Views: 0 Author: Site Editor Publish Time: 2025-09-19 Origin: Site

IR Paint Drying uses infrared energy to quickly and efficiently cure paint, offering faster drying times and better quality compared to traditional methods. In 2025, many industries recognize this technology for its impressive speed and consistent results. Users achieve superior finish quality and reduce energy consumption. Environmental benefits also attract attention. Beginners find the process straightforward and safe, especially with practical tips from experts.

IR paint drying uses infrared energy to cure paint quickly, reducing drying times significantly compared to traditional methods.

This technology ensures a high-quality finish by heating paint evenly, preventing common defects like bubbling and cracking.

Infrared systems convert up to 96% of energy into usable heat, leading to lower energy costs and a smaller environmental footprint.

Operators can adjust the intensity and duration of infrared exposure, allowing for precise control over the drying process.

IR paint drying is versatile, suitable for various paint types and surfaces, including automotive, industrial, and woodworking applications.

Safety is crucial; operators should wear protective gear and monitor temperatures to avoid overheating and damage.

Using infrared technology can enhance productivity by increasing throughput and reducing bottlenecks in paint shops.

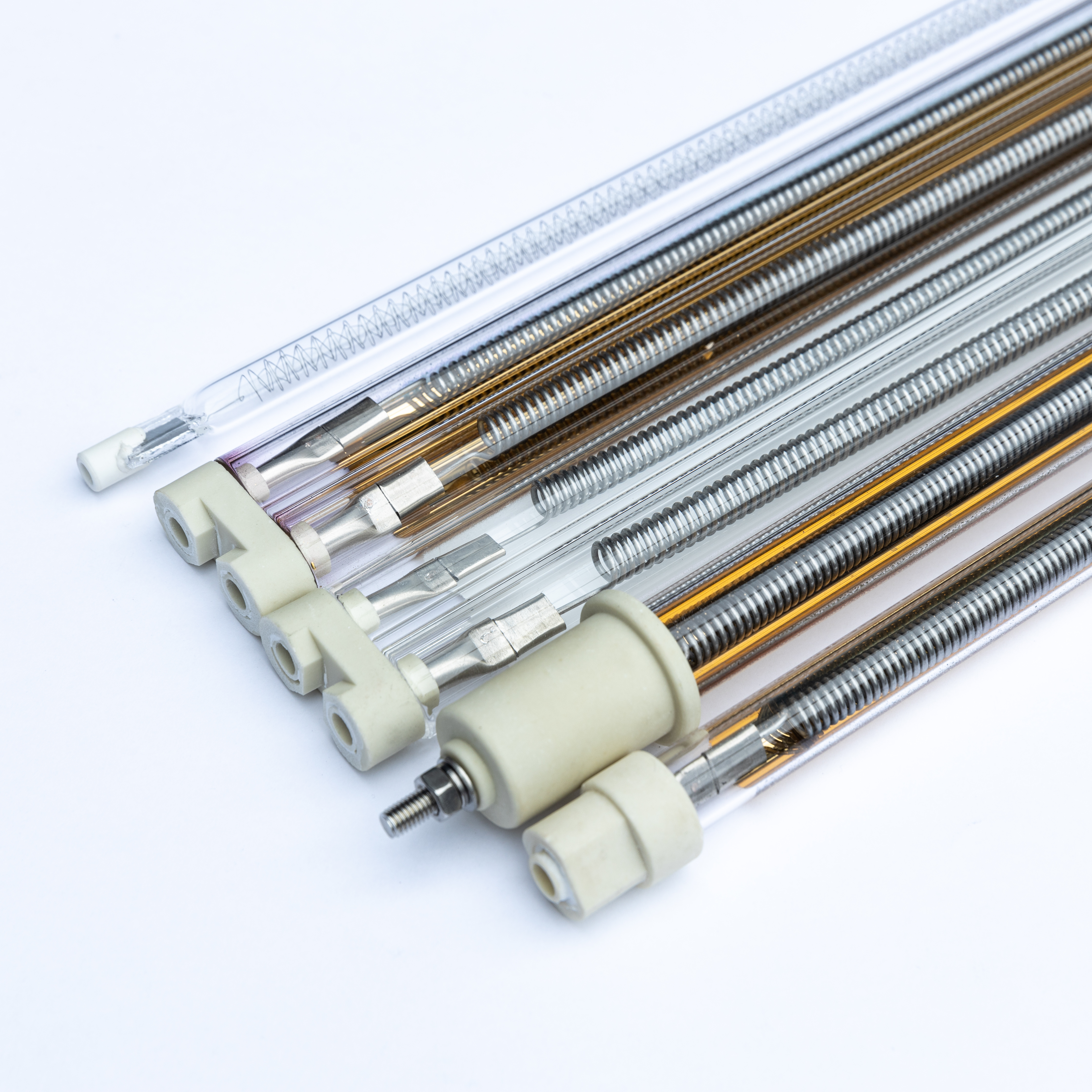

Investing in quality infrared equipment, like Quartz IR emitters, ensures durability and consistent performance for optimal results.

IR paint drying refers to a modern technique that uses infrared energy to cure paint layers quickly and efficiently. This method has gained popularity in industries that require fast turnaround and high-quality finishes. In ir paint drying, specialized equipment emits infrared radiation, which targets the painted surface directly. The process accelerates the drying of both water-based and solvent-based paints. Many automotive, manufacturing, and printing businesses now rely on ir paint drying to improve productivity and reduce downtime.

Huai'an Infrared Heating Technology stands out as a leading manufacturer in this field. The company produces Quartz IR emitters, which deliver consistent and powerful infrared energy for various applications. Their products support ir paint drying in settings ranging from small workshops to large-scale industrial operations. By choosing advanced infrared solutions, users achieve superior results and maintain high standards in their finished products.

