Views: 0 Author: Site Editor Publish Time: 2025-09-15 Origin: Site

Infrared paint curing transforms DIY projects by delivering faster drying, improved finish quality, and substantial energy savings. Traditional paint curing often leads to uneven results and longer waiting times, while infrared technology provides consistent results and rapid curing. Today, infrared paint curing lamps offer accessible solutions for both novice and experienced users.

Upgrading to infrared paint curing can help any DIYer achieve professional-grade outcomes with less effort.

Infrared paint curing speeds up drying times by 50-75%, allowing DIYers to finish projects in hours instead of days.

This technology provides a smoother finish by reducing defects like micro-bubbles and moisture retention.

Infrared curing is energy-efficient, leading to lower utility bills and reduced environmental impact.

The versatility of infrared lamps allows them to work on various surfaces, including metal, wood, and plastic.

Different types of infrared lamps (short, medium, long wave) cater to specific project needs, enhancing user flexibility.

Infrared curing minimizes dust and contaminants during the drying process, resulting in cleaner finishes.

Using infrared technology reduces the need for touch-ups, saving time and effort for DIYers.

Investing in an infrared paint curing lamp can elevate the quality of DIY projects, making them look more professional.

Infrared paint curing uses radiant energy to deliver heat directly to painted surfaces. This process relies on the physics of thermal energy transfer, where infrared radiation moves energy from the lamp to the object without heating the surrounding air. Unlike conventional paint curing, which often uses convection ovens to warm the air and then the object, infrared paint curing targets the surface itself. This direct approach leads to faster and more uniform heating.

Infrared curing ovens use high-intensity radiant heat for faster curing.

They are more energy-efficient compared to conventional methods.

Key applications include paint curing, powder coating, and adhesive setting.

The radiant energy in infrared paint curing improves temperature uniformity and reduces defects. This results in smoother finishes and fewer imperfections. By focusing energy on the painted area, infrared paint curing also minimizes wasted heat, making it an efficient choice for both home and auto projects.

Infrared paint curing lamps come in three main types: short wave, medium wave, and long wave. Each type serves different needs:

Short Wave: Delivers intense heat quickly. Ideal for thick coatings or metal surfaces.

Medium Wave: Provides balanced heating. Suitable for most general paint curing tasks.

Long Wave: Offers gentle, deep penetration. Works well for delicate materials or heat-sensitive surfaces.

DIYers can select the right lamp based on their project requirements. Short wave lamps excel in auto body repairs, while medium and long wave lamps suit furniture or craft projects.

Infrared paint curing stands out for its remarkable speed and efficiency. The technology directly targets surfaces with radiant heat, which enhances the curing process. Conventional methods rely on convection heating, which is slower and less precise. Infrared paint curing promotes uniform heating and reduces energy costs.

Many users report that infrared paint curing can reduce drying times by 50-75%, often curing paint in just minutes instead of hours.

DIYers appreciate the flexibility of infrared paint curing. It adapts to a wide range of surfaces and paint types, making it suitable for both home improvement and auto repairs. The compact size of many infrared paint curing lamps also saves space in workshops.

Advantage | Description |

|---|---|

Blazing Speed | Curing times can be 50-75% faster than convection, often curing in minutes. |

Energy Efficiency | Direct heating leads to less wasted energy, resulting in significant savings. |

Space Savings | IR ovens are shorter than convection tunnels for the same throughput. |

Infrared paint curing offers a modern solution for anyone seeking professional results in less time. Its efficiency, speed, and adaptability make it a top choice for DIYers looking to upgrade their paint curing process.

Infrared paint curing delivers remarkable time savings for DIY enthusiasts. The technology uses focused radiant energy to accelerate the drying process, targeting the painted surface directly. This method eliminates the need for prolonged waiting periods associated with traditional paint curing. DIYers can complete projects in a fraction of the time, allowing for more productivity and less downtime.

Infrared paint curing achieves quick and even drying by minimizing moisture retention and reducing the risk of surface imperfections. Users report that drying times decrease by up to 75%, transforming multi-day projects into tasks that finish within hours. Efficient drying means that hobbyists and professionals alike can move on to the next stage of their work without delay.

