Author: Site Editor Publish Time: 2025-07-29 Origin: Site

I have seen how advanced IR technology, especially Quartz IR emitters from YFR heating Tech, transforms pet bottle manufacturing with remarkable energy savings. The shift to Energy-efficient PET bottle manufacturing delivers real results. For example, the SoftBoost heating hopper heats rPET granules quickly while cutting energy use by up to 79%. The table below shows how these solutions drive efficiency, support 100% rPET, and optimize every step.

Benefit Category | Description | Quantifiable Impact / Feature |

|---|---|---|

Energy Efficiency | Rapid heating of rPET granules | Up to 79% less energy consumption |

rPET Compatibility | Preserves resin quality for higher recycled content use | Maintains PET properties |

Process Optimization | Real-time energy monitoring | Enhanced operational efficiency |

Waste Reduction | Minimizes resin degradation and scrap | Less waste produced |

VOC and Energy Reduction | Efficient heat recovery and cooling | Lower heating and cooling costs |

Advanced IR technology cuts energy use in PET bottle production by up to 79%, saving costs and reducing environmental impact.

Near-infrared (NIR) heating heats PET preforms faster and more evenly, improving product quality and speeding up production.

Using 100% recycled PET (rPET) is now possible with modern IR systems, supporting circular economy goals and lowering plastic waste.

Lightweighting strategies reduce material use without losing strength, lowering costs and carbon emissions.

Flexible IR heating modules adapt quickly to different bottle shapes and sizes, enabling fast mold changes and high-speed output.

The Double Gate (DoGa) system and preferential heating methods boost energy efficiency and allow precise control of bottle quality.

Leading brands adopt advanced IR technology to meet sustainability targets while maintaining high production rates.

Ongoing innovations in IR heating, recycling, and lightweighting position PET bottle manufacturing for a more sustainable future.

When I look at the fundamentals of IR and NIR heating in PET bottle manufacturing, I see a process built on precision and control. The goal is to heat PET preforms evenly before stretch blow moulding. This prevents defects like thin spots or stress cracks. NIR heating stands out because it matches the absorption spectrum of PET. This means energy transfers more efficiently, and heating happens faster and more uniformly than with older mid-infrared methods.

The science behind this involves the Beer-Lambert Law, which explains how PET absorbs NIR radiation. I adjust lamp distance, power, and preform rotation to achieve a uniform temperature. This ensures every part of the preform—neck, middle, and bottom—reaches the right heat for proper stretching. Consistent rotation and lamp adjustment help me avoid uneven heating zones. With NIR, I can run faster heating cycles, save energy, and use compact equipment. This optimized heating technology also reduces wear on machine parts and lowers cooling needs. I can adapt quickly to different preform sizes and shapes, which keeps production flexible and efficient.

I have watched PET bottle production evolve from traditional, energy-intensive methods to streamlined, efficient systems. In the past, I relied on conduction or convection heating, using electrical resistances or oil-fired heaters. These methods consumed a lot of energy and took longer to heat the material. I needed separate units for drying, crystallizing, and preheating, which made the process complex and increased energy use.

With the introduction of advanced IR technology, I now use infrared rotary dryers that directly heat the polymer chains. This allows me to combine drying and crystallizing into one step. Processing time drops from hours to just 10–20 minutes. I see energy savings of 20–50% compared to traditional methods. The heat distribution is more even, which improves PET material quality and reduces defects. I also notice that the risk of polymer degradation goes down, and the process aligns better with sustainability goals. The shift to IR has made stretch blow moulding more reliable and cost-effective.

