Views: 0 Author: Site Editor Publish Time: 2025-07-26 Origin: Site

Heidelberg presses support several alternatives to the traditional infrared printing lamp. The most common options include Quartz IR Emitters, UV lamps, LED curing systems, and hot air dryers. Each drying technology offers distinct advantages for printing applications. The table below summarizes key features:

Drying System | Description & Usage | Advantages |

|---|---|---|

Infrared printing | Uses radiant heat for fast drying of water-based and solvent inks. | Low cost, energy efficient, fast start-up, compact, retrofittable. |

UV lamp | Cures inks with broad-spectrum UV light. | Higher production speed, quality control, upgradeable, supports LED UV retrofits. |

LED curing | Employs narrow-wavelength UV for modern, energy-efficient drying. | 50–80% energy savings, long lamp life, low maintenance, safer, no ozone or mercury emission. |

Hot air dryer | Relies on warm air, suitable for basic printing needs. | Low cost, simple operation, low maintenance. |

Huai'an Infrared Heating Technology and YFR lead the market by providing advanced lamp solutions engineered for Heidelberg compatibility. When selecting a drying system, users should consider their Heidelberg model, print requirements, energy efficiency, and total cost of ownership.

Heidelberg presses support several drying options including infrared lamps, UV lamps, LED curing, hot air dryers, and hybrid systems.

Quartz IR emitters provide fast, energy-efficient drying with long lamp life and are ideal for water-based inks and long print runs.

UV lamp systems cure inks instantly, improve print quality, and save energy but may require higher initial investment and special inks.

LED curing offers the best energy savings, long lamp life, and safe operation, making it great for short runs and sensitive materials.

Hot air dryers are simple, low-cost solutions suitable for basic drying needs but work slower than lamp-based systems.

Hybrid drying systems combine infrared and UV or LED technologies to maximize flexibility, energy efficiency, and print quality.

Choosing the right drying system depends on print job needs, substrate type, budget, and Heidelberg machine compatibility.

Regular cleaning and maintenance of lamps and reflectors extend equipment life and ensure consistent drying performance.

Infrared printing technology plays a vital role in Heidelberg machines. This method uses radiant heat to dry inks quickly and efficiently. The core component is the infrared lamp, which contains a tungsten filament inside a quartz tube. When heated, the filament emits infrared radiation that targets the printed surface. This process ensures rapid drying and consistent print quality.

Quartz IR emitters stand out as the primary source of infrared radiation in Heidelberg presses. These lamps use quartz glass tubes for high temperature resistance and excellent infrared transparency. The tungsten filament inside the tube heats up rapidly, delivering fast response times and precise output control. Special coatings on the quartz tube, such as gold or white ceramic, reflect heat directionally and minimize energy loss. Twin-tube designs, like those found in many Heidelberg Speedmaster models, provide extra mechanical strength and allow for longer lamp lengths.

Short wave infrared lamps operate at wavelengths between 1.0 and 1.4 μm. They deliver rapid heating and high power output, making them ideal for fast drying in printing equipment and paint applications. Gold reflectors focus the heat, increasing drying speed and improving print turnaround.

Medium wave lamps cover wavelengths from 1.4 to 3.2 μm. Fast response medium wave and carbon medium wave types fall within this range. These lamps offer efficient heating for industrial processes, including PET bottle blowing and general drying tasks. The quartz tube construction ensures durability and consistent performance.

Carbon infrared lamps provide even higher heating efficiency. Their design suits demanding industrial heating applications, where rapid and uniform heat distribution is essential. These lamps often appear in processes requiring intense, focused heat.

