Author: Site Editor Publish Time: 2025-08-08 Origin: Site

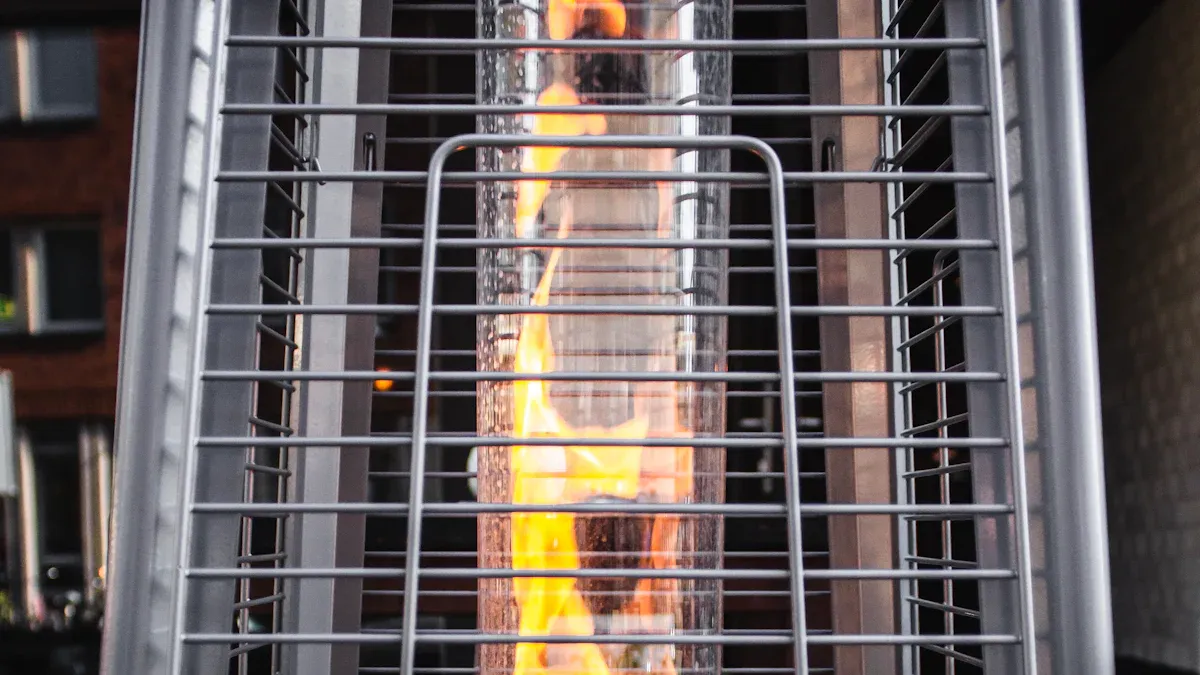

Quartz heater elements stand out because they provide warmth quickly, offer an energy-efficient heating solution, and deliver targeted infrared heat. I often see both pros and cons when using a quartz heater:

Advantages: fast heat-up time, energy efficient operation, and simple controls make these heaters user-friendly.

Disadvantages: limited coverage, air dryness, and a shorter lifespan than other types.

I trust quartz heaters for their rapid response. For advanced performance, YINFRARED’s Twin tube Fast Medium Wave Infrared Lamp leads the way in industrial quartz heater technology.

Quartz heater elements heat up very fast, providing almost instant warmth through efficient infrared radiation.

They deliver targeted, energy-efficient heat that warms objects directly, reducing wasted energy in unused spaces.

Quartz heaters operate quietly and have a compact, portable design, making them ideal for noise-sensitive and small areas.

These heaters work best for spot or zone heating but are less effective for warming large or drafty rooms evenly.

Quartz tubes are fragile and require careful handling and regular cleaning to maintain performance and extend lifespan.

Safety is crucial; always choose certified heaters with features like tip-over shut-off and overheat protection.

Quartz heaters excel in industrial uses such as drying, curing, and thermoforming due to their rapid response and precise control.

Proper installation, maintenance, and matching the heater to your space and needs ensure safe, efficient, and long-lasting operation.