Infrared paint curing empowers users to finish home improvement tasks rapidly, making it ideal for those who value speed and efficiency.

Automotive paint drying often requires precision and speed. Infrared paint curing excels in auto repair settings by providing rapid results. The technology ensures that paint curing occurs evenly across metal surfaces, preventing common issues such as bubbling or uneven finishes. Auto body shops and DIY mechanics benefit from reduced turnaround times, allowing vehicles to return to service quickly.

Infrared paint curing lamps deliver consistent heat, which is essential for professional quality drying in automotive applications. The process supports efficient drying, minimizing the risk of defects and ensuring a flawless finish. By adopting infrared paint curing, auto repair professionals achieve superior results while saving valuable time.

Infrared paint curing enhances the quality of paint finishes by promoting smoother surfaces. The direct application of radiant energy reduces the likelihood of micro-bubbles and trapped moisture, which often cause surface irregularities. Studies highlight that the use of infrared reflection materials, such as silica nano/microparticles, can decrease surface temperature by approximately 27 °C. This temperature reduction helps maintain the integrity of the paint during curing.

Key Findings | Description |

|---|---|

Infrared Reflection | Silica nano/microparticles improve infrared radiation reflection in paint. |

Temperature Reduction | Material lowers temperature by about 27 °C, aiding the curing process. |

Quality Preservation | Particles help maintain paint quality, enhancing the final finish. |

Infrared paint curing supports the creation of uniform coatings, resulting in a visually appealing and durable surface. The process ensures that each layer of paint cures evenly, contributing to a professional-grade appearance.

Paint curing with infrared technology significantly reduces the occurrence of defects. Common problems, such as milky haze or uneven surfaces, often stem from trapped moisture or micro-bubbles. Infrared paint curing addresses these issues by applying low-heat energy at an optimal distance, typically 60–75 cm from the surface. Sweeping the lamp across the painted area for several minutes per pass, while maintaining relative humidity below 50%, leads to fewer imperfections.

Milky haze in varnish usually appears within six hours of application.

Micro-bubbles and moisture cause this defect.

Using infrared paint curing lamps at the correct distance and humidity eliminates these problems.

Infrared paint curing creates a controlled environment for drying, which minimizes the need for touch-ups and rework. The result is a flawless finish that meets the standards of both home and automotive projects.

Infrared paint curing stands out for its energy efficiency. Curing represents one of the most energy-intensive steps in painting, especially in automotive and industrial settings. Infrared paint curing systems use focused heat to cure coatings faster and more efficiently than traditional convection ovens. This targeted approach reduces overall power consumption, making it a cost-effective solution for DIYers and professionals.

Infrared paint curing technology consumes less energy than conventional methods.

Focused heat accelerates curing, reducing the time and energy required.

Efficient drying leads to lower utility bills and a smaller environmental footprint.

Switching to infrared paint curing can significantly lower fuel costs. The technology eliminates the need for extensive hot air circulation, which is common in traditional paint curing equipment. By accelerating the curing process, infrared paint curing systems reduce the amount of energy needed to achieve optimal results.

Infrared paint curing systems decrease energy consumption by curing coatings quickly.

Upgrading to efficient curing technologies leads to substantial savings on fuel and electricity.

DIYers and auto shops benefit from reduced operational expenses while maintaining high-quality finishes.

Infrared paint curing offers a sustainable and economical alternative to conventional drying methods. The combination of lower power consumption and reduced fuel costs makes it an attractive choice for anyone seeking efficient drying and professional results.

Infrared paint curing creates a cleaner environment during the drying process. The technology uses radiant energy to heat the painted surface directly. This method reduces air movement in the workspace. Less air movement means fewer dust particles and contaminants settle on the wet paint. DIYers notice that infrared paint curing helps maintain a pristine finish.

Paint curing with infrared lamps limits the risk of airborne debris. The lamps do not rely on fans or forced air. This approach keeps the workspace quiet and clean. Many users report that their projects show fewer imperfections after drying with infrared paint curing.

