Author: Site Editor Publish Time: 2025-10-29 Origin: Site

In today’s manufacturing industry, achieving efficient, precise, and clean heating is vital. Among all industrial heating technologies, the infrared heating lamp has become a preferred solution for coating drying, metal treatment, and composite processing. Its speed, control, and energy efficiency make it a cornerstone of modern production lines.

An infrared heating lamp emits electromagnetic radiation in the infrared spectrum, which directly transfers energy to objects without relying on air as a medium. Unlike convection systems, IR lamps heat materials from the inside out, providing faster, cleaner, and more uniform results.

For instance, during steel paint drying, infrared energy penetrates the paint layer and heats the steel substrate simultaneously, resulting in a smooth, defect-free surface finish. This process is especially efficient when using high-intensity short-wave IR lamps designed for industrial coatings.

To explore how these systems are designed for heavy-duty applications, see our page on Infrared Heating Systems for Industrial Applications.

Infrared lamps can be categorized by wavelength, lamp structure, and application type. Understanding these distinctions is key to selecting the right heating source for your process.

| Type | Wavelength Range | Key Features | Common Applications |

|---|---|---|---|

| Short-Wave (Near-IR) | 0.8–2.5 µm | Extremely fast response, deep heat penetration | Metal and steel coating drying, automotive painting |

| Medium-Wave IR | 2.5–6 µm | Balanced heating and surface efficiency | Plastic molding, coating drying, paper processing |

| Long-Wave IR | >6 µm | Gentle heating for sensitive materials | Wood drying, comfort and environmental heating |

If you’re unsure which wavelength fits your process, refer to our Infrared Lamp Selection Guide for detailed wavelength–material matching recommendations.

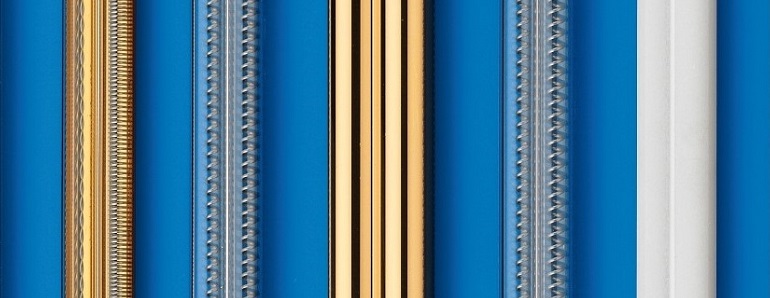

Infrared heating lamps differ by construction and emitter material:

Quartz Tube IR Lamps: Ideal for short-wave heating; fast on/off response.

Carbon Fiber Lamps: Medium-wave emission with high efficiency and longer lifespan.

Ceramic Infrared Emitters: Designed for low-temperature, long-wave applications.

Gold Reflector IR Lamps: Use reflective coatings to maximize directional heating efficiency.

To learn more about reflective lamp advantages, see our Gold Reflector IR Lamp Solutions.

Infrared heating lamps are applied across a wide range of industries:

Drying and Curing: Paint, ink, and adhesive coatings.

Pre-Heating and Forming: Glass, plastic, and metal forming lines.

Environmental and Comfort Heating: Architectural or cleanroom heating systems.

Each application requires careful tuning of lamp power, wavelength, and arrangement to achieve uniform heating and process control.

Selecting the right infrared lamp depends on multiple factors:

Every material absorbs infrared energy differently.

Metals absorb short-wave IR effectively.

Coatings and plastics perform best under medium-wave IR.

The correct wavelength minimizes energy waste and prevents surface overheating.

High-speed production lines benefit from lamps with high radiant flux and fast thermal response. Infrared lamps can be configured in modular heating zones to match conveyor speeds or curing times, ensuring uniform treatment.

The geometry of the lamp array affects heating uniformity.

For example:

Vertical panels for large sheets.

Tunnel-shaped assemblies for continuous lines.

Zoned arrays for width/thickness variation.

Learn more about customized configurations on our Infrared Heating Solutions Page.

Infrared lamps achieve 20–50% higher energy efficiency than convection ovens. Heat is applied only where it’s needed — directly on the target surface — reducing energy loss. Zoned control and reflective coatings further enhance performance.

Modern systems use PLC or SCR controllers to manage lamp output dynamically. Real-time temperature sensors ensure process precision while maintaining safety through automatic shutdown mechanisms and heat shielding.

In a typical steel coating line, infrared heating lamps provide rapid, uniform drying without damaging the surface.

Step 1: Short-wave IR penetrates both paint and steel substrate.

Step 2: The substrate heat assists in curing the paint from within.

Step 3: Temperature sensors maintain stability across varying thicknesses.

Step 4: Drying time is reduced by up to 60% compared to hot-air systems.

The result is a high-quality, glossy finish with minimal energy cost and shorter production cycles.

For more details, see our dedicated overview of Infrared Paint Drying Lamps.

Plastic Forming: Pre-heating before thermoforming improves surface quality.

Glass Processing: Controlled IR heating enables even bending and coating.

Textile and Film Drying: Rapid moisture evaporation preserves material integrity.

Powder Coating Curing: Infrared lamps achieve consistent finishes with lower energy input.

| Benefit | Description |

|---|---|

| Fast Response | Immediate heat generation without preheating. |

| Energy Savings | Direct radiation reduces system losses. |

| High Productivity | Faster curing and drying increase line output. |

| Compact Design | Space-efficient compared to convection ovens. |

| Improved Product Quality | Minimizes defects and surface irregularities. |

| Clean Operation | No combustion or air contamination. |

Evaluate Material Absorption: Identify which IR wavelength provides optimal heating.

Perform Energy Simulation: Determine lamp power and spacing for uniform heating.

Use Reflectors: Gold or ceramic reflectors increase radiant efficiency.

Control Temperature Precisely: Employ zoned and feedback-controlled operation.

Maintain Clean Surfaces: Keep lamp tubes and reflectors free of dust for consistent output.

At Huai’an Yinfrared Heating Technology, we specialize in developing customized infrared lamp systems designed for industrial coating, drying, and forming applications.

We provide:

Tailored wavelength solutions based on your materials.

Modular lamp assemblies for new or retrofitted lines.

Engineering support from design to installation.

Reliable after-sales maintenance and technical consultation.

Explore our full range of Infrared Heating Products to find solutions built for your manufacturing environment.

Infrared heating lamps offer an unmatched combination of speed, efficiency, and precision. Whether for steel coating, plastics forming, or textile drying, they deliver superior results while reducing energy costs and environmental impact.

By choosing Huai’an Yinfrared Heating Technology, you gain access to decades of expertise in wavelength control, lamp engineering, and process optimization — ensuring your system operates at peak performance.