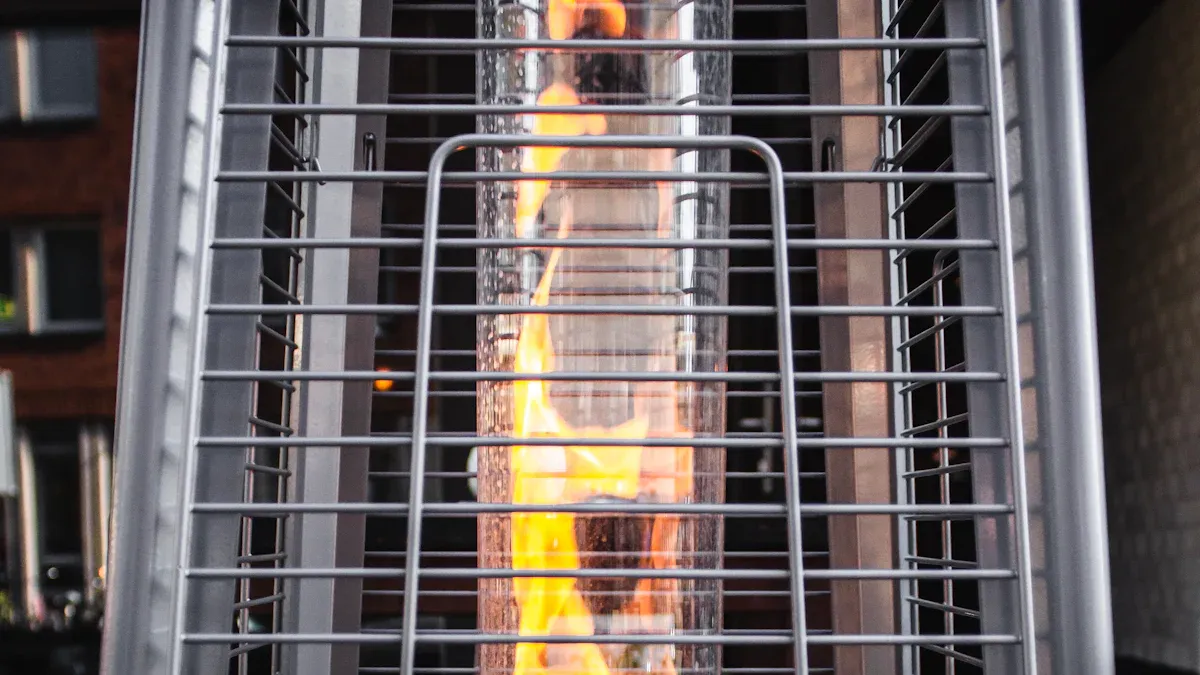

Infrared heating systems deliver targeted thermal energy using advanced electromagnetic technology. These systems provide precise and efficient heat, making them essential for industrial environments that demand both accuracy and energy savings. Factories, warehouses, distribution centers, garages, and workshops often rely on infrared heating solutions to maintain optimal working conditions. Many facilities use these heating systems for zonal heating, ensuring that specific work areas or production lines receive consistent warmth without wasting energy on unused spaces. Modern designs focus on durability and performance, setting high standards for innovation and quality.

Infrared heating systems deliver direct, efficient heat by warming objects and surfaces instead of air, saving energy and improving comfort.

These systems heat quickly, often reaching full power in seconds, which speeds up industrial processes and reduces fuel costs.

Different types of infrared heaters suit various needs, including short-wave for fast heating and carbon heaters for gentle, even warmth.

Infrared heating improves air quality by avoiding air movement, reducing dust and allergens in the workplace.

Though initial costs and installation require planning, infrared systems offer long-term savings through lower energy use and maintenance.

Infrared heaters are widely used in industries like manufacturing, paint drying, agriculture, and warehousing for precise and reliable heating.

Regular maintenance, including cleaning and inspections, keeps infrared systems safe and efficient over their long lifespan.

Choosing the right infrared heating solution and professional installation ensures optimal performance and energy savings.

