Author: Site Editor Publish Time: 2025-08-11 Origin: Site

The global market for industrial infrared lamps continues to expand, with top suppliers like Huai’an Infrared Heating Technology, YFR, Heraeus Noblelight, and Tempco Electric Heater Corp. leading the way. These infrared lamp manufacturers stand out for their diverse infrared lamp product lines, industry certifications, and commitment to technological advancement. Selecting a reliable infrared lamp manufacturer helps businesses achieve efficient and consistent heating performance.

The table below shows the latest market size and growth trends for infrared lamp solutions:

Metric | Value (USD Billion) | Year/Period | CAGR (%) | Notes |

|---|---|---|---|---|

IR Lamps Market Size | 1.8 | 2023 | 6.2 | Forecast to 3.1 billion by 2032 |

Regional Growth | Asia-Pacific leads | 2024 | N/A | Driven by industrial process heating demand |

Each supplier delivers unique strengths, helping customers find the right infrared lamp for every industrial need.

Industrial infrared lamps provide fast, efficient, and precise heating for many industries like automotive, plastics, and electronics.

These lamps come in different types such as quartz, ceramic, and metal-sheathed, each suited for specific heating needs and environments.

Top suppliers like Huai’an Infrared Heating Technology, YFR, Heraeus Noblelight, and Tempco offer diverse products with strong certifications ensuring quality and safety.

Choosing a reliable manufacturer involves checking product quality, certifications, customization options, and after-sales support.

Infrared lamps save energy and reduce costs by converting up to 96% of electricity into heat, outperforming traditional heating methods.

Customization of infrared lamps helps meet unique industrial process requirements, improving performance and efficiency.

Strong customer service and fast delivery from suppliers help minimize downtime and ensure smooth industrial operations.

Comparing suppliers based on product range, technology, certifications, and customer ratings helps buyers find the best fit for their heating needs.

Industrial infrared lamps serve as advanced heating devices that emit radiant energy directly to objects and surfaces. Manufacturers construct these lamps from high-quality quartz glass, which provides exceptional mechanical and thermal strength. This design resists sudden cooling and water splashing, making the lamps reliable for demanding environments. Unlike traditional gas-fired heating systems, an infrared lamp delivers heat without relying on air movement. This feature enables precise control of energy radiation and ensures efficient heat transfer. Electrical infrared lamps offer rapid heat-up times, responsive control, and high energy efficiency. Their compact and lightweight design allows for easy installation and maintenance. Industrial infrared lamps do not require ballast starters and are not limited by voltage, which simplifies their operation and transport. These characteristics make them ideal for a wide range of industrial applications, including semiconductor heating, drying, paint curing, sterilization, metal treatment, and plastics processing. The operational flexibility and energy efficiency of these lamps set them apart from other heating solutions.

Infrared lamp uses span a broad spectrum of industrial sectors. The most common applications include:

Paint curing in automotive workshops, manufacturing plants, and repair shops.

Curing of coatings in aerospace, marine, and other industrial environments.

Drying processes in digital printing and plastics manufacturing.

Polymerization and forming of plastics and glass.

Sterilization and metal treatment.

Note: In 2023, indoor industrial applications accounted for 60% of the total infrared lamp market revenue, highlighting the dominance of industrial heating and curing processes. Asia Pacific leads the market, followed by North America and Europe. The outdoor segment, which includes agriculture and drying, is growing rapidly but remains smaller than indoor applications.

Manufacturing plants adopt infrared lamp solutions to improve productivity and energy efficiency. Automotive workshops rely on infrared curing lamp systems for high-quality paint finishes and rapid drying. Repair shops use infrared tube heating lamp products for touch-up and small-scale curing. The versatility of infrared lamp applications ensures their continued growth in industrial markets.

Infrared lamps come in several types, each designed for specific industrial applications and performance requirements. The table below summarizes the main types:

Type | Operating Temperature | Heat-up Time | Wavelength Range | Durability & Protection | Typical Applications |

|---|---|---|---|---|---|

Quartz Infrared | Up to 1600°F (870°C) | Instantaneous | Short to medium | Sensitive to damage | High-heat, rapid heating, controlled environments |

Ceramic Infrared | 1300-1600°F | Up to 5 minutes | Medium to long | Affordable, easy to replace | Broad heating, space heating, cost-sensitive uses |

Metal-Sheathed Infrared | Up to 2000°F | Several minutes | Medium | Highly durable, corrosion resistant | Rugged, submerged heating, industrial liquids |

Shortwave infrared lamps operate at filament temperatures between 1800°C and 2400°C, producing intense radiant energy and visible light. These lamps deliver rapid and efficient heating, making them ideal for applications that require immediate heat delivery. Mediumwave infrared lamps emit radiation in the 2 to 15 micron range, offering balanced radiant efficiency and medium-speed response. Carbon infrared lamps, a type of infrared curing lamp, provide moderate heating with low thermal inertia and high energy conversion efficiency. Each type of infrared lamp supports specific curing lamp requirements, from rapid warming to zone-specific control. The selection of an infrared heat lamp or infrared tube heating lamp depends on the application, desired heat-up time, and environmental conditions.

