Author: Site Editor Publish Time: 2025-09-15 Origin: Site

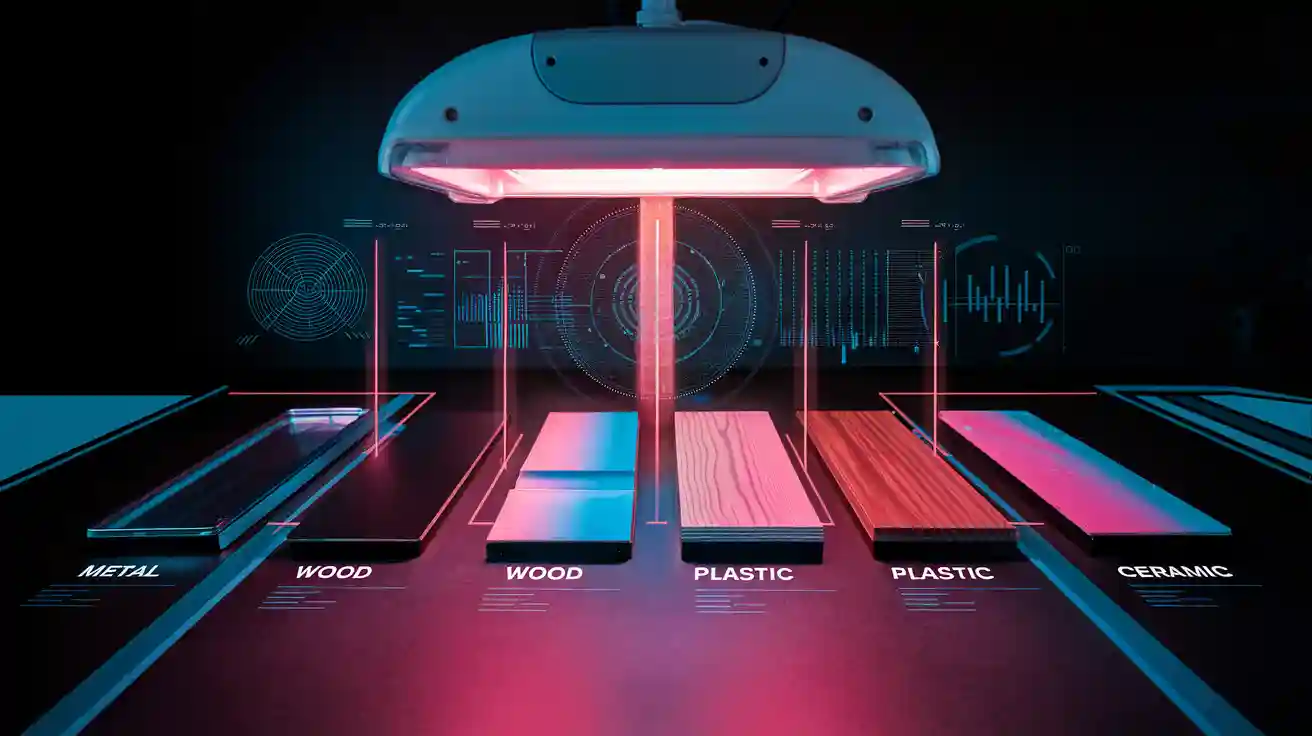

Infrared paint curing does not offer the same results for every material. The material type, paint formulation, and curing technology each play a critical role in the process. Recent studies show that silica nano/microparticles respond with high effectiveness and a significant temperature drop, while cotton fabric with titanium dioxide coatings sees much lower results.

Material Type | Effectiveness in IR Curing | Temperature Reduction |

|---|---|---|

Silica nano/microparticles | High | ~27 °C |

Cotton fabric with TiO2 | Low | 3.91 °C |

Professionals and DIY enthusiasts should always consider the unique needs of their project. Advanced infrared solutions from Huai'an Infrared Heating Technology can help achieve optimal curing for many applications.

Infrared paint curing effectiveness varies by material type, paint formulation, and technology used.