Infrared heating systems operate by emitting infrared radiation, a form of electromagnetic energy with wavelengths between 700 nanometers and 1 millimeter. Infrared heaters use specialized elements, such as quartz IR emitters, to generate this energy. When activated, these emitters release infrared radiation that travels through the air and directly interacts with objects and surfaces. Unlike conventional heating systems, which rely on heating the air, infrared heating technology focuses on transferring energy through radiant waves. This process mimics the way sunlight warms the earth, providing direct and consistent heat.

Infrared radiation comes in several types, including short-wave, medium-wave, and long-wave. Each type suits different industrial environments and applications. Short-wave infrared heaters deliver intense, rapid heat, making them ideal for processes that require quick temperature changes. Medium-wave and long-wave infrared heaters provide gentler, more uniform heating, which benefits applications like paint drying and glass tempering. The efficiency of infrared heating systems depends on the temperature of the emitter, as higher temperatures result in greater radiant energy output.

Infrared heating systems excel at direct object heating. Infrared radiation passes through the air without warming it, targeting only the surfaces and materials in its path. This radiant energy penetrates both the surface and interior of objects, ensuring uniform heating. Industrial infrared heaters, such as those produced by Huai’an Infrared Heating Technology, use advanced quartz IR emitters to maximize this effect. These emitters reach full power within seconds, enabling rapid heating and minimizing energy waste.

Direct object heating offers several advantages. It eliminates the need for air circulation, reducing dust movement and improving air quality. Infrared heaters provide even warmth, preventing cold spots and stratification. The focused nature of radiant heating allows facilities to target specific zones, optimizing energy use and reducing operational costs.

Infrared heating systems differ fundamentally from conventional air-based heating systems. Traditional heaters rely on convection, where heated air circulates through ducts or open spaces to transfer warmth. This method often leads to uneven heating, energy loss, and the movement of dust and allergens. Infrared heaters, on the other hand, use radiant energy to warm objects directly, bypassing the air as a medium.

Infrared heaters transfer heat through radiation, delivering targeted warmth to surfaces and people.

Conventional heating systems use convection, heating air that then warms objects indirectly.

Radiant heating provides consistent, even warmth without causing air movement or noise.

Infrared heating avoids common issues like dust circulation and cold spots, making it a healthier and more efficient choice for industrial environments.

Facilities that adopt infrared heating technology benefit from improved comfort and reduced operating costs. The absence of air movement also enhances workplace safety and cleanliness.

Response time plays a critical role in industrial heating applications. Infrared heaters, especially those equipped with quartz IR emitters, offer instantaneous heating. These systems reach full power in one to two seconds, delivering rapid and intense heat suitable for demanding processes. Conventional heating systems require longer preheating phases, as they must first warm the air before transferring heat to objects.

Heater Type | Response Time Characteristics | Comparison to Traditional Heating Systems |

|---|---|---|

Quartz Infrared Heaters | Instantaneous heating; rapid, intense heat for high-heat tasks | Faster response due to direct radiant energy delivery |

Ceramic Infrared Heaters | Up to 5 minutes to reach full temperature | More efficient than convection systems |

Metal-Sheathed Infrared Heaters | Additional time to heat up but durable | Still faster than traditional systems |

General Infrared Heating | Rapid heat-up by direct radiant energy transfer | Higher thermal efficiency and faster response |

Infrared heating systems provide fast heating rates and higher thermal efficiency. The direct transfer of radiant energy ensures that industrial processes can start quickly, improving throughput and reducing energy consumption. Facilities using infrared heaters experience significant energy savings, with up to 50% lower fuel costs compared to conventional heating systems.

Huai’an Infrared Heating Technology’s quartz IR emitters exemplify these benefits. Their products offer precise temperature control, strong penetrating power, and directional heating, all of which contribute to superior efficiency and performance in industrial settings.

Infrared heating systems offer a diverse range of solutions tailored for industrial and commercial environments. Facilities select from several types of infrared heaters, heating panels, and industrial emitters to meet specific process requirements and spatial constraints.

Infrared heaters deliver targeted radiant energy for efficient and precise heating. Manufacturers design these devices to suit various wavelengths and applications.