When I use a quartz heating element, I rely on a simple but powerful scientific principle: resistance heating. Inside each quartz tube, a high-resistance wire—often made from nickel-chromium or tungsten—heats up as electric current passes through it. This process, known as Joule heating, transforms electrical energy directly into heat. The quartz tube then emits this energy as infrared radiation, which warms objects and surfaces efficiently without needing to heat the surrounding air.

I find that this direct transfer of heat makes quartz tube heaters ideal for targeted applications, especially where I need fast, efficient warmth.

Here’s a quick overview of how these elements work:

Aspect | Explanation |

|---|---|

Heating Principle | Electric current passes through a high-resistance wire inside a quartz tube, generating heat. |

Heat Transfer | The heat moves to the quartz tube walls and radiates as infrared energy. |

Quartz Material | Quartz glass resists high temperatures and ensures efficient heat transfer. |

Construction Elements | Key parts include the quartz tube, heating wire, and insulation. |

Application | This design supports reliable, versatile heating in industrial and scientific settings. |

One of the main reasons I choose quartz tube heating is the fast heat-up time. The structure of quartz tube heaters allows them to reach operating temperatures in just seconds. The quartz material transmits infrared radiation almost instantly, so I get immediate warmth without waiting for the air to heat up. This rapid response is especially valuable in industrial processes where precise, zone-controlled heating is critical.

Medium wave technology sets quartz heating elements apart from other electric heaters. These elements emit infrared radiation in the 1.4 to 2.4 micrometer range, which matches the absorption characteristics of many materials. I notice several advantages when I use medium wave quartz tube heating:

Radiant efficiency reaches about 60%, so energy use stays low.

The heat targets specific areas, minimizing energy waste.

The elements heat up and cool down quickly, giving me precise temperature control.

They operate quietly, which I appreciate in noise-sensitive environments.

Medium wave quartz tube heating works well for drying, curing, and heating processes that require uniform, gentle warmth.

YINFRARED’s Twin tube Fast Medium Wave Infrared Lamp demonstrates how advanced design can boost performance. The twin tube design uses two parallel quartz tubes, each housing a heating element. This configuration increases the surface area and overall heat output. I see several benefits from this approach:

More infrared radiation reaches the target, improving efficiency.

The lamp heats up rapidly, which supports high-speed industrial processes.

Heat distribution stays uniform, so I avoid hotspots and ensure consistent results.

The durable construction extends the lifespan of the heating element.

In my experience, the combination of medium wave technology and twin tube design in quartz heater elements delivers unmatched speed, efficiency, and control for demanding applications.

When I evaluate quartz heater elements, I always weigh the advantages and disadvantages to determine if they fit my needs. The pros and cons vary depending on whether I use them in a home office, workshop, or industrial setting. I rely on quartz heaters for their rapid heating and targeted warmth, but I also consider their limitations.

Here’s a quick table summarizing the most common pros and cons I encounter:

Pros (Advantages) | Cons (Disadvantages) |

|---|---|

Fast heating time: Quartz elements heat up in seconds, providing almost immediate warmth. | Limited heating range: Effective for spot heating but not for warming entire rooms evenly. |

Targeted and energy-efficient zonal heating: Infrared radiation heats objects directly, reducing wasted energy on unused space. | Hot surface safety risks: Quartz tubes and grills can reach high temperatures, posing burn hazards. |

Silent operation: Most models lack fans, resulting in quiet or silent use, suitable for noise-sensitive environments. | Poor air circulation: Unlike fan heaters, quartz heaters do not circulate warm air, potentially causing cold spots. |

Compact and portable design: Lightweight and often slim or wall-mountable, easy to move and install. | Not ideal for overnight use: Lack of thermostats or timers can lead to overheating or safety risks during sleep. |

Nearly 100% electrical energy conversion to radiant heat, efficient for short bursts in small or moderate zones. | Reduced efficiency in large or drafty spaces: Performance drops significantly in bigger or poorly insulated areas. |

Suitable for garages, workshops, bathrooms, home offices, and outdoor enclosures with wind protection. | Maintenance challenges: Fragile quartz tubes prone to cracking, dust buildup reducing efficiency, and element degradation over time. |

Safety features recommended: Tip-over shut-off, overheat protection, cool-touch casing, and certifications (UL/ETL). | Safety concerns: Tip-over risks can cause fires or burns if placed near flammable materials or fabrics. |

I always notice how quickly a quartz heater element reaches operating temperature. The fast response time means I get warmth almost instantly, which is essential in industrial processes and spot heating at home. I find this rapid heating especially useful in environments where I need immediate comfort or precise thermal control.

