Author: Site Editor Publish Time: 2025-09-18 Origin: Site

Industrial ir paint drying delivers impressive time and energy savings across many sectors. Manufacturers see up to 93% energy savings and over 60% less energy use with this solution. Huai'an Infrared Heating Technology offers advanced infrared lamps, making ir paint drying the preferred solution for those seeking speed and efficiency.

Ir paint drying technology saves over 70% of energy compared to traditional ovens.

Targeted heating reduces energy consumption and CO2 emissions, especially for large metal components.

Operators choose ir paint drying for its speed, reliability, and practical solution to energy challenges.

Infrared paint drying can save over 70% of energy compared to traditional ovens, making it a cost-effective choice.

This technology provides instant heat, significantly reducing drying times and increasing production efficiency.

Infrared systems ensure uniform heat distribution, leading to consistent finishes and fewer defects in products.

Operators benefit from reduced downtime, as infrared drying eliminates long warm-up and cool-down periods.

Infrared heating supports eco-friendly practices by lowering CO2 emissions and energy consumption.

The technology is versatile, suitable for various industries including automotive, manufacturing, and agriculture.

Infrared systems are designed with safety features, ensuring a secure working environment for operators.

Upgrading to infrared heating can enhance product quality and improve overall operational efficiency.

Industrial infrared paint drying relies on surface heating to deliver efficient results. Infrared heating panels emit radiant energy that targets the surface of painted materials. This direct approach allows the process to heat objects from the outside in, ensuring rapid drying and curing. Operators see a significant reduction in drying times because infrared technology focuses energy exactly where it is needed. The process eliminates the need for prolonged exposure to high temperatures, which can damage sensitive coatings. Huai'an Infrared Heating Technology’s infrared lamps achieve energy conversion rates up to 96%, maximizing the effectiveness of each drying cycle.

Infrared heating panels use radiant energy to penetrate the surface and activate molecular vibrations within the paint layer. This method differs from traditional drying, which relies on conduction and convection to transfer heat from the exterior to the interior. Infrared technology creates a quick heating response, allowing for even heat distribution across the entire surface. The process ensures that drying occurs uniformly, reducing the risk of uneven finishes or defects. Operators benefit from consistent results and improved quality control.

Short wave infrared heating panels deliver instant heat and excel in industrial drying applications. These systems provide zone-specific control and high heat output efficiency. Operators use short wave infrared technology for metal treatment, outdoor heating, and rapid drying of large components. The process supports environmentally friendly operations and cost-efficient production.

Medium wave infrared heating panels offer balanced performance for plastics, glass, textiles, and digital printing. These systems feature 60% radiant efficiency and medium-speed response. Durable construction and long life expectancy make medium wave infrared technology a reliable choice for continuous industrial drying and curing. The process supports even heat distribution, which is essential for maintaining product quality.

Carbon infrared heating panels excel in drying water-based coatings and varnishes. These systems provide gentle, uniform heat distribution, making them suitable for sensitive materials. Operators use carbon infrared technology for applications that require non-contact heating and rapid processing. The process ensures consistent drying without compromising the integrity of the coating.

Huai'an Infrared Heating Technology offers a comprehensive lineup of infrared heating panels, including Short Wave, Medium Wave, and Carbon IR Heaters. Each system addresses specific industrial needs, from quick heating response to even heat distribution and high-quality finishes.

Application Description | |

|---|---|

Carbon Infrared Emitters | Efficient for drying water-based coatings and varnishes. |

Golden 8 Infrared Emitters | Designed for specific applications in the drying of coatings and paints. |

Round Tube IR Emitters | Used in various coating processes to enhance drying efficiency. |

Infrared Special Emitters | Tailored for unique industrial applications requiring specific heating profiles. |

Infrared Boosters | Added to existing systems to alleviate production bottlenecks by increasing drying capacity. |

Heater Type | Efficiency and Suitability | Key Features |

|---|---|---|

Short-Wave IR | Ideal for rapid heating, suitable for industrial drying, metal treatment, and outdoor heating. | Instant heat delivery, zone-specific control, high heat output efficiency, environmentally friendly, cost-efficient |

