Energy Savings: Facility managers often mention noticeable reductions in heating costs after switching to Roberts Gordon heaters.

Customizability: Installers appreciate the flexibility of the CORAYVAC® system. The ability to design custom layouts helps them address unique building shapes.

Maintenance: Some users note that regular cleaning and inspection keep the system running smoothly. The modular design makes servicing easier.

“Our CORAYVAC® system keeps our warehouse comfortable all winter. We saw a 30% drop in our gas bill after installation.”

— Operations Manager, Midwest Distribution Center

I also see a few points of constructive feedback. Some customers mention that the initial setup can be complex, especially for custom systems. I always recommend working with experienced installers to ensure optimal performance.

Overall, I trust Roberts Gordon infrared tube heaters to deliver reliable, efficient heating. The positive reviews from a wide range of industries reinforce my confidence in their products.

When I look at Detroit Radiant, I see a manufacturer with a broad selection of heating solutions. The company offers several series of infrared tube heaters, each designed for specific environments and applications. I often recommend the HL3 Series for large industrial spaces. This model features high-efficiency burners and heavy-duty construction. For commercial garages or workshops, I turn to the DR Series. It provides reliable performance in smaller areas. The MP Series stands out for its versatility. I can use it in both commercial and light industrial settings. Detroit Radiant also produces outdoor-rated models, such as the LS Series, which I find ideal for patios or loading docks.

Here is a quick overview of their main product lines:

Series | Best For | Key Features |

|---|---|---|

HL3 | Large industrial spaces | High efficiency, robust build |

DR | Garages, workshops | Compact, reliable |

MP | Mixed-use spaces | Versatile, easy installation |

LS | Outdoor applications | Weather-resistant, CSA certified |

I appreciate that Detroit Radiant offers both straight and U-tube configurations. This flexibility allows me to match the heater layout to the building’s shape and heating needs.

Detroit Radiant integrates advanced technology into its infrared tube heaters. I notice that their burners use a unique design to maximize radiant output while minimizing fuel consumption. The reflectors feature high-polish aluminum, which directs more energy downward. This design improves comfort and reduces wasted heat. Many models include two-stage operation. I can adjust the heat output based on demand, which saves energy during mild weather. The company also uses corrosion-resistant materials. This extends the lifespan of the heaters, especially in harsh environments.

I value the diagnostic controls built into many Detroit Radiant models. These controls help me troubleshoot issues quickly. The sealed combustion system draws air from outside the building. This feature improves safety and keeps indoor air clean.

In my experience, Detroit Radiant tube heaters deliver consistent and efficient heating. The HL3 Series provides strong radiant coverage in warehouses and factories. I have seen these heaters maintain comfortable temperatures even in spaces with high ceilings. The DR Series works well in smaller shops. It heats up quickly and distributes warmth evenly. Outdoor models like the LS Series withstand rain and snow. I trust them to perform reliably in exposed locations.

I often measure the effectiveness of infrared tube heaters by how well they reduce energy costs. Detroit Radiant models consistently lower utility bills for my clients. The heaters operate quietly and require minimal maintenance. I find that their long service life adds value over time.

Tip: For best results, I always size and position the heaters according to the manufacturer’s guidelines. This ensures optimal performance and comfort.

When I evaluate Detroit Radiant tube heaters, I always consider both the initial investment and the long-term value. Detroit Radiant positions its products in the mid-range of the market, making them accessible for many commercial and industrial buyers. I have seen entry-level models start at around $900. More advanced or high-output units can reach $2,500 or more, especially when you add custom features or outdoor weatherproofing.

Installation costs can vary. In my experience, a straightforward installation in a standard garage or workshop might add $500 to $1,200 to the total price. Larger industrial projects with multiple units or complex venting can push installation costs higher. I always recommend budgeting for professional installation to ensure safety and optimal performance.

Here is a quick reference table for Detroit Radiant pricing:

Model Series | Typical Price Range | Installation Estimate | Notable Features |

|---|---|---|---|

DR Series | $900–$1,400 | $500–$1,000 | Compact, reliable |

HL3 Series | $1,200–$2,500 | $800–$1,500 | High efficiency, robust build |

LS Series | $1,300–$2,700 | $1,000–$1,800 | Outdoor rated, weatherproof |

Tip: I always advise clients to factor in the total cost of ownership. Detroit Radiant heaters often deliver energy savings that offset the initial investment over time.

I find that Detroit Radiant offers good value, especially for buyers who want a balance of performance, durability, and price. The company’s warranty coverage and reputation for reliability add peace of mind.

I have spoken with many facility managers and installers who use Detroit Radiant tube heaters. Most share positive feedback about the brand’s reliability and performance. Users often mention that the heaters provide steady, comfortable warmth, even in large or drafty spaces. I hear frequent praise for the HL3 Series, which many describe as a workhorse for industrial environments.