Tip: Position the infrared lamp at the recommended distance to maximize cleanliness and minimize dust exposure.

Infrared paint curing reduces the need for touch-ups after drying. The focused heat ensures even curing across the entire surface. Uneven drying often leads to blemishes or spots that require extra attention. Infrared paint curing eliminates these issues by providing consistent results.

DIYers save time and effort because the paint curing process produces a smooth, flawless finish. Minimal touch-ups mean that projects reach completion faster. The drying phase becomes more predictable, and users can trust the outcome.

Benefit | Description |

|---|---|

Fewer Imperfections | Consistent curing prevents blemishes |

Time Savings | Less rework needed after drying |

Professional Results | Projects look polished and well-finished |

Infrared paint curing adapts to a wide range of surfaces. The technology works well on metal, wood, plastic, and composite materials. DIYers use infrared paint curing for home furniture, auto body panels, and craft projects. The radiant energy penetrates different materials, ensuring thorough drying and curing.

Paint curing with infrared lamps does not damage delicate surfaces. Users select the appropriate lamp type for each project. Short wave lamps suit metal surfaces, while medium and long wave lamps work for wood and plastic. This flexibility makes infrared paint curing a valuable tool for diverse DIY tasks.

Infrared paint curing supports many types of paint. Users apply the technology to water-based, solvent-based, and powder coatings. The curing process adjusts to the specific requirements of each paint type. Infrared paint curing delivers reliable drying for automotive finishes, home décor paints, and specialty coatings.

Paint curing with infrared lamps ensures that each paint type reaches its optimal hardness and durability. DIYers achieve consistent results regardless of the product used. The drying phase remains efficient and effective for every project.

Note: Always check the manufacturer’s guidelines for recommended curing times and lamp settings for each paint type.

Selecting the right infrared paint curing lamp for DIY projects requires careful consideration of several factors. Experts recommend evaluating portability, power and coverage, safety features, and price range before making a purchase.

DIYers often move equipment between workspaces. A portable infrared paint curing lamp offers flexibility for home garages and auto shops. Lightweight designs and adjustable stands make transportation and setup easier. Compact models suit small projects, while larger units provide coverage for bigger surfaces.

The power rating and coverage area determine how efficiently a lamp can handle paint curing and drying tasks. Higher wattage lamps deliver faster results and support larger projects. Coverage depends on the lamp’s design and reflector quality. Users should match the lamp’s power to their typical project size for optimal performance.

IR Type | Wavelength Range (microns) | Temperature Range | Primary Applications |

|---|---|---|---|

Short Wave IR | 0.76 – 2.0 | Up to 5000°F | High-intensity industrial heating |

Medium Wave IR | 1.4 – 3.0 | Up to 1750°F | Drying, plastics, glass, textiles |

Long Wave IR | Above 3.0 | 100–500°C | Comfort and space heating |

Short wave lamps excel in rapid paint curing for metal surfaces. Medium wave lamps suit general drying tasks, while long wave lamps provide gentle heat for delicate materials.

Safety remains a top priority when using infrared paint curing lamps. Look for models with overheat protection, sturdy construction, and insulated handles. Some lamps include automatic shut-off timers and protective grills to prevent accidental burns. Reliable safety features ensure worry-free operation during curing and drying.

Infrared paint curing lamps vary in price based on power, features, and brand reputation. Entry-level models offer basic functionality for small projects. Premium units provide advanced controls and larger coverage areas. DIYers should balance their budget with the lamp’s capabilities to achieve the best value.

Tip: Always compare lamp specifications and user reviews before investing in a new infrared paint curing lamp.

