Views: 0 Author: Site Editor Publish Time: 2025-11-04 Origin: Site

In today’s competitive leather manufacturing environment, the coating and finishing processes demand greater precision, faster throughput, lower energy consumption, and improved consistency of quality. One emerging technology that aligns precisely with these requirements is infrared (IR) heating—specifically for the coil-coating, roll-coating, curing, and finishing of leather surfaces. This article examines infrared heating in leather coating, presents selection criteria, explores different categories of infrared systems, and demonstrates how a well-designed IR drying or curing system can deliver measurable gains in productivity, energy efficiency, and finished-leather properties.

The coating of leather typically involves applying a topcoat, pigment, lacquer, or protective film to a substrate—natural or synthetic leather. After application, the coating needs to be dried, cured, and bonded to the substrate under controlled thermal conditions.

Traditional systems use convection (hot air) or conduction (heated rollers). However, these methods often lead to longer residence times, uneven drying, higher energy usage, and larger dryer footprints.

Infrared heating offers a number of advantages in this context:

Direct heat transfer: IR radiation delivers heat directly into the coating-substrate system without relying solely on heated air. It can penetrate surface layers and generate heat from within, accelerating moisture evaporation and film formation.

Reduced drying time and footprint: IR radiation can be applied in a non-contact manner and configured dynamically, reducing dryer length and substrate dwell time.

Higher energy efficiency: Far-infrared or medium-wave IR systems transfer radiation directly into the product, minimizing losses associated with heating large volumes of air or ducting. Energy savings can exceed 50 % compared with steam or hot-air drying systems.

Improved drying uniformity: Because IR radiation can simultaneously heat surface and subsurface layers, the risk of surface overdrying while underlying layers remain wet is reduced.

Given these advantages, integrating infrared heating into leather coating lines offers tangible benefits. However, successful implementation demands careful selection of system parameters and an understanding of the relevant categories of IR heating.

Infrared systems are commonly categorized by wavelength: near-infrared (NIR), medium-wave (MWIR), and far-infrared (FIR). Different wavelengths have different penetration depths and absorption properties for water and polymer coatings.

For leather coating, wavelengths in the range of approximately 2.0 µm to 6.0 µm are particularly effective, as they match absorption peaks of water and leather polymers. Longer wavelengths (medium or far IR) penetrate deeper, effectively heating interior layers of the leather/coating system.

Recommendation: Choose emitter types whose wavelength suits both the coating formulation (thickness, pigmentation, binder chemistry) and substrate (natural or synthetic).

Power density affects how rapidly the coating dries or cures and how uniform the heating is. High power density yields faster curing but risks thermal damage such as discoloration, shrinkage, or scorching. Controlling power and exposure time is critical.

Uniformity is equally important—heater spacing, zoning across width, and real-time power control must be optimized.

Leather coating involves multiple layers: substrate, primer, and topcoat. The IR system must heat through the coating and into the substrate to ensure complete drying and adhesion.

Leather’s porous structure requires heat to penetrate pores and vaporize interior moisture while preventing surface overheating. Matching the IR wavelength and exposure time to the material stack is essential.

Line speed defines the available residence time for drying and curing. High-speed lines require higher power density and optimized emitter placement. One major benefit of IR is shorter dryer length, which saves space and improves throughput.

Infrared heating improves energy efficiency when paired with proper insulation, reflectors, and control systems. Integration with existing coaters and conveyors must ensure consistent timing and prevent heat damage to nearby components.

Leather coatings are heat-sensitive. Excessive surface temperatures can cause blistering, adhesion failure, color change, or substrate shrinkage. Controlled heating ramps and real-time temperature monitoring are essential to prevent these issues.

Infrared emitters can produce intense localized heating. Effective monitoring of emitter output, substrate temperature, and moisture removal ensures safety and consistent results. Automatic interlocks, shielding, and ventilation are also important considerations.