Here are some common themes I notice in customer reviews:

Durability: Many users report that their Detroit Radiant heaters run for years with minimal maintenance. The robust construction stands up to daily use.

Energy Savings: Facility managers often see a noticeable drop in heating bills after switching to Detroit Radiant models.

Quiet Operation: I hear from shop owners who appreciate the low noise level, which helps maintain a comfortable work environment.

Easy Installation: Installers like the straightforward setup and clear instructions.

“Our HL3 heaters keep our warehouse warm all winter. We have saved hundreds on our energy bills since the upgrade.”

— Maintenance Supervisor, Midwest Distribution Center

Some users mention the importance of regular cleaning, especially in dusty environments. I always remind clients to follow the manufacturer’s maintenance guidelines to ensure peak performance.

Overall, I trust Detroit Radiant tube heaters to deliver reliable, efficient heating. The positive feedback from a wide range of industries reinforces my confidence in recommending these products for both new installations and retrofit projects.

When I look at Space-Ray, I see a brand that offers a broad selection of heating solutions for many environments. I often recommend their low-intensity and high-intensity models for warehouses, manufacturing plants, and agricultural buildings. The LTU Series stands out for its versatility. I use it in both commercial and industrial spaces. The LTS Series works well in smaller workshops and garages. For outdoor or semi-exposed areas, I turn to the SRP Series, which handles wind and moisture with ease.

Space-Ray also provides specialized models for poultry and livestock barns. These heaters maintain consistent temperatures, which helps improve animal comfort and productivity. I appreciate that Space-Ray designs both straight and U-tube configurations. This flexibility lets me match the heater to the building’s layout and heating needs.

Here is a quick overview of their main product lines:

Series | Best For | Key Features |

|---|---|---|

LTU | Large industrial spaces | High output, robust design |

LTS | Small shops, garages | Compact, easy installation |

SRP | Outdoor, semi-exposed | Weather-resistant, durable |

Poultry/Livestock | Agricultural barns | Uniform heat, CSA certified |

Space-Ray integrates advanced technology into its infrared tube heaters. I notice that their burners use a unique design to maximize radiant output and minimize fuel consumption. The reflectors feature high-polish aluminum, which directs more energy downward. This design improves comfort and reduces wasted heat. Many models include two-stage operation. I can adjust the heat output based on demand, which saves energy during mild weather.

I value the diagnostic controls built into many Space-Ray models. These controls help me troubleshoot issues quickly. The sealed combustion system draws air from outside the building. This feature improves safety and keeps indoor air clean. Space-Ray also uses corrosion-resistant materials, which extend the lifespan of the heaters in harsh environments.

In my experience, Space-Ray infrared tube heaters deliver steady and efficient heating. The LTU Series provides strong radiant coverage in warehouses and factories. I have seen these heaters maintain comfortable temperatures even in spaces with high ceilings. The LTS Series works well in smaller shops. It heats up quickly and distributes warmth evenly. Outdoor models like the SRP Series withstand rain and wind. I trust them to perform reliably in exposed locations.

I often measure the effectiveness of infrared tube heaters by how well they reduce energy costs. Space-Ray models consistently lower utility bills for my clients. The heaters operate quietly and require minimal maintenance. Their long service life adds value over time.

Tip: For best results, I always size and position the heaters according to the manufacturer’s guidelines. This ensures optimal performance and comfort.

When I evaluate Space-Ray infrared tube heaters, I always consider both the upfront investment and the long-term value. Space-Ray positions its products in the mid-range of the market. I find that this makes them accessible for many commercial and industrial buyers. Entry-level models, such as the LTS Series, often start around $900. More advanced or high-output units, like the LTU or SRP Series, can reach $2,500 or more, especially when you add custom features or weatherproofing.

Installation costs vary based on the complexity of the project. In my experience, a straightforward installation in a standard garage or workshop might add $500 to $1,200 to the total price. Larger industrial projects with multiple units or complex venting can push installation costs higher. I always recommend budgeting for professional installation to ensure safety and optimal performance.

Here is a quick reference table for Space-Ray pricing:

Model Series | Typical Price Range | Installation Estimate | Notable Features |

|---|---|---|---|

LTS Series | $900–$1,400 | $500–$1,000 | Compact, easy installation |

LTU Series | $1,200–$2,500 | $800–$1,500 | High output, robust design |

SRP Series | $1,300–$2,700 | $1,000–$1,800 | Outdoor rated, weatherproof |

Tip: I always advise clients to factor in the total cost of ownership. Space-Ray heaters often deliver energy savings that offset the initial investment over time.

I find that Space-Ray offers good value, especially for buyers who want a balance of performance, durability, and price. The company’s warranty coverage and reputation for reliability add peace of mind.