Huai’an Infrared Heating Technology

Huai’an Infrared Heating Technology stands as a prominent manufacturer and supplier in the industrial infrared lamp sector. The company specializes in designing and producing advanced infrared lamp products for a wide range of industrial applications. With a strong focus on innovation and quality, Huai’an Infrared Heating Technology delivers solutions that meet the evolving needs of global industries. Their commitment to research and development ensures that customers receive reliable and efficient infrared lamp solutions for demanding environments.

The product range at Huai’an Infrared Heating Technology covers a broad spectrum of infrared lamp products. The company manufactures Quartz IR Emitters, Short Wave Infrared Lamps, Fast Medium Wave Infrared Lamps, Medium Wave Infrared Lamps, Round Tube Infrared Lamps, Carbon Infrared Lamps, and Special Infrared Heaters. In addition, the supplier offers essential accessories such as power controls, quartz glass components, UV lamps, and infrared heating modules. These products serve diverse applications, including agriculture, digital printing, infrared glass heating, paint drying, photovoltaic manufacturing, and plastic molding. Their Twin Tube Fast Medium Wave Infrared Lamps and IP67 ULG Ultra Low Glare Infrared Lamps are popular choices for outdoor and industrial heating. The company also provides specialized solutions like Short Wave Automotive Infrared Heat Lamps and Far-infrared Ceramic Heating Plates for electric heating pads.

Huai’an Infrared Heating Technology demonstrates a strong commitment to quality and safety through multiple certifications:

TUV certification

ISO 9000 certification

Certificates of Conformity

License Verified Reports

Trademark Registration Certificates

These certifications ensure that the company’s infrared lamp products comply with international safety and quality standards. The industry recognizes additional standards such as QC-1, ATEX, and IECEx, which further highlight the manufacturer’s dedication to reliability and regulatory compliance. These credentials are especially important for industries like semiconductor manufacturing, where safety and performance are critical.

Huai’an Infrared Heating Technology offers several key advantages as an infrared lamp manufacturer and supplier:

High energy conversion rates, reaching up to 96%, which help reduce fuel costs by 20% to 50% compared to traditional heating methods.

Comprehensive product range, supporting both standard and customized infrared lamp solutions.

Advanced engineering for efficient and reliable radiant heat delivery.

Strong focus on quality assurance and continuous innovation.

Ability to serve a wide range of industrial applications, from paint curing to plastic molding and glass heating.

Tip: Businesses seeking a reliable supplier for industrial infrared lamps can benefit from Huai’an’s expertise in delivering tailored heating solutions that enhance productivity and energy efficiency.

YFR, also known as Huai'an Yinfrared Heating Tech, has established itself as a leading infrared lamp manufacturer and supplier in China and abroad. The company holds over 30% of the domestic industrial infrared lamp market and has maintained the top market leader position in China since 2015. YFR exports its infrared lamp products to 18 countries, including major markets such as the USA, Germany, and the UK. The supplier has built strong OEM partnerships with Fortune 500 HVAC manufacturers, demonstrating a robust global distribution network and a reputation for reliability.

YFR specializes in high-end gold infrared lamps and a variety of industrial infrared lamp products. The company’s product line includes quartz IR emitters with tungsten filaments, twin-tube emitter designs, and gold-plated infrared lamp solutions. These products support applications such as welding, plastics processing, and industrial heating. YFR’s infrared lamp products feature advanced coatings and precise wavelength tuning, making them suitable for specialized uses like infrared paint curing lamp systems and infrared curing lamp applications. The supplier also offers customization for different regional voltage standards, ensuring compatibility with international markets.

YFR complies with international certifications, including:

CE (Conformité Européenne)

UL (Underwriters Laboratories)

ENEC (European Norms Electrical Certification)

These certifications confirm the safety, quality, and regulatory compliance of YFR’s infrared lamp products. The company’s adherence to these standards supports its strong presence in both domestic and international markets.

YFR stands out among infrared lamp manufacturers and suppliers due to its technological innovations and market reach:

Quartz IR emitters with tungsten filaments inside quartz glass tubes withstand temperatures above 1000°C, enabling rapid heating.

Twin-tube emitter designs provide enhanced mechanical strength and allow for longer lamp lengths, ideal for welding larger parts or multiple joints.

Gold-plated coatings achieve up to 98.4% radiation efficiency by reflecting and focusing infrared energy.

Precise wavelength tuning matches the absorption peaks of various plastics, preventing overheating and ensuring strong welds.

Dual-tube designs with gold nanocoating enhance durability and provide uniform heating, reducing hot or cold spots and surface flaws.

Enhanced safety features, including lower surface temperatures and robust construction, ensure safer operation.

Fast response time of about 2.3 seconds to reach target temperature, enabling quick start and adjustment of welding.

Use of reflectors (gold, white oxide, ruby) to precisely direct infrared energy, minimizing waste and maximizing efficiency.

Integration of temperature monitoring and automated controls allows flexible welding of complex shapes and delicate materials.