Medium-Wave IR | Balanced performance, suitable for plastics, glass, textiles, and digital printing. | 60% radiant efficiency, medium-speed response, durable construction, long life expectancy |

Long-Wave IR | Provides gentle, uniform heat, suitable for saunas and indoor comfort heating. | High heating uniformity, environmentally friendly, non-contact heating for rapid processing |

Infrared heating panels from Huai'an Infrared Heating Technology support a wide range of industrial drying and curing processes. Operators select the appropriate system type based on material, application, and desired heat distribution. The flexibility and efficiency of infrared technology continue to drive advancements in industrial drying.

Industrial operations demand solutions that deliver measurable benefits. Infrared paint drying stands out by offering faster processes and consistent results. These advantages help manufacturers improve productivity, reduce costs, and maintain high standards.

Infrared technology provides instant heat. Operators do not wait for long warm-up periods. The system delivers energy directly to the painted surface, which speeds up the drying process. Medium-wave infrared emitters heat water in paint quickly, leading to rapid evaporation. Carbon infrared emitters also dry water-based paints efficiently, using less energy than traditional methods. The ability of infrared radiation to penetrate the paint allows for drying from the inside out. This approach prevents surface issues and improves the overall quality of the finish.

Infrared Drying Method | Key Benefits |

|---|---|

Medium-wave infrared emitters | Heat water in paint directly, speeding up evaporation |

Carbon infrared emitters | Dry water-based paints efficiently, using less energy |

Infrared radiation penetration | Dries paint from the inside out, preventing surface defects and improving quality |

Operators notice a significant reduction in drying time, which leads to higher throughput and better use of resources.

Infrared paint drying systems minimize downtime in industrial settings. Focused infrared energy heats only the product, not the surrounding air or equipment. This targeted approach reduces operating costs and allows for immediate production. There are no lengthy warm-up or cool-down periods. Curing times drop by 50% or more compared to convection methods. This efficiency means that production lines can run continuously, with fewer interruptions.

Benefit | Description |

|---|---|

Curing Time Reduction | Reduces curing times by 50% or more compared to convection methods |

Energy Efficiency | Focused IR energy heats only the product, lowering operating costs |

Instant Operation | No lengthy warm-up or cool-down periods, enabling immediate production |

Reduced downtime translates into higher productivity and lower maintenance needs, making infrared systems a smart investment for any industrial operation.

Infrared paint drying ensures a uniform finish across all surfaces. The technology distributes heat evenly, which eliminates hot spots and cold zones. Operators achieve consistent color and texture, even on complex shapes or large components. This uniformity reduces the risk of defects and rework, saving both time and materials.

Even heat distribution prevents uneven drying.

Consistent results improve product appearance and durability.

Operators can trust the process for high-volume production.

Manufacturers rely on infrared systems to maintain strict quality control. The precise application of heat allows for repeatable results, batch after batch. Infrared drying reduces the chance of bubbles, cracks, or other imperfections. Operators can monitor and adjust the process easily, ensuring every product meets industry standards.

Infrared paint drying supports high-quality finishes and reliable curing, which strengthens a company’s reputation for excellence.

The benefits of infrared paint drying extend beyond speed. They include improved quality, reduced waste, and greater operational efficiency. Companies that adopt this technology gain a competitive edge in today’s fast-paced market.

Industrial facilities prioritize energy efficiency to reduce operational costs and environmental impact. Infrared heating technology delivers up to 65% less energy consumption compared to conventional ovens. Operators see dramatic savings in both energy and time. Infrared ovens use radiant energy to heat surfaces directly, minimizing waste and maximizing efficiency. The following table highlights the differences between infrared ovens and traditional systems:

Feature | IR Ovens | Conventional Ovens |

|---|---|---|

Energy Consumption | More energy efficient | Consumes more energy |

Operational Costs | Lower operational costs | Higher operating costs |

Drying Times | Significantly faster | Slower drying times |

Manufacturers who switch to infrared heating experience faster drying cycles and lower energy bills. The direct application of infrared energy ensures that only the product receives heat, which eliminates unnecessary energy loss. This targeted approach supports long-term savings and improved energy efficiency.