Energy efficiency has become a top priority in PET bottle manufacturing. I see the impact not only in lower costs but also in reduced environmental harm. The production of 1,000 PET bottles releases significant carbon dioxide and sulfur oxides. Fine particulate matter and marine aquatic ecotoxicity also pose challenges. The table below shows some of the environmental impacts per 1,000 bottles:

Environmental Impact Category | PET Bottle Emissions / Impact |

|---|---|

Carbon Dioxide (CO2) Emissions | Significant gaseous emissions |

Sulfur Oxides (SOx) Emissions | 2.02 × 10⁻⁶ kg SOx |

Fine Particulate Matter (PM2.5) | Mainly from cooling with compressed air |

Marine Aquatic Ecotoxicity | 481,609.65 kg 1,4-DB eq |

Acidification Potential | 2.02 × 10⁻⁶ kg SOx |

Eutrophication (Calcium Phosphorus) | 0.212 kg PO4 |

By focusing on energy efficiency and using optimized heating technology, I can cut emissions and lower the carbon footprint of every bottle. High-value recycling and efficient processes reduce greenhouse gas emissions and waste. I believe that every improvement in energy use brings us closer to a more sustainable future for PET packaging.

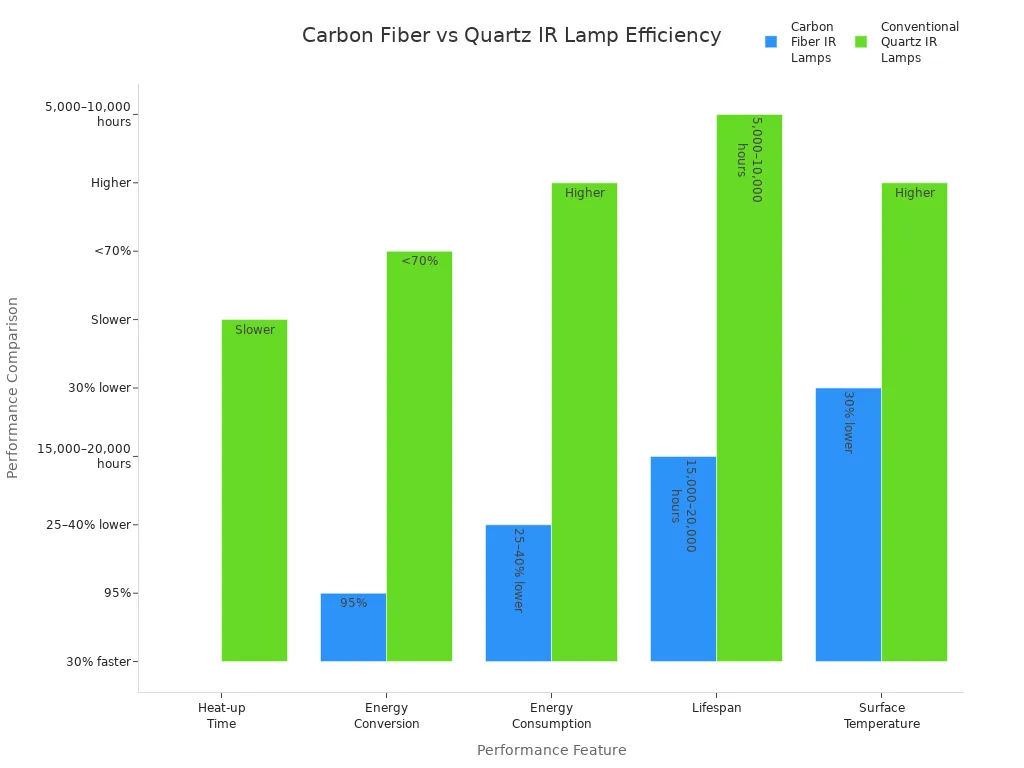

I have seen firsthand how energy-efficient pet bottle manufacturing relies on advanced near-infrared (NIR) heating systems. These systems, especially those from YFR heating Tech, use carbon fiber IR lamps that outperform conventional quartz IR lamps in almost every aspect. The difference starts with the wavelength. Carbon fiber IR lamps emit far-infrared radiation, which penetrates PET preforms deeply and evenly. This results in faster, more uniform heating.