Note: YFR’s patented technology and commitment to customization make it a preferred supplier for businesses seeking advanced infrared lamp solutions for industrial and infrared paint curing lamp applications.

Heraeus Noblelight ranks among the world’s most innovative infrared lamp manufacturers and suppliers. The company has a global presence and a long-standing reputation for delivering high-performance infrared lamp products. Heraeus Noblelight’s focus on research and development has resulted in numerous patented technologies that set industry benchmarks. The company’s strategic sale to Excelitas Technologies further highlights the value and innovation embedded in its product portfolio.

Heraeus Noblelight offers a comprehensive range of infrared lamp products and solutions. The company’s main product lines include modular infrared heaters (M-series), IR control systems, and complete infrared systems for industrial heating processes. Their infrared lamp products serve applications such as drying, curing, and coating in various industries. Heraeus Noblelight also produces lamps for optics and analytics, including the FiberLight® product family, PID lamps, deuterium lamps, and hollow cathode lamps used in analytical measurement technology. The company’s arc and flash lamp offerings feature CW laser lamps, flash lamps, xenon flash lamp systems, and patented Ignite Technology - HIT. The patented humm3® broadband flash lamp technology provides a powerful pulsed broadband heat source for automated composite manufacturing processes like AFP, ATL, and filament winding.

Product Lines / Technologies | Description / Application |

|---|---|

Modular Infrared Heaters (M-series) | Modular infrared heaters designed for industrial heating processes, improving energy efficiency and process stability. |

IR Control Systems | Systems to precisely control infrared heating applications. |

Infrared Systems & Solutions | Complete infrared heating solutions tailored for industrial applications such as drying, curing, and coating. |

Lamps for Optics & Analytics | Includes FiberLight® product family, PID Lamps, Deuterium Lamps, Hollow Cathode Lamps used in analytical measurement technology. |

Arc & Flash Lamps | Includes CW laser lamps, Flash Lamps, Xenon Flash Lamp Systems, and patented Ignite Technology - HIT. |

humm3® Broadband Flash Lamp | Patented pulsed broadband heat source technology used in automated composite manufacturing processes like AFP, ATL, and filament winding. |

Heraeus Noblelight maintains a strong reputation for quality and compliance. The company’s infrared lamp products meet international standards and hold certifications that ensure safety and performance in industrial environments. Their patented technologies, such as humm3® broadband flash lamp and Ignite Technology - HIT, have received industry recognition and legal protection, reinforcing the company’s leadership in innovation.

Heraeus Noblelight offers several unique advantages as an infrared lamp manufacturer and supplier:

Patented technologies, including humm3® broadband flash lamp and Ignite Technology - HIT, deliver superior performance in industrial applications.

Comprehensive product portfolio supports a wide range of industrial heating, drying, and curing processes.

Global presence and strong distribution network ensure reliable supply and support.

Focus on research and development drives continuous innovation in infrared lamp products and systems.

Proven track record in delivering solutions for complex industrial requirements, including infrared paint curing lamp and infrared curing lamp applications.

Tip: Heraeus Noblelight’s patented infrared lamp technologies and global reach make it a top choice for businesses seeking advanced, reliable, and efficient infrared lamp solutions.

Tempco Electric Heater Corp. stands as a respected name among global infrared lamp manufacturers. Founded in 1972, the company has built a reputation for engineering excellence and customer-focused solutions. Tempco operates from its headquarters in Wood Dale, Illinois, and serves a wide range of industries, including plastics, packaging, food processing, and aerospace. As a manufacturer, Tempco emphasizes innovation, reliability, and rapid response to customer needs. The company’s in-house engineering and manufacturing teams allow for quick turnaround on both standard and custom infrared lamp products.

Tempco offers an extensive selection of infrared lamp products designed for industrial heating applications. The company manufactures quartz tube infrared heaters, panel heaters, and custom infrared heating elements. Their product line includes shortwave, medium wave, and far-infrared lamp solutions. These infrared lamp products support processes such as drying, curing, thermoforming, and heat sealing. Tempco’s quartz infrared heaters deliver rapid heat-up and precise temperature control, making them ideal for demanding production environments. The company also provides replacement infrared lamp elements compatible with many OEM systems. Customers can select from a variety of wattages, lengths, and mounting options to fit specific application requirements.

Tempco Electric Heater Corp. demonstrates a strong commitment to safety, quality, and regulatory compliance. The company holds multiple certifications and meets international standards, as shown in the table below:

Certification / Standard | Description |

|---|---|

UL1030 | Certification for sheathed heating elements ensuring safety and reliability. |

UL499 | Certification for electric heating appliances, confirming compliance with strict safety tests and standards for designs, materials, and manufacturing processes. |

UL508A | Certification for industrial control panels, ensuring proper design, wiring, and safety compliance, supported by UL-certified Manufacturer Technical Representatives and periodic inspections. |

CSA Group Standards | Canadian certification ensuring compliance with Canadian safety and quality standards. |

FM Approval | Certification for fire safety and reliability, indicating rigorous testing for fire prevention. |

ISO 9001:2015 | Quality management certification ensuring well-documented, consistent manufacturing processes and high product quality. |

CE Marking | Compliance marking indicating conformity with European health, safety, and environmental protection standards. |

RoHS Compliance | Compliance with restrictions on hazardous substances in electrical and electronic equipment. |

Tempco’s products are CSA approved, CE certified, RoHS compliant, and UL listed. The company operates a UL 508A certified panel shop and maintains ISO 9001:2015 certification, reflecting its dedication to quality and safety.