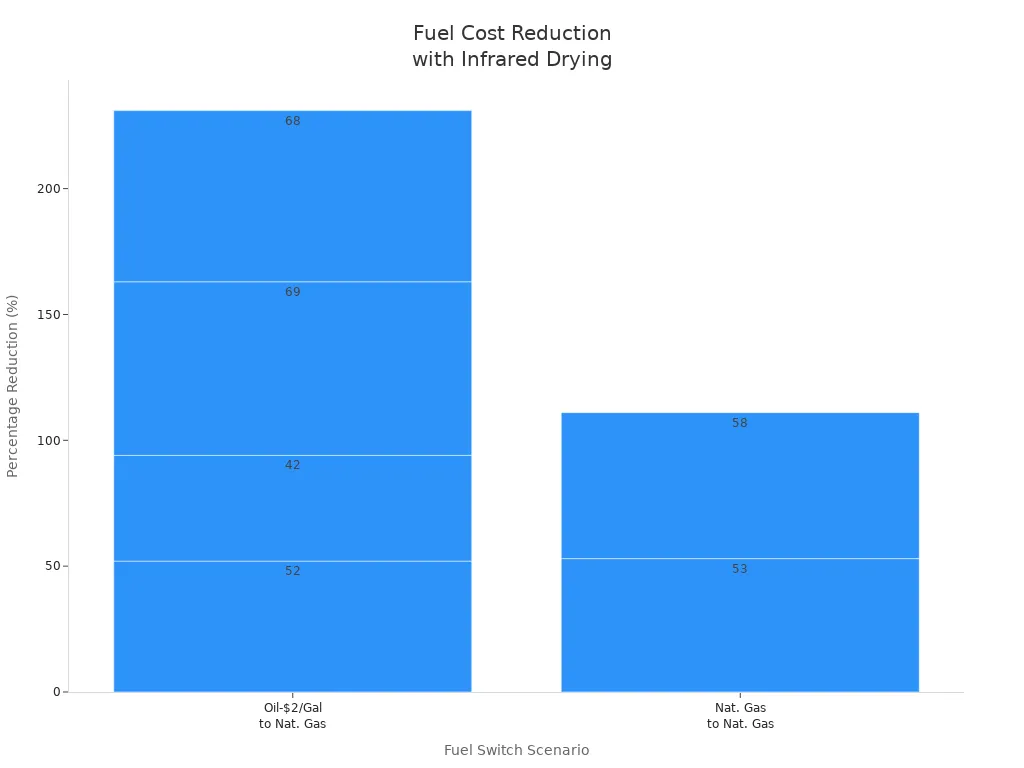

Infrared heating systems from Huai'an Infrared Heating Technology offer substantial reductions in fuel costs. Facilities report annual savings ranging from 20% to 50% after upgrading to infrared paint drying solutions. The following table demonstrates the cost savings achieved by switching to infrared heating:

Previous Fuel Cost | New Fuel Cost | Annual Savings | Percentage Reduction |

|---|---|---|---|

Oil - $2/Gal | Nat. Gas | $20,855 | 52% |

Nat. Gas | Nat. Gas | $8,280 | 53% |

Nat. Gas | Nat. Gas | $8,140 | 58% |

Oil - $2/Gal | Nat. Gas | $7,060 | 42% |

Oil - $2/Gal | Nat. Gas | $7,452 | 69% |

Oil - $2/Gal | Nat. Gas | $41,692 | 68% |

Operators benefit from low operating costs and consistent performance. Infrared heating modules convert up to 96% of input energy into usable heat, which further enhances energy efficiency and savings. These improvements support a more sustainable and eco-friendly heating solution for industrial environments.