When I ask myself, "how energy-efficient are quartz infrared heaters?" I look at their ability to convert nearly all electrical energy into radiant heat. This efficiency makes them a cost-effective choice for targeted heating. I use quartz heaters in spaces where I want to minimize energy waste and maximize output. Their energy-efficient operation helps me save on utility bills, especially during short bursts of use in small or moderate zones.

Quartz tube heating excels at delivering focused warmth. I use quartz heating elements to direct heat exactly where I need it, whether I am drying paint in a workshop or warming a specific area in my home. This targeted approach increases efficiency and reduces wasted energy. I appreciate the ability to control heat zones with precision.

I prefer quartz heaters in noise-sensitive areas because they operate silently. Most models lack fans, so I never have to worry about disruptive sounds. This quiet operation makes quartz heater elements ideal for bedrooms, offices, and libraries.

Quartz heaters require minimal upkeep compared to other types. I clean the quartz tubes occasionally to maintain efficiency, but I rarely need to perform complex repairs. The simple design and lack of moving parts contribute to their long-lasting performance. However, I remain aware that dust buildup can reduce efficiency over time.

Safety remains a priority for me when using quartz heaters. The hot surfaces of quartz tubes and grills can pose burn hazards, especially in busy environments. I always look for models with tip-over shut-off, overheat protection, and cool-touch casings. These features help reduce risks and make the heaters safer for residential and industrial use.

One of the main disadvantages I encounter is the fragility of quartz tubes. The glass construction makes them prone to cracking if handled roughly or exposed to sudden impacts. I take care during installation and maintenance to avoid damage. This fragility can lead to higher maintenance needs compared to more robust heater types.

Quartz heaters excel at spot heating but struggle to warm large or drafty spaces evenly. I use them for zonal heating in workshops, garages, and small rooms. In bigger areas, I notice cold spots and reduced efficiency. This limitation means I must carefully plan heater placement to achieve optimal results.

Quartz heating technology can dry out the air in enclosed spaces. I sometimes experience discomfort due to reduced humidity, especially during extended use. I mitigate this drawback by using humidifiers or limiting heater operation time.

Tip: I always assess the size and insulation of my space before choosing a quartz heater element. This helps me avoid common drawbacks of quartz heating technology and ensures I get the most efficient and cost-effective solution.

I often compare quartz heaters to other types to understand their long-lasting performance and maintenance needs. Here’s a table that highlights key metrics:

Metric | PTC Heat | Nichrome Coil | Quartz Infrared |

|---|---|---|---|

Self-Regulating | Yes | No | No |

Startup Time | Fast | Medium | Fast |

Safety Cutoff Needed | No | Yes | Yes |

Repair Complexity | Low | Medium | Medium |

Quartz infrared heaters require safety cutoffs and have medium repair complexity. I find that they are not self-regulating, so I pay close attention to safety features and regular maintenance. Despite these disadvantages, I value their fast startup and efficient heating.

Note: I always choose quartz heater elements with certifications and built-in safety features to ensure reliable, long-lasting operation.

When I compare a quartz heater to a ceramic heater, I notice several important differences in performance and safety. Quartz heaters deliver instant, focused heat using infrared radiation. I find this direct approach very efficient for spot heating. The heat warms objects and people quickly, not the air, so I get immediate comfort.

Ceramic heaters, on the other hand, use convection. They heat up a ceramic plate, and a fan blows warm air into the room. This method spreads heat more evenly but takes longer to feel warm. I often use ceramic heaters in offices or bedrooms because they have cooler surfaces and built-in safety features like tip-over protection and overheat sensors. These features make them safer for homes with children or pets.