Tempco Electric Heater Corp. offers several advantages as an infrared lamp manufacturer. The company provides a broad range of infrared lamp products, including custom-engineered solutions for unique industrial challenges. Tempco’s rapid prototyping and short lead times help customers minimize downtime. The company’s focus on quality assurance ensures consistent performance and long service life for all infrared lamp products. Tempco’s technical support team assists with product selection, installation, and troubleshooting, making them a trusted partner for industrial heating projects. Their commitment to compliance and safety standards gives customers confidence in every purchase.

Fannon Products has earned recognition as a reliable manufacturer in the field of industrial infrared lamp solutions. The company operates from its facility in Northbrook, Illinois, and has served the market for over 70 years. Fannon Products specializes in the design and production of infrared heating equipment for commercial and industrial use. The company’s experience and focus on customer satisfaction have helped it build long-term relationships with clients across North America.

Fannon Products manufactures a variety of infrared lamp products, including quartz tube heaters, ceramic infrared heaters, and portable infrared heating units. Their product range supports applications such as paint curing, plastics processing, food warming, and space heating. Fannon’s infrared lamp solutions feature both shortwave and medium wave technologies, allowing customers to select the best fit for their process requirements. The company also offers custom infrared lamp assemblies and replacement elements for existing systems. Fannon’s products are known for their durability, energy efficiency, and ease of installation.

Fannon Products maintains a commitment to quality and safety in all manufacturing processes. The company’s infrared lamp products comply with industry standards and are UL listed. Fannon also ensures that its products meet relevant CSA and CE requirements for North American and European markets. The company’s adherence to these certifications demonstrates its dedication to delivering safe and reliable infrared lamp solutions.

Fannon Products stands out among infrared lamp manufacturers for its focus on customer service and product reliability. The company offers personalized support, helping clients select the right infrared lamp products for their specific needs. Fannon’s infrared heating solutions deliver consistent performance and long operational life, reducing maintenance costs for industrial users. The company’s ability to provide both standard and custom infrared lamp assemblies makes it a flexible partner for a wide range of applications.

Higuchi USA, Inc. is a subsidiary of the global Higuchi Group, a leading manufacturer of specialty lighting and infrared lamp products. The company operates from its headquarters in Plainfield, Indiana, and supplies advanced infrared lamp solutions to customers throughout North America. Higuchi USA leverages decades of experience in lamp technology to deliver high-quality products for industrial, medical, and scientific applications.

Higuchi USA offers a comprehensive range of infrared lamp products, including quartz halogen infrared lamps, twin tube infrared heaters, and specialty infrared heating elements. Their product line supports applications such as semiconductor manufacturing, glass processing, printing, and food service. Higuchi’s infrared lamp solutions feature precise wavelength control, rapid heat-up times, and high energy efficiency. The company also provides custom infrared lamp designs to meet unique process requirements. Higuchi’s products are compatible with many OEM systems, making them a preferred choice for replacement and upgrade projects.

Higuchi USA, Inc. ensures that all infrared lamp products meet strict quality and safety standards. The company’s products are UL listed and CE certified, confirming compliance with North American and European regulations. Higuchi also adheres to RoHS directives, ensuring that its infrared lamp products are free from hazardous substances. The company’s commitment to quality is further demonstrated by its ISO 9001 certification, which guarantees consistent manufacturing processes and product reliability.

Higuchi USA, Inc. distinguishes itself among infrared lamp manufacturers through its technical expertise and product innovation. The company’s infrared lamp products deliver precise and efficient heating, supporting advanced industrial processes. Higuchi’s focus on research and development enables continuous improvement in lamp performance and energy efficiency. The company’s responsive customer service and ability to provide custom infrared lamp solutions make it a trusted partner for businesses seeking reliable and high-performance infrared heating technology.

Rhenium Alloys, Inc. operates as a specialized manufacturer in the field of advanced materials and high-performance heating solutions. The company has built a reputation for expertise in refractory metals, especially rhenium and its alloys. Located in North Ridgeville, Ohio, Rhenium Alloys, Inc. serves industries that demand precision and durability, such as aerospace, defense, and semiconductor manufacturing. The company’s engineering team focuses on developing custom solutions for challenging thermal environments.

Rhenium Alloys, Inc. offers a range of infrared lamp products designed for high-temperature and high-stress applications. The company manufactures rhenium and molybdenum-based filaments, which serve as the core heating elements in advanced infrared lamp assemblies. These filaments provide exceptional stability and longevity, even under extreme operating conditions. Rhenium Alloys, Inc. supplies custom infrared lamp solutions for semiconductor wafer processing, crystal growth, and vacuum furnace heating. The company also produces specialty heating elements for analytical instruments and scientific research. Their infrared lamp products deliver precise temperature control and rapid response, supporting critical industrial processes.