Infrared ovens feature compact designs that maximize floor space and streamline operations. Facilities using infrared heating systems observe several improvements in operational efficiency:

Improvement Type | Description |

|---|---|

Fast Response and Shorter Cycle Times | Infrared heating elements reach process temperatures rapidly, reducing overall cycle times. |

High Heating Rates and Efficiency | Infrared ovens convert up to 88% of input energy into usable heat, minimizing waste. |

Precise, Controllable Output | Advanced control systems enable fine-tuning of temperature profiles for sensitive materials. |

Uniform and Consistent Heating | Infrared ovens deliver superior temperature uniformity, preventing hot spots during processing. |

Lower Maintenance Requirements | Fewer moving parts lead to reduced downtime and maintenance costs. |

Reduced Noise | Minimal air movement results in quieter operation, enhancing workplace comfort. |

Operators select infrared heating for its reliability and space-saving benefits. Compact ovens allow for flexible installation and integration into existing production lines. The efficiency of infrared heating supports higher throughput and long-term savings.

Infrared paint drying systems contribute to a cleaner industrial environment. Facilities experience several advantages when using infrared heating:

Infrared curing significantly reduces curing time, allowing coatings to harden in 4 to 8 hours instead of several days or weeks.

Controlled heat from infrared lamps accelerates solvent evaporation, resulting in more durable and effective coatings.

Faster curing minimizes imperfections, producing a cleaner finish and reducing waste.

Operators value the eco-friendly heating solution provided by infrared technology. The reduction in energy consumption and waste supports sustainability goals and improves workplace safety. Infrared heating systems help manufacturers achieve energy efficiency while maintaining high standards for product quality.

Infrared heating technology from Huai'an Infrared Heating Technology delivers measurable energy efficiency, cost savings, and operational improvements. Facilities that adopt infrared solutions benefit from reduced energy use, lower fuel costs, and a cleaner, more efficient production environment.

Infrared paint drying technology has become essential in many sectors. Companies rely on infrared heating to improve efficiency, reduce energy consumption, and deliver consistent results. The following table highlights common industries and their specific use cases:

Industrial Sector | Specific Use Case |

|---|---|

Coating Industry | Drying and curing painted products such as automobiles, furniture, and home appliances. |

Electronics Industry | Curing, soldering, and drying electronic components for stable performance. |

Food Industry | Baking and drying food products to enhance taste and shelf life. |

Other Fields | Drying plastic films, printing inks, and shaping textiles for efficient heating. |

Automotive manufacturers use infrared heating to cure paint on vehicles and parts. This method ensures a flawless finish and reduces the risk of defects. Infrared lamps from Huai'an Infrared Heating Technology deliver rapid, uniform heat, which shortens drying cycles and increases throughput. Operators can adjust the wavelength for optimal energy transfer, matching the paint type and substrate. The result is a durable, high-quality surface that meets industry standards.

Manufacturing facilities integrate infrared heating into their production lines for drying coatings, adhesives, and inks. The technology supports precise, non-contact heating, which is ideal for sensitive materials. Infrared systems heat only the target area, minimizing wasted energy and improving process control. Huai'an’s CE-certified and TUV-compliant infrared lamps offer seamless integration, allowing manufacturers to upgrade existing lines with minimal disruption.

Agricultural operations benefit from infrared heating in seed drying, greenhouse climate control, and equipment coating. Infrared technology provides fast, even drying, which preserves product quality and reduces spoilage. Farmers and equipment manufacturers value the energy savings and reliability of Huai'an’s infrared solutions. The compact design of these systems fits easily into agricultural facilities, supporting efficient workflows.

Operators in every sector appreciate the ability to tailor infrared emitters to specific products and processes. This customization ensures efficient energy transfer and precise heating, even for small or complex components.

Many industries have reported measurable improvements after adopting infrared paint drying. Curing times often drop by 50-75% compared to convection methods, allowing parts to cure in minutes. This acceleration increases production capacity and reduces energy costs.

Technology | Measurable Result | Impact on Process |

|---|---|---|

REVO Accelerated | Curing time reduced by hours, enabling more repairs in less time. | Increases throughput and technician efficiency. |

REVO Speed | Fastest curing time, reducing repair cycle time and rework. | Enhances overall repair efficiency. |

Infrared Curing | Curing times 50-75% faster than convection, parts cure in minutes. | Improves energy efficiency and reduces costs. |

Curing times reduced by hours with advanced infrared systems.