Infrared heating operates on a simple scientific principle. Infrared rays possess strong penetrability, allowing them to transfer energy directly to the paint layer. When the infrared energy reaches the surface, it heats the paint and the underlying substrate. This direct transfer boosts the evaporation rate of water or solvents within the paint. The mid-infrared band, with wavelengths between 2.5 and 3.5 micrometers, proves especially effective for drying thick paint layers. This targeted approach ensures that the paint dries evenly and thoroughly.

The efficiency of infrared heating sets it apart from traditional methods. Infrared energy does not waste heat on the surrounding air. Instead, it focuses on the painted area, reducing energy consumption and speeding up the process. Huai'an Infrared Heating Technology’s Quartz IR emitters exemplify this efficiency. Their products convert up to 96% of input energy into usable heat, making ir paint drying both cost-effective and environmentally friendly.

Tip: Infrared heating allows users to control the drying process with precision. Adjusting the intensity and duration of exposure helps achieve the desired finish quality every time.

IR paint drying continues to transform industries by offering a reliable, fast, and energy-efficient solution. As more businesses adopt this technology, the benefits of infrared heating become even more apparent.

Infrared paint dryers use a unique method to speed up paint drying and curing. When the infrared paint dryer lamp emits energy, the paint and the surface beneath it absorb this energy. The molecules in the paint begin to vibrate, which raises the temperature quickly. This direct heating causes the solvents or water in the paint to evaporate at a much faster rate than with traditional methods. The process ensures that both the surface and the deeper layers of paint receive even heat, which leads to a consistent finish.

Infrared energy does not waste heat on the surrounding air. Instead, it targets the painted area directly. This approach allows for precise control over the drying process. Operators can adjust the intensity and duration of exposure, which helps achieve the desired level of paint curing. The result is a high-quality finish with less risk of defects like bubbling or uneven drying.

The drying process with infrared paint dryers follows a clear sequence:

The operator applies paint to the surface.

The infrared paint dryer lamp positions over the painted area.