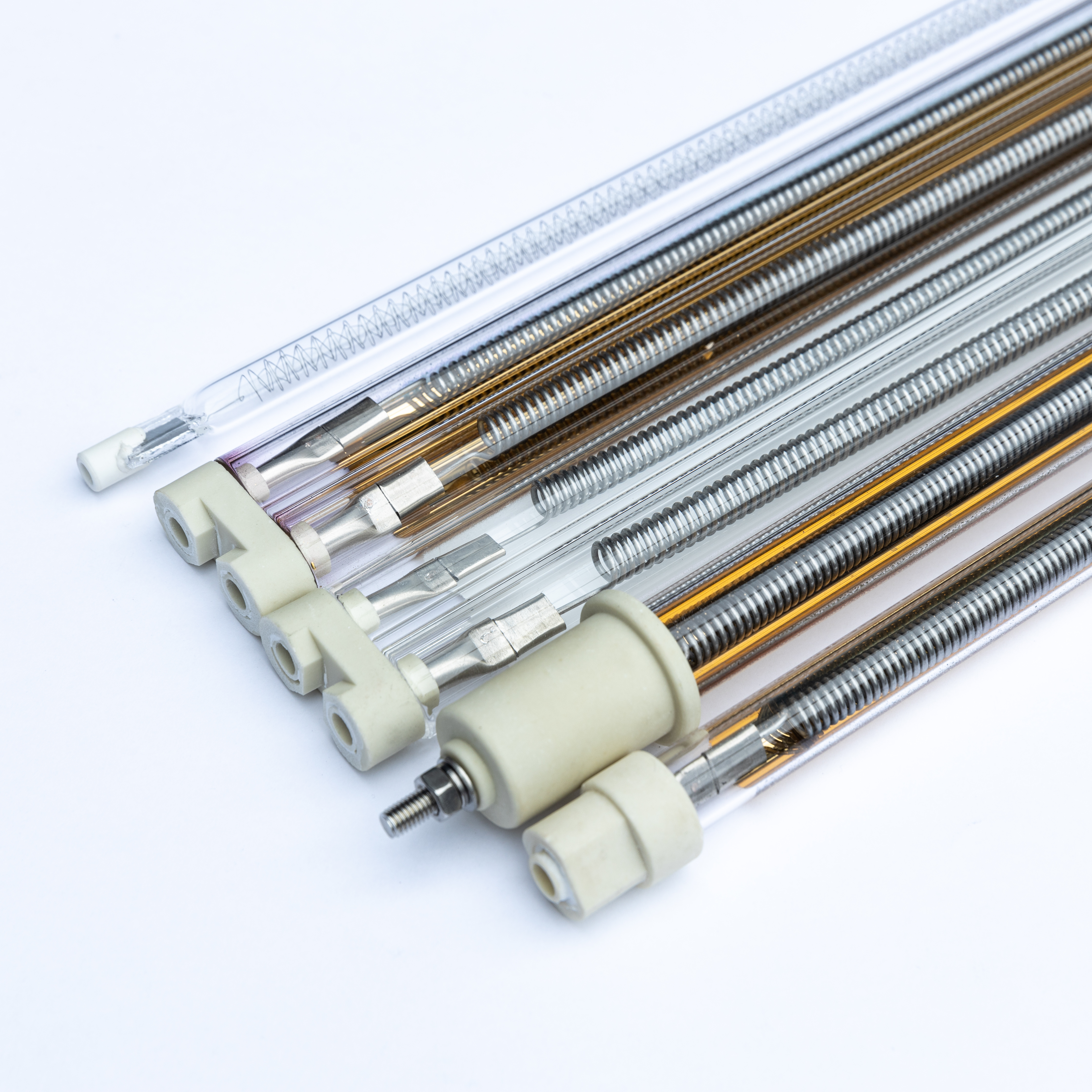

Infrared systems are classified by wavelength, emitter type, and configuration.

Wavelengths below 1.5 µm.

High power density and rapid response.

May cause surface overheating and is rarely ideal for full leather coating.

Suitable for thin topcoat flash-drying applications only.

Wavelengths in the range of 1.5–6 µm.

Excellent absorption by water and polymer coatings.

Provides balanced penetration, uniform heating, and gentle drying.

Most commonly used for leather coating due to its balance of energy efficiency and process control.

Wavelengths above 6 µm.