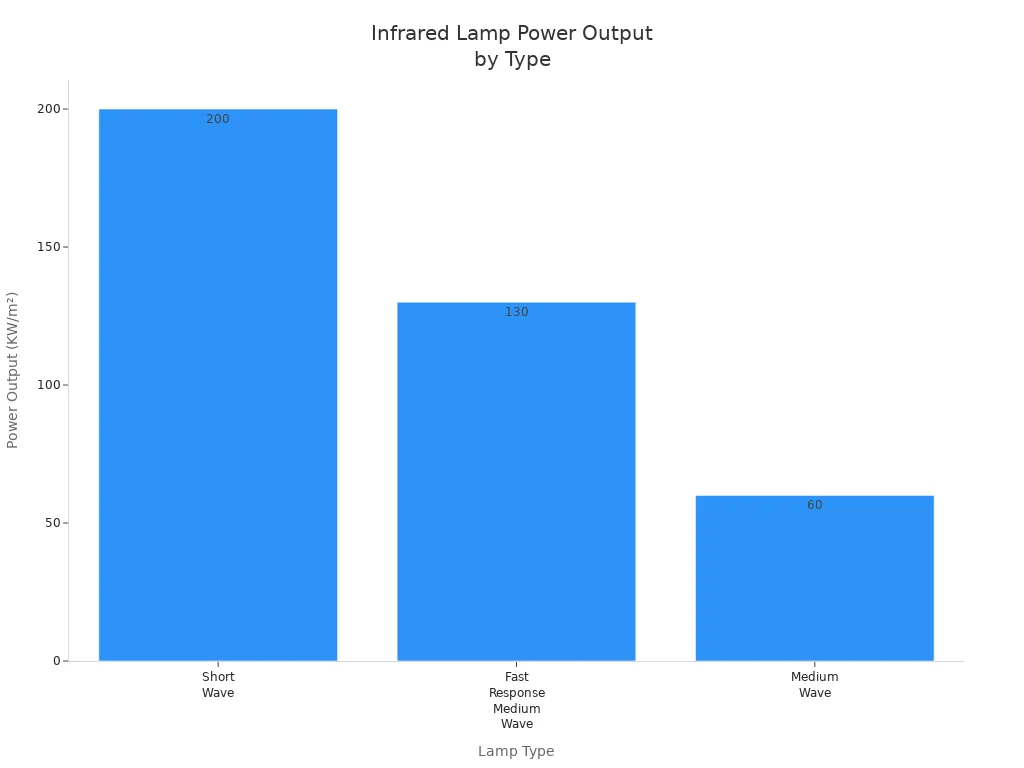

Lamp Type | Wavelength Range (μm) | Power Output (KW/m²) | Reflector Type | Typical Applications |

|---|---|---|---|---|

Short Wave | 1.0 - 1.4 | Up to 200 | Gold, White Ceramic | Printing equipment, paint drying |

Fast Response Medium Wave | 1.4 - 2.0 | 130 | Gold, White Ceramic | PET bottle blowing, industrial heating |

Carbon Medium Wave | 2.0 - 2.5 | N/A | N/A | High heating efficiency applications |

Medium Wave | 2.2 - 3.2 | 60 | Gold, White Ceramic | General industrial drying and heating |

Replacement IR lamps for Heidelberg presses, such as those from Huai'an Infrared Heating Technology, feature robust quartz tube construction and advanced reflector coatings. These lamps provide high thermal stability, uniform temperature distribution, and strong resistance to chemicals. The twin-tube design increases mechanical strength, supporting lamp lengths up to 3.5 meters. Users benefit from fast heating rates, controllable output, and reliable performance in demanding printing environments. Lamp life typically ranges from 5,000 to 20,000 hours, with most products offering a one-year warranty.

Infrared printing delivers significant energy savings compared to traditional drying methods. Quartz IR emitters convert up to 86% of electrical power into radiant heat, ensuring minimal energy waste. Fast medium wave lamps, for example, consume 40% less power than standard halogen lamps. Many print shops report a return on investment period of about three months after upgrading to energy-efficient IR lamps. This rapid ROI results from lower operating costs and reduced downtime. The high efficiency and long lamp life of modern infrared solutions make them a smart choice for Heidelberg printing operations.

UV lamp systems have transformed the way Heidelberg presses handle print drying and cure processes. These systems use advanced UV-LED technology to deliver instant curing of inks. Operators can handle printed sheets immediately after printing, which increases production speed and reduces bottlenecks. UV lamp systems generate minimal heat, so they protect sensitive substrates from deformation and improve worker safety. The high intensity of UV light ensures a high level of curing efficiency, producing consistent gloss and superior print quality.

UV lamp systems also offer significant energy savings. They consume less power than traditional mercury lamps and do not produce ozone, making them environmentally friendly. The compact design of modern UV lamps allows easy integration into most Heidelberg presses. Operators benefit from instant on/off operation, which eliminates waiting times and increases work efficiency. UV lamp life often reaches 20,000 to 30,000 hours, reducing replacement frequency and maintenance costs.

However, some curing issues may arise at very high printing speeds if the irradiation intensity is not sufficient. UV lamp systems require close proximity to the printing material and high-quality UV inks to achieve optimal results. The initial investment for UV lamp technology can be higher, but the long-term savings and improved print quality often justify the cost.