Short wave infrared heaters operate at high temperatures and emit energy with wavelengths between 0.78 and 1.4 micrometers. These heaters excel in manufacturing lines, automotive paint drying, and plastic forming. Quartz tube heaters, a common short wave heat lamp, provide rapid response and large surface coverage. Facilities benefit from fast heating and high temperature output, making these infrared heaters ideal for processes demanding quick thermal changes.

Medium wave infrared heaters emit energy with wavelengths from 1.4 to 3 micrometers. These devices suit applications such as packaging equipment, laboratory instruments, and semiconductor processing. Ceramic infrared heaters, often used in this category, deliver localized heat and withstand high temperatures. Their compact design and ceramic core insulation ensure reliable performance in environments requiring precise temperature control.

Fast medium wave infrared heaters bridge the gap between short and medium wave devices. These heaters reach operating temperature within seconds and provide uniform heating. Twin tube lamps, such as those from Huai’an Infrared Heating Technology, offer enhanced strength and flexibility for industrial paint drying and glass tempering. Facilities use these infrared heaters for processes that require both speed and consistency.

Carbon infrared heaters utilize carbon fiber elements to produce medium to long wave infrared energy. These heaters deliver gentle, even warmth and maintain stable performance over extended periods. Facilities often install carbon infrared heaters in environments where comfort and air quality matter, such as warehouses and agricultural spaces. Their energy efficiency and low glare make them suitable for both indoor and outdoor applications.

Tip: Selecting the right infrared heater depends on the process requirements, desired response time, and the nature of materials being heated.

Infrared heating panels provide direct radiant heat through solid, wall- or ceiling-mounted devices. These panels operate at surface temperatures between 80°C and 120°C, ensuring quick and efficient heating for targeted indoor spaces.

Wall and ceiling mount infrared heating panels offer versatile installation options. Facilities use these infrared heating devices in offices, bathrooms, and production areas where focused heating is needed. The slim profile and good insulation prevent energy loss, while the mounting distance ensures optimal radiant coverage. Unlike heating films, which are hidden and suited for whole-room heating, panels remain visible and easy to maintain. Their design supports efficient, direct heating without relying on convection.

Feature | Industrial Infrared Heating Panels | Other Infrared Heaters / Hybrid Heaters |

|---|---|---|

Wattage Density | Around 1000-1200W per square meter | Can be higher or lower; hybrid heaters often have misleading wattage density (e.g., 2000W at small size, mostly convection) |

Surface Temperature | At least 80-90°C (effective infrared radiation) | Often lower (40-50°C), indicating convection or hybrid heating |

Insulation Level | Good insulation to prevent energy loss; low backside temperature | Poor insulation leads to heat loss through backside, warming walls instead of room |

Thickness | Slim profile around 2cm thickness; mounting distance 4-5cm | Thicker (around 10cm) due to need for air gap for convection |

Industrial emitters form the backbone of many infrared heating systems. These components deliver high-intensity radiant energy for demanding industrial processes.

Quartz IR emitters stand out for their durability and rapid heating capabilities. Facilities rely on these emitters for manufacturing, paint drying, and plastic molding. The advanced design, including gold reflector technology, directs over 92% of electrical energy as usable heat. Quartz IR emitters reach temperatures above 800°C, supporting harsh industrial environments and reducing operational costs. Their long lifespan and low maintenance requirements make them a preferred choice for automated production lines. Huai’an Infrared Heating Technology offers a comprehensive range of quartz IR emitters, including YFR Gold Reflector Quartz Halogen Infrared Heaters and Twin Tube Lamps, ensuring consistent and uniform heating.

Advantages of quartz IR emitters:

Rapid heating and precise temperature control

High energy efficiency and reduced downtime

Long service life and resistance to corrosion

Seamless integration into automated systems

Round tube lamps provide flexible infrared heating for various industrial applications. These heat lamps feature a quartz tube construction and deliver both infrared and convection heating. Facilities use round tube lamps for furnace environments, zoning, and processes requiring customizable arrays. The robust design ensures reliable performance in dusty, moist, or explosive atmospheres.

Common industrial applications:

Manufacturing lines

Furnace heating

Paint curing

Wafer processing

Note: Huai’an Infrared Heating Technology supplies a wide range of infrared heaters, heat lamps, and infrared heating devices, including quartz IR emitters, twin tube lamps, and carbon infrared heaters. Their products support diverse industrial needs and offer tailored solutions for specialized applications.

