Infrared emitters convert electrical energy into infrared radiation, producing heat through either semiconductor materials or heating elements. These devices play a critical role in industrial heating by providing rapid, contactless, and precise thermal energy. Infrared radiation targets specific areas, reducing energy waste and improving efficiency. Industries benefit from lower fuel consumption, faster heating, and the ability to match the emission spectrum to the material’s absorption needs. This technology also supports sustainability by minimizing harmful emissions and optimizing energy use.

Infrared emitters convert electrical energy into targeted heat quickly and without contact, improving efficiency and reducing energy waste.

Different types of infrared emitters, like semiconductor and heating element types, suit various industrial needs based on wavelength and heating speed.

Infrared LEDs offer energy-efficient, long-lasting, and low-heat infrared light ideal for sensing, security, and automation applications.

Infrared heaters deliver heat directly to materials, saving energy by avoiding heating the surrounding air and enabling faster processing.

Choosing the right infrared emitter depends on matching the wavelength to the material, required heating speed, and environmental conditions.

Regular maintenance, including cleaning and inspection, extends the life and performance of infrared emitters and heaters.

Infrared emitters provide safer operation with features like automatic shutoff and dust resistance, but proper installation and safety practices remain essential.

Using certified infrared heaters ensures reliable performance, energy savings, and compliance with safety standards in industrial settings.

Infrared emitters serve as devices that generate infrared radiation by converting electrical energy into heat. These components play a vital role in many modern technologies, especially in infrared heaters. Engineers design infrared emitters to deliver targeted thermal energy, which allows for efficient heating without direct contact. Industries rely on these devices for processes that demand precision and speed. Infrared emitters support applications ranging from industrial manufacturing to healthcare diagnostics.

Tip: Infrared emitters provide non-contact heating, which reduces contamination risks and improves process control.

Infrared heaters use these emitters to deliver rapid and consistent heat. The technology behind infrared emitters enables industries to optimize energy use and minimize waste.

Infrared emitters come in several types, each with unique operating principles and applications. The following table outlines the main categories and their characteristics:

Infrared Emitter Type | Operating Principle | Key Components | Typical Applications |

|---|---|---|---|

Active Infrared Sensors | Emit infrared light using an IR LED; detect objects by sensing reflected or interrupted IR light. | IR LED (emitter), IR receiver | Proximity detection, automatic doors |

Passive Infrared Sensors | Detect infrared radiation naturally emitted by objects, especially heat from living beings. | Pyroelectric or thermal elements | Motion-sensitive lighting, security |

Pyroelectric Infrared Sensors | Generate electrical signals when exposed to changing IR radiation intensity. | Pyroelectric crystals | Temperature variation detection |

Thermopile Infrared Sensors | Measure temperature differences caused by IR radiation absorption. | Thermoelectric elements | Non-contact temperature measurement |

Infrared heaters often utilize quartz, carbon, or ceramic emitters to achieve specific heating profiles. Manufacturers select the emitter type based on the required wavelength, response time, and application environment.

Infrared emitters also include IR LEDs, edge emitting lasers, and VCSELs. These components support proximity sensors, touchless interfaces, barcode scanners, and medical devices. Advanced models, such as Quartz IR Emitters, offer high efficiency and precise control for demanding industrial settings.

High-quality infrared emitters and infrared heaters possess several distinguishing features that enhance performance and reliability. The following list highlights key attributes:

Rapid heating: Achieve target temperatures in seconds, improving process speed.

Adjustable power range: Support versatile applications with settings from 500W to 2000W.

Energy efficiency: Consume up to 40% less power than traditional halogen lamps, reducing operational costs.

Long lifespan: Operate for at least 10,000 hours, minimizing downtime.

Precise temperature control: Maintain consistent heating within ±1°C.

Fast response time: Enable immediate start and stop of heating processes.

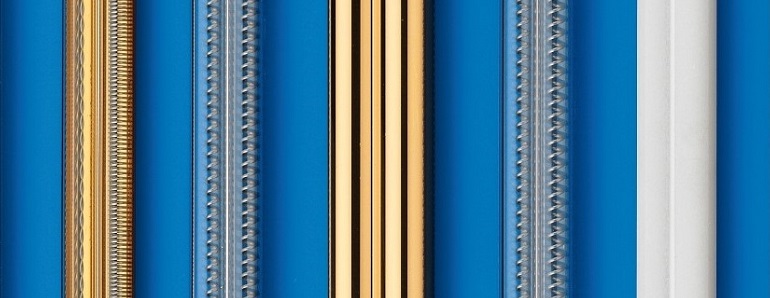

Reflector coatings: Gold or ceramic coatings reflect up to 90% of infrared radiation, maximizing energy delivery.