I have spoken with many facility managers and installers who use Space-Ray tube heaters. Most share positive feedback about the brand’s reliability and performance. Users often mention that the heaters provide steady, comfortable warmth, even in large or drafty spaces. I hear frequent praise for the LTU Series, which many describe as a workhorse for industrial environments.

Here are some common themes I notice in customer reviews:

Durability: Many users report that their Space-Ray heaters run for years with minimal maintenance. The robust construction stands up to daily use.

Energy Savings: Facility managers often see a noticeable drop in heating bills after switching to Space-Ray models.

Quiet Operation: I hear from shop owners who appreciate the low noise level, which helps maintain a comfortable work environment.

Easy Installation: Installers like the straightforward setup and clear instructions.

“Our LTU heaters keep our warehouse warm all winter. We have saved hundreds on our energy bills since the upgrade.”

— Maintenance Supervisor, Midwest Distribution Center

Some users mention the importance of regular cleaning, especially in dusty environments. I always remind clients to follow the manufacturer’s maintenance guidelines to ensure peak performance.

Overall, I trust Space-Ray tube heaters to deliver reliable, efficient heating. The positive feedback from a wide range of industries reinforces my confidence in recommending these products for both new installations and retrofit projects.

When I work with Modine, I see a brand that has built its reputation on reliability and versatility. Modine offers a wide range of infrared heaters designed for both commercial and industrial environments. I often recommend Modine units for spaces like warehouses, garages, and workshops. Their heaters use robust construction and straightforward controls, which makes them easy to install and maintain. I find that Modine’s focus on durability appeals to facility managers who want long-lasting solutions. These heaters perform well in areas where consistent, even heat is essential. I have seen Modine models used in both new construction and retrofit projects, which shows their adaptability.

Schwank stands out to me for its commitment to energy efficiency and innovation. I have installed Schwank infrared heaters in many commercial and hospitality settings. Their product line includes both gas and electric models, which gives me flexibility when designing heating systems for different applications. Schwank’s heaters use advanced reflector technology to maximize radiant output and minimize energy waste. I appreciate their sleek designs, which blend well with modern architecture. Schwank heaters excel in environments where aesthetics matter as much as performance. Restaurants, patios, and showrooms benefit from the comfortable warmth and quiet operation these units provide. I trust Schwank when I need a balance of efficiency, style, and reliability.

Bromic has earned my respect as a pioneer in the infrared heaters market, with over 45 years of experience. I often choose Bromic for outdoor commercial and residential spaces that demand both performance and visual appeal. Their heaters come in both gas and electric models, which allows me to match the right technology to each project. Bromic uses premium materials and modern, minimalist designs that enhance the look of any space. I have installed Bromic units in upscale restaurants, hotel patios, and luxury homes. These heaters create a comfortable outdoor ambiance, even in windy conditions, because they warm objects and people directly rather than the air.

Here is a quick comparison of Bromic and similar brands:

Brand | Unique Features | Best-Use Scenarios | Price Range | Heating Technology | Customer Feedback Highlights |

|---|---|---|---|---|---|

Bromic | Gas & electric models; premium materials; modern design | Outdoor commercial & residential; freestanding or mounted | $674–$4,000+ | Infrared heat (gas & electric) | Praised for energy efficiency, ease of use, and aesthetics |

I receive positive feedback from clients who value Bromic’s energy efficiency and ease of use. Many mention the heaters’ ability to create a cozy, inviting atmosphere outdoors. I recommend Bromic when style, durability, and performance are top priorities.

Tip: When selecting infrared heaters for outdoor use, always consider wind resistance and mounting options to ensure optimal comfort.

When I work with Infratech, I see a brand that specializes in electric infrared heaters for both residential and commercial spaces. Infratech focuses on sleek, architectural designs that blend seamlessly into modern environments. I often recommend their heaters for luxury patios, outdoor dining areas, and upscale residential decks. The company uses quartz element technology, which delivers fast, even heat without visible light. This feature creates a comfortable atmosphere without glare.

Infratech offers a wide range of mounting options. I can install their heaters flush with the ceiling, surface-mounted, or even recessed for a clean look. Their controls integrate with smart home systems, which appeals to clients who want advanced automation. I appreciate the corrosion-resistant materials. These heaters perform well in coastal or humid environments.

Here is a quick table summarizing Infratech’s strengths:

Feature | Benefit |

|---|---|

Quartz element | Fast, even heat; no visible light |

Architectural design | Blends with modern décor |

Smart controls | Integrates with home automation |

Multiple mounting | Flexible installation options |

I trust Infratech when aesthetics and performance matter equally. Their infrared heaters create inviting spaces for both homes and businesses.

Dr. Infrared stands out to me as a leader in portable, user-friendly infrared heaters for homes and small offices. I often choose Dr. Infrared when clients need supplemental heating in bedrooms, living rooms, or workshops. Their heaters use a combination of quartz and PTC (Positive Temperature Coefficient) elements. This hybrid approach provides efficient, consistent warmth.