Silica nano/microparticles show high effectiveness in infrared curing, while cotton fabric with titanium dioxide coatings performs poorly.

Infrared curing offers faster drying times and improved energy efficiency compared to traditional methods.

Selecting the right infrared lamp type is crucial for achieving optimal results based on the material and paint used.

Proper surface preparation enhances paint adhesion and ensures even heat distribution during curing.

Monitoring temperature and adjusting lamp intensity prevents damage to heat-sensitive materials like plastics and wood.

Infrared curing can significantly reduce operational costs and energy consumption, making it a cost-effective choice for industries.

Testing a small area before full-scale application helps identify the best settings for each material and paint combination.

Infrared paint curing uses radiant energy to dry and harden paint on various surfaces. This process has gained popularity in both industrial and DIY settings because it offers faster results than traditional methods. Infrared paint curing ovens deliver high-intensity radiant heat directly to coated surfaces. This approach reduces cure times and improves energy efficiency. Many industries rely on infrared paint curing for applications such as powder coating, adhesive setting, and ink drying. Companies like Huai'an Infrared Heating Technology provide advanced solutions that help users achieve consistent and high-quality finishes.

Infrared paint curing ovens minimize substrate heating and energy waste.

The process supports a wide range of coatings and materials.

Users experience improved final product quality and reduced operational costs.

Infrared heat operates by emitting electromagnetic waves that transfer energy directly to the paint and substrate. This energy causes the molecules in the paint to vibrate, generating heat from within. The result is a rapid and uniform curing process. Scientists use several techniques to study how infrared heat interacts with different materials during curing.

Evidence Type | Description |

|---|---|

Infrared Thermography (IRT) | IRT images reveal thermal and optical inhomogeneities in paint and substrate materials, indicating variations in composition and moisture content that affect curing. |

Heat Absorption Variability | Areas where heat is not uniformly absorbed are observed, leading to darker regions in IRT images. |

Trans-illumination Technique | This technique detects defects or structural variations in layers closest to the canvas, which are not visible on the surface. |

These scientific methods help manufacturers optimize infrared paint curing for different materials. They also ensure that the curing process delivers reliable and repeatable results.

Curing with infrared heat offers several advantages over conventional drying methods. Infrared paint curing provides faster drying times, which increases productivity in both large-scale and small-scale operations. The direct application of infrared heat reduces energy consumption and lowers operational costs. Infrared paint curing also minimizes the risk of surface defects, such as bubbling or uneven finishes.

Tip: Infrared paint curing works best when users match the lamp type and wavelength to the specific material and paint formulation.

Many professionals choose infrared paint curing because it delivers consistent results and supports a wide range of applications. Companies like Huai'an Infrared Heating Technology offer specialized lamps and modules that maximize the benefits of curing with infrared heat.