Here’s a quick comparison:

Feature | Quartz Heater | Ceramic Heater |

|---|---|---|

Heating Method | Infrared Radiation | Convection (Fan-Assisted) |

Heat-Up Time | Instant | Quick, but slower |

Energy Efficiency | High (focused) | Moderate (continuous) |

Surface Temperature | Very Hot | Cooler (fan cooled) |

Safety | Needs careful placement | Safer, cool-touch |

Best Use | Spot/zone heating | Small rooms, bedrooms |

I always choose a quartz heater when I need fast, targeted warmth. For general room heating and safety, I prefer ceramic heaters.

When I use an oil-filled heater, I notice it works very differently from a quartz heater. Oil-filled heaters rely on convection. They heat oil inside metal fins, and the warmth spreads slowly through the air. This process takes time, so I do not feel immediate heat. However, once the oil heats up, it retains warmth for a long period, even after I turn the heater off.

Quartz heaters provide instant heat. I find them much more efficient for quick comfort. However, the surface of a quartz heater gets extremely hot, which can be a safety concern in homes with children or pets. Oil-filled heaters have cooler exteriors, making them safer for family spaces.

I use oil-filled heaters when I want steady, gentle heat in a well-insulated room. For fast, focused heating, I always reach for a quartz heater.

Comparing a quartz heater to a metal coil heater, I see clear differences in durability, heat delivery, and cost. Metal coil heaters, sometimes called traditional infrared metal sheath heaters, use a metal element inside a protective tube. They transfer heat mainly by air conduction, which means the warmth spreads through the air rather than by direct radiation.

Metal coil heaters excel in industrial settings where I need durability and resistance to mechanical damage. They handle dry burning and oxidation better than quartz tubes. I often use them in lower temperature ovens, environmental chambers, and places where uniform heat conduction is critical. They are also less expensive and use mature technology.

Quartz heaters, in contrast, provide higher surface temperatures and more focused radiant heat. I choose them for applications that demand instant, targeted warmth. However, I must handle them carefully because the quartz tubes are fragile.

In my experience, metal coil heaters outperform quartz heaters in harsh environments where durability and uniform heating matter most. For rapid, efficient spot heating, quartz heaters remain my top choice.

When I compare quartz heaters to carbon infrared heaters, I notice several important differences in how they deliver heat, their efficiency, and the comfort they provide. Both use infrared technology, but the experience and applications vary greatly.

I often choose a quartz heater when I need fast, intense heat. Quartz heaters use a tungsten filament inside a quartz tube, which heats up quickly and emits shortwave infrared radiation. This type of heat feels immediate and powerful. I see quartz heaters used in industrial settings, large commercial spaces, and situations where I need to warm an area from a distance. The high element temperature and bright glow make them ideal for rapid, focused heating.

On the other hand, carbon infrared heaters use a carbon fiber element. They emit mid to far infrared radiation, which feels softer and more natural on the skin. The surface temperature stays lower, and the glow is gentle rather than harsh. I find carbon heaters perfect for indoor comfort, especially in living rooms, bedrooms, or wellness spaces. The heat feels cozy and is experienced as warmer, even though the output is technically lower than quartz.

Here are some key differences I have observed:

Quartz heaters provide instant, high-intensity warmth and are best for large or open areas.

Carbon infrared heaters offer a softer, more natural-feeling heat that is ideal for close-range comfort.

Quartz elements reach higher temperatures and deliver brighter, more direct heat.

Carbon heaters operate at lower temperatures, which makes them safer for prolonged use in homes.

I notice that carbon heaters retain heat longer, which can lead to energy savings over time.

Quartz heaters often include metal reflectors to focus the heat, making them effective for spot or zone heating.