The lamp emits infrared energy, which penetrates the paint layer.

The energy heats the paint and substrate, causing rapid evaporation of moisture or solvents.

The paint curing process completes as the temperature reaches the optimal level.

The operator inspects the surface for a smooth, even finish.

This process reduces drying time significantly. Many users report that infrared paint dryers can cut drying and curing time by more than half compared to air drying. The technology also supports both water-based and powder coatings, making it versatile for different applications.

Note: Infrared paint dryers allow for semi-automatic operation, which makes positioning easy and increases paint shop throughput by up to 80%.

Infrared paint drying and curing require specialized equipment. Each type of equipment offers unique features to meet different needs.

Equipment Type | Specifications |

|---|---|

Constructed of galvanized steel, designed for efficient absorption of infrared. | |

Electric Infrared Heaters | Used for industrial process heating applications. |

Thermoreactor® | Developed for drying, melting, and polymerization of paints. |

Catalytic Infrared Heaters | Efficient gas catalytic IR equipment for the finishing industry. |

REVO Speed | Uses short wave, electric infrared curing technology for fast curing times. |

REVO Speed | Quick heating and cooling times with built-in fans. |

REVO Speed | Cures both filler and coatings from the inside out, saving time and energy. |

The infrared paint dryer lamp stands at the core of the drying process. Lamps such as Quartz IR emitters and Twin Tube Fast Medium Wave Infrared Lamps from Huai'an Infrared Heating Technology deliver powerful, targeted energy. These lamps provide fast, even heating, which is essential for high-quality paint drying and curing. The design of these lamps allows for quick heating and cooling, which saves time and energy. Operators can use these lamps for both small touch-ups and large-scale projects.

Quartz IR emitters deliver radiation energy directly to the painted object.

Twin Tube Fast Medium Wave Infrared Lamps offer efficient heating for paint drying and curing.

Printing Quartz Infrared Lamps and Fast Medium Wave IR Lamps serve specialized needs in printing and industrial applications.

Infrared paint dryers often include advanced controls and accessories. These features help operators manage the drying process with precision. Power controls allow for adjustment of intensity and duration, which ensures optimal paint curing. Accessories such as quartz glass covers protect the lamps and improve energy efficiency. Built-in fans in some models cool the unit down in seconds, which increases safety and reduces downtime between jobs.

Fast, semi-automatic operation makes positioning simple.

Curing temperature reaches optimal levels almost instantly.

High-quality, complete cure uses significantly less energy.

Infrared paint dryers have transformed the way industries approach paint drying and curing. The combination of advanced lamps, precise controls, and efficient accessories delivers faster drying time, superior finish quality, and reliable results every time.

Infrared technology delivers rapid drying results. The system directs infrared energy straight to the painted surface. This method heats the paint and substrate quickly. Operators notice a dramatic reduction in drying times compared to conventional air or convection methods. Many industries report that infrared paint drying allows for faster packaging and shipping of finished products. The process supports high-volume production schedules and reduces bottlenecks in paint shops.

Huai'an Infrared Heating Technology’s Quartz IR emitters achieve up to 96% energy conversion rates. This high efficiency means more heat reaches the paint, speeding up evaporation and curing. Users experience consistent results, even with thick or multi-layer coatings. The ability to control exposure time and intensity ensures optimal drying for every project.

Tip: Fast drying with infrared technology minimizes the risk of dust contamination and surface defects, leading to cleaner, smoother finishes.

Infrared paint drying produces improved finish quality. The technology heats paint layers evenly, preventing common issues such as bubbling, cracking, or uneven curing. Operators see a noticeable difference in the smoothness and durability of the final coat. The process also enhances color retention and gloss, which is essential for automotive and industrial applications.

A four-zone infrared system installation led to dramatically improved curing times for paint, allowing for quicker packaging and shipping of products.

The infrared system resulted in a significant reduction in annual fuel consumption and enhanced employee comfort, contributing to overall efficiency in the production process.