Industrial facilities increasingly choose infrared heating systems for their exceptional energy efficiency. These systems convert up to 96% of input energy into usable heat, making them a leading choice for energy-efficient heating in demanding environments. Quartz IR emitters, such as those from Huai’an Infrared Heating Technology, deliver this high conversion rate by focusing radiant energy directly on objects and surfaces. This direct transfer minimizes heat loss and ensures that nearly all generated energy contributes to the heating process.

Infrared panels and heaters stand out for their ability to provide targeted warmth. Unlike conventional systems that waste energy by heating large volumes of air, infrared technology delivers radiant heat precisely where it is needed. This approach not only reduces energy consumption but also supports sustainable operations.

Switching to infrared heating systems can result in substantial fuel cost savings for industrial users. Facilities often report reductions in fuel expenses ranging from 30% to 50%. For example, GM’s Inland Division plant in Euclid, Ohio, achieved a remarkable 75% reduction in energy costs after installing gas infrared heaters, lowering annual energy expenses from $106,000 to $27,000. Textile companies have also reported annual savings of approximately $47,000 by integrating infrared booster ovens, which cut drying times in half.

The following table highlights the operational advantages of infrared heating compared to conventional systems:

Metric | Infrared Heating System | Conventional Heating System |

|---|---|---|

Process Efficiency | 85% | 15% |

Annual Energy Usage | 2,541,176 kWh | 44,000 MMBTU |

Annual Scrap Losses | $100,000 | $200,000 |

Annual Maintenance Labor Cost | $13,500 | $54,000 |

Total Annual Operating Cost | $410,400 | $557,000 |

These figures demonstrate that infrared heating systems not only lower fuel costs but also reduce maintenance and scrap losses, further improving the bottom line for industrial operations.

Infrared heating systems provide a unique approach to workplace comfort. By delivering radiant energy directly to objects and people, these systems create a warm and comfortable environment without relying on air movement. While some concerns exist about perfectly uniform heat distribution in very large spaces, most industrial designs offer highly effective localized heating. This targeted approach ensures that work zones remain comfortable, even in facilities with high ceilings or open layouts.

Targeted radiant heat reduces cold spots.

Employees experience consistent warmth in designated areas.

Facilities can adjust heating zones for maximum comfort and efficiency.

One of the most significant advantages of infrared heating lies in its ability to maintain air quality. Traditional convection systems circulate air, which can stir up dust and allergens. Infrared heaters, by contrast, operate silently and do not require fans or blowers. This absence of air movement leads to a cleaner, healthier workspace and minimizes the spread of airborne particles.

Facilities that prioritize air quality and employee well-being often select infrared heating for its ability to deliver warmth without compromising indoor environmental standards.

Infrared heating systems support sustainability goals by minimizing emissions and reducing energy consumption. These systems use direct radiant heat, which warms objects and people efficiently, resulting in lower overall wattage requirements compared to convection-based electric heaters. When powered by renewable energy sources, infrared panels and heaters produce virtually zero on-site emissions, making them a clean alternative to gas or oil-based systems.

Aspect | Infrared Panels | Electric Heaters |

|---|---|---|

Energy Efficiency | Nearly 100% at point of use | Nearly 100% at point of use |

Energy Consumption | Lower wattage due to direct radiant heat | Higher wattage due to convection |

Heating Method | Direct radiant heat warms objects/people | Mainly heats air via convection |

Environmental Impact | Greener with renewables; no emissions | Greener with renewables; no emissions |

Heat Loss | Minimal due to direct heating | More heat loss as air warms and disperses |

Control | Precise zonal heating | Less efficient due to convection |

Infrared heating aligns with global efforts to reduce carbon emissions and promote energy-efficient solutions. Facilities benefit from lower energy bills, a smaller carbon footprint, and the ability to implement zonal heating, which avoids wasting energy on unused spaces.

Infrared heating systems represent a greener, more sustainable choice for industrial and commercial applications, especially when paired with renewable energy sources.