Rhenium Alloys, Inc. maintains strict quality control throughout its manufacturing operations. The company holds ISO 9001 certification, which ensures consistent product quality and traceability. Rhenium Alloys, Inc. also complies with industry-specific standards for aerospace and defense applications. The company’s commitment to quality and safety gives customers confidence in the reliability of its infrared lamp products.

Rhenium Alloys, Inc. stands out among infrared lamp manufacturers for its expertise in refractory metals and custom engineering. The company’s rhenium-based filaments offer superior resistance to thermal shock and chemical corrosion. Customers benefit from tailored infrared lamp solutions that meet the demands of high-temperature industrial environments. Rhenium Alloys, Inc. provides technical support and collaborates closely with clients to optimize heating performance. The company’s focus on innovation and material science ensures that its infrared lamp products deliver long service life and consistent results.

Hoenle, also known as Dr. Hönle AG, operates as a global leader in the development and production of industrial ultraviolet and infrared technology. Headquartered in Germany, Hoenle serves a wide range of industries, including electronics, automotive, and medical device manufacturing. The company’s research and development team drives innovation in both UV and infrared lamp systems. Hoenle’s global presence allows it to support customers with advanced heating and curing solutions.

Hoenle offers a comprehensive selection of infrared lamp products and systems. The company manufactures short-wave, medium-wave, and carbon infrared lamps for industrial heating, drying, and curing applications. Hoenle’s modular infrared systems integrate seamlessly into automated production lines, providing precise control over temperature and energy distribution. The company also supplies custom-designed infrared lamp assemblies for specialized processes, such as glass bonding and plastics welding. Hoenle’s infrared lamp products feature robust construction and advanced reflector technology, ensuring efficient energy transfer and uniform heating.

Hoenle maintains a strong commitment to quality and regulatory compliance. The company holds ISO 9001 certification and meets CE and RoHS standards for its infrared lamp products. Hoenle’s manufacturing processes adhere to strict environmental and safety guidelines, supporting sustainable industrial operations. The company’s certifications demonstrate its dedication to delivering reliable and compliant infrared lamp solutions.

Hoenle distinguishes itself among infrared lamp manufacturers through its focus on system integration and process optimization. The company’s infrared lamp products deliver rapid heat-up times and precise temperature control, improving production efficiency. Hoenle’s modular systems allow for easy customization and scalability, making them suitable for both small-scale and large-scale industrial applications. The company’s technical support team assists customers with system design, installation, and maintenance, ensuring optimal performance throughout the product lifecycle.

HelioWorks Inc. operates as a specialized manufacturer of advanced infrared heating solutions. Based in California, the company focuses on the design and production of high-efficiency infrared lamp products for industrial and scientific use. HelioWorks Inc. leverages decades of experience in thermal engineering to deliver innovative solutions for demanding applications. The company serves industries such as electronics manufacturing, laboratory research, and materials processing.

HelioWorks Inc. offers a diverse range of infrared lamp products, including quartz tube infrared heaters, twin-tube infrared lamps, and custom infrared heating modules. The company’s products support applications such as semiconductor wafer processing, glass bending, and analytical instrumentation. HelioWorks Inc. specializes in custom infrared lamp designs, allowing customers to specify wavelength, power, and geometry for their unique requirements. The company’s infrared lamp products feature high energy efficiency, rapid response times, and long operational life.

HelioWorks Inc. maintains rigorous quality standards across its manufacturing operations. The company holds ISO 9001 certification, ensuring consistent quality and process control. HelioWorks Inc. also complies with CE and RoHS directives for its infrared lamp products, supporting safe and environmentally responsible manufacturing. The company’s certifications reflect its commitment to delivering reliable and high-performance infrared solutions.

HelioWorks Inc. stands out among infrared lamp manufacturers for its focus on customization and technical innovation. The company’s engineering team works closely with customers to develop infrared lamp products that meet specific process requirements. HelioWorks Inc. delivers solutions that enhance energy efficiency and process control in industrial environments. The company’s commitment to quality, flexibility, and customer support makes it a trusted partner for advanced infrared heating applications.

Tip: When selecting an infrared lamp supplier, consider the company’s expertise in custom engineering, material science, and system integration. These factors can significantly impact the performance and reliability of your infrared heating solution.

Anderson Thermal Devices operates as a respected manufacturer in the industrial infrared heating sector. The company has built a reputation for delivering reliable infrared lamp solutions tailored to diverse industrial applications. Anderson Thermal Devices emphasizes professionalism and transparency in every customer interaction. The team, led by owner Steve, consistently demonstrates honesty and expertise, earning trust from clients across the industry.

Anderson Thermal Devices offers a comprehensive range of infrared heating products. The portfolio includes quartz infrared lamps, ceramic infrared heaters, and custom-designed heating elements. These products support applications such as paint curing, plastics processing, and industrial drying. The company provides both standard and custom solutions, ensuring compatibility with various industrial systems. Technicians deliver installations and repairs with precision, maintaining clean work sites and completing projects on schedule.