I find Dr. Infrared models easy to use. Most units feature digital thermostats, remote controls, and safety features like tip-over protection and overheat shutoff. The compact design allows for easy movement from room to room. I have noticed that these heaters operate quietly, which makes them ideal for bedrooms or study areas.

Tip: Dr. Infrared heaters work best as zone heaters. I use them to target specific rooms, which helps reduce overall energy costs.

I recommend Dr. Infrared for anyone seeking affordable, reliable infrared heaters for personal spaces.

EdenPURE has built a reputation for safe, efficient infrared heaters designed for residential use. I often suggest EdenPURE models for families who want a portable heater with advanced safety features. Their heaters use copper heating chambers, which provide gentle, even warmth without drying out the air.

EdenPURE units come with air purification options. I find this feature valuable for clients with allergies or respiratory concerns. The heaters include child and pet safety locks, making them a good choice for homes with young children or pets. I appreciate the simple controls and easy maintenance.

Here are some scenarios where I recommend EdenPURE infrared heaters:

Supplemental heating in living rooms or bedrooms

Homes with children or pets

Spaces where air quality is a concern

EdenPURE combines comfort, safety, and air quality in a single package. I trust their infrared heaters for reliable home heating.

When I consider affordable and accessible heating solutions for homes and small offices, Duraflame stands out as a brand that consistently delivers value and convenience. I have worked with many clients who want supplemental heat without the hassle of complex installation or high energy bills. Duraflame infrared heaters meet these needs with a focus on portability, user-friendly controls, and safety.

Duraflame specializes in electric heaters that use infrared quartz technology. This approach allows the heater to warm people and objects directly, rather than just heating the air. I find this method both efficient and comfortable, especially in living rooms, bedrooms, and home offices. The gentle heat produced by these units helps maintain natural humidity levels, which prevents the air from becoming too dry during winter.

Here are some features I often highlight when recommending Duraflame:

Portability: Most models come with caster wheels and compact designs. I can easily move them from room to room as needed.

Safety: Duraflame includes tip-over protection, overheat shutoff, and cool-touch exteriors. These features give me peace of mind, especially in homes with children or pets.

Aesthetic Appeal: Many Duraflame heaters feature realistic 3D flame effects and wood cabinet finishes. These units add a cozy ambiance to any space, blending well with traditional or modern décor.

Simple Controls: I appreciate the digital thermostats, remote controls, and programmable timers. These options make it easy to set and maintain a comfortable temperature.

Tip: I always advise clients to use Duraflame infrared heaters as zone heaters. By targeting specific rooms, you can reduce your central heating usage and save on energy costs.

Duraflame offers a range of models, from basic units to more decorative options that mimic fireplaces. I have seen these heaters used effectively in apartments, dorm rooms, and even small retail spaces. The combination of affordability and ease of use makes Duraflame a popular choice for renters and homeowners alike.

I also value the brand’s commitment to customer support. Duraflame provides clear instructions and responsive service, which helps users get the most out of their heaters. While these units may not heat large industrial spaces, they excel in personal and supplemental heating roles.

When I compare the performance of leading infrared tube heaters, I focus on heat output, coverage area, and consistency. Each space heater model delivers radiant energy differently, depending on its design and intended application. I have seen that Space-Ray infrared tube heaters do not assign fixed coverage areas. Instead, I select the right heater based on building heat loss calculations. Factors such as geographic location, building materials, and how the space is used all influence the final choice. In my experience, coverage can range from 500 square feet in a small workshop to over 10,000 square feet in a large warehouse.

Space-Ray uses aluminized steel emitter tubes that undergo a calorization process. This process increases emissivity to about 0.80–0.83 and improves corrosion resistance. As a result, these infrared tube heaters achieve radiant efficiencies around 65.2%. Thermal efficiency varies by model, from 75% to 83%, while combustion efficiency approaches 99.9%. This tailored approach allows me to match the heat output and coverage to the specific needs of each space.

Liberty Electric Products offers gas tube infrared heaters with thermal efficiencies up to 93%. Their models range from 30,000 to 200,000 BTU/hr, making them suitable for both low and high ceiling spaces. I often use their two-stage infrared tube heaters for large industrial areas because the self-regulating burner modulation provides high radiant output and energy savings. Single-stage models work well in smaller spaces with lower ceilings.

Superior Radiant Products stands out with its unique 10-sided, deep-dish reflector design. This feature reflects nearly all infrared energy downward, minimizing heat loss and boosting fuel efficiency. Their patented jet stream burner technology ensures uniform heat distribution along the tube, which reduces hot spots and thermal breakdown. I find that these design elements deliver more effective heat to the occupied zone, optimizing coverage based on installation specifics.

In my projects, I always prioritize models that offer uniform heating and high efficiency. The right infrared tube heater can eliminate cold spots, reduce drafts, and maintain comfort even in challenging environments. I have seen that the best models adapt to the unique requirements of each space, whether it is a small garage or a massive industrial facility.