Leading manufacturers of industrial infrared heating systems, such as Huai’an Infrared Heating Technology, demonstrate a strong commitment to quality and safety. Their products carry certifications like License Verified Reports, Certificates of Conformity, TUV certification, and Trademark Registration Certificates. Across the industry, companies often hold ISO 9001:2015 certification, CE Marking, and UL Standard 499 approval, ensuring compliance with international standards for product safety, reliability, and environmental protection.

These certifications provide assurance that infrared heating systems meet rigorous quality benchmarks and deliver consistent, high-performance results in demanding industrial environments.

Industrial facilities often face significant upfront costs when adopting infrared heating systems. High-quality infrared heaters, panels, and emitters require advanced materials and engineering, which increases the initial investment. Companies must budget for specialized equipment, including quartz IR emitters and control modules. These components deliver precise infrared radiation but come at a premium compared to conventional heating units.

Installing infrared heating systems presents unique challenges in industrial environments.

High ceilings can cause warm air to rise away from work zones, making ground-level heating less effective.

Large open spaces demand strategic placement of infrared heaters to avoid cold spots and ensure even coverage.

Poor insulation leads to substantial heat loss, reducing the efficiency of infrared radiation.

Frequent door openings allow cold air to enter and warm air to escape, complicating temperature maintenance.

Zoning becomes necessary because different areas have distinct heating needs that a single system may not address.

Infrared panels typically reach only about three meters, so precise placement is essential to maximize the reach of infrared radiation.

Obstacles such as machinery or shelving can block the direct line-of-sight heating that infrared systems rely on.

Improper installation or mounting reduces heating effectiveness and may increase running costs, especially if electricity prices fluctuate.

Infrared heating systems excel in targeted applications but require careful assessment of the industrial space. Warehouses, hangars, and production halls benefit from direct, even warmth provided by infrared radiation. These systems focus heat on occupied zones, minimizing heat loss even with open doors or drafts. However, very large open spaces or segmented zones may need multiple infrared heaters and precise layout planning.

Not every industrial environment suits infrared heating.

Infrared heaters work best in spaces needing focused heating rather than uniform warmth across large volumes of air.

Facilities must evaluate energy source compatibility, such as electricity or natural gas, before installation.

Some heater types, like quartz infrared, deliver rapid, intense heat but are less effective for slow, long-term heating of expansive areas.

Ceramic infrared heaters provide affordable broad heating but take longer to reach full temperature.

Metal-sheathed infrared heaters offer durability for harsh environments but require additional warm-up time.

Heater Type | Best Suited Industrial Spaces | Limitations and Notes |

|---|---|---|

Quartz Infrared | High-heat applications requiring rapid, intense heat; suitable for heating objects in controlled environments | Not suitable for slow, long-term heating of large spaces; best for small, focused heating zones |

Ceramic Infrared | Affordable broad heating for entire rooms or small areas; suitable for space heating in warehouses, production halls | Takes up to 5 minutes to reach full temperature; less ideal for specialized object heating |

Metal-Sheathed Infrared | Rugged industrial environments such as manufacturing plants, logistics hubs, multizone warehouses; suitable for submerged heating of liquids | Requires additional warm-up time; ideal for harsh environments; protects against damage and corrosion |

Near-infrared heating systems operate at extremely high temperatures and pose specific safety risks. Infrared radiation can penetrate deeply into eye tissues, potentially causing thermal injury or eye damage. Prolonged or uncontrolled exposure may lead to skin aging effects and thermal burns. Scientific studies confirm that near-infrared radiation affects the cornea and skin more than far-infrared, which primarily warms tissue without known negative health impacts at typical exposure levels.

Proper installation practices reduce these risks. Facilities must use approved flexible connectors for gas-fired systems, follow venting requirements, and maintain clearances from combustible materials. Modern infrared heaters often feature enclosed heating elements and flame enclosures to minimize fire hazards and burns.

Operating high-temperature infrared heating equipment requires strict safety measures.

Use heating elements designed for high-stress, high-temperature environments to minimize accident risks.

Perform regular inspections to detect wear, oxidation, or damage and remove residue to maintain efficiency.

Ensure proper installation with uniform spacing and compatible electrical connections to prevent hotspots and mechanical strain.

Inspect wiring connections and heater housing for damage, keeping vents unobstructed.