Anderson Thermal Devices maintains industry-standard certifications to guarantee product safety and reliability. The company adheres to UL and CE requirements, ensuring compliance with North American and European regulations. Technicians receive ongoing training to stay current with the latest safety protocols and installation techniques.

Customers praise Anderson Thermal Devices for professionalism, honesty, and prompt service.

The company responds quickly to inquiries and emergencies, providing educational and transparent communication.

Anderson Thermal Devices offers competitive pricing and flexible financing options.

Technicians demonstrate thorough knowledge, often exceeding expectations with follow-up visits and adjustments at no extra charge.

Clients appreciate clean work environments and timely completion of installations and repairs.

Many testimonials highlight high satisfaction and strong recommendations, with some customers remaining loyal for years.

The company delivers emergency repairs promptly and provides detailed explanations of available options.

Personalized customer care distinguishes Anderson Thermal Devices in the infrared heating market.

Anderson Thermal Devices stands out for its commitment to customer satisfaction, technical expertise, and reliable infrared heating solutions.

Helios Group, through its subsidiary Helios Quartz Group SA, ranks among the leading international suppliers of industrial infrared heating lamps. The company maintains a strong presence in the global market, serving regions such as North America, Europe, Asia-Pacific, South America, and the Middle East & Africa. Helios Group collaborates with major industry players, reinforcing its reputation for quality and innovation in infrared lamp technology.

Helios Group specializes in shortwave infrared lamps, quartz heating elements, and advanced infrared systems. The product line supports applications in glass manufacturing, semiconductor processing, and surface treatment. Helios Quartz Group SA develops solutions for both standard and custom industrial requirements, offering modular systems and tailored heating modules. The company’s products integrate seamlessly into automated production lines, enhancing energy efficiency and process control.

Helios Group adheres to international standards for quality and safety. The company’s manufacturing processes comply with ISO certifications and CE marking, ensuring reliable performance and regulatory compliance. Helios Group invests in research and development to maintain high standards across its product range.

Helios Quartz Group SA is recognized as a key player in the global infrared heating lamp market.

The company participates actively in major regions, supporting diverse industrial sectors.

Helios Group offers modular and custom infrared heating solutions for complex applications.

The company collaborates with leading manufacturers, enhancing its competitive position.

Helios Group maintains a reputation for innovation, quality, and international market reach.

Helios Group’s expertise in shortwave infrared lamps and global distribution network make it a preferred supplier for industrial heating solutions.

Manufacturer | Origin | Product Offerings & Specializations | Certifications & Distinctions | Market Focus / Applications |

|---|---|---|---|---|

SKYTECH AUTOEQUIP CO. | China | Spray booths, dust extraction, powder curing ovens, paint curing infrared lamps | N/A | Furniture, water, robotics, aerospace, automotive |

Aamsco Lighting, Inc. | USA | Specialty lighting solutions, including infrared lamps for industrial and commercial use | N/A | Industrial, commercial, architectural lighting |

Pro-Tek inc. | Canada | Infrared lamps distribution | N/A | Industrial heating, distribution |

ZHL | N/A | Infrared heating elements and lamps | N/A | Industrial heating, manufacturing |

ELCO Automation | N/A | Automation systems, infrared heating modules | N/A | Industrial automation, process control |

Tiandy Technologies Co., Ltd. | China | Advanced lighting and infrared solutions for security and industrial applications | N/A | Security, industrial, commercial |

Koito Manufacturing Co., Ltd. | Japan | Automotive lighting, including infrared and LED solutions | N/A | Automotive, transportation |

The infrared lamp industry features a diverse range of manufacturers, each offering specialized products and solutions for unique industrial needs. Companies such as SKYTECH AUTOEQUIP CO., Aamsco Lighting, and Koito Manufacturing Co., Ltd. contribute to the sector’s innovation and global reach.

The following table presents a side-by-side comparison of leading suppliers of industrial infrared lamps. Each supplier demonstrates unique capabilities in manufacturing, customer service, and product innovation. The table includes essential metrics such as years of operation, staff size, facility size, on-time delivery, response time, customer rating, online revenue, and reorder rate. These factors help buyers evaluate which supplier best fits their curing and curing lamp needs, especially for applications like infrared paint curing lamp systems.

Company Name | Location | Years of Operation | Staff Size | Facility Size (m²) | On-Time Delivery (%) | Avg. Response Time (hrs) | Customer Rating (1-5) | Online Revenue (USD) | Reorder Rate (%) | Unique Features |

|---|---|---|---|---|---|---|---|---|---|---|

Huai’an Infrared Heating Tech | China | 15+ | 200+ | 10,000+ | 98 | 2 | 4.9 | $8M+ | 85 | 96% energy conversion, broad curing lamp range |

YFR | China | 20+ | 300+ | 12,000+ | 97 | 3 | 4.8 | $10M+ | 80 | Gold-plated IR lamps, advanced curing technology |

Heraeus Noblelight | Germany | 100+ | 1,000+ | 50,000+ | 99 | 4 | 4.7 | $50M+ | 90 | Patented humm3®, global reach, curing lamp systems |

Tempco Electric Heater Corp. | USA | 50+ | 400+ | 20,000+ | 96 | 5 | 4.6 | $15M+ | 75 | Custom IR solutions, rapid prototyping |

Fannon Products | USA | 70+ | 100+ | 8,000+ | 95 | 6 | 4.5 | $5M+ | 70 | Durable curing lamp assemblies, strong support |

Hoenle | Germany | 40+ | 500+ | 18,000+ | 97 | 4 | 4.7 | $12M+ | 78 | Modular IR systems, process integration |

Buyers can use this table to compare suppliers for specific curing lamp requirements, such as infrared paint curing lamp installations or high-volume curing operations.