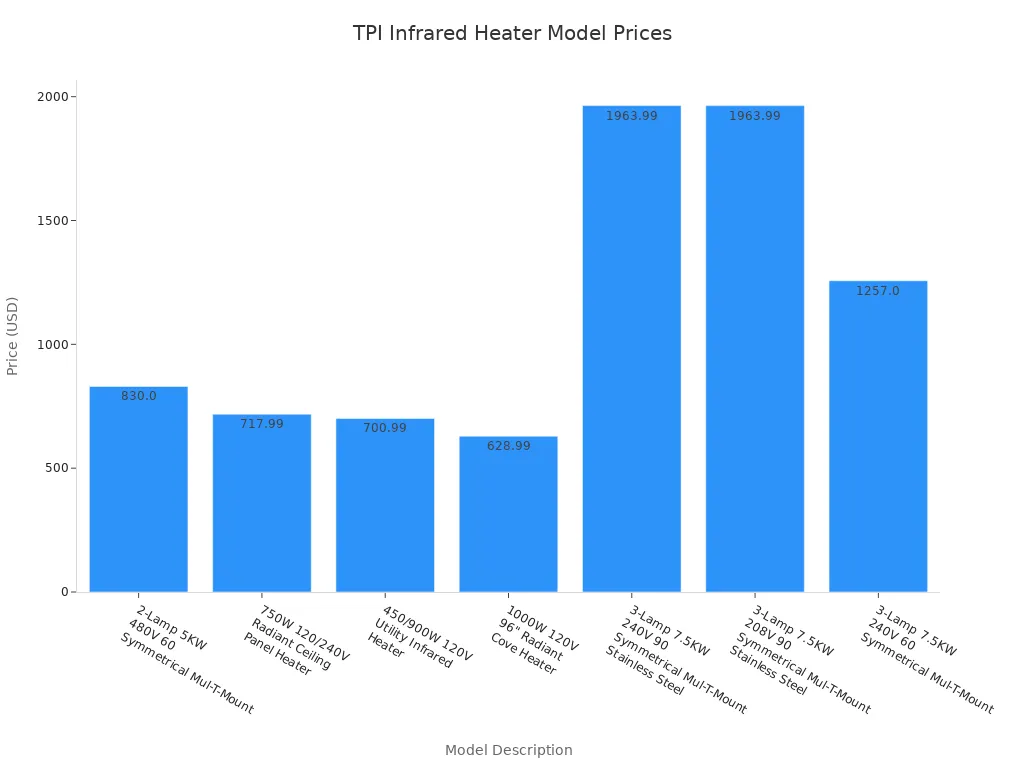

Price plays a significant role when I recommend an infrared tube heater for any space. I always compare the cost of different models, considering both the initial investment and long-term operating expenses. Industrial-grade heaters, such as those from TPI, range from about $629 to nearly $2,000. These prices reflect the commercial-grade specifications and durability required for demanding environments.

Here is a quick comparison of TPI infrared tube heater models:

Brand | Model Description | Price (USD) |

|---|---|---|

TPI | 2-Lamp 5KW 480V 60 Symmetrical Mul-T-Mount Infrared Heater | $830.00 |

TPI | 750W 120/240V Radiant Ceiling Panel Heater | $717.99 |

TPI | 450/900W 120V Utility Infrared Heater | $700.99 |

TPI | 1000W 120V 96" Radiant Cove Heater | $628.99 |

TPI | 3-Lamp 7.5KW 240V 90 Symmetrical Mul-T-Mount Infrared Heater w/ Stainless Steel Housing | $1,963.99 |

TPI | 3-Lamp 7.5KW 208V 90 Symmetrical Mul-T-Mount Infrared Heater w/ Stainless Steel Housing | $1,963.99 |

TPI | 3-Lamp 7.5KW 240V 60 Symmetrical Mul-T-Mount Infrared Heater | $1,257.00 |

I notice that Roberts-Gordon infrared radiant tube heaters command higher prices due to their advanced technology and industrial-grade design. In contrast, Dr. Infrared Heater offers more affordable portable models that still provide effective heating for smaller spaces. This price difference reflects the intended use and sophistication of each space heater model.

When I advise clients, I always stress the importance of considering total cost of ownership. High-efficiency models may cost more upfront, but they often deliver energy savings and reduced maintenance over time. I find that investing in a quality infrared tube heater pays off in both comfort and long-term savings.