Aspect | Advantages | Limitations |

|---|---|---|

Start-up | Instant full power, no preheating | N/A |

Heat Generation | Low heat, prevents deformation | N/A |

Maintenance | Low cost, long UV lamp life | N/A |

Intensity | High, supports fast production | May not fully cure ink at highest speeds |

Energy Consumption | Lower than traditional lamps | Higher initial cost |

Environmental Impact | No ozone, safer for operators | Cannot emit short-wave UV, limiting some varnish curing |

Infrared curing remains a popular choice for Heidelberg printing machines. This method uses radiant heat from specialized lamps to dry inks efficiently. Infrared lamps provide fast response times and precise temperature control, which helps maintain print quality and supports a wide range of substrates. Operators can adjust lamp output to match the specific requirements of each print job, ensuring consistent results.

Infrared curing excels in applications where rapid drying is essential. The technology supports high-speed production and reduces the risk of smudging or marking. Infrared lamps also offer long lamp life and reliable performance, making them a cost-effective solution for many print shops. While infrared curing does not match the instant results of UV lamp systems, it provides a balance between speed, energy efficiency, and versatility.

Some curing issues may occur with thick ink layers or specialty coatings, as infrared heat relies on evaporation rather than photochemical reactions. However, modern infrared systems, such as those from Huai'an Infrared Heating Technology, deliver robust performance and energy savings.

Hot air dryers represent a traditional approach to drying in Heidelberg presses. These systems use controlled streams of heated air to evaporate moisture from printed sheets. Heidelberg’s DryStar delivery dryers use patented round-nozzle technology to apply hot air uniformly, ensuring fast and consistent drying even at high production speeds. The air cushion created by this system stabilizes sheet travel and maintains print quality.

Operators can monitor energy consumption with integrated energy meters, allowing precise adjustments to optimize efficiency. Hot air dryers with heat recovery systems recycle exhaust heat, reducing energy use by up to 20% and lowering CO2 emissions. This supports sustainable and cost-effective printing operations.

While hot air dryers do not offer the instant cure of UV lamp systems, they remain reliable for basic printing needs. They are easy to operate and maintain, making them suitable for many print shops focused on cost control and environmental responsibility.

Hybrid solutions combine multiple drying and curing technologies to maximize efficiency and print quality in Heidelberg presses. Many print shops now use systems that integrate both infrared and uv lamp modules. This approach allows operators to switch between drying methods based on the type of ink, substrate, and production speed.

A typical hybrid system may include an infrared module for initial drying and a uv lamp module for final cure. The infrared section quickly removes moisture from water-based inks. The uv lamp then completes the cure process, ensuring that the ink bonds fully to the substrate. This combination reduces the risk of smudging and improves resistance to abrasion.

YFR offers advanced hybrid solutions designed for Heidelberg machines. Their systems feature modular construction, which allows easy installation and maintenance. Operators can adjust the balance between infrared and uv output to match specific print jobs. YFR’s hybrid modules support both conventional and uv inks, making them suitable for a wide range of applications.

Tip: Hybrid systems provide flexibility for print shops that handle diverse jobs. Operators can optimize drying and curing for each run, improving turnaround times and reducing waste.

Hybrid solutions also help reduce energy consumption. By using infrared for the initial drying phase, the system lowers the load on the uv lamp. This extends lamp life and decreases overall power usage. Many hybrid modules include smart controls that monitor temperature and uv intensity, ensuring consistent results.

The table below highlights the main features of hybrid drying systems for Heidelberg presses:

Feature | Benefit |

|---|---|

Dual drying modules | Supports both infrared and uv lamp curing |

Modular design | Easy integration and maintenance |

Smart controls | Precise temperature and uv intensity control |

Energy efficiency | Reduces power consumption and lamp wear |

Versatility | Handles various inks and substrates |

Hybrid systems do have some limitations. They require a higher initial investment than single-technology solutions. Operators must also train staff to manage both infrared and uv modules. However, the long-term benefits often outweigh these challenges. Print shops gain the ability to cure a wider range of inks and coatings, meet tight deadlines, and deliver consistent quality.

YFR’s hybrid solutions have proven compatibility with Heidelberg Speedmaster and other popular models. Their engineering team provides support for installation and ongoing maintenance. Many users report improved productivity and lower operating costs after upgrading to hybrid drying systems.

Hybrid solutions represent the future of print drying and curing. They offer unmatched flexibility, energy savings, and print quality for Heidelberg presses.

Heidelberg presses support a wide range of drying and curing alternatives. Most modern models, such as the Speedmaster series, accept upgrades like Quartz IR Emitters, UV lamp systems, and hybrid modules. The heidelberg qm di 46/4 model also allows for these enhancements. Print shops should check the technical specifications of their heidelberg machine before selecting a new drying system. Compatibility ensures that the system integrates smoothly and maintains optimal print quality.