Manufacturers choose infrared technology for its reliability and repeatability. The system supports both water-based and powder coatings, making it versatile for different paint types. Consistent heating ensures that each layer cures properly, resulting in a professional-grade finish every time.

Infrared paint drying stands out for its energy efficiency. The system converts up to 96% of input energy into usable heat, reducing fuel expenses by 20% to 50% compared to traditional methods. This efficiency translates into lower operating costs and a smaller environmental footprint. Many facilities report significant reductions in annual energy consumption after switching to infrared technology.

Infrared paint drying also proves environmentally friendly. The process minimizes the need for air conditioning in vehicles and lowers emissions of harmful gases. Recent research shows that using silica nano/microparticles with infrared systems can decrease car temperatures by approximately 27 °C. These benefits support sustainability goals and help companies meet regulatory standards.

Benefit | Description |

|---|---|

High Energy Conversion | Up to 96% of input energy becomes usable heat |

Cost Savings | Reduces fuel expenses by 20%-50% |

Environmental Impact | Lowers emissions and supports eco-friendly operations |

Note: Huai'an Infrared Heating Technology’s products carry CE and TUV certifications, ensuring safety and quality for every user.

Infrared paint drying stands out for its remarkable versatility. This technology adapts to a wide range of paint types, surfaces, and industry needs. Operators use IR systems for water-based, solvent-based, and powder coatings. The process works well on metals, plastics, wood, and composite materials.

Huai'an Infrared Heating Technology designs Quartz IR emitters and Twin Tube Fast Medium Wave Infrared Lamps for multiple industries. These products support automotive repair shops, manufacturing plants, digital printing facilities, and even agricultural operations. Each sector benefits from the precise control and consistent results that IR drying provides.

Key areas where IR paint drying excels:

Automotive refinishing: Delivers fast, even curing for car panels, bumpers, and custom parts.

Industrial manufacturing: Handles large-scale production lines with different coating requirements.

Printing and packaging: Ensures rapid drying of inks and coatings on paper, plastics, and films.

Woodworking: Cures stains, varnishes, and paints on furniture and cabinetry.

Agriculture: Dries protective coatings on equipment and storage units.

Application Area | Paint Types Supported | Example Equipment |

|---|---|---|

Automotive | Water-based, powder, solvent | Quartz IR emitters, Twin Tube IR Lamps |

Manufacturing | Powder, solvent, water-based | Electric IR Heaters, Thermoreactor® |

Printing | Inks, coatings | Printing Quartz Infrared Lamps |

Woodworking | Stains, varnishes, paints | Carbon Infrared Heaters |

Agriculture | Protective coatings | Fast Medium Wave IR Lamps |

Tip: IR paint drying systems allow operators to adjust lamp intensity and exposure time. This flexibility ensures optimal results for both small touch-ups and large-scale projects.

Manufacturers value IR technology for its ability to handle diverse tasks without sacrificing quality or efficiency. The same equipment often serves multiple purposes, reducing the need for specialized tools. This adaptability makes IR paint drying a smart investment for businesses seeking reliable, future-proof solutions.

Infrared paint dryers deliver unmatched speed in curing and drying paint. Operators see dramatic reductions in drying times compared to traditional air or convection methods. Infrared energy heats the paint and substrate directly, which accelerates evaporation and curing. For example, a furniture manufacturer switched to medium wave infrared heaters and reduced drying time from two hours to just fifteen minutes. In another case, a pallet manufacturer used a modular infrared system and achieved drying times as short as 20 seconds. These results highlight the efficiency of IR technology in high-volume production environments.

Traditional methods rely on ambient air or convection heat. These approaches often require extended periods for paint to cure, especially with thick coatings or water-based products. Operators must wait for the air to circulate and gradually remove moisture. This process can slow down production schedules and increase the risk of defects due to uneven drying.

Tip: IR paint drying works best for water-based adhesives, stains, and paints in busy manufacturing settings. Fast drying supports higher throughput and reduces bottlenecks.