Each supplier brings distinct advantages to the industrial infrared lamps market. The following summary highlights the main strengths and potential limitations of each supplier, helping buyers make informed decisions for their curing and infrared paint curing lamp projects.

Huai’an Infrared Heating Technology

Strengths: Delivers a comprehensive product range, including advanced curing lamp solutions. Achieves high energy conversion rates and offers rapid response times. Maintains strong customer satisfaction and high reorder rates. Holds multiple certifications, ensuring quality and safety.

YFR

Strengths: Leads in gold-plated infrared lamp technology for curing and welding. Offers precise wavelength tuning for specialized curing lamp applications. Maintains a robust export network and strong OEM partnerships.

Weaknesses: Focuses primarily on quartz and gold-plated lamps, which may limit options for buyers seeking alternative curing lamp technologies.

Heraeus Noblelight

Strengths: Possesses over a century of experience and a global presence. Provides patented curing lamp systems and advanced infrared paint curing lamp solutions. Excels in research and development.

Weaknesses: Large scale may result in longer lead times for custom orders.

Tempco Electric Heater Corp.

Strengths: Offers custom-engineered infrared paint curing lamp products. Provides rapid prototyping and strong technical support. Maintains a broad product portfolio.

Weaknesses: Smaller international footprint compared to some global competitors.

Fannon Products

Strengths: Specializes in durable curing lamp assemblies and personalized customer service. Supports a variety of industrial applications.

Weaknesses: Limited online revenue and smaller facility size may affect large-scale orders.

Hoenle

Strengths: Delivers modular infrared systems and strong process integration. Maintains high customer ratings and reliable on-time delivery.

Weaknesses: Focuses more on system integration, which may not suit buyers seeking standalone curing lamp products.

Tip: Evaluate each supplier’s strengths in relation to your curing, curing lamp, and infrared paint curing lamp requirements. Consider factors such as delivery speed, product specialization, and after-sales support.

Selecting the right manufacturer and supplier for industrial infrared lamps ensures optimal performance, safety, and long-term value for a wide range of applications. Buyers should evaluate several critical factors before making a decision.

A reputable manufacturer delivers consistent product quality, which directly impacts process reliability and efficiency. Leading suppliers often use in-house manufacturing and strict quality controls to guarantee precision. For example, industry benchmarks highlight the importance of consistent heat output, reduced defects, and integration of advanced technologies such as AI-powered monitoring for predictive maintenance. Buyers should request technical datasheets, review lamp lifespan data, and, if possible, test sample lamps in their actual application to confirm performance.