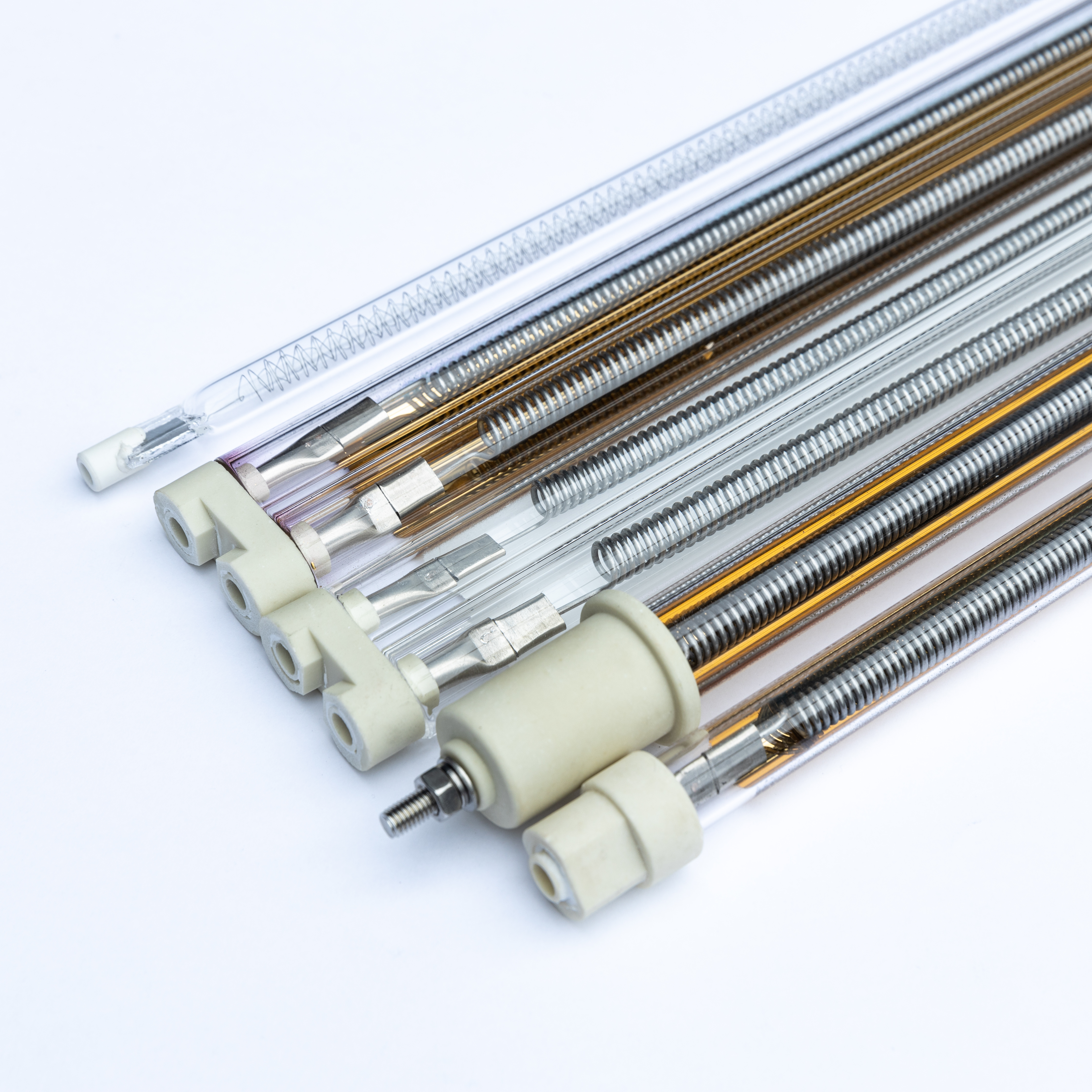

Infrared paint curing lamps come in several types, each designed to meet specific drying and curing needs. Manufacturers produce lamps with different wavelengths, power outputs, and structural designs. These differences affect how efficiently the lamp cures paint on various materials.

Shortwave infrared lamps deliver intense energy that penetrates deep into the paint layer. This technology speeds up the curing process and produces a smooth, durable finish. Medium wave infrared lamps provide gentler heat, making them suitable for materials that require slower, more controlled drying. Carbon infrared heaters offer a balance between speed and uniformity, often used for delicate surfaces or specialty coatings.

Huai'an Infrared Heating Technology manufactures a wide range of infrared lamps, including Short Wave Infrared Lamps, Medium Wave Infrared Lamps, and Carbon Infrared Heaters. Their products feature advanced engineering for energy efficiency and consistent performance. Many industries rely on these lamps for automotive, industrial, and DIY applications.

Note: Selecting the right lamp type depends on the material, paint formulation, and desired curing speed.

Several popular infrared paint curing lamps illustrate the diversity of available options:

Solary Infrared Lamp: Uses red visible light to dry and cure paint, resulting in a durable and smooth finish.

AMT-3CH Infrared Lamp: Features three powerful shortwave panels that penetrate deeply into the paint layer. This lamp reduces drying times and ensures a superior finish. Adjustable arms and telescopic height settings allow users to cure full panels or multiple sections at once.