Infrared paint dryers produce consistent, high-quality finishes. The technology delivers even heating across the painted surface, which prevents common issues such as bubbling, cracking, or uneven curing. Manufacturers of decorative wood panels use IR systems to control the drying process and save energy. These systems process up to 10 meters of decorative wood per minute, ensuring every panel receives uniform heat and cures properly.

Traditional drying methods can struggle to maintain consistent quality. Air drying may lead to surface imperfections, especially in environments with fluctuating temperatures or humidity. Convection ovens sometimes cause overheating or under-curing in certain areas, resulting in a less durable finish.

Infrared systems, such as Quartz IR emitters from Huai'an Infrared Heating Technology, allow operators to adjust lamp intensity and exposure time. This control ensures optimal results for both small touch-ups and large-scale projects. The ability to fine-tune the process leads to professional-grade finishes and reliable repeatability.

Infrared paint drying offers significant cost advantages over traditional methods. IR systems convert up to 96% of input energy into usable heat, which reduces fuel expenses by 20% to 50%. Facilities that adopt IR technology report lower annual energy consumption and decreased operating costs. The rapid drying process also minimizes labor expenses, as operators spend less time monitoring and handling painted items.

Method | Energy Conversion | Typical Drying Time | Operating Cost |

|---|---|---|---|

Infrared | Up to 96% | Minutes/Seconds | Low |

Air/Convection | 40-60% | Hours | Higher |

Traditional air and convection methods often require longer drying times and more energy. These systems may need additional ventilation or climate control, which increases utility bills. Extended drying periods can also slow down production, leading to higher labor costs and reduced profitability.

Manufacturers seeking to improve efficiency and reduce expenses increasingly choose infrared paint drying. The combination of speed, quality, and energy savings makes IR technology a smart investment for modern operations.

Infrared paint drying technology offers clear advantages in specific scenarios. Operators in automotive repair shops often choose IR systems for spot repairs and refinishing tasks. The rapid curing process allows technicians to complete jobs in minutes, which increases throughput and customer satisfaction. IR paint dryers also excel in environments with strict deadlines, such as manufacturing plants and assembly lines. Production managers rely on the speed and consistency of IR drying to maintain tight schedules and reduce bottlenecks.

Facilities that handle water-based or powder coatings benefit greatly from infrared technology. These coatings require precise temperature control for optimal curing. IR paint dryers, such as Quartz IR emitters from Huai'an Infrared Heating Technology, deliver targeted heat that ensures even drying across all layers. This capability reduces the risk of defects and improves the durability of the finished product.

Operators working with large or irregularly shaped surfaces find IR systems especially useful. Traditional convection ovens may struggle to provide uniform heat distribution. Infrared lamps, including Twin Tube Fast Medium Wave Infrared Lamps, adapt easily to different shapes and sizes. This flexibility supports industries like woodworking, printing, and agriculture, where surfaces vary widely.

Tip: IR paint drying works best for quick touch-ups, high-volume production, and specialty coatings that demand precise control.

Environmental considerations also influence the choice of IR technology. Companies aiming to reduce energy consumption and emissions often switch to infrared systems. The high energy conversion rate—up to 96%—translates to lower operating costs and a smaller carbon footprint. Facilities with limited space appreciate the compact design of IR paint dryers, which fit easily into existing workflows.

The following table highlights common situations where IR paint drying outperforms traditional methods:

Situation | IR Paint Drying Advantage | Example Equipment |

|---|---|---|

Automotive spot repairs | Fast curing, minimal downtime | Quartz IR emitters |

High-volume manufacturing | Consistent results, increased throughput | Twin Tube Fast Medium Wave IR Lamps |

Water-based/powder coatings | Precise temperature control | Printing Quartz Infrared Lamps |

Irregular surfaces | Uniform heat distribution | Carbon Infrared Heaters |

Energy-saving initiatives | Lower energy use, reduced emissions | IP67 ULG Ultra Low Glare IR Lamps |

Paint shops and production facilities should consider IR paint drying when speed, quality, and efficiency are top priorities. The technology adapts to a wide range of applications, making it a smart choice for modern operations. Huai'an Infrared Heating Technology provides reliable solutions that help businesses achieve superior results in every project.