The features offered by top infrared tube heaters have a direct impact on user experience, safety, and efficiency. I always look for models that combine advanced technology with practical benefits. Here is a summary of the most common features and their impact:

Feature | Description | Impact on User Experience |

|---|---|---|

Heating Element | Made from tungsten or specialty alloys, coiled to produce radiant energy. | Provides efficient and reliable heat generation. |

Reflective Surface | Positioned behind the element to reflect infrared radiation towards the target area. | Maximizes heat output and directs warmth effectively. |

Protective Shield | Safety barrier preventing contact with hot elements. | Enhances safety by reducing burn and fire risks. |

Quartz/Conductive Tube | Houses the heating element, made from high thermal conductivity materials like quartz. | Intensifies and focuses infrared output, improving durability and heat transfer efficiency. |

Energy Efficiency | High conversion efficiency minimizes wasted energy. | Lowers operating costs and supports environmental sustainability. |

Immediate Heat Output | Infrared heaters provide near-instant warmth without warm-up time. | Improves comfort and productivity by delivering quick heat. |

Uniform Heating | Infrared heat is absorbed directly by objects, providing consistent warmth. | Eliminates cold spots and drafts, ideal for large or open spaces. |

Reduced Airborne Contaminants | No reliance on air movement reduces dust and allergens circulation. | Supports healthier indoor air quality. |

Low Maintenance | Fewer moving parts and corrosion-resistant materials. | Reduces upkeep efforts and costs. |

Control Systems | Advanced thermostatic or programmable controls. | Allows precise temperature management and energy savings. |

Safety Features | Overheat protection, tip-over shutoff, and protective shielding. | Ensures user safety and regulatory compliance. |

Certifications | Compliance with UL, ETL, CE standards. | Guarantees safety and efficiency standards are met, important for regulated environments. |

I have worked with models like the DAYTON gas infrared tube heater, which uses a fan to force hot gas along the tube. This design enables a larger coverage area compared to other gas ceiling heaters. The heater can operate with inside or outside air for combustion and can be installed vented or unvented. I find this versatility valuable for large spaces such as factories and warehouses. Safety features like CSA Blue Star Certification, mounting chains, and gas shutoff ensure compliance with safety standards. The heater operates at 480 °F, using aluminum radiant tube and reflector materials to support efficient heat distribution and safety in commercial or industrial environments.

When I select a space heater, I always prioritize features that enhance efficiency, safety, and ease of use. Advanced control systems, high-quality materials, and robust safety certifications make a significant difference in daily operation. I recommend choosing infrared tube heaters that match the specific needs of your space and provide the best combination of performance, price, and features.

When I help clients select the right infrared tube heater, I always match the model to the specific environment and heating challenge. Each type of infrared heater excels in different scenarios. I rely on both manufacturer recommendations and real-world user feedback to guide my choices. The table below summarizes the best use cases for each major infrared heater type:

Infrared Heater Model Type | Best Use Cases |

|---|---|

Tube Heaters | Industrial drying, manufacturing processes, commercial spaces needing focused and efficient heat delivery |

Quartz Heaters | Medical and healthcare settings, animal incubation, space heating, industrial drying, food and chemical processing, glass manufacturing |

Ceramic Heaters | Agricultural and veterinary applications, industrial drying |

Electric Infrared Heaters | Residential and office heating for energy-efficient, low-cost comfort |

Gas-based Infrared Heaters | Large-scale industrial or outdoor heating where high capacity is needed |

Far Infrared Heaters | Saunas, yoga studios, allergy-sensitive environments due to gentle, non-drying heat |

I have seen tube heaters perform exceptionally well in large industrial settings. They deliver focused, efficient heat that supports manufacturing lines and drying processes. When I work with commercial spaces like warehouses or distribution centers, I often recommend tube heaters for their ability to provide even warmth across wide areas.

Quartz heaters offer versatility. I use them in medical facilities, animal care, and food processing plants. Their rapid response and precise control make them ideal for environments where temperature consistency matters. I also rely on quartz heaters for glass manufacturing, where uniform heating is critical.

Ceramic heaters shine in agricultural and veterinary settings. I have installed them in barns and animal enclosures to provide gentle, consistent warmth. Their durability and efficiency make them a staple in industrial drying applications as well.

For residential and office spaces, I prefer electric infrared heaters. They offer energy-efficient comfort and easy installation. I often recommend these models for supplemental heating in homes, apartments, and small offices.

Gas-based infrared heaters stand out in large-scale industrial or outdoor environments. I use them for heating expansive warehouses, sports arenas, and outdoor patios. Their high capacity ensures reliable performance even in challenging conditions.

Far infrared heaters create a unique comfort experience. I have installed them in saunas, yoga studios, and spaces where gentle, non-drying heat is essential. They also work well in environments sensitive to allergens, as they do not circulate dust or dry out the air.

Tip: Always assess the specific needs of your space before choosing a heater. The right model can improve comfort, efficiency, and safety for your application.

By matching the heater type to the use case, I ensure optimal performance and long-term satisfaction for every project.