The table below highlights the key differences between carbon fiber IR lamps and conventional quartz IR lamps:

Feature | Carbon Fiber IR Lamps | Conventional Quartz IR Lamps |

|---|---|---|

Wavelength | Far-infrared (3–10 μm) enabling deep, uniform penetration | Short-wave (0.8–1.4 μm), surface-focused heating |

Heat-Up Time | 30% faster heat-up, reducing cycle times | Slower heat-up times |

Energy Conversion | Converts over 95% of electricity into usable IR radiation | Less than 70% energy conversion |

Energy Consumption | 25–40% lower energy use, reducing operational costs | Higher energy consumption |

Lifespan | 15,000–20,000 hours (2–3 times longer) | 5,000–10,000 hours |

Thermal Distribution | Uniform, prevents hot spots and surface overheating | Surface overheating risk |

Surface Temperature | 30% lower surface temperature, reducing factory heat and cooling needs | Higher surface temperatures |

Precision Control | Adaptive wavelength output for preform thickness and color variations | Limited control |

I notice that these improvements translate directly into energy savings and higher production efficiency. For example, I have seen defect rates drop from 1–2% to less than 0.1% after switching to carbon IR lamps. The longer lifespan of these lamps means less downtime and lower maintenance costs. On a 72-lamp machine, I can save up to €18,000 per year in energy costs. The cooler operation also reduces the need for factory cooling, which supports a more energy-efficient process overall. I value the sustainability benefits, such as zero heavy metals and full recyclability, which align with my commitment to responsible manufacturing.

The Double Gate (DoGa) concept has changed how I approach energy-efficient pet bottle manufacturing. This system uses NIR heaters arranged so that PET preforms pass in two lanes on both sides of the lamps. I do not need primary reflectors, which allows more direct and effective heating.

The DoGa concept delivers several advantages:

I achieve up to 30% energy savings compared to older stretch blow molding systems.

At the CCEP Knetzgau site, the system saves up to 560,000 kWh annually.

The InnoPET Blomax machine processes 20,000 2.0-liter and 30,000 1.5-liter containers per hour, showing impressive throughput.

The compact design fits easily into existing production lines, making upgrades simple.

I can precisely align the system within the bottle shop, which supports flexible and sustainable operations.

This approach not only boosts energy-efficient technology but also supports my sustainability goals. I see how the DoGa concept helps me optimize process flow and maintain high output without sacrificing quality.

Preferential heating has become a vital tool in my energy-efficient pet bottle manufacturing strategy. This method lets me target specific areas of the PET preform, which is especially useful for complex shapes like oval bottles. I interrupt the rotation of the preform during heating, so only certain sections receive extra heat. This ensures even material distribution and uniform wall thickness.

I have used preferential heating to produce lighter bottles without compromising strength. For example, Henkel adopted this technology and achieved 14% material savings on a 250ml bottle while maintaining quality. KHS has relied on this process since 1997, proving its long-term value. I have seen energy consumption drop by up to 40% with this method, which supports both operational flexibility and sustainability.

Simulation studies confirm what I observe on the production floor. Preferential heating leads to more uniform weight distribution and better mechanical strength, such as improved top-load capacity and side-wall rigidity. I can optimize preform heating and bottle design, which allows me to save material and energy while still meeting strict quality standards.

Energy-efficient pet bottle manufacturing depends on these advanced heating strategies. By combining NIR heating, the Double Gate concept, and preferential heating, I achieve significant energy saving, lower costs, and better product quality. I see these innovations as essential for the future of PET production.

I have seen the shift toward 100% rPET compatibility become a top priority in PET bottle manufacturing. Modern equipment, including solutions from YFR heating Tech, now supports the use of recycled PET at full capacity. This transition to rpet materials relies on several advanced features:

Sidel’s Starlite-R Nitro bottle base uses a wave-shaped design that works seamlessly with 100% rPET, ensuring high resistance to deformation and breakage.

Optimized mold base geometry and efficient venting systems allow for easy shaping and high-speed production, even with recycled resin.

Dual cooling systems and advanced stretch rod designs help maintain bottle stability and consistent quality.

These systems fit into existing blow molding machines, making upgrades simple and cost-effective.

Integration of Industry 4.0 technologies, such as AI and IoT, enables real-time monitoring and process optimization, which is crucial when handling recycled PET.

Smart features like Conti loop AI and predictive maintenance ensure stable operation and reduce downtime, even with the variability of rPET resin.

I have also followed the development of CapFormer thermoforming technology, which now allows for commercial-scale production of 100% rPET caps. This innovation supports bottle-to-bottle recyclability, making the entire package recyclable and advancing circular economy goals.