Operators must prioritize safety when using infrared paint drying equipment. They should wear protective eyewear and gloves to shield themselves from intense light and heat. Technicians need to keep the workspace clear of flammable materials. They should position infrared lamps at a safe distance from the painted surface to prevent overheating. Using a three-dimensional infrared heating lamp helps distribute heat evenly, reducing the risk of damage. Beginners should avoid rapid temperature increases, which can cause paint defects or substrate warping. Monitoring the surface temperature with an infrared thermometer ensures the process remains within safe limits. Many professionals recommend combining infrared boosters with hot air for controlled drying, which minimizes risks and improves results.

Tip: Always check the equipment’s certification, such as CE or TUV, to confirm safety standards.

Infrared paint drying technology supports a wide range of paint types. Water-based and powder coatings respond well to infrared energy, making them popular choices in automotive and industrial settings. Oil-based paints also show distinct behaviors under IR drying. The following table summarizes how different oil paints react:

Type of Paint | Behavior Under IR Drying | Observations |

|---|---|---|

Oil Paint with Zinc | Cracks start in the acrylic primer and propagate through layers, leading to brittleness. | Increased cross-linking due to reactions with free fatty acids, resulting in fragile paint films. |

Oil Paint with Titanium | Cracking confined to the paint film, indicating flexibility. | Weaker and more flexible behavior compared to zinc white, showing less susceptibility to deeper cracks. |

Technicians should select paint types based on the substrate and desired finish. Water-based coatings cure quickly and evenly with infrared, while powder coatings benefit from precise temperature control. Operators must remain aware that high humidity can affect the finish, especially with water-based paints.

Beginners achieve optimal results by following proven setup strategies. They should use an infrared thermometer to monitor surface temperature throughout the drying process. Employing a moisture meter helps check surface dryness before starting. Operators need to check weather conditions 48 hours in advance using a reliable weather app. Starting painting mid-morning, after dew has evaporated but before peak heat, yields the best results. Allowing 24-48 hours before rain ensures proper curing. The 'Chase the sun' technique helps optimize drying times by taking advantage of natural light and warmth. Operators should avoid painting within four hours of sunset to guarantee adequate drying time. Maintaining humidity levels between 40% and 70% prevents surfactant bleed and ensures a smooth finish.

Control energy usage to save time and costs.

Utilize video clips, webinars, and online sessions for guidance.

Use a three-dimensional infrared heating lamp for even illumination.

Note: Beginners should combine practical advice with manufacturer guidelines to maximize efficiency and achieve professional results.

Infrared paint drying technology continues to evolve rapidly in 2025. Manufacturers introduce advanced products that improve efficiency and user experience. The IP67 ULG Ultra Low Glare Infrared Lamp stands out as a recent innovation. This lamp provides powerful infrared heating while reducing glare, which increases comfort and safety for operators. Engineers design these lamps for outdoor and indoor use, making them suitable for a wide range of environments.

Huai'an Infrared Heating Technology leads the market with Quartz IR emitters and Twin Tube Fast Medium Wave Infrared Lamps. These products deliver precise energy control and fast response times. New models feature improved durability and enhanced energy conversion rates. Many systems now include smart controls that allow technicians to adjust settings remotely. This capability supports automation and integration with digital workflows.

Tip: Smart infrared systems help operators monitor drying progress and optimize energy use, which improves productivity.

Infrared paint drying finds applications in many industries. Automotive repair shops use IR lamps for quick spot repairs and refinishing. Manufacturing plants rely on infrared ovens and heaters to cure coatings on metal, plastic, and composite parts. Printing facilities adopt Quartz IR emitters to dry inks and coatings on paper and film. Woodworking shops use carbon infrared heaters to cure stains and varnishes on furniture and cabinetry.