VEVOR 2000W Lamp: Delivers a strong 2000W output and adjustable working distance. The sturdy frame and quick baking capability make it ideal for large surfaces.

The following table summarizes key specifications and features:

Product Name | Power | Working Distance | Baking Area | Features |

|---|---|---|---|---|

Solary Infrared Lamp | N/A | N/A | N/A | Direct penetration for smooth finish |

AMT-3CH Infrared Lamp | N/A | N/A | N/A | Three shortwave panels for fast curing |

VEVOR 2000W Lamp | 2000W | 23-31 in | 31.5x31.5 in | Adjustable frame, quick baking |

Infrared paint curing lamps also vary in their temperature range and adjustability. For example, the VEVOR 2000W Lamp operates between 104-167℉ (40-75℃), allowing users to tailor the curing process to the paint and substrate. Adjustable frames and telescopic arms help position the lamp for optimal coverage and efficiency.

Huai'an Infrared Heating Technology offers specialized infrared heating modules for unique industrial needs. Their lamps achieve up to 96% energy conversion, reducing fuel costs and improving operational performance. Certifications such as CE and TUV ensure safety and reliability in demanding environments.

When choosing an infrared paint curing lamp, users should consider the lamp’s wavelength, power, and adjustability. Matching these features to the material and paint type leads to better results and greater efficiency. Advanced infrared solutions from Huai'an Infrared Heating Technology support a wide range of applications, helping professionals and DIY enthusiasts achieve high-quality finishes with confidence.

Metals respond efficiently to infrared paint curing because they conduct heat rapidly. This property allows the infrared energy to penetrate the surface and distribute warmth evenly. The process delivers faster drying times compared to traditional convection methods. However, the color and reflectivity of the metal can influence how much infrared energy the surface absorbs. Darker metals absorb more infrared heat, while lighter or reflective surfaces may require adjustments in lamp intensity or positioning.

The following table highlights key differences between infrared and convection curing for metals:

Feature | Infrared Curing | Convection Curing |

|---|---|---|

Speed | 50-75% faster than convection | Slower, takes tens of minutes |

Energy Efficiency | Direct heating, less wasted energy | Heats air first, more energy consumption |

Uniformity | Can struggle with complex shapes | Excellent for complex shapes, consistent |

Color Dependence | Affected by color reflectivity | Not dependent on color or substrate |

Part Geometry Challenges | Requires careful management | Handles mixed material/thickness loads better |

Infrared paint curing works best with powder coatings on metals. The process enhances the flow and adhesion of the coating, resulting in a smooth and durable finish. Proper temperature control is essential for achieving high-quality results. Manufacturers often select powder coatings because they respond well to rapid and consistent heating. This method also reduces the risk of trapped solvents, which can cause defects in the finish.

Infrared paint curing provides consistent and rapid heating of metal surfaces.

It improves the flow of powder coatings, leading to better adhesion and fewer defects.

Minimal airflow during curing prevents dust or particles from settling on the surface.

The process dries coatings from the inside out, reducing the risk of bubbles or blisters.

Infrared paint curing delivers faster drying times for metals than conventional ovens. The direct application of infrared energy shortens the drying and curing cycle, which increases productivity in industrial and automotive paint drying applications. Achieving the correct curing temperature is critical for the durability and appearance of the finish. When manufacturers control the temperature precisely, they produce coatings that meet industry standards and last longer.

Curing temperature is critical for the performance of powder coatings.

Proper temperature control ensures high-quality finishes.

Achieving the right temperature is essential for the longevity and aesthetic appeal of coated surfaces.

Note: Huai'an Infrared Heating Technology offers advanced infrared lamps that allow precise temperature control, supporting optimal results for coatings on metals.

Plastics present unique challenges during infrared paint curing. Many plastics have lower melting points than metals, making them sensitive to high temperatures. Infrared energy must be carefully managed to avoid warping or damaging the substrate. Shortwave infrared lamps can deliver intense heat, but medium wave or carbon infrared heaters often provide better control for plastics.