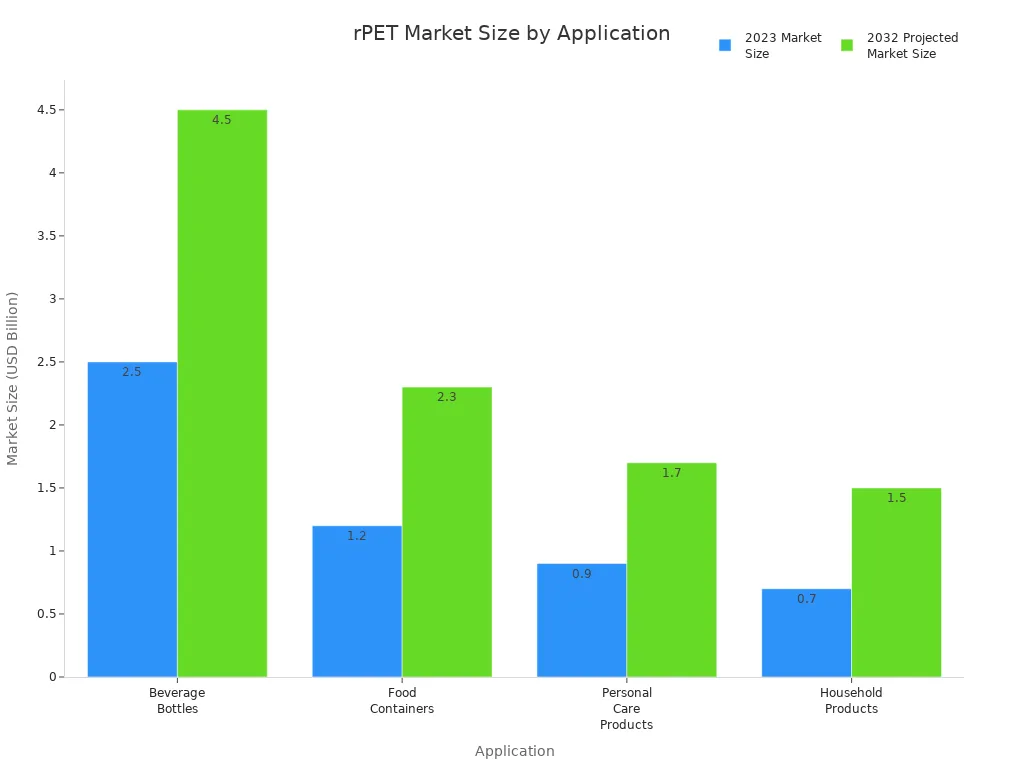

The rPET market continues to expand rapidly as brands respond to growing environmental demands and consumer expectations for eco-friendly packaging. I track the latest market data to stay ahead:

Metric | Value |

|---|---|

Market size (2023) | USD 8.5 billion |

Projected market size (2032) | USD 15.6 billion |

CAGR (2023-2032) | 7.1% |

Application | Market Size 2023 (USD Billion) | Projected Market Size 2032 (USD Billion) |

|---|---|---|

Beverage Bottles | 2.5 | 4.5 |

Food Containers | 1.2 | 2.3 |

Personal Care Products | 0.9 | 1.7 |

Household Products | 0.7 | 1.5 |

Asia Pacific leads the market with a 45% share, and the U.S. shows strong growth. The beverage sector remains the largest user of recycled PET, but I see significant gains in food, personal care, and household products. This growth reflects the industry’s commitment to sustainable practices and the increasing demand for recyclable and recycled packaging.

I recognize that adopting 100% rPET in PET bottle production delivers clear sustainability benefits. Life cycle assessments show that PET bottles made with recycled content have a lower environmental footprint than glass or aluminum alternatives. The use of 100% rPET reduces reliance on virgin plastic, lowers carbon emissions, and supports the circular economy. I see that innovations like lightweighting and improved recyclability further reduce resource use.