Fastest curing cycles in the industry, minimizing rework and delays.

Direct heating leads to significant energy savings and lower operational costs.

Huai'an Infrared Heating Technology’s products demonstrate these benefits across automotive, manufacturing, and agricultural applications. Their CE certification and TUV compliance guarantee safety and reliability. Integration remains straightforward, making it easy for operators to upgrade and realize immediate gains in efficiency and energy use.

Industrial environments demand robust safety measures. Infrared paint drying systems from Huai'an Infrared Heating Technology prioritize operator safety through advanced protection features. Each infrared heating module includes thermal cut-off switches and temperature sensors. These components monitor the system and prevent overheating. Operators benefit from automatic shut-off functions, which reduce the risk of accidents. The design of the infrared lamps ensures that surfaces remain cool to the touch, even during extended operation. This feature protects workers from burns and other injuries.

A clean and safe workspace remains essential in every facility. Infrared heating technology produces minimal emissions and does not require open flames or combustible fuels. This approach lowers the risk of fire and exposure to harmful substances. Operators can work confidently, knowing that the infrared systems support a secure environment.

Safety features in modern infrared heating systems help companies maintain compliance with workplace regulations and protect their teams.

Certifications play a critical role in verifying the safety and quality of infrared paint drying products. Huai'an Infrared Heating Technology ensures that each infrared heating solution meets strict international standards. The following table highlights key certifications that support product reliability and safety:

Certification | Description |

|---|---|

CE | Conformity to European standards |

LVD | Low Voltage Directive compliance |

SGS | Quality assurance certification |

ISO | International Organization for Standardization |

ROHS | Restriction of Hazardous Substances compliance |

These certifications confirm that the infrared heating equipment operates safely and efficiently. They also demonstrate a commitment to environmental responsibility and product excellence.

Reliability defines the performance of any industrial heating system. Huai'an Infrared Heating Technology designs its infrared lamps for long service life and consistent output. Each infrared heating module undergoes rigorous testing before leaving the factory. Operators experience fewer breakdowns and less downtime, which supports continuous production.

Infrared heating systems deliver stable energy transfer, ensuring that every drying cycle meets quality standards. The robust construction of the infrared lamps withstands demanding industrial conditions. Facilities that use these systems report high levels of satisfaction with both performance and durability.

Reliable infrared heating technology helps companies achieve consistent results, reduce maintenance costs, and maintain a strong reputation for quality.

Automation continues to transform the industrial landscape, especially in infrared paint drying. Modern paint booths now feature advanced automation that streamlines the drying process. These systems use precise controls to manage heat application and airflow, which leads to consistent results and reduced manual intervention. Modular interfaces allow seamless integration of infrared drying units into automated production lines. This integration boosts productivity and ensures each product receives the optimal amount of infrared energy for drying.

Automation Feature | Impact on Infrared Paint Drying |

|---|---|

Smart automation in paint booths | Enhances efficiency with advanced controls and energy management |

Controlled heat and airflow | Optimizes drying, reduces waste, and improves finish quality |

Modular system interfaces | Enables easy integration into automated production environments |

Automated infrared heating systems help operators maintain high throughput while minimizing errors. Facilities that adopt these solutions see faster cycle times and improved energy savings.

Smart controls play a vital role in optimizing infrared paint drying operations. These systems automatically monitor and adjust energy use, which maximizes efficiency. Operators can make real-time adjustments to airflow, temperature, and humidity, ensuring each batch receives the right conditions for drying. Smart controls also provide instant data on energy usage, helping facilities identify areas for further improvement.

Smart control systems enhance energy efficiency by monitoring and optimizing energy use.

Real-time adjustments to airflow, temperature, and humidity ensure maximum operational efficiency.

Operators receive immediate feedback on energy consumption, supporting continuous improvement.

Automated settings adapt to the size and complexity of each job, reducing waste and unnecessary energy use.