Safety features: Include automatic shutoff, IP65 dust and water resistance, and EMI shielding.

Certifications: Meet CSA, UL, and other standards for safety and reliability.

Infrared heaters equipped with these features deliver superior performance in industrial, medical, and scientific applications. Users benefit from faster processing, improved product quality, and enhanced safety.

Note: Infrared heaters certified to American National Standard Z83.20 and UL-listed components ensure safe operation in demanding environments.

Infrared emitters and infrared heaters continue to evolve, offering advanced solutions for industries that require efficient, precise, and reliable thermal energy.

Infrared emitters transform electrical energy into infrared radiation through advanced physical processes. When electrical current passes through the emitter, it excites electrons within the material. This excitation causes the release of energy in the form of infrared radiation, which falls outside the visible spectrum. The process relies on temperature differences at the nanoscale, especially between components like diodes and antennas. When a diode reaches a higher temperature than a connected resistor or antenna, it pushes current directionally, generating a voltage that results in the emission of infrared photons. This mechanism leverages solid-state physics, quantum mechanics, and thermodynamics to achieve efficient conversion.

Infrared radiation represents electromagnetic energy emitted by objects above absolute zero. The intensity and wavelength of this radiation depend on the temperature and material properties of the emitter. In industrial settings, this direct conversion enables rapid and targeted delivery of infrared heat, minimizing energy loss and maximizing process efficiency.

Note: Infrared heaters convert nearly all input electricity into radiant heat, providing instant warmth to objects and surfaces rather than heating the surrounding air. This direct approach reduces energy waste and improves overall heating performance.

Semiconductor-based infrared emitters operate using principles such as electroluminescence and Joule heating. When an electric current flows through a semiconductor junction, electrons and holes recombine, releasing energy as infrared photons. In some advanced designs, materials like graphene enable efficient broadband thermal emission in the mid-infrared range. The emission spectrum depends on the temperature of the semiconductor and the quantum confinement effects within the material. Quantum dots, for example, restrict electron movement, creating discrete energy levels that enhance infrared photon emission. These mechanisms allow precise control over the wavelength and intensity of emitted infrared radiation, making semiconductor emitters ideal for applications requiring accuracy and fast response.

Heating element-based infrared emitters use materials such as mono-crystalline silicon, silicon carbide, platinum, or antimony-doped tin dioxide. When electrical current passes through these materials, it generates heat via Joule heating. The heated element emits broadband thermal radiation, primarily in the infrared range. Manufacturers select materials for their high melting points, oxidation resistance, and stable electrical properties. Micro-machined membrane structures can withstand temperatures up to 1300 K, ensuring reliable and efficient operation. The emission mechanism in these emitters is fundamentally thermal, producing radiant heat that can be directed and controlled for industrial processes.

The effectiveness of infrared emitters in industrial applications depends on the wavelength of the emitted infrared radiation. Different types of emitters produce varying wavelengths, which influence their suitability for specific tasks. The following table summarizes the main categories:

Infrared Type | Wavelength Range (μm) | Description and Relevance |

|---|---|---|

Near-IR (NIR) | 0.75 - 1.4 | Shortest IR wavelengths; used in applications requiring high energy and fast response |

Mid-IR (MIR) | 1.4 - 3 | Intermediate wavelengths; balance between penetration and energy |

Far-IR (FIR) | 3 - 1000 | Longest IR wavelengths; typically lower energy, used for heating and sensing where deeper penetration or specific absorption bands are targeted |

Short-wave (near-IR) emitters, such as quartz halogen lamps, deliver fast response and high surface temperatures, making them suitable for processes that demand rapid heating. Medium-wave emitters, often constructed as quartz cassette-style lamps, operate at moderate temperatures and serve applications where a balance between energy and penetration is needed. Long-wave (far-IR) emitters, including ceramic heaters, provide lower temperature output and deeper penetration, ideal for heating applications that require specific absorption characteristics.

Tip: The temperature of the emitter determines the peak wavelength of infrared radiation. Higher temperatures shift the emission toward shorter wavelengths, increasing energy output and enabling faster heating cycles.

Quartz IR Emitters from Huai’an Infrared Heating Technology exemplify high-performance industrial infrared emitters. These products achieve energy efficiency ratings between 92% and 96%, with radiant energy conversion efficiency reaching up to 86%. Their rapid heat-up time of 1–2 seconds and precise temperature control (±1°C) support demanding industrial processes. Compared to traditional halogen lamps, these emitters deliver up to 40% energy savings, making them a preferred choice for applications that require reliable and efficient infrared heat.