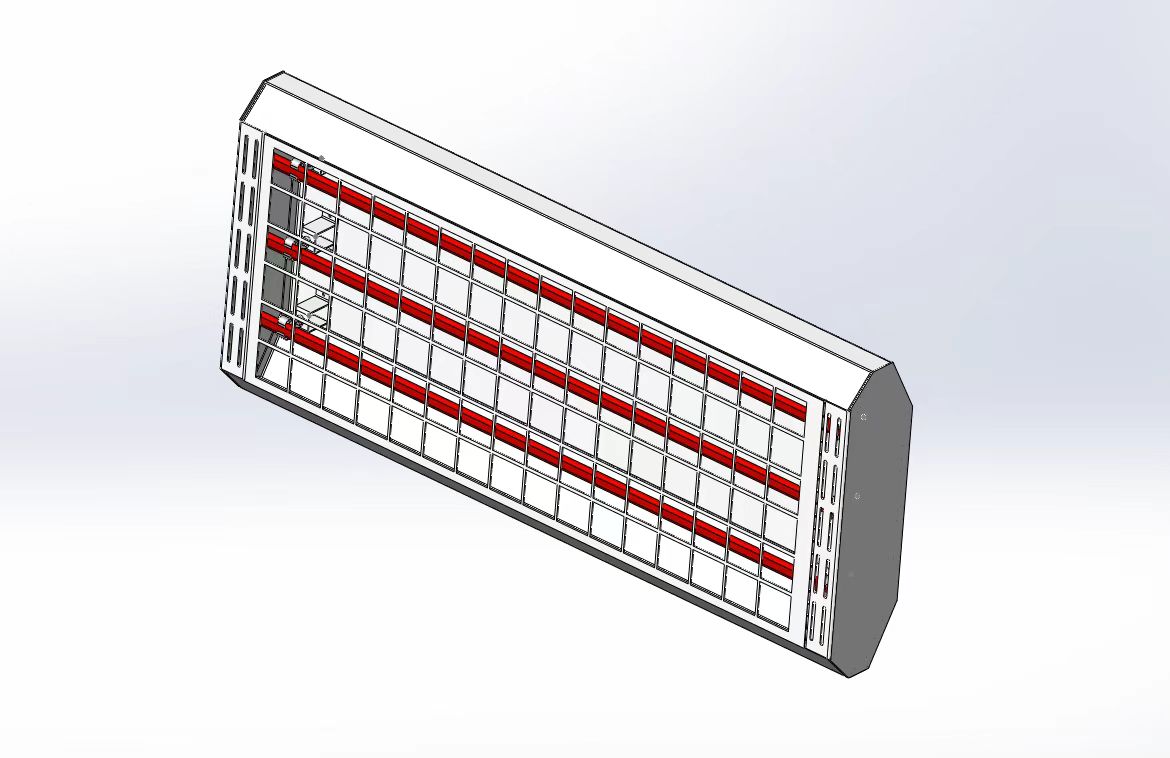

Huai'an Infrared Heating Technology offers a versatile range of infrared paint curing lamps designed for both home and industrial use. The product line includes short wave, medium wave, and long wave lamps, each tailored for specific curing and drying needs. These lamps utilize advanced radiant energy technology, achieving up to 96% energy conversion efficiency. Users can select from Twin Tube Fast Medium Wave Infrared Lamps for quick paint curing or Carbon Infrared Heaters for broader applications. The lamps feature quartz glass construction, CE and TUV certifications, and optional power controls for precise temperature management.

High energy efficiency reduces fuel costs by 20% to 50%.

Multiple wavelength options suit various paint curing and drying tasks.

Certified for safety and quality with CE and TUV marks.

Accessories available for enhanced control and customization.

Durable construction ensures long-term reliability.

Advanced features may increase the initial investment for some users.

Industrial-grade models may require more workspace.

Huai'an Infrared Heating Technology infrared paint curing lamps work best for DIYers seeking professional-grade results and energy savings. These lamps suit home workshops, auto body repairs, and small-scale industrial projects. Users who value performance, versatility, and safety will benefit most from this product line.

The DKKDETOHO 3000W infrared paint curing lamp delivers powerful performance for rapid paint curing and drying. This model features a robust 3000-watt heating element, adjustable stand, and wide coverage area. The lamp supports short wave infrared technology, making it ideal for automotive and metal surface applications. Users can adjust the lamp’s height and angle for targeted curing. Built-in timers and temperature controls help maintain consistent curing conditions.