Maintain proper mounting away from combustibles and secure mounts firmly.

Follow manufacturer guidelines for operation and maintenance, consulting manuals and digital resources.

Conduct a full inspection before each heating season to prevent failures and ensure safe operation.

Facilities should always consult professionals for installation, maintenance, and repairs. Adhering to manufacturer manuals and local codes ensures safe and reliable use of infrared heating systems.

Effective planning forms the foundation for a reliable infrared heating system in industrial environments. Facility managers begin by conducting safety checks, inspecting lamps, mounting points, and verifying that controls and safety interlocks function properly. They assess process requirements, considering material characteristics, production volume, and energy efficiency goals. Selecting the right infrared lamps involves matching the wavelength and power level to the specific application, whether for paint drying, plastic molding, or glass heating. The installation team mounts and aligns components to ensure even heat distribution and secure placement. Control settings are configured to match the material and process, adjusting temperature and radiation intensity as needed. During startup, operators load materials correctly, activate lamps and circulation fans, and monitor initial temperature and humidity levels. Continuous monitoring with real-time data helps maintain uniform heating and allows for quick adjustments.

Facilities often choose modular designs and accessories, such as power controls and quartz glass, from Huai’an Infrared Heating Technology. These components support flexible layouts and simplify future upgrades.

Professional installation enhances both performance and longevity of industrial infrared heating systems. Certified technicians handle equipment placement, integration, and safety compliance. They evaluate ductwork, perform load calculations, and test system components, including gas pressures, electrical connections, and airflow. Comprehensive testing ensures optimal heat distribution and safe operation. Quality installation directly impacts system efficiency and extends service life. Technicians provide customer education and documentation, supporting proper operation and maintenance. Customized installation plans address unique requirements, such as ductwork modifications and integration with existing systems. Adherence to manufacturer specifications and local codes guarantees quality assurance. Post-installation testing, including combustion analysis for gas-fired equipment, confirms safe exhaust venting and optimal fuel-air mixture. Proper installation reduces energy consumption and delivers significant cost savings over time.

Routine maintenance keeps industrial infrared heating systems operating efficiently and safely. Facility teams regularly clean dust and debris from heating elements and vents, preventing heat output reduction and fire hazards. Monthly inspections of wiring connections check for security, damage, or corrosion. Mounting hardware receives attention to ensure stability. Maintenance schedules and safety protocols protect equipment and maintain performance. Temperature monitoring systems detect malfunctions or inadequate heating. Personnel receive training on proper shutdown procedures to ensure safety during maintenance.

Maintenance Task | Frequency | Purpose |

|---|---|---|

Clean heating elements & vents | Monthly | Prevent heat loss and fire hazards |

Inspect wiring connections | Monthly | Ensure safety and reliability |

Check mounting hardware | Monthly | Maintain heater stability |

Temperature monitoring | Ongoing | Detect malfunctions |

Personnel training | As needed | Ensure safe maintenance procedures |

Annual cleaning and inspection routines extend the lifespan of infrared heating systems. Teams shut off gas and electrical supply before maintenance. They inspect and clean burners, air filters, igniters, blower components, flue pipes, reflectors, and heat exchanger tubes. Dust and debris are removed from blower wheels and burner boxes. Damaged igniters are replaced, and observation windows are cleaned or replaced if necessary. Housing gaskets receive inspection and repair. Flue pipes are checked for soot or dirt and cleaned to avoid obstructions. Reflector sections are wiped with a damp cloth to remove oxidation. Vent terminals and fresh air inlets are kept clear to maintain safety air switch operation. Heat exchanger tubes are visually inspected and cleaned of carbon or scale deposits. Air filters are replaced regularly to maintain combustion efficiency. Burner settings are adjusted to ensure optimal flame characteristics.

Facility managers schedule annual infrared inspections of energized electrical systems, following NFPA 70B recommendations. Critical equipment may require quarterly or semiannual inspections, depending on operational importance and environmental changes. Professional data management systems help track inspection history and optimize schedules.