Agriculture benefits from infrared technology as well. Farmers use IR lamps to dry protective coatings on equipment and storage units. The versatility of infrared systems allows operators to handle different paint types and substrates with ease. Many businesses report increased throughput and improved finish quality after switching to IR paint drying.

Industry | Application Area | Example Equipment |

|---|---|---|

Automotive | Spot repairs, refinishing | Quartz IR emitters, Twin Tube IR Lamps |

Manufacturing | Coating cure | Electric IR Heaters, Thermoreactor® |

Printing | Ink and coating drying | Printing Quartz Infrared Lamps |

Woodworking | Stain and varnish cure | Carbon Infrared Heaters |

Agriculture | Protective coating dry | Fast Medium Wave IR Lamps |

Infrared paint drying technology supports sustainability goals in 2025. The process uses infrared radiation to heat the coating surface directly. This method reduces drying times and lowers energy consumption compared to traditional convection ovens. Facilities that adopt IR systems report significant reductions in fuel expenses and carbon emissions.

Operators choose infrared paint drying to meet environmental standards and reduce their ecological footprint. The technology minimizes the need for air conditioning and ventilation, which further decreases energy use. Many products from Huai'an Infrared Heating Technology carry CE and TUV certifications, which guarantee safety and quality.

Direct heating of the coating surface

Shorter drying cycles

Lower energy consumption

Reduced emissions

Note: Infrared paint drying helps companies achieve sustainability targets while maintaining high-quality results.

Infrared technology continues to shape the future of paint drying. Manufacturers invest in research and development to create smarter, safer, and more efficient systems. The growing adoption of IR paint drying in agriculture, printing, and manufacturing demonstrates its value across diverse sectors. Businesses that embrace these innovations position themselves for success in a competitive and environmentally conscious market.

Infrared paint drying offers fast, efficient, and high-quality results. Beginners benefit from easy operation and consistent finishes. In 2025, IR technology stands out as a smart investment for modern paint shops. Experts recommend focusing on features such as precise wavelength control, robust construction, and great reflector design when selecting equipment.

Feature | Importance |

|---|---|

Precise Wavelength Control | Optimal absorption for specific materials |

Unmatched Emitter Quality | Durability and consistent output |

Great Reflector Design | Maximizes energy efficiency and uniform intensity |

Quartz IR emitters from Huai'an Infrared Heating Technology meet these standards. Seek expert advice to ensure the best results for your projects.

Most water-based, solvent-based, and powder coatings respond well to IR paint drying. Operators achieve optimal results by selecting paints designed for rapid curing and high-temperature resistance.

Infrared paint drying equipment meets strict safety standards. Products from reputable manufacturers, such as Huai'an Infrared Heating Technology, carry CE and TUV certifications. Operators should always follow safety guidelines and wear protective gear.

Yes. IR paint drying systems convert up to 96% of input energy into usable heat. Facilities often report energy savings of 20% to 50% compared to traditional drying methods.

IR paint drying significantly reduces curing times. Many users see drying times drop from hours to minutes. The exact speed depends on paint type, thickness, and equipment settings.

Operators should clean lamp surfaces regularly and inspect electrical connections. Replacing worn-out lamps ensures consistent performance. Most systems require minimal maintenance when used according to manufacturer instructions.

Yes. IR paint drying systems adapt to both small touch-ups and large surfaces. Adjustable lamp arrays and modular designs allow coverage of wide areas in automotive, industrial, and agricultural applications.

Infrared technology delivers even heating, which helps prevent defects like bubbling or cracking. Operators achieve smooth, durable finishes with consistent color and gloss.

Power controls, quartz glass covers, and built-in fans enhance performance. These accessories help regulate temperature, protect lamps, and ensure efficient operation.