High wattage enables fast paint curing and drying.

Adjustable stand provides flexibility for different project sizes.

Short wave IR technology ensures deep penetration and uniform results.

Timer and temperature controls support precise application techniques.

Larger size may limit portability for some users.

High power consumption may not suit small-scale projects.

The DKKDETOHO 3000W infrared paint curing lamp suits DIYers and professionals handling auto repairs and large home improvement projects. Users who need rapid drying and consistent curing for metal surfaces will find this lamp effective. Its adjustable features make it a strong choice for those seeking control and efficiency.

Note: For best results, maintain a constant temperature between 320° and 400°F during curing. Position the infrared paint curing lamp about 4 inches from the surface and monitor temperature after 3-5 minutes. Adjust the lamp’s distance as needed to achieve uniform drying.

The VEVOR Infrared Curing Lamp stands out for its robust construction and user-friendly design. This lamp uses advanced short wave technology to deliver rapid and uniform heat directly to painted surfaces. The adjustable stand allows users to position the lamp at various heights, making it suitable for both small and large projects. The digital control panel provides precise temperature and timer settings, which helps users achieve consistent results during paint curing. The lamp features a wide reflector that ensures even distribution of radiant energy, reducing the risk of uneven drying.

Delivers fast and efficient infrared paint curing for a variety of surfaces.

Adjustable stand and wide reflector offer flexibility for different project sizes.

Digital controls allow for accurate temperature and time management.

Durable materials ensure long-term reliability in home and auto workshops.

Easy assembly and intuitive operation make it accessible for beginners.

The lamp’s size may require additional workspace in smaller garages.

Higher wattage can increase energy consumption during extended use.

Some users report that the lamp becomes hot to the touch after prolonged curing sessions.

The VEVOR Infrared Curing Lamp works best for DIYers who need reliable and efficient paint curing for both home improvement and automotive projects. Its versatility makes it ideal for users who frequently switch between different types of surfaces and paint. Those who value precise control over drying times and temperatures will benefit most from this model.

The AMT-3CH Infrared Paint Curing Lamp features a triple-head design, which provides broad coverage for large-scale projects. Each head operates independently, allowing users to target multiple areas simultaneously. The lamp uses medium wave infrared technology, which penetrates deeply into coatings for thorough curing. The adjustable arms and sturdy base offer stability and flexibility during operation. The built-in safety features include overheat protection and a timer function, which help prevent accidental overheating during drying.

Triple-head design covers more surface area, reducing overall drying time.

Independent controls for each lamp head allow for customized curing.

Medium wave technology ensures deep and even paint curing.

Safety features enhance user confidence during extended use.

Sturdy construction withstands frequent repositioning in busy workshops.

The lamp’s larger footprint may not suit compact workspaces.

Assembly can take longer due to the multi-head configuration.

Higher price point compared to single-head models.

The AMT-3CH Infrared Paint Curing Lamp suits professionals and advanced DIYers who handle large or multiple projects at once. Its broad coverage and independent controls make it ideal for auto body shops and users who require efficient, high-volume paint curing. Those who prioritize safety and thorough drying will appreciate this lamp’s advanced features.

The Solary 4KW Infrared Paint Curing Lamp delivers powerful performance with its 4000-watt output. This lamp uses short wave infrared technology to provide intense, focused heat for rapid paint curing. The adjustable stand and swivel head allow users to direct heat precisely where needed. The lamp includes a digital timer and temperature control, which help users manage the curing process with accuracy. The heavy-duty frame and wheels make it easy to move the lamp around large workspaces.

High wattage enables extremely fast drying and curing for thick coatings.

Short wave technology delivers concentrated heat for professional results.

Adjustable stand and swivel head offer maximum flexibility.

Digital controls improve accuracy during paint curing sessions.

Mobile design with wheels enhances portability in large garages or shops.

The lamp’s high power output may not be necessary for small DIY projects.

Larger size requires more storage space when not in use.