Aspect | Environmental Impact | Economic Impact |

|---|---|---|

Sustainability | Reduces reliance on virgin plastic, lowers carbon footprint, promotes circular economy practices | Encourages investments in recycling infrastructure and production capacity |

Recycling Technology | Advances improve quality and safety of rPET, enabling food-grade packaging | Drives innovation and market expansion |

Market Growth | Driven by consumer awareness and regulations, especially in North America, Europe, and Asia-Pacific | Growth in rPET markets fosters industry growth and job creation |

Product Innovation | Improved bottle design enhances recyclability and strength | Cost-effective packaging solutions without compromising sustainability |

I have seen major beverage companies invest in rPET initiatives, which creates jobs and expands recycling capacity. These efforts make eco-friendly packaging more accessible and cost-effective. By supporting the transition to rPET materials, I help meet sustainability targets and respond to consumer demand for responsible, recyclable products.

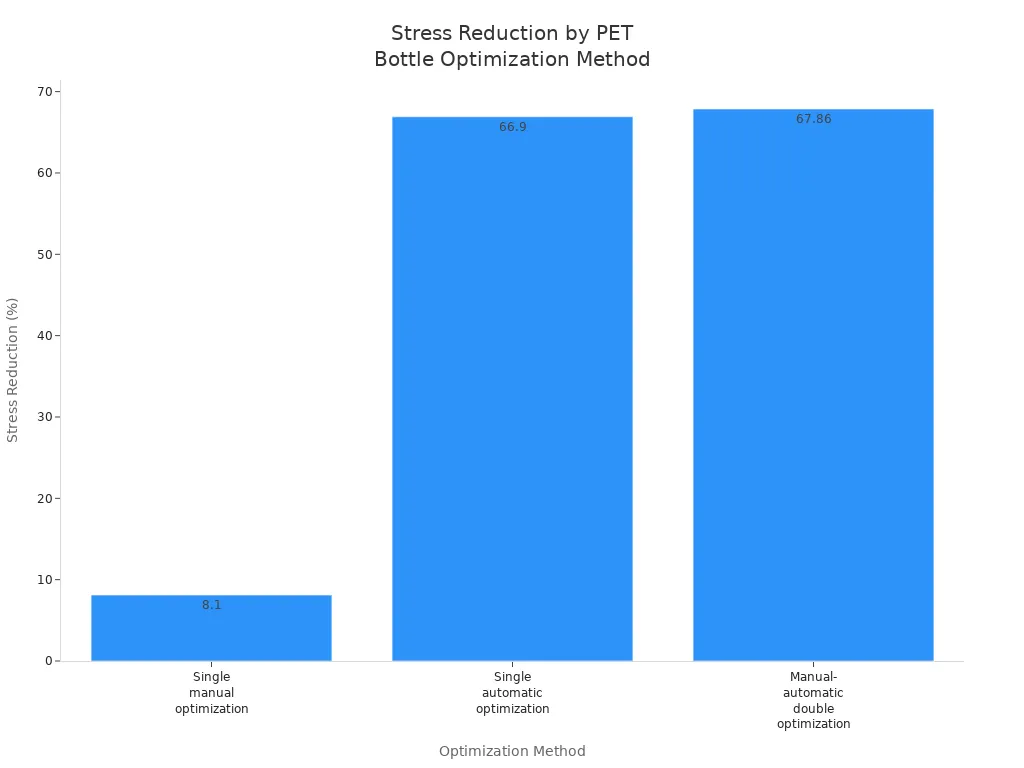

I have seen lightweighting become a core strategy in PET bottle manufacturing. By focusing on reducing material use without sacrificing strength or performance, I help companies lower costs and minimize environmental impact. Structural optimization stands out as one of the most effective approaches. When I apply single manual optimization, I can achieve stress reductions between 8.10% and 52%. Automatic optimization increases this to nearly 67%, and combining both methods pushes the reduction even further.

Optimization Method | Stress Reduction (%) | Iterations |

|---|---|---|

Single manual optimization | 8.10–~52 | N/A |

Single automatic optimization | 66.90 | 20 |

Manual-automatic double optimization | 67.86 | 17 |

I also use material and process optimization. By adding special chemicals to PET, I can enhance its mechanical properties and multifunctionality, which supports further material reduction. Careful control of temperature and air pressure during blow molding lets me fine-tune bottle thickness and quality. I have noticed that optimizing bottle design and capacity mix, based on local sales data and waste tonnage, helps reduce overall plastic waste.