Primarily surface heating; shallower penetration depth.

Effective for thin coatings or surface curing where deep heat penetration is not required.

Provides smooth surface finishes while minimizing internal substrate stress.

Conveyor-Type Tunnel Dryers: Continuous leather feed through top/bottom emitter zones.

Zoned IR Modules: Emitters grouped in controllable zones for staged heating profiles.

IR + Convection Systems: Combine radiation with airflow for improved vapor removal and stability.

Spot Emitters: Used for localized heating, pre-treatment, or edge finishing.

Natural leather is porous, containing residual moisture even after tanning. Its polymer matrix absorbs IR radiation efficiently within the 2–6 µm range. Coating formulations—lacquers, pigments, or protective films—must be matched to the IR wavelength and heat intensity.

Temperature gradients form within the leather during drying: surface water evaporates first, creating a cooling effect, while internal layers remain warmer. This internal heat aids moisture migration and promotes even drying. However, if the leather is not constrained during drying, shrinkage of up to 20–30 % can occur.

Wavelength and Emitter Selection:

Medium-wave IR emitters are generally the best fit for leather coating, offering efficient heating with minimal substrate stress.

Emitter Power Density and Spacing:

Power density should match the coating thickness and line speed. Emitters must be spaced to provide uniform heating across the entire width.

Temperature Monitoring and Control:

Continuous temperature sensing ensures substrate integrity. Excessive heat can damage surface appearance and physical properties.

Residence Time and Conveyor Design:

Conveyor systems must maintain consistent substrate flatness and speed for even exposure. Pre-heat and post-cooling zones help control temperature transitions.

System Integration and Safety:

Reflective housings improve energy efficiency by directing IR radiation toward the substrate. Safety interlocks and cooling mechanisms protect operators and equipment.

Reduced Dryer Length:

Infrared systems can shorten dryer sections by up to half, allowing faster line speeds or smaller plant layouts.

Improved Adhesion and Finish:

IR heating promotes deeper bonding between coating and substrate, enhancing surface smoothness, gloss, and color uniformity.

Energy Savings:

Infrared dryers consume significantly less energy compared to hot-air systems by eliminating air pre-heating losses.

Higher Throughput:

Faster drying cycles and adjustable power settings allow operators to increase productivity while maintaining coating quality.

Process Flexibility:

IR systems can easily adapt to new coating materials or thicknesses by modifying emitter output or conveyor speed.

Pilot Testing: Conduct trials to determine optimal wavelength, emitter distance, and conveyor speed before full-scale implementation.

Substrate Constraint: Keep the leather flat and tensioned to minimize shrinkage during heating.

Moisture Monitoring: Ensure adequate drying without surface sealing or trapped moisture.

Use of Reflectors and Insulation: Prevent energy loss and ensure uniform heat distribution.

Avoid Overheating: Control surface temperature to prevent discoloration and structural damage.

Maintenance: Keep emitter surfaces clean and replace lamps as per manufacturer specifications.

Safety: Use shields and interlocks to protect operators from direct IR exposure.

Infrared heating provides leather finishers with a powerful tool to enhance coating quality, reduce energy use, and increase production speed. By selecting the right emitter wavelength—typically medium-wave IR—along with proper control systems and substrate handling, manufacturers can achieve superior coating results and sustainable energy performance.

Key Implementation Steps:

Assess existing coating line parameters.

Define energy and quality improvement targets.

Select appropriate emitter wavelength and system layout.

Conduct pilot runs and measure coating adhesion, shrinkage, and uniformity.

Implement control systems for temperature and power modulation.

Establish maintenance routines for consistent performance.

Infrared heating in leather coating delivers measurable improvements in productivity, surface quality, and environmental performance—making it an essential technology for modern leather finishing lines.

By intelligently integrating infrared heating into leather coating processes, manufacturers can meet the dual challenges of efficiency and quality. The technology enables faster drying, uniform finishes, and significant energy savings—hallmarks of an optimized production line.

Huai’an Yinfrared Heating Technology specializes in designing customized IR heating solutions tailored for the leather industry, ensuring each client achieves consistent quality and operational excellence.

Last modified: 2025-11-04