Initial investment is higher than entry-level models.

The Solary 4KW Infrared Paint Curing Lamp is best suited for professional auto body shops and experienced DIYers who need rapid, high-capacity paint curing. Its powerful output and advanced controls make it ideal for demanding projects that require quick turnaround and flawless drying. Users who work on large vehicles or industrial equipment will find this lamp especially beneficial.

The S 1000W Handheld Infrared Curing Lamp offers a compact and portable solution for small-scale paint curing and drying tasks. This lamp features a 1000-watt halogen tube that delivers focused infrared energy directly to the painted surface. The handheld design allows users to maneuver the lamp easily, making it ideal for spot repairs and touch-ups. The lamp includes an adjustable timer, which helps users control the curing process with precision. Its lightweight construction and ergonomic handle ensure comfortable use during extended drying sessions. The lamp’s stainless steel cover resists oxidation, and the high-quality halogen tube provides a long service life. Users can set up the lamp quickly, making it suitable for both home garages and mobile repair jobs.

Portable and lightweight design enables easy handling for spot repairs.

Adjustable timer supports precise control over curing and drying times.

Quick setup allows users to start paint curing tasks without delay.

Durable materials, including stainless steel and high-quality halogen tubes, extend the lamp’s lifespan.

Ergonomic handle reduces fatigue during prolonged use.

Lower wattage limits coverage area, making it less suitable for large projects.

Manual operation requires users to hold the lamp during the curing process.

Not ideal for full-panel paint curing or high-volume drying tasks.

The S 1000W Handheld Infrared Curing Lamp works best for DIYers and professionals who need a portable solution for small paint curing and drying jobs. It excels in touch-up work, on-site repairs, and engine drying where precision and mobility matter most. Users who value quick setup and easy maneuverability will benefit from this lamp. It is especially useful for those who perform frequent spot repairs or need a reliable tool for mobile paint curing applications.

Lamp Model | Power | Coverage Area | Timer Range | Portability | Best Use Case | Safety Features | Durability | Price Range |

|---|---|---|---|---|---|---|---|---|

Huai'an Infrared Heating Technology Lamps | Varies | Varies | Optional controls | Medium to High | Home/Auto/Industrial | CE, TUV, Power Controls | High | $$$ |

DKKDETOHO 3000W Infrared Curing Lamp | 3000W | Large | Yes | Medium | Auto/Metal Surfaces | Timer, Temp Controls | High | $$ |

VEVOR Infrared Curing Lamp | 2000W+ | Medium to Large | Yes | Medium | Home/Auto Versatility | Digital Controls, Wide Reflector | High | $$ |

AMT-3CH Infrared Paint Curing Lamp | 3000W+ | Extra Large | Yes | Low | Professional/Large Projects | Overheat Protection, Timer | High | $$$ |

Solary 4KW Infrared Paint Curing Lamp | 4000W | Extra Large | Yes | Medium | Professional/Auto Shops | Digital Controls, Swivel Head | High | $$$$ |

S 1000W Handheld Infrared Curing Lamp | 1000W | Small (Spot) | Yes | High | Touch-Ups/Spot Repairs | Stainless Steel Cover, Halogen Tube | Medium-High | $ |

Tip: Choose a lamp that matches your typical project size and workspace. For quick spot repairs and mobile jobs, a handheld lamp like the S 1000W offers unmatched convenience. For larger surfaces or frequent paint curing, consider a higher wattage model with broader coverage.

Selecting the right lamp depends on the size of the project. Small touch-up jobs require compact, handheld lamps, while larger surfaces benefit from high-wattage models with broad coverage. Users should match the lamp’s power and reflector design to the area they plan to cure. For example, a triple-head lamp suits auto body panels, while a single-head lamp works well for furniture or crafts.