Industry leaders like Sidel and Husky have demonstrated the power of lightweight bottle production. Sidel’s RightWeight 0.5L bottle is about 34% lighter than the average commercial bottle, yet it offers 32% more top-load resistance and does not require nitrogen dosing. Husky’s EcoBase preform design reduces resin use in the bottle base by up to 2.5%. Their lightweight neck and closure system saves 1.88 grams per bottle, resulting in annual resin savings of over 22,000 metric tons and cost savings of $26.6 million.

Lightweighting delivers clear economic and environmental benefits. When I reduce the amount of resin in each bottle, I cut raw material costs and lower transportation expenses due to lighter loads. For example, Husky’s innovations save more than 57,000 metric tons of CO2 emissions each year. Sidel’s StarLite PET bottle base not only reduces weight but also improves base resistance and stability, ensuring bottle integrity and safety.

Company | Lightweighting Innovation | Material Savings | Performance Benefits | Cost Impact |

|---|---|---|---|---|

Sidel | RightWeight 0.5L bottle | ~34% lighter (7.95g) | 32% more resistant top load | Maintains cost efficiency |

Sidel | StarLite PET bottle base | Unique base shape | Increased resistance and stability | No compromise on safety |

Husky | Lightweight neck & closure | 1.88g per bottle | 22,560 metric tons resin saved/year | $26.6 million saved/year |

I rely on IR heating technology to achieve high precision and efficiency in material distribution. By reheating PET preforms with infrared, I soften the body while keeping the neck rigid, which creates the optimal temperature gradient for stretch blow molding. Near-infrared (NIR) heating penetrates deeper into the preform, ensuring uniform temperature between the inner and outer layers. This uniformity allows me to use less material while maintaining mechanical strength and transparency. Tests show that NIR heating reduces heating times by up to 50% and energy consumption by up to 40%. Companies like REMSA have increased bottle output by 10% and shortened oven length by one meter using NIR-equipped machines.

I see that lightweighting, supported by precise IR heating, not only reduces costs but also helps protect the environment. By adopting these strategies, I contribute to a more sustainable future for PET packaging.

I have seen firsthand how flexibility shapes the future of PET bottle manufacturing. Every production run brings new demands—different bottle shapes, sizes, and neck finishes. YFR heating Tech’s Quartz IR emitters give me the control I need to meet these challenges. The advanced IR heating modules deliver precise, even heat to every preform, regardless of its geometry. I can switch between a 0.2-liter sports drink bottle and a 3.0-liter household cleaner container without missing a beat.

The modular design of modern PET bottle machines supports this adaptability. I can change molds quickly, often in just 15 minutes, and adjust for different preform neck standards in about two hours. The all-electric drive system, with six servo drives, ensures stable output and smooth transitions between product types. I rely on user-friendly interfaces with automatic temperature regulation and PLC control, which help me fine-tune heating profiles for each bottle design. This flexibility lets me respond to market trends and customer requests with speed and confidence.

Tip: Quick mandrel replacement—swapping all 108 mandrels in just 15 minutes—means I can minimize downtime and keep production moving.

High-speed production is essential in today’s competitive market. I need to deliver large volumes without sacrificing quality. YFR heating Tech’s IR solutions make this possible. The near-infrared (NIR) short-wave heating system rapidly brings preforms to the ideal temperature, reducing cycle times and energy consumption. I see output rates ranging from 6,000 to 14,000 bottles per hour on standard lines, with some high-performance machines reaching up to 24,000 bottles per hour.