To make the comparison clearer, I have summarized the main features in the table below:

Feature | Carbon Infrared Heater | Quartz (Halogen) Infrared Heater |

|---|---|---|

Element Material | Carbon fiber with halogen gas | Halogen gas with tungsten filament inside quartz tube |

Infrared Wavelength | Mid/Far infrared | Shortwave infrared |

Surface/Element Temperature | Lower element temperature, softer radiant heat | High element temperature, high output |

Heat Intensity | Softer, more natural-feeling heat, gentle glow | High-intensity, direct, and very effective heat |

Heating Experience | Heats skin efficiently, feels warmer at close range | Brighter heat, suitable for heating from longer distances |

Service Life | Longer service life | Shorter service life |

Ideal Use | Indoor comfort, close proximity heating | Industrial, large-scale, or distant heating |

Energy Efficiency | Energy-saving due to longer heat retention | Instant, powerful heating but less energy efficient |

Heat Dispersion | Wide, gentle dispersion | Focused or wide, effective from height |

Tip: I always match the heater type to the space and comfort level I want. For quick, powerful heat in a workshop or warehouse, I rely on quartz. For relaxing warmth in my living room, I prefer carbon infrared.

By understanding these differences, I can select the right heater for each environment, ensuring both comfort and efficiency.

I often see quartz heater elements excel in drying and curing processes across industries like automotive, pharmaceuticals, and paper manufacturing. These heaters generate infrared radiation that penetrates materials, raising temperatures quickly and evenly. When I use quartz infrared heaters for drying, I notice a significant increase in production rates and energy savings. The heaters can boost wet paper temperature by about 10℃, improving dehydration and dryness. Their ability to convert over 90% of electrical energy into infrared heat makes them one of the best applications for efficiency. I appreciate how the quartz tube’s chemical inertness prevents contamination, which is critical in clean or high-purity environments.

Quartz heaters reach operating temperature in seconds.

They improve drying uniformity and reduce product damage.

I achieve precise temperature control, which is essential for sensitive materials.

In thermoforming, I rely on quartz heater elements for their rapid, controlled infrared heat. These heaters provide instant-on performance, often reaching full output in about three seconds. I can customize power density and tube arrangement to match specific process needs. This flexibility supports automated production lines and custom tooling. The result is faster cycle times, lower energy consumption, and improved product quality. I value the durability and precise thermal control quartz heaters offer, which reduces maintenance costs and boosts operational efficiency.

Quartz heaters play a vital role in printing and textile industries. I use them for rapid drying of inks, varnishes, and coatings. Their ability to deliver even, targeted heat eliminates cold spots and speeds up production. In textiles, I benefit from zone control and fast heating, which are necessary for efficient processing. The clean operation of quartz heaters, with no harmful emissions, makes them safe for indoor use. Their instant on/off capability fits perfectly with high-speed production environments.

When I work in food processing, I choose quartz heater elements for their even heat distribution and energy efficiency. These heaters convert nearly all input energy into heat, reducing consumption and operating costs. I find them durable and low-maintenance, with no risk of toxic emissions. The fast heating speed improves cooking efficiency, especially for high-temperature foods like pizzas and pastries. Quartz heaters provide warmth directly to food and surfaces, ensuring thorough and safe cooking.

YINFRARED’s Twin tube Fast Medium Wave Infrared Lamp stands out in these industrial settings. Its rapid response, customizable design, and high energy absorption make it ideal for demanding applications such as drying, curing, and thermoforming.

I often recommend quartz heater elements for spot heating in both commercial and residential spaces. These heaters emit infrared radiation that directly warms objects and people, making them perfect for targeted comfort. I find them especially useful in workshops, garages, and outdoor areas where wind or drafts would reduce the effectiveness of other heaters. Proper installation and maintenance ensure safe, efficient operation. I always check for secure mounting and test thermal protectors regularly.

Consideration | Explanation | Recommended Action |

|---|---|---|

Avoid localized overheating | Buildup on quartz sheath reduces heater life | Clean deposits, adjust watt density |

Prevent thermal shock | Sudden temperature changes can crack tubes | Shut off power, inspect element |

Secure installation | Prevent floating or movement | Use guards, maintain proper liquid levels |

For small spaces, I prefer small quartz room heaters. These units provide targeted, energy-efficient zonal heating by focusing infrared energy on specific areas. I notice that quartz heaters reach up to 96% radiant efficiency, converting most energy into usable heat. Their quick response and quiet operation make them a top choice for bedrooms, offices, and other confined areas. I also appreciate their clean, non-polluting performance, which suits high hygiene requirements.