Factor | Description |

|---|---|

Heating Element Materials | Options include quartz, tungsten wire, ceramic, and glass/metal filaments, each with unique properties. |

Enclosure Materials | Materials like stainless steel, aluminum, and iron are important for durability and heat reflection. |

Customization Options | Consider shield material, insulation, voltage, power source, and optional features for specific needs. |

Budget plays a crucial role in the decision-making process. Entry-level lamps offer basic features for occasional use, while premium models provide advanced controls and larger coverage. Users should balance their investment with the frequency and scale of their paint curing projects. Accessories such as adjustable stands and digital timers may increase the initial cost but enhance convenience and results.

Safety features protect users during operation. Lamps with anti-scald designs, smooth edges, and thickened bases reduce the risk of burns and injuries. High-quality halogen tubes and anti-oxidation covers ensure reliable performance and long-term durability. A stable base prevents shakes, which is essential for even curing and user safety.

Safety Feature | Description |

|---|---|

Anti-Scald Design | Prevents overheating and accidental burns, ensuring the lamp remains cool to the touch. |

Smooth Edges | Reduces the risk of hand scratches and injuries during use. |

High-Quality Halogen Tubes | Ensures effective heating while maintaining safety standards. |

Anti-Oxidation Cover | Protects the lamp from wear and tear, enhancing durability. |

Thickened Base | Provides stability to avoid shakes during operation. |

Long Lifespan | Designed for 6000 hours of use, ensuring reliability for frequent applications. |

Tip: Always check for safety certifications and user-friendly features before purchasing a lamp.

Proper setup and positioning maximize the effectiveness of infrared paint curing. Users should select a lamp with precise wavelength control to match the material being cured. High-quality reflectors direct most of the infrared energy to the target, improving efficiency. Versatile mounting options allow for flexible installation and optimal coverage. Consistent power density across the lamp surface ensures even drying without hot or cold spots.

Best Practice | Description |

|---|---|

Precise Wavelength Control | Different materials absorb IR energy best at specific wavelengths. Choose a lamp that fits your needs. |

Great Reflector Design | High-quality reflectors boost efficiency by directing over 95% of IR energy to the target. |

Versatile Mounting Options | Flexible installation allows for optimal coverage and efficient use of space. |

Thermal Management | Effective heat dissipation prevents overheating, enhancing safety and longevity. |

Consistent Power Density | Uniform output across the lamp surface ensures even curing without hot or cold spots. |

Note: Position the lamp at the recommended distance from the surface to avoid overheating and ensure uniform results.

Regular maintenance extends the lifespan of the lamp and ensures safe operation. Users should clean reflectors and covers to maintain heat efficiency. Inspecting power cords and connections prevents electrical hazards. Replacing worn halogen tubes and checking for oxidation on metal parts keeps the lamp performing at its best. A well-maintained lamp delivers consistent paint curing and drying for every project.

Routine checks and cleaning help prevent unexpected breakdowns and maintain optimal curing performance.

Infrared paint curing offers DIYers faster drying, improved finish, and energy savings. The Huai'an Infrared Heating Technology lamp stands out as a top choice for most home and auto users. Many users see better results in curing and paint curing with this advanced technology. They can upgrade their toolkit and experience professional-quality drying on every project.

Try infrared paint curing for your next project and see the difference for yourself!

Infrared paint curing uses radiant energy to dry paint quickly. The lamp emits infrared waves that heat the painted surface directly. This process speeds up drying and improves finish quality.

Most infrared lamps work with water-based, solvent-based, and powder coatings. Users should check manufacturer guidelines for compatibility with specialty paints or finishes.

Manufacturers design infrared paint curing lamps with safety features like overheat protection and insulated handles. Users should follow instructions and keep the workspace ventilated for safe operation.

Infrared curing can reduce drying times by up to 75%. Many users finish projects in minutes instead of hours, making the process much more efficient.

Infrared lamps use energy efficiently. Advanced models convert up to 96% of energy into heat, which lowers power consumption and reduces utility costs.

Infrared paint curing works on metal, wood, plastic, and composite materials. Users select the appropriate lamp type for each surface to achieve optimal results.

Users should clean reflectors and covers regularly. Inspect power cords and connections for damage. Replace worn tubes as needed. Routine maintenance ensures consistent performance and safety.