Facilities that implement smart controls in their infrared heating systems achieve greater consistency and lower operational costs.

Sustainability remains a top priority for industries using infrared paint drying. Recent advancements in infrared heating technology, such as medium-wave carbon infrared emitters, have significantly improved energy efficiency. These emitters use up to 30% less energy than conventional short-wave emitters, making them ideal for drying water-based inks and coatings. Accelerated heating reduces overall energy consumption, which lowers greenhouse gas emissions and supports environmental goals.

Advancement Type | Benefit Description |

|---|---|

Medium-wave carbon infrared emitters | Improve energy efficiency and drying effectiveness for water-based inks and coatings |

Energy consumption | Carbon emitters use up to 30% less energy than short-wave emitters |

Heating acceleration | Faster heating with reduced energy use, enhancing overall drying efficiency |

Infrared heating systems also contribute to cleaner production environments. They eliminate the need for open flames and reduce the release of volatile organic compounds. Companies that invest in advanced infrared technology demonstrate a commitment to both operational excellence and environmental stewardship.

The future of industrial paint drying will rely on smarter, more efficient infrared solutions that save energy and protect the environment.

Infrared heating delivers faster drying, lower energy use, and greater efficiency for industrial paint applications. Companies like Huai'an Infrared Heating Technology lead the way with advanced solutions that boost productivity and cut costs. Experts recommend upgrading to infrared heating for applications such as chipboard, roofing, and furniture, where results include better quality and shorter drying times:

Application | Technology Used | Benefits |

|---|---|---|

Laminated Chipboard Production | Fast Response Mediumwave Infrared Heaters | Improved quality control, reduced power demand |

Roofing Panels | Shortwave NIR Technology | Better foam adhesion, safety improvements |

Furniture Manufacturing | Medium Wave Infrared Heaters | |

High-End Consumer Products | Medium Wave Carbon Infrared Lamps | Energy savings, even heat application |

Technology advancements and regulatory compliance drive adoption.

European innovation sets new standards for precision and smart connectivity.

The future of industrial drying will rely on smarter, more sustainable infrared heating systems that help businesses stay competitive.

Industrial IR paint drying uses infrared lamps to heat and cure paint on surfaces. The process delivers rapid drying, energy savings, and consistent results. Operators choose this method for its efficiency and reliability in industrial environments.

Infrared paint drying targets only the painted surface. The technology converts up to 96% of input energy into usable heat. Facilities report up to 65% less energy consumption compared to conventional ovens.

Automotive, manufacturing, agriculture, and electronics industries use infrared paint drying. Operators rely on this technology for coating, curing, and drying applications. The versatility of infrared lamps supports a wide range of industrial needs.

Huai'an Infrared Heating Technology designs infrared systems with advanced safety features. Thermal cut-off switches and temperature sensors protect operators from overheating and burns. The systems produce minimal emissions, supporting a safe work environment.

Huai'an Infrared Heating Technology offers Short Wave, Medium Wave, and Carbon Infrared Lamps. Each type suits specific applications, such as rapid drying, gentle heating, or water-based coatings. Operators select the lamp based on material and process requirements.

Infrared paint drying delivers uniform heat distribution. Operators achieve consistent finishes and reduce defects. The technology supports strict quality control, helping manufacturers meet industry standards.

Infrared heating modules from Huai'an Infrared Heating Technology feature compact designs and advanced controls. Operators integrate these systems easily into existing lines. CE certification and TUV compliance ensure reliable performance and safety.

Huai'an Infrared Heating Technology’s lamps carry CE certification and TUV compliance. These certifications confirm product safety, reliability, and adherence to international standards.

Tip: For more details on product specifications, contact Huai'an Infrared Heating Technology or visit their official website.

IR Paint Drying in 2025: The Ultimate Beginner's Guide To Faster, Eco-Friendly Curing

Infrared Paint Drying: How It Speeds Up Production Without Sacrificing Finish Quality

Infrared Powder Coating Lamps: Pros, Cons, and Key Benefits Explained

How Infrared Heaters Help You Achieve a Smooth, Professional Paint Finish