Paint adhesion on plastics depends on both the surface preparation and the curing process. Infrared paint curing can improve adhesion by promoting even drying and reducing the risk of trapped solvents. However, not all plastics respond equally. Some require special primers or surface treatments to ensure the paint bonds properly. The right combination of paint formulation and infrared wavelength leads to a durable and attractive finish.

Use medium wave or carbon infrared heaters for plastics to prevent overheating.

Monitor the surface temperature closely during drying and curing.

Apply primers or adhesion promoters when necessary.

Test a small area before full-scale application to ensure compatibility.

Tip: Professionals recommend adjusting lamp distance and intensity to match the specific type of plastic and paint used.

Wood absorbs and releases moisture, which affects how it responds to infrared paint curing. Infrared energy penetrates the surface and heats the wood from within, promoting even drying. However, uneven moisture content can lead to inconsistent results. Careful monitoring of both temperature and humidity ensures a smooth and uniform finish.

Infrared paint curing offers several advantages for wood surfaces. The process softens paint without burning or producing dust, making it ideal for restoring antique wood or old painted trim. Infrared tools also reduce the risk of fire compared to traditional heat guns. The result is a clean, smooth surface ready for refinishing or repainting.

Infrared paint removers are safer for antique wood and old painted trim.

They soften paint without burning or producing dust, making them effective for old lead-based paint.

Infrared tools have a lower risk of fire or damage compared to heat guns.

Wood can scorch or crack if exposed to excessive heat during drying and curing. Professionals recommend using lower-intensity infrared lamps and monitoring the process closely. Testing on a small area helps prevent damage and ensures the best results.

Note: Huai'an Infrared Heating Technology provides adjustable infrared modules that allow users to fine-tune the curing process for wood, reducing the risk of damage and improving finish quality.

Composites combine two or more materials to create a product with enhanced properties. These materials often include polymers, fibers, and resins. Each component reacts differently to heat. The polymeric binders in composites require precise thermal input to achieve proper crosslinking. If the temperature rises too high, the composite may degrade or deform. Manufacturers must understand the unique makeup of each composite to select the right infrared curing method.

Achieving uniform results on composites can be challenging. The different layers and materials within a composite may absorb heat at different rates. This can lead to uneven curing, which affects the final appearance and performance. Laminar airflow helps distribute heat evenly across the surface. Turbulent airflow, on the other hand, can cause pressure fluctuations and inconsistent results. Professionals often use medium wave or carbon infrared heaters to provide controlled, even heat for composite materials.

Curing paint on composites with infrared heat requires careful planning. The following table highlights key considerations:

Consideration | Description |

|---|---|

Temperature Sensitivity | Composites may degrade or deform at high curing temperatures (150-200°C), necessitating low-temperature solutions. |

Airflow Type | Laminar flow is preferred for uniform heat distribution, while turbulent flow must be controlled to avoid pressure fluctuations. |

Curing relies on precise thermal input for crosslinking polymeric binders.

Improper curing can lead to issues like poor adhesion and cracking.

Low-temperature powder coatings can be used to mitigate thermal sensitivity.

Tip: Always test a small area before full-scale curing to ensure the composite can withstand the selected infrared settings.

Glass and ceramics have high heat resistance, making them suitable for many industrial applications. However, these materials can still experience damage if exposed to rapid or uneven heating. Medium-wave infrared tubes match the absorption characteristics of glass, allowing for even heating. This helps prevent damage and ensures a smooth, durable finish.

Paint bonding on glass and ceramics depends on both the surface preparation and the curing process. Infrared paint curing promotes strong adhesion by providing consistent heat. This process helps the paint bond tightly to the surface, reducing the risk of peeling or flaking. Short-wave infrared tubes can deliver intense heat for rapid processing, which is especially useful for specialty coatings.

Thermal shock occurs when a material experiences a sudden change in temperature. This can cause glass or ceramics to crack or shatter. Infrared heating minimizes thermal shock and reduces the risk of cracking. Medium-wave infrared tubes provide even heating, which is crucial for preventing thermal shock. Short-wave infrared tubes offer rapid processing, further lowering the risk.