When I select an infrared space heater for a small space, I focus on safety, efficiency, and proper placement. I always start with a heat load calculation. This ensures the space heater matches the insulation level and the desired temperature rise. Oversizing or undersizing the heater leads to inefficiency and discomfort. I check the product documentation for minimum mounting heights and BTU/hr capacity. Mounting the heater at the correct height prevents hot spots and maximizes the radiant footprint.

I always maintain proper clearance from combustibles. This step is critical for safety in any indoor environment. I recommend using accessories such as thermostats, cutoff valves, and vent caps to enhance both safety and efficiency. Ventilation plays a key role. Vented heaters reduce heat loss, while unvented models require increased airflow, which can raise fuel consumption.

Here is my checklist for choosing an infrared space heater for small spaces:

Calculate the correct heater size based on insulation and temperature needs.

Maintain safe clearance distances from combustibles.

Place the heater to ensure even heat distribution and avoid cold spots.

Provide adequate ventilation to support combustion and prevent gas buildup.

Schedule regular maintenance to keep the heater efficient.

Use the correct gas type and pressure for optimal operation.

Hire a qualified professional for installation to meet safety standards.

I often place the heater with the burner end near doors or cold walls. This targets areas with the greatest heat loss. Positioning the heater to face a concrete floor helps the thermal mass absorb and re-radiate heat. I choose shorter heaters and mount them as high as possible. This approach maximizes efficiency and extends equipment life.

For small workshops, garages, or home offices, I recommend portable space heaters with built-in safety features. These models offer flexibility and easy relocation. Many portable infrared heaters come with tip-over protection and overheat shutoff, which adds peace of mind in tight indoor spaces.

Tip: Always check local codes and manufacturer guidelines before installing any space heater in a small space.

Heating large areas such as warehouses, gymnasiums, or distribution centers requires a strategic approach. I always begin by sizing and laying out the infrared space heater system to ensure even heat distribution. Radiant heat reduces convection losses, which allows me to maintain comfort at lower air temperatures. This approach improves energy efficiency and lowers operating costs.

I prefer perimeter mounting of heaters in large spaces. This method reduces heat loss by about 15%. I use multiple heaters rather than a single large unit. This strategy addresses airflow and eliminates cold spots. Coverage near cold walls and overhead doors is essential to prevent heat loss and maintain comfort.

Here is a table of recommended heater series for large areas:

Heater Series | Description | Stage Type | Suitability for Large Areas |

|---|---|---|---|

HL3 Series | Premium quality tube heater | Two Stage | Highly recommended |

DX3L Series | Premium single stage tube heater | Single Stage | Highly recommended |

DET3 Series | Economical two stage tube heater | Two Stage | Suitable |

DES3 Series | Economical single stage tube heater | Single Stage | Suitable |

I always select a heater model based on the specific needs of the space. For example, the HL3 Series and DX3L Series deliver excellent efficiency and coverage. These models work well in large commercial or industrial environments. I use DET3 and DES3 Series when budget is a concern, but I still want reliable performance.

I recommend using a combination of portable and fixed infrared heaters in large spaces. Portable models help target temporary work zones or areas with fluctuating occupancy. Fixed tube heaters provide consistent background warmth.

Note: Always consult a heating professional to design the optimal layout for your large space. Proper planning ensures maximum comfort and efficiency.

Industrial environments demand robust, energy-efficient, and reliable heating solutions. I always look for infrared space heater models with advanced features and durable construction. Two-stage operation, patented technology, and fewer on/off cycles contribute to documented fuel savings and enhanced comfort.

Here is a table of top heater models for industrial use:

Model Series | Key Features | Industrial Suitability Reasons |

|---|---|---|

HL3 Series | Two-stage, patented tech, fewer cycles, fuel savings, enhanced comfort | Energy efficient, durable, widely used in industrial settings, reliable long-term operation |

HLV Series | Two-stage, multiple burner, engineered vacuum system | Designed for challenging industrial layouts, robust vacuum operation |

REV Series | Premier plus, two-stage, multi-configurable, high infrared factor | High performance, adaptable to various layouts, enhanced radiant emission |

MP3 Series | Fully modulating, BACnet/Modbus/Zigbee compatible | Advanced energy efficiency, control integration for industrial automation |

DX3L Series | Single stage, high-quality materials, stainless steel burner | Durable and long-lasting for industrial use |

DET3 Series | Economical, two-stage, fewer cycles, enhanced comfort | Cost-effective with industrial-grade performance |

DES3 Series | Economical, single stage, stainless steel burner | Streamlined for economy without sacrificing industrial performance |

-SB & -SS Series | Stainless steel construction, suitable for wet, contaminated, or outdoor applications | Exceptional durability and corrosion resistance for harsh industrial environments |

I always prioritize models that comply with safety standards and use durable materials. Stainless steel construction and corrosion resistance are essential for harsh or wet environments. I select heaters that offer quiet operation and compatibility with advanced control systems. This ensures integration with industrial automation and building management systems.