Industrial facilities investing in infrared heating systems should expect higher initial equipment costs compared to conventional options. Infrared heaters, panels, and emitters use advanced materials such as quartz and carbon, which contribute to their durability and performance. These components deliver precise and efficient heating, making them suitable for demanding industrial environments. The upfront investment covers not only the heaters themselves but also essential accessories like power controls and mounting hardware. Over time, the robust construction of infrared equipment helps reduce the frequency of replacements.

Installation fees for infrared heating systems can vary based on facility size, layout, and the complexity of the heating requirements. Professional installation ensures optimal placement and integration with existing infrastructure. Technicians assess the workspace, plan for even heat distribution, and configure control systems. While the initial installation cost may be higher than that of traditional systems, the long-term benefits often outweigh the upfront expense. Facilities that prioritize energy efficiency and targeted heating find that the investment pays off through improved performance and lower operational costs.

Infrared heating systems stand out for their efficient energy use. These systems typically consume between 75 and 150 watts per square foot, depending on the application and insulation quality. By directly heating objects and people, infrared technology minimizes heat loss and reduces the need to warm large air volumes. This approach leads to lower energy bills and supports sustainability goals. Facilities using infrared heaters often report up to 30% less energy consumption compared to traditional heating methods.

The long-term savings associated with infrared heating systems can be substantial. Facilities benefit from reduced fuel costs, with many reporting savings of 20% to 50% over conventional systems. Infrared heaters require minimal maintenance, which further lowers ongoing expenses. Their long lifespan spreads the initial investment over more years, making them a cost-effective choice for industrial applications. Over time, the combination of lower energy use, reduced maintenance, and fewer replacements results in significant financial advantages.

A direct comparison between traditional and infrared heating systems highlights the advantages of modern infrared technology. The following table summarizes key differences:

Aspect | Infrared Heating Systems | Traditional Heating Systems |

|---|---|---|

Energy Consumption | Up to 30% less energy used, leading to lower bills | Higher energy use due to heating large air volumes |

Heating Method | Directly heats objects and people, minimizing heat loss | Heats air, causing heat loss through ventilation |

Efficiency | Considered 100% efficient under UK SAP regulations | Less efficient due to heat loss |

Long-term Cost Savings | Can reduce heating costs by 30-50% when used efficiently | Higher ongoing energy and maintenance costs |

Maintenance | Low maintenance, minimal servicing needed | More frequent maintenance and repairs |

Lifespan | Longer lifespan, spreading initial cost over more years | Shorter lifespan, more frequent replacements |

Installation Cost | Higher initial cost but offset by long-term savings | Generally lower initial cost but higher operating costs |

Environmental Impact | Lower emissions due to efficient energy use | Higher emissions due to inefficiencies |

Infrared heating systems offer significant long-term operating cost advantages. Their direct heating approach reduces energy consumption and maintenance needs. Although the initial investment may be higher, the savings over time and improved efficiency make infrared technology a smart choice for industrial heating.

Infrared heaters play a vital role in modern manufacturing and processing environments. Facilities across industries rely on these systems for their speed, precision, and energy efficiency. Huai’an Infrared Heating Technology offers a comprehensive range of infrared heaters and emitters, including quartz IR emitters and carbon heaters, to address diverse industrial needs.

Manufacturers use infrared heaters for a variety of processes that demand rapid, uniform heating. These systems excel in:

Embossing, laminating, molding, and thermoforming plastics, where quick and even heat is essential before pressing or shaping.

Cutting and welding plastics, as infrared heaters melt surfaces efficiently and minimize particle formation.

General industrial heating, such as warming engine blocks, mirrors, and filter housings with precise control.

Infrared heaters deliver heat directly to materials, improving production speed and product quality. Facilities benefit from reduced energy consumption and increased throughput.

Paint drying and curing represent key applications for infrared heaters. These systems provide efficient drying of coatings, paints, and varnishes, including water-based and powder coatings. By transmitting radiant energy directly to the coated surface, infrared heaters shorten drying times and enhance finish quality. Many automotive and industrial paint lines use quartz IR emitters from Huai’an Infrared Heating Technology to achieve consistent results and lower operating costs.

The photovoltaic industry depends on infrared heaters for processes like wafer heating and glass tempering. These systems offer precise, contactless heating tailored to the absorption spectrum of the materials. Infrared heaters enable fast, uniform temperature control, which is critical for high-quality solar panel production. Huai’an Infrared Heating Technology provides specialized emitters and modules designed for the unique requirements of photovoltaic manufacturing.