Infrared heating minimizes thermal shock and reduces cracking in glass and ceramics.

Medium-wave IR tubes provide even heating, matching the absorption needs of glass.

Short-wave IR tubes deliver intense heat for fast, safe processing.

Note: Selecting the right infrared wavelength and intensity is essential for safe and effective curing on glass and ceramics. Huai'an Infrared Heating Technology offers a range of solutions to meet these needs.

Thermal conductivity plays a major role in the outcome of infrared paint curing. Materials with high thermal conductivity, such as metals, transfer heat quickly across their surfaces. This property allows infrared energy to spread evenly, resulting in faster and more uniform curing. In contrast, materials with low thermal conductivity, like wood or certain plastics, absorb and retain heat more slowly. This difference can lead to uneven drying or surface defects if not managed properly.

Infrared paint curing relies on the ability of the substrate to absorb and distribute heat. The adjustment of infrared emitters to match the absorption properties of the paint and substrate is crucial for effective curing. When the heat transmission capacity is high, production speeds increase and energy savings become significant. The following points highlight how thermal conductivity influences infrared paint curing:

Infrared heat emitters enhance drying efficiency by rapidly converting radiation into heat.

Proper adjustment of infrared emitters to the paint’s absorption properties ensures effective curing.

High heat transmission capacity allows for faster production, improved quality, and energy savings.

Selecting the right infrared wavelength and lamp type, such as those offered by Huai'an Infrared Heating Technology, helps optimize the curing process for different materials.

Paint formulation directly affects the success of infrared paint curing. Each type of paint—whether water-based, solvent-based, or powder coating—responds differently to infrared energy. Water-based coatings often benefit from infrared paint curing because the process accelerates evaporation and reduces drying time. Solvent-based paints may require careful control of temperature to prevent defects like bubbling or blistering.

Powder coatings, commonly used on metals, respond well to infrared curing due to their ability to melt and flow evenly under controlled heat. The chemical composition of the paint, including pigments and binders, also determines how efficiently it absorbs infrared energy. Manufacturers must consider these factors when selecting both the paint and the curing method.

Material thickness influences how infrared paint curing performs. Thicker materials absorb and retain more heat, which can extend the curing time. Thin substrates, on the other hand, heat up quickly and may reach the desired curing temperature faster. However, rapid heating of thin materials can sometimes cause warping or surface imperfections if not monitored closely.

Infrared paint curing works best when users match the lamp intensity and wavelength to the thickness of the material. For example, shortwave infrared lamps penetrate deeper and are suitable for thicker substrates, while medium wave or carbon infrared heaters provide gentler heat for thinner or more delicate materials. Adjusting the curing process based on material thickness ensures a smooth, durable finish and prevents damage.

Tip: Always test infrared paint curing settings on a small section of the material before full-scale application. This approach helps identify the optimal balance between heat input and curing quality.

Surface preparation plays a critical role in the success of infrared paint curing. A clean, well-prepared surface allows paint to adhere properly and ensures even heat distribution during the curing process. Dust, oil, or old paint residues can create barriers that prevent infrared energy from reaching the substrate. These contaminants may cause uneven drying, poor adhesion, or visible defects in the final finish.

Professionals recommend several steps to achieve optimal surface preparation:

Remove all dust, grease, and loose particles using appropriate cleaning agents.

Sand the surface to create a uniform texture that promotes paint adhesion.

Apply primers or adhesion promoters when working with challenging materials like plastics or composites.

Ensure the surface is completely dry before applying paint or starting the curing process.

Proper surface preparation not only improves the bond between the paint and the substrate but also enhances the efficiency of infrared curing. When the surface is smooth and free of contaminants, infrared energy penetrates evenly, resulting in a consistent and durable finish. Skipping these steps can lead to issues such as bubbling, peeling, or incomplete curing.

Tip: Always inspect the surface under good lighting before painting. Even small imperfections can affect the final result after infrared curing.