Feature | Description |

|---|---|

Output Range | 6,000 – 14,000 bottles per hour (bph) |

Bottle Volume Range | 0.2 – 3.0 liters |

Mold Cavities Configuration | 4, 6, or 8 cavities, allowing scalable output |

Mold Changeover Time | 15 minutes for blow mold change; 2 hours for preform neck standard changeover |

Drive System | All-electric with 6 servo drives for stable, high output |

Heating System | NIR short-wave heating for efficient preform heating and lower power consumption |

Modularity | Separate mold cavities and ovens for easy installation/removal and output scaling |

User Interface | Automatic temperature regulation and PLC control |

I use IR camera-based quality control systems that inspect every bottle in real time. These systems process thermal images immediately after sealing, using neural networks to detect defects without slowing the line. I can reject faulty bottles instantly, ensuring only top-quality products reach the next stage. The modular and scalable design of these inspection systems fits seamlessly into multiple production lines, supporting high-speed environments.

High precision ensures every bottle meets strict quality standards.

Energy efficiency keeps operational costs low.

Quick mold changeovers let me adapt to new products rapidly.

Modular cavity configurations allow me to scale output as needed.

With YFR heating Tech’s IR solutions, I achieve the flexibility to handle any order and the speed to meet even the largest demands. This combination keeps my production lines efficient, reliable, and ready for the future.

I have watched the world’s top brands lead the way in adopting advanced IR technology for PET bottle production. Companies like Coca-Cola and Henkel have set benchmarks by integrating energy-efficient solutions into their manufacturing lines. I see how these brands focus on sustainability, cost savings, and product quality. Their commitment inspires others in the industry to follow suit.

Origin Materials and Husky Technologies have taken a bold step by introducing FDCA-based hybrid polymers in PET bottle production. They use Husky’s commercial-scale injection molding equipment to process PET/F, a novel material with up to 100% bio content. This innovation delivers enhanced performance, full recyclability, and tunable mechanical properties. I find it impressive that these advancements fit seamlessly into existing PET production systems. The results show that sustainable PET bottle manufacturing is not just possible but commercially viable.

YFR heating Tech plays a crucial role in this transformation. I rely on their Quartz IR emitters to achieve precise, energy-efficient heating. Their solutions help me reduce energy consumption, improve product consistency, and support the use of recycled materials. I see how their technology enables brands to meet strict environmental standards and maintain high-speed production.

Note: Leading brands prove that investing in advanced IR technology brings measurable benefits—lower costs, better sustainability, and reliable quality.