Quartz heater elements operate almost silently, producing less than 45 dB of noise. I often use them in noise-sensitive environments like libraries, bedrooms, and offices. Their fanless design ensures ultra-quiet performance, earning them the nickname "silent heaters." This feature makes them an excellent space heater option for anyone who values a peaceful atmosphere.

In my experience, the ideal use cases for quartz heater elements include industrial drying, curing, thermoforming, printing, food processing, spot heating, and providing warmth in small or noise-sensitive spaces. Their rapid response, energy efficiency, and targeted heat delivery make them a smart choice for anyone seeking the best applications for efficiency.

When I select a quartz heater, I always start by evaluating the specific requirements of my application. I consider several factors to ensure I choose the right heater for the job:

Temperature Range and Lifespan: I check the temperature range needed for my process. Running a heater below its maximum capacity extends its lifespan and improves reliability.

Energy Efficiency: I look for heaters that are slightly overdesigned for my needs. This approach increases durability and reduces the risk of premature failure.

Air Circulation and Uniformity: I assess whether my materials or workspace need additional airflow. Proper air movement prevents overheating and ensures even heating, especially for temperature-sensitive items.

Environmental Conditions: I examine the environment for dust, debris, or obstructions. Quartz heaters require a clear line of sight to transfer heat effectively. In dirty environments, I prefer heaters with internal reflectors because they need less maintenance.

Ramp-Up and Cool-Down Times: I determine if my process benefits from rapid heating. For fast-moving production lines, I rely on quartz tube heaters for their quick response. For stable, slower processes, I may consider alternatives.

Tip: I always match the heater’s features to my workspace and process needs. This careful assessment helps me avoid costly mistakes and ensures optimal performance.

Safety remains my top priority when working with quartz heater elements. I make sure every heater I use meets recognized safety standards and certifications. Here are the key points I follow:

I only use heaters that comply with UL, ANSI, and NFPA standards. These certifications guarantee safe operation and reduce fire and electrical shock risks.

For installation, I follow the National Electrical Code (NFPA 70) to ensure proper wiring, grounding, and overcurrent protection.

I look for heaters with built-in safety features, such as grounded construction and thermal protectors.

I check for UL listing, CSA certification, or CE marking, especially for industrial and high-voltage applications. These marks indicate compliance with North American and European safety requirements.

I always verify that the heater’s wattage and voltage match my electrical system to prevent overloads.

Certification | Description | Why I Check It |

|---|---|---|

UL/CSA/CE | Safety and performance standards for North America and Europe | Ensures reliability and legal compliance |

NFPA 70 | National Electrical Code for installation | Reduces fire and shock hazards |

Built-in Safety | Grounded, thermal protection | Prevents overheating and electrical faults |

Note: I never compromise on safety. Certified heaters provide peace of mind, warranty protection, and consistent performance.

To maximize the lifespan of my quartz heater elements, I follow a strict maintenance routine. Here’s how I keep my heaters running efficiently:

I perform routine inspections to catch wear, dust buildup, or early signs of failure.

I clean the heating elements regularly to remove dust and scale, which can block heat transfer.

I check and secure all electrical connections to prevent energy loss and safety hazards.

I use thermostats or programmable controllers to keep temperatures within recommended limits and avoid overheating.

I make sure airflow is not blocked in convection systems, which helps prevent internal temperature spikes.

I inspect for visible damage, such as cracks, corrosion, or discoloration, and replace damaged parts promptly.

I follow manufacturer guidelines for wiring and power to avoid overloading the system.

I schedule preventive maintenance and replace worn components before they fail.

Regular cleaning and inspection help me avoid unexpected downtime and costly repairs. I always use compatible parts and follow installation best practices to ensure safe, long-lasting operation.

By carefully assessing my needs, prioritizing safety, and maintaining my equipment, I ensure my quartz heater elements deliver reliable, efficient heat for every application.

When I install a quartz heater element, I always treat the process as critical to both safety and performance. Proper installation not only extends the life of the heater but also ensures I get the most efficient and reliable heat output. Over the years, I have developed a checklist that helps me avoid common mistakes and maximize the benefits of quartz heating technology.