A table below outlines common heidelberg models and compatible drying solutions:

Heidelberg Model | Compatible Alternatives |

|---|---|

Speedmaster Series | IR, UV, Hybrid, Hot Air |

heidelberg qm di 46/4 | IR, UV, Hot Air |

Printmaster Series | IR, Hot Air |

GTO Series | IR, UV |

Note: Always consult with suppliers like Huai'an Infrared Heating Technology and YFR for guidance on model compatibility.

Proper installation of drying systems in heidelberg presses ensures reliable performance. Technicians should follow a step-by-step process to avoid issues. Begin by disconnecting the press from power. Remove the old lamp or dryer module. Inspect the mounting area and clean all surfaces thoroughly. Dust and ink residue can affect the new system's efficiency.

Next, position the new IR emitter, UV lamp, or hybrid module according to the manufacturer’s instructions. Secure all fasteners and check alignment. Connect the wiring, making sure all contacts are clean and free of corrosion. Reconnect the press to power and run a test cycle. Monitor the system for proper operation and check for any unusual noises or heat buildup.

Tip: Keep a clean workspace during installation. Use lint-free cloths and approved cleaning agents to maintain a dust-free environment.

Regular cleaning and maintenance extend the life of drying systems in heidelberg presses. Operators should schedule cleaning at least once a week. Begin by powering down the press and allowing all components to cool. Remove protective covers and gently clean lamp surfaces with a soft, clean cloth. Avoid touching the quartz tube with bare hands, as oils can reduce efficiency.

Inspect reflectors and cooling fans for dust buildup. Use compressed air to clean hard-to-reach areas. Check wiring and connectors for signs of wear or corrosion. Replace any damaged parts promptly. Document each cleaning session in a maintenance log.

A simple cleaning checklist for heidelberg presses:

Power off and cool down the system.

Remove covers and clean lamp surfaces.

Inspect and clean reflectors.

Clean cooling fans and air vents.

Check wiring and connectors.

Record cleaning and maintenance actions.

Regular cleaning prevents overheating and ensures consistent drying performance. Suppliers like Huai'an Infrared Heating Technology and YFR offer support for cleaning procedures and replacement parts.

Selecting the right drying and curing technology for a Heidelberg press depends on print job requirements, budget, and operational goals. Each alternative offers unique strengths and trade-offs. The table below compares the main options in terms of performance, cost, and ease of use:

Technology | Performance | Initial Cost | Operational Cost | Ease of Use | Typical Application |

|---|---|---|---|---|---|

Fast drying for water-based inks; safe, no toxic fumes | Low | Low | Simple controls, easy retrofit | General commercial printing | |

UV lamp | Instant curing, high gloss, supports special effects | Medium-High | Medium-Low | Requires safety measures | High-speed, specialty print runs |

LED curing | Consistent output, low heat, long lamp life | High | Very Low | Minimal maintenance, instant start | Short runs, sensitive substrates |

Hot air dryer | Reliable for basic drying, slower than lamp systems | Low | Medium | Straightforward operation | Entry-level, long print runs |

Hybrid system | Optimized for diverse inks and substrates, flexible | High | Low | Modular, requires training | Mixed ink types, complex runs |

Note: Hybrid systems allow operators to combine IR drying with UV or LED curing, optimizing each run for print quality and efficiency.

Cost considerations play a major role in choosing a drying solution for Heidelberg machines. IR lamp systems offer a low initial investment and affordable operation, making them ideal for shops with frequent, long print runs. UV lamp systems require a higher upfront cost but deliver faster production cycles and reduce ink waste, which lowers material expenses over time. LED curing systems demand the highest initial investment, yet their long lamp life and minimal energy use result in significant savings during extended runs. Hot air dryers remain the most budget-friendly to install, but their slower drying speed can limit throughput on high-volume runs.

Hybrid systems, which combine IR and UV or LED modules, provide the greatest flexibility. They suit print shops that handle a wide variety of substrates and ink types. While the initial cost is higher, the ability to tailor each run for optimal drying or curing leads to improved efficiency and reduced waste. Many Heidelberg users finance or lease advanced UV and hybrid systems to manage upfront costs. Over time, energy-efficient technologies like LED and hybrid modules help lower utility bills and maintenance expenses, supporting a positive return on investment.

IR lamp: Best for frequent, long runs with water-based inks.

UV lamp: Ideal for specialty print runs needing instant curing and high gloss.

LED curing: Suited for short runs, sensitive materials, and sustainability goals.

Hot air dryer: Reliable for basic, long runs with minimal complexity.