Infrared heat intensity directly impacts the speed and quality of paint curing. Selecting the correct intensity and wavelength for the material and paint type is essential for achieving professional results. Different materials respond best to specific types of infrared lamps.

Short-wave infrared lamps deliver intense energy, making them highly effective for heating metal surfaces. These lamps can rapidly bring metal substrates to the desired curing temperature.

Medium-wave and long-wave infrared lamps provide gentler, more controlled heat. These options work well for curing paints on plastics, wood, and composites, as well as for drying adhesives.

Uniform heating across the surface prevents defects such as blistering, warping, or uneven finishes. Consistent heat application ensures that the paint cures evenly, resulting in a smooth and durable coating.

Infrared lamps can drastically reduce curing times. Processes that once required hours can now be completed in minutes, increasing productivity and reducing energy consumption.

Huai'an Infrared Heating Technology offers a comprehensive range of infrared lamps, including short-wave, medium-wave, and carbon infrared heaters. Their products allow users to match the lamp type and intensity to the specific needs of each project. By selecting the right infrared solution, professionals and DIY users can achieve high-quality finishes while saving time and energy.

Note: Always monitor the curing process and adjust lamp distance or intensity as needed. This approach helps prevent overheating and ensures the best possible results for every material.

Selecting the right curing method starts with understanding the material. Metals, plastics, wood, composites, glass, and ceramics each respond differently to infrared paint curing. Metals conduct heat quickly, making them ideal for rapid and uniform curing. Plastics need careful temperature control because they can warp or melt. Wood absorbs moisture, so it requires even heat distribution to prevent cracking. Composites have layers that may heat at different rates, which can affect the final result. Glass and ceramics resist high temperatures but can suffer from thermal shock if heated too quickly.

Professionals assess the substrate before choosing a curing process. They consider the thickness, shape, and surface condition of the material. For example, thin materials heat up faster and may need lower intensity. Complex shapes might require adjustable infrared lamps to reach all surfaces. By evaluating these factors, users can select the most effective infrared paint curing approach for their applications.

The type of paint plays a major role in the curing process. Infrared paint curing works especially well with water-based coatings and powder coatings. Water-based paints dry faster when exposed to infrared energy, which speeds up production and reduces wait times. Powder coatings melt and flow evenly under the right infrared wavelength, creating a smooth and durable finish.

To achieve professional-quality drying, users must match the infrared lamp’s wavelength, shape, and power output to the paint’s absorption characteristics. This precise adjustment allows for efficient drying and minimizes thermal stress on the substrate. For example, shortwave infrared lamps deliver intense energy for metals and powder coatings, while medium wave or carbon infrared heaters suit plastics and wood. Matching the right technology to the paint and substrate ensures optimal curing and supports versatile applications across industries.

Tip: Adjusting the infrared emitter to the paint’s needs helps evaporate solvents quickly and keeps surrounding areas cooler. This approach protects sensitive materials and improves results in both industrial and DIY applications.

Safety remains a top priority during infrared paint curing. Users must monitor the curing process to prevent overheating, especially with heat-sensitive materials like plastics and wood. Proper ventilation is important because some paints release fumes during curing. Operators should wear protective gear, such as gloves and safety glasses, to avoid burns or exposure to chemicals.

Infrared lamps should be positioned securely and kept at the recommended distance from the surface. This prevents accidental contact and ensures even heat distribution. Regular maintenance of infrared equipment also reduces the risk of malfunction and extends the life of the lamps. By following these safety practices, professionals and DIY users can achieve reliable results and protect themselves during all curing applications.

Infrared paint curing stands out for its cost-effectiveness and energy efficiency. Many industries choose this method to reduce operational expenses and improve productivity. Infrared technology delivers heat directly to the painted surface, which minimizes wasted energy and shortens curing times.

Several key points highlight the advantages of infrared paint curing over traditional methods:

Infrared curing systems offer significant energy savings. They operate at lower temperatures and require less time to complete the curing process.