Preparation and Placement

I start by selecting a location that allows for optimal heat distribution. I avoid placing the heater near flammable materials or in areas with poor ventilation. Good airflow prevents overheating and helps maintain a stable temperature. I always check that the mounting surface can support the heater’s weight and withstand high temperatures.

Electrical Connections

I make sure all electrical connections are tight and secure. Loose wiring can cause arcing or energy loss, which leads to safety hazards. I ground every heater and use surge protection with the correct size fuses or breakers. This step protects both the equipment and the facility from electrical faults.

Protecting Heater Elements

I handle quartz tubes with care to prevent contamination. Even a small amount of oil or dust can trap heat and cause the element to burn out prematurely. I use gloves during installation and clean the tubes before powering up. For leads and terminations, I use proper insulation and, if necessary, add cold sections to shield them from excessive heat.

Sizing and Controls

I always match the heater’s wattage and size to the application. Oversized or undersized heaters can cause cycling, hot spots, or uneven heating. I install advanced controllers, such as PID or solid-state relays, to maintain precise temperature control and prevent excessive cycling. Proper sensor placement ensures accurate feedback and safe operation.

Safety Features and Compliance

I only use quartz heaters that comply with national safety standards and include temperature control switches. I follow the manufacturer’s instructions closely, as improper installation can lead to serious risks. For industrial applications, I look for products with certifications like CE, LVD, ISO, and RoHS. YINFRARED’s Twin tube Fast Medium Wave Infrared Lamp, for example, offers these certifications and customizable options to fit specific installation needs.

Tip: I always ensure good indoor ventilation and avoid prolonged direct exposure to infrared heat, especially for sensitive groups like infants or pregnant women.

Installation Step | Key Action | Why It Matters |

|---|---|---|

Placement | Choose safe, ventilated location | Prevents overheating/fire |

Electrical Connections | Tighten, ground, and protect wiring | Ensures safety and reliability |

Element Handling | Keep tubes clean and contamination-free | Extends heater lifespan |

Controls and Sizing | Use correct wattage and advanced controllers | Maintains efficiency/safety |

Compliance | Follow standards and manufacturer guidelines | Reduces risk, ensures quality |

By following these steps, I achieve a safe, efficient, and long-lasting installation. I always prioritize safety and compliance, knowing that a well-installed quartz heater delivers the best performance for both industrial and commercial applications.

When I evaluate quartz heater elements, I focus on their rapid heat-up, energy efficiency, and targeted warmth. I rely on the table below to summarize the most important factors:

Factor | Description |

|---|---|

Heat-Up Speed | Heats in seconds for instant comfort |

Durability | Prone to thermal shock, needs careful handling |

Maintenance | Simple cleaning keeps performance high |

Suitability | Best for quick, focused heating tasks |

I always match the heater to my needs. For industrial use, I recommend YINFRARED’s Twin tube Fast Medium Wave Infrared Lamp for its advanced performance and reliability.

I notice quartz heater elements reach full temperature in just seconds. The quartz tube transmits infrared energy almost instantly, so I get immediate warmth without waiting for the air to heat up.

I always check for safety features like tip-over shut-off and cool-touch casings. I keep heaters out of reach and never leave them unattended. Proper placement and certified models help me ensure a safe environment.

I clean the quartz tubes regularly to remove dust and debris. I inspect for cracks or discoloration. I follow the manufacturer’s instructions for safe operation and maintenance.

I find quartz heaters work best for spot or zone heating. They do not heat large spaces evenly. For bigger rooms, I use multiple units or consider a different heating solution.

In my experience, quartz heater elements last between 5,000 and 7,000 hours with proper care. I avoid rough handling and keep the tubes clean to extend their service life.

Yes, I notice quartz heaters can reduce humidity in enclosed spaces. I use a humidifier or limit heater use to maintain comfortable air quality.

I assess the size of my space, desired temperature, and safety requirements. I look for certified products with the right wattage and features. For industrial needs, I recommend customizable options like YINFRARED’s Twin tube Fast Medium Wave Infrared Lamp.

I find quartz heaters very efficient for targeted heating. They convert almost all electrical energy into infrared heat, which warms objects directly and reduces wasted energy.