Hybrid system: Optimal for shops with diverse print jobs and changing requirements.

Printers should evaluate their typical run length, substrate variety, and finishing needs before selecting a system. Energy efficiency, maintenance, and the ability to adapt to future print trends all influence the total cost of ownership.

Selecting the right curing solution for a Heidelberg press starts with understanding the specific requirements of each print job. Operators must match the curing technology to the substrate, ink type, and desired finish. For example, UV lamp systems excel in high-speed production environments where instant curing and high gloss are essential. LED curing works best for short runs on sensitive materials, while infrared lamps provide reliable drying for water-based inks during long runs.

Key factors to consider include:

Substrate compatibility for proper ink adhesion.

End-use requirements such as chemical resistance or food safety.

Print job details like speed, color intensity, and finish.

Ink type and its match with the curing equipment.

Color management needs for accurate results.

Environmental considerations, such as low-migration inks for sensitive applications.

Balancing performance with cost-effectiveness.

Operators should also focus on best practices. Proper storage of inks, optimizing press settings, and regular cleaning of press components all contribute to consistent print quality. Surface treatment of substrates and continuous quality control checks help maintain high standards. Clean lamps and reflectors ensure efficient curing throughout every run.

Tip: Clean equipment and regular cleaning routines reduce downtime and improve production run speed.

Budget plays a critical role in the decision-making process. The initial purchase price of a curing system, such as a high-speed UV curing machine, can reach several thousand dollars. Operational costs include power consumption, which depends on the total wattage and production run speed. Maintenance expenses, like UV lamp replacement, add to the overall cost. Payment terms, delivery time, and shipping terms also affect the budget.

Compatibility with Heidelberg presses requires attention to physical parameters, which can influence installation costs. The choice of lamp technology impacts both upfront and ongoing expenses. Operators must consider curing temperature and speed requirements for each run. A thorough budget plan should cover purchase price, operational and maintenance costs, shipping, and installation.

Note: Clean installation and regular cleaning routines help extend equipment life and reduce unexpected expenses.

Reliable supplier support ensures long-term success with alternative curing systems. Suppliers like Huai'an Infrared Heating Technology and YFR offer quality assurance and warranty coverage. For example, YFR provides a one-year warranty on select products, emphasizing safety and durability. Huai'an Infrared Heating Technology supports customers with refund policies and product reliability guarantees.

Training and after-sales services also play a vital role. Heidelberg’s apprenticeship programs train technicians in operating, cleaning, and maintaining presses. These programs combine classroom instruction with hands-on experience, ensuring operators can clean and maintain equipment effectively. Ongoing mentorship and structured oversight help technicians stay engaged and ready for any production run.

A strong supplier relationship provides access to technical support, spare parts, and troubleshooting guidance. Clean communication channels and responsive service teams help operators address issues quickly, keeping every run on schedule.

Clean equipment, regular cleaning, and strong supplier support form the foundation for successful production in any Heidelberg print shop.

UV LED curing stands out as the most energy-efficient and environmentally friendly alternative for Heidelberg presses, reducing electricity use by up to 85% and eliminating hazardous emissions. Print shops benefit from instant on/off operation, long lamp life, and compatibility with heat-sensitive substrates. While initial investment and equipment compatibility require careful planning, the industry trend favors sustainable solutions. Trusted suppliers like Huai'an Infrared Heating Technology and YFR provide expert support, helping printers select the best system for their needs and future-proof their operations.

Heidelberg presses support Quartz IR Emitters, UV lamps, LED curing systems, hot air dryers, and hybrid solutions. Each technology offers unique benefits for print drying and curing.

Quartz IR Emitters convert up to 86% of electrical energy into radiant heat. This high efficiency reduces power consumption and lowers operating costs for print shops.

Most modern Heidelberg presses, including the Speedmaster series, accept UV lamp upgrades. Always check model specifications and consult with suppliers for compatibility.

Operators should clean lamp surfaces weekly, inspect reflectors, and check wiring. Regular maintenance extends lamp life and ensures consistent drying performance.

Hybrid systems support both conventional and UV inks. Operators can switch between drying methods to match specific print jobs and substrates.

Replacement IR lamps from leading brands often last between 5,000 and 20,000 hours. Actual lifespan depends on usage and maintenance.

Initial purchase price, installation, energy consumption, and maintenance all affect total cost. Print shops should evaluate their production needs and budget before selecting a system.

Suppliers like Huai'an Infrared Heating Technology and YFR provide expert guidance, training, and after-sales support for Heidelberg-compatible drying solutions.

content is empty!