Traditional curing ovens often run at high temperatures, typically between 150–200°C (300–400°F). This high energy demand increases utility costs and puts more strain on facility resources.

Low-temperature cure (LTC) powders allow curing at 120–140°C (250–285°F). This adjustment can reduce energy consumption by up to 30%. For example, a European automotive supplier reported a 22% reduction in energy costs after switching to LTC powders.

UV-curable powders present another efficient option. These powders can cut curing energy consumption by 40% and reduce production time per unit by half compared to conventional methods.

The following table summarizes the cost and efficiency differences between infrared and traditional curing:

Curing Method | Typical Temperature | Energy Consumption | Curing Time | Cost Savings |

|---|---|---|---|---|

Traditional Oven | 150–200°C | High | Longer | Baseline |

Infrared (LTC) | 120–140°C | Up to 30% lower | Shorter | 22% reduction |

UV-Curable Powder | Lower | Up to 40% lower | Half the time | Significant |

Manufacturers benefit from these savings in several ways. Lower energy use means reduced utility bills and a smaller carbon footprint. Faster curing times increase throughput, allowing more products to move through the production line each day. These improvements help businesses remain competitive in markets where efficiency and sustainability matter.

Huai'an Infrared Heating Technology designs infrared lamps and modules with energy efficiency in mind. Their products convert up to 96% of input energy into usable heat, which further reduces operational costs. Many users see a 20% to 50% drop in fuel expenses when they switch from traditional ovens to advanced infrared solutions.

Tip: Companies that invest in energy-efficient curing technology often recover their initial costs quickly through lower utility bills and increased productivity.

Infrared paint curing delivers different results depending on the material. Industry experts emphasize the importance of precise temperature control and understanding chemical composition for optimal curing. Localized infrared heating proves valuable for sensitive applications, such as electric vehicle batteries, by protecting surrounding components. Professionals achieve quick and effective results by adjusting systems to match the product and process. Choosing the right method ensures consistent results. Readers seeking improved efficiency should explore advanced infrared solutions from Huai'an Infrared Heating Technology or consult experts for specific material needs.

An infrared paint curing lamp uses radiant energy to dry and harden paint on surfaces. This technology speeds up the curing process and improves finish quality. Many industries rely on infrared paint curing lamp systems for efficient and consistent results.

An infrared paint curing lamp can cure paint on metals, plastics, wood, composites, glass, and ceramics. Each material responds differently. Users must adjust the infrared paint curing lamp settings to match the substrate and paint type for optimal results.

An infrared paint curing lamp delivers heat directly to the painted surface. This direct application reduces wasted energy and shortens curing times. Many manufacturers report lower utility bills after switching to an infrared paint curing lamp.

An infrared paint curing lamp can safely cure paint on heat-sensitive materials like plastics and wood. Operators must monitor temperature and adjust the infrared paint curing lamp intensity to prevent warping or damage.

Powder coatings and water-based paints respond well to an infrared paint curing lamp. These paints cure quickly and evenly. Users should match the infrared paint curing lamp wavelength to the paint formulation for best results.

Professionals assess the material, paint type, and desired curing speed before selecting an infrared paint curing lamp. Shortwave lamps suit metals, while medium wave or carbon lamps work better for plastics and wood. Adjustability is key for complex shapes.

An infrared paint curing lamp can reduce curing time by up to 75% compared to conventional ovens. The infrared paint curing lamp heats the paint layer directly, allowing for faster drying and increased productivity.

Regular cleaning and inspection keep an infrared paint curing lamp operating efficiently. Users should check for dust buildup, inspect electrical connections, and replace worn components. Proper maintenance extends the life of the infrared paint curing lamp.

Infrared Paint Drying: How It Speeds Up Production Without Sacrificing Finish Quality

Infrared Powder Coating Lamps: Pros, Cons, and Key Benefits Explained

How Infrared Heaters Help You Achieve a Smooth, Professional Paint Finish

Industrial Infrared Heating Lamps: Revolutionizing PET Blow Molding, Paint Curing, and Beyond