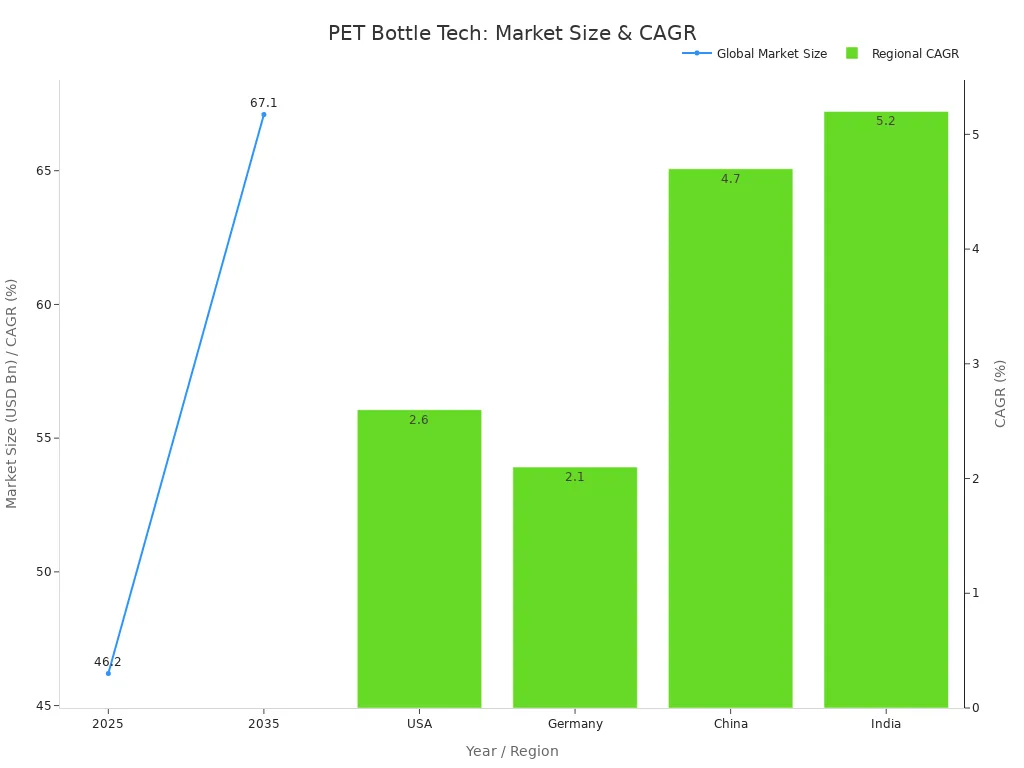

I track the pet bottle market closely and notice several clear trends shaping its future. The industry focuses on sustainability, recyclability, and cost-effectiveness. Beverage companies drive demand, holding more than half of the market share. Injection stretch blow molding (ISBM) stands out as the dominant technology, offering precision and efficiency.

Aspect | Details |

|---|---|

Market Trends | Focus on sustainability, recyclability, cost-effectiveness; beverage industry drives demand (>52% share) |

Dominant Technology | Injection stretch blow molding (ISBM) with ~59.8% market share by 2035; offers precision, efficiency, lightweight and durable bottles with minimal waste |

Market Size & Growth | USD 46.2 billion in 2025 to USD 67.1 billion by 2035; CAGR ~3.8% over 2025-2035 |

Regional Growth | Asia-Pacific emerging economies key drivers; USA CAGR 2.6%, Germany 2.1%, China 4.7%, India 5.2% |

Sustainability Drivers | Increasing use of recycled PET (rPET), regulatory pressures, circular economy adoption |

Challenges | High production costs for sustainable materials, competition from alternative packaging |

Consumer Preferences | Demand for lightweight, portable bottles (500 ml to 1 liter leading segment) |

Environmental Regulations | Strict packaging waste laws in Europe (e.g., Germany) pushing rPET adoption |

I see the market growing steadily, with projections showing a compound annual growth rate of about 4.18% between 2025 and 2030. Food, beverage, and pharmaceutical sectors drive this expansion. Regulatory pressures push manufacturers to invest in eco-friendly alternatives, such as rpet. Kraft Heinz’s launch of 100% recycled PET bottles in 2024 shows how brands respond to these demands. I expect innovations in recycling and sustainable packaging to fuel further growth and adoption of energy-efficient manufacturing technologies.

The future of PET bottle production depends on continued investment in advanced IR technology, automation, and sustainable materials. I believe that by embracing these trends, I can help shape a more efficient and responsible industry.

Advanced IR technology, especially with YFR heating Tech’s Quartz IR emitters, has transformed PET bottle production. I see energy use drop by up to 30%, faster mold changes, and higher output.

Impact Area | Key Benefit |

|---|---|

Energy Consumption | 15–30% reduction |

Production Output | Up to 8,000 bottles/hour |

Waste Reduction | Fewer defects, less rework |

I recommend adopting NIR heating for precise, efficient preform processing.

Modular, smart machines support rapid changeovers and real-time monitoring.

Ongoing innovation in lightweighting and recycling drives sustainability and growth.

Embracing these solutions positions manufacturers for long-term success in a changing market.

I achieve faster, more uniform heating with IR technology. This reduces energy use and improves product quality. I also see fewer defects and lower operational costs.

I use Quartz IR emitters to convert up to 96% of energy into radiant heat. This high efficiency helps me cut fuel costs by 20% to 50% compared to traditional heating methods.

Yes, I can process 100% rPET with advanced IR heating. The technology maintains resin quality and supports circular economy goals.

I rely on precise IR heating to control material distribution. This lets me reduce bottle weight without sacrificing strength or clarity.

I reach output rates of 6,000 to 24,000 bottles per hour, depending on machine configuration and bottle size.

Yes, I find IR modules compact and modular. I can upgrade my lines quickly with minimal downtime.

YFR heating Tech holds TUV certification, Certificate of Conformity, and a Trademark Registration Certificate.

I trust their products for quality and safety.

Contact Method | Details |

|---|---|

Phone | +86-13852327847 |

Website |