Plastic molding operations require controlled, rapid heating to ensure proper material flow and shape retention. Infrared heaters deliver targeted energy, supporting processes such as deburring, molding, and thermoforming. Facilities use these systems to boost throughput and reduce dwell times, resulting in higher productivity and energy savings.

Facilities seeking tailored solutions can consult Huai’an Infrared Heating Technology for technical support and custom infrared heater configurations.

Infrared heaters also address the unique challenges of commercial environments, such as warehouses and agricultural facilities.

Warehouses often struggle with uneven heating due to large open spaces and frequent door openings. Infrared heaters, especially tube heaters, are customized based on ceiling height and door locations. Strategic placement keeps floors and objects warm, which then radiate heat throughout the space. Zoning with thermostats allows for night setbacks and further energy savings. Many customers report up to 50% lower energy costs compared to forced air systems.

Application Area | Infrared Heater Solution | Key Benefit |

|---|---|---|

Loading docks | Tube heaters | Direct warmth, less heat loss |

Storage aisles | Panel heaters | Even heat, improved comfort |

Open bays | Zoned systems | Energy efficiency |

Agricultural facilities benefit from infrared heaters that provide direct radiant heat to animals and surfaces. These systems deliver instant warmth similar to sunlight, improving comfort and fuel utilization. Infrared heaters work effectively in spaces with high air movement, where conventional systems often fail. Strategic installation over pens or growing areas ensures consistent temperatures and healthier environments for livestock and crops.

Huai’an Infrared Heating Technology offers tailored infrared heater solutions and technical support for specialized commercial and agricultural needs.

Facility managers recognize that infrared heating systems deliver efficient, targeted warmth for industrial and commercial spaces. These systems offer high energy conversion rates, lower fuel costs, and improved air quality. Drawbacks include initial investment and installation planning. Industrial applications range from manufacturing to agriculture.

Factor | Key Considerations | Impact on Adoption Decision |

|---|---|---|

Fuel Selection | Availability, price, emissions, compatibility | Operating costs, sustainability |

Installation Type | Ceiling, wall, floor mounting | Heat distribution, maintenance, space usage |

Innovation Opportunities | Energy efficiency, smart controls, IoT connectivity | Performance optimization, cost savings |

Application Requirements | Facility type, workflow | Tailored heating solutions |

Facility managers should evaluate their facility’s needs and consider advanced solutions like Quartz IR Emitters. Consulting a reputable manufacturer ensures tailored recommendations and reliable support. Explore energy-efficient, high-performance heating options to optimize operations and sustainability.

An infrared heating system uses electromagnetic waves to deliver direct heat to objects and surfaces. Facilities install these systems to achieve efficient, targeted warmth in industrial and commercial environments.

Infrared heating warms objects directly through radiant energy. Traditional heating systems rely on convection, heating air first. Infrared technology provides faster response times and higher energy efficiency.

Manufacturing, automotive, agriculture, and warehousing industries gain significant advantages. These sectors require precise, rapid heating for processes like paint drying, plastic molding, and glass tempering.

Infrared heaters meet strict safety standards. Manufacturers design systems with protective enclosures and certified components. Facilities must follow installation guidelines and conduct regular maintenance to ensure safe operation.

Facility teams perform routine checks, clean heating elements, and inspect wiring monthly. Annual inspections include cleaning burners, reflectors, and filters. Proper maintenance extends equipment lifespan and maintains efficiency.

Tip: Scheduling regular inspections helps prevent downtime and ensures optimal performance.

Facilities often report energy savings of 20% to 50% compared to conventional systems. Infrared heaters convert up to 96% of input energy into usable heat, reducing fuel costs and supporting sustainability goals.

Manufacturers offer tailored solutions. Facilities select from various heater types, wavelengths, and mounting options. Technical support ensures systems match process requirements and spatial constraints.

Application | Recommended Infrared Solution |

|---|---|

Quartz IR Emitters | |

Warehousing | Panel Heaters, Tube Heaters |

Agriculture | Carbon Infrared Heaters |