For industrial spaces such as airplane hangars, manufacturing plants, or recycling facilities, I recommend the HL3, HLV, and REV Series. These models deliver high performance and long-term reliability. The MP3 Series offers full modulation and advanced control integration, which is ideal for facilities with complex heating needs.

Portable infrared space heaters also play a role in industrial settings. I use them for temporary work zones, equipment maintenance, or emergency heating. Their flexibility and ease of deployment make them valuable tools in dynamic industrial environments.

Tip: Always schedule regular maintenance and safety checks for all industrial space heaters. This practice ensures efficiency, safety, and compliance with regulations.

Selecting the right infrared tube heater for outdoor spaces requires careful planning. I always start by assessing the size and layout of the area. Outdoor environments present unique challenges because wind and cold air can quickly reduce the effectiveness of any space heater. I make sure to properly size the heater for the intended coverage. Oversizing wastes energy and increases maintenance, while undersizing leaves guests or workers uncomfortable. I focus on the actual area where people gather, such as patios, restaurant terraces, or event venues.

I recommend mounting the heater above or around seating areas. This approach ensures that the radiant energy reaches people directly, warming objects and floors rather than just the air. I pay close attention to wind exposure. In windy locations, I increase the wattage or add more heaters to maintain comfort. I also place heaters near points where cold air enters, such as overhead doors or open sides, to counteract drafts.

Here are the main factors I consider when choosing a space heater for outdoor use:

Mount the heater above seating or gathering areas for maximum comfort.

Evaluate wind exposure and increase capacity if the space is open or breezy.

Select the right heater type. Quartz tube element heaters, like those from Infratech, offer safety and require less clearance than gas open flame models.

Check for safety features. I look for models with no open flames and flexible mounting options.

Consider control systems. Options range from simple switches and timers to advanced smart home integration for convenience and energy savings.

Choose durable, corrosion-resistant finishes. I prefer heaters that blend with outdoor décor and withstand harsh weather.

Review brand reputation and product reliability. I trust brands with proven track records and long-rated element life.

I always match the heater’s output to the insulation quality of the space. Well-insulated outdoor areas, such as covered patios with windbreaks, need less heating power. Open spaces require higher capacity or multiple units. I find that quartz tube heaters provide efficient, targeted warmth and allow for lower ambient temperatures while maintaining comfort.

Here is a quick comparison table of key considerations for outdoor infrared tube heaters:

Factor | Why It Matters | My Recommendation |

|---|---|---|

Sizing & Coverage | Ensures efficient heating and comfort | Calculate area and match heater output |

Placement | Maximizes radiant effect on people/objects | Mount above or near seating zones |

Wind Exposure | Wind can dissipate heat quickly | Add capacity or shield from wind |

Heater Type | Affects safety and installation flexibility | Use quartz tube for safety and clearance |

Controls | Impacts convenience and energy management | Choose smart or programmable controls |

Durability & Finish | Outdoor spaces face weather and corrosion | Select corrosion-resistant models |

Aesthetics | Heaters should blend with the environment | Pick color and design to match décor |

Tip: I always test the heater’s coverage in the actual outdoor space before finalizing installation. This step helps me adjust placement and capacity for real-world conditions.

When I design heating for outdoor spaces, I prioritize comfort, safety, and energy efficiency. I select space heaters that deliver reliable performance and withstand the elements. By considering these factors, I ensure that every outdoor area remains warm and inviting, even on chilly days.

After comparing each infrared heater, I see that the best choice depends on your unique needs. I always match the heater to the space, application, and budget. Every infrared heater offers different features, so I look for the right fit. I recommend using this quick checklist:

Identify your space and application.

Set your budget for the heater.

Review energy efficiency and safety features.

Compare each infrared heater’s performance.

Choose the heater that meets your goals.

I encourage you to share your infrared heater experiences or ask questions below. I want to help you find the perfect heater for your project.

I find that infrared tube heaters deliver heat directly to objects and people. This method reduces energy waste and provides faster, more even warmth. I see lower operating costs and improved comfort in most applications.

I always measure the length, width, and height of the area. I check insulation quality and note how often doors open. I use manufacturer sizing charts or consult a heating expert to match the heater’s output to my space.

Yes, I trust infrared tube heaters with proper installation and regular maintenance. I always look for models with safety certifications like CSA or UL. I follow manufacturer guidelines and keep clearances from combustibles to ensure safe operation.

I recommend hiring a licensed professional for installation. I know that proper setup ensures safety, efficiency, and compliance with local codes. Incorrect installation can lead to performance issues or safety hazards.

I perform basic maintenance like cleaning reflectors and checking for dust buildup every few months. I schedule annual inspections by a professional. Regular care keeps my heater running efficiently and extends its lifespan.

I have seen top efficiency from brands like Yinfrared, Reznor, and Superior Radiant Products. These brands use advanced reflectors and burner technology. I always compare energy ratings before making a decision.