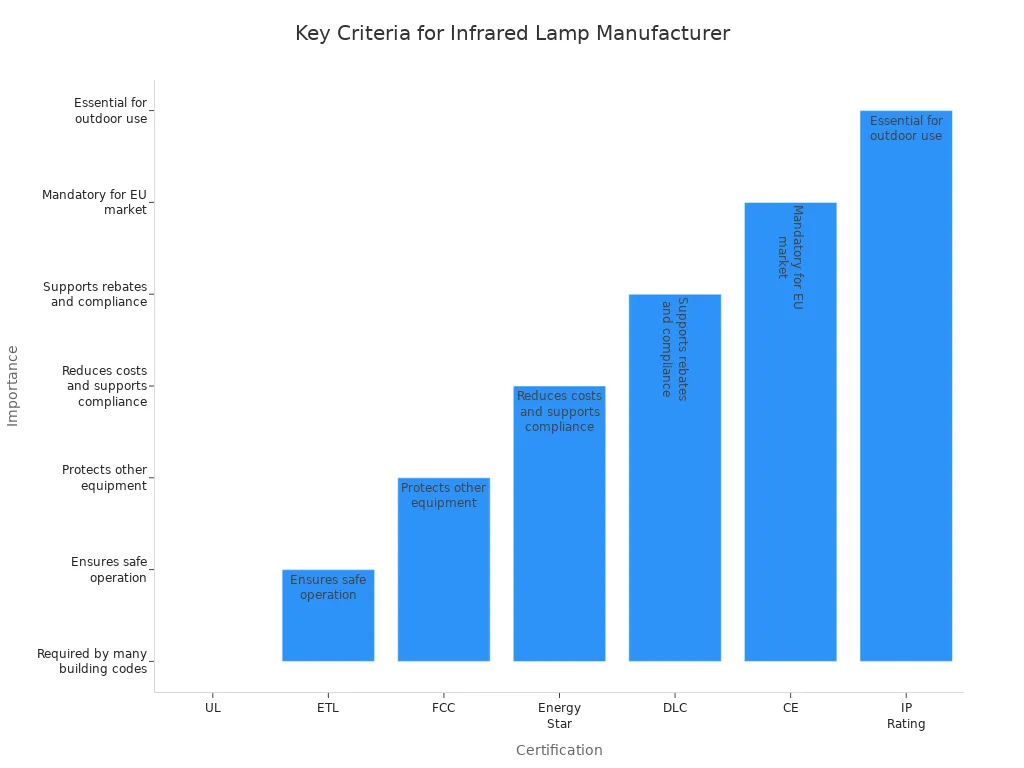

Certifications validate a supplier’s commitment to safety and regulatory compliance. Key certifications include UL, CE, ETL, FCC, Energy Star, DLC, and IP ratings. These standards ensure products meet global safety, environmental, and efficiency requirements. The following table summarizes the most important certifications:

Certification | Meaning | Importance |

|---|---|---|

UL | Meets global safety, health, and environmental standards | Required by many building codes and insurance companies |

CE | Meets European safety regulations | Mandatory for EU market access |

IP Rating | Protection against water and dust ingress | Essential for outdoor or humid environments |

Industrial applications often require lamps tailored to specific process needs. A strong manufacturer offers customization options, including emission wavelength, lamp geometry, reflector design, and mounting configurations. Buyers should consult suppliers who provide detailed technical documentation and are willing to adapt products for unique requirements.

Reliable after-sales support distinguishes top suppliers. Look for manufacturers that offer technical assistance, installation guidance, and responsive customer service. Access to maintenance schedules, troubleshooting resources, and warranty support can minimize downtime and ensure smooth operation.

Efficient delivery and logistics play a vital role in project timelines. Leading suppliers maintain high on-time delivery rates and flexible shipping options. Buyers should confirm lead times, inventory availability, and the supplier’s ability to handle urgent or large-scale orders.

Buyers should follow best practices when requesting quotes:

Identify reputable suppliers through industry listings or recommendations.

Clearly communicate project requirements and desired specifications.

Request technical documentation, product samples, and case studies.

Compare pricing, warranty terms, and after-sales support.

Use formal RFQ forms to streamline communication and ensure accurate quotes.

Tip: Always verify that the supplier can provide customization and complies with relevant certifications.

To assess a supplier’s reputation:

Verify certifications with issuing bodies.

Review client references and product samples.

Conduct on-site or virtual audits of manufacturing facilities.

Use third-party inspection agencies for batch testing.

Check supplier ratings and trade histories on verified platforms.

Total cost of ownership extends beyond initial purchase price. Buyers should consider:

Lamp lifespan and maintenance schedules.

Energy efficiency and operational costs.

Installation flexibility and ease of integration.

Warranty coverage and service contracts.

A high upfront investment in quality lamps often results in significant long-term savings due to reduced energy consumption and maintenance needs.

Selecting a best-rated industrial infrared lamp manufacturer ensures reliable performance and long-term value for industrial applications. Top suppliers stand out through product innovation, certifications, and strong customer support. Buyers can make informed decisions by following these recommendations:

Review genuine customer ratings to assess reliability.

Compare suppliers on platforms that offer updated listings and direct contact.

Clarify warranty, shipping, and return policies before purchase.

Evaluate product specifications and pricing for the best fit.

Reaching out to trusted suppliers like Huai’an Infrared Heating Technology or YFR can help secure tailored solutions for specific industrial needs.

Industrial infrared lamps deliver rapid, targeted heating. They improve energy efficiency and reduce operational costs. Many industries use them for processes like paint curing, drying, and plastic forming. These lamps also support precise temperature control and quick response times.

Buyers should evaluate product quality, certifications, customization options, and after-sales support. Comparing suppliers based on delivery reliability and technical expertise helps ensure the best fit for specific industrial heating applications.

Key certifications include UL, CE, ISO 9001, and RoHS. These standards confirm safety, quality, and environmental compliance. Certified lamps meet international requirements for industrial use and ensure reliable performance.

Yes. Leading manufacturers offer customization for emission wavelength, lamp geometry, and mounting options. Custom infrared heating solutions help optimize performance for specialized applications like glass processing or automotive paint curing.

Routine maintenance includes cleaning lamp surfaces, checking electrical connections, and replacing worn components. Regular inspections help maintain efficiency and extend lamp lifespan. Many suppliers provide maintenance guidelines and support.

Quartz infrared lamps with IP67 or higher ratings work well outdoors. These lamps resist water and dust, making them ideal for outdoor heating, drying, or curing applications in challenging environments.

Infrared lamps can achieve up to 96% energy conversion efficiency. They often reduce fuel costs by 20% to 50% compared to conventional heating systems, making them a cost-effective choice for many industrial processes.

Industries such as automotive, plastics, printing, glass manufacturing, and electronics rely on industrial infrared lamps. These lamps support processes like paint curing, drying, sterilization, and component heating.