LED infrared technology uses light-emitting diodes to generate invisible infrared radiation. Engineers design these devices to emit specific wavelengths by selecting semiconductor materials with precise bandgap energies. Infrared leds operate efficiently, converting electrical energy directly into infrared light with minimal heat loss. This efficiency makes them ideal for applications where energy savings and longevity matter.

Infrared led lights offer several advantages over traditional infrared sources. They consume less power, produce less heat, and last much longer. The compact size of infrared leds allows integration into a wide range of devices, from industrial sensors to consumer electronics. Manufacturers often choose infrared led lighting for its reliability and ability to deliver targeted illumination without disturbing human operators.

Tip: Infrared led lights provide invisible illumination, making them perfect for environments where visible light could interfere with operations or safety.

The core principle behind how do led infrared lights work is electroluminescence. This process enables infrared leds to emit light efficiently and reliably. The following steps outline how electroluminescence produces infrared emission in light-emitting diodes:

A forward bias is applied to the p-n junction of the infrared led, reducing the potential barrier and allowing electrons and holes to enter the active region.

In the active region, electrons from the conduction band recombine with holes in the valence band, releasing energy as photons.

For infrared led lights, the semiconductor materials used—such as Gallium Arsenide—have smaller direct bandgaps, resulting in photon emission within the infrared spectrum.

The bandgap energy determines the wavelength of the emitted light. Smaller bandgaps produce longer wavelengths, which fall into the infrared range.

A continuous flow of current maintains steady electron-hole recombination, ensuring consistent infrared photon emission.

Material selection, such as GaAs and its alloys, directly influences the wavelength and efficiency of infrared led lighting.

This mechanism allows infrared leds to deliver precise and stable infrared output, making them essential for modern sensing and communication technologies.

Industries rely on infrared led lights for a wide range of applications. Infrared leds play a critical role in machine vision systems, enabling quality control in pharmaceutical packaging and electronics assembly. Production lines use infrared led lighting for monitoring and automation, including break-beam sensors and optical encoders. Agricultural operations benefit from infrared leds in sorting machines that detect ripeness and contaminants.

Infrared led lights also support warehouse automation, safety interlocks, and emerging Industry 4.0 solutions such as thermal monitoring and gas sensing. Their invisible illumination does not disturb workers, while their energy efficiency reduces operational costs. The durability and long lifespan of infrared leds make them suitable for harsh industrial environments, where shock and vibration resistance is essential.

Aspect | LED Infrared Lights (Near-Infrared LEDs) | Traditional Infrared Emitters (Incandescent IR Bulbs) |

|---|---|---|

Energy Efficiency | High efficiency (30–50% wall-plug efficiency); converts more electrical input into useful IR light | Low efficiency (~10% useful light output; ~90% energy lost as heat) |

Power Consumption | Uses a fraction of the power to achieve equal or better IR output | High power consumption due to energy lost as heat |

Lifespan | Very long lifespan, typically 25,000 to 50,000+ hours | Short lifespan, around 1,000 hours |

Heat Emission | Low heat output, reducing energy waste and cooling requirements | High heat output, wastes energy and increases cooling needs |

Environmental Impact | Mercury-free, RoHS-compliant, eco-friendly, less waste due to longer life | May contain mercury, higher waste due to frequent replacements |

Durability | Encapsulated in epoxy, resistant to vibration and shock | More fragile, prone to failure |

Infrared led lighting stands out for its non-intrusive operation, compact size, and ability to enhance defect detection beyond visible light. These features support real-time sensing and control in smart factories, making infrared leds a cornerstone of modern industrial automation.

Infrared heaters deliver thermal energy by emitting infrared radiation directly from heated elements to target materials. This process bypasses the need to heat the surrounding air, resulting in rapid and efficient heating. The core principle behind how infrared heaters work involves the direct transfer of energy through electromagnetic waves. These waves travel through air and are absorbed by objects, which then convert the radiant energy into heat. Reflectors made from materials such as aluminum or quartz focus and direct the infrared radiation, maximizing heat delivery and minimizing energy loss. Engineers select heating elements like tungsten, quartz, ceramic, or carbon fiber to match the specific requirements of each industrial application.

Aspect | Description |

|---|---|

Heating Principle | Direct transfer of thermal energy via infrared radiation from heated elements to target materials, bypassing air heating. |

Heating Elements | Materials such as tungsten, quartz, ceramic, carbon fiber, or halogen that emit infrared waves when heated. |

Infrared Radiation | Electromagnetic waves that travel through air and are absorbed by objects, converting radiant energy into heat efficiently and rapidly. |

Reflectors | Made from aluminum, stainless steel, ceramic, or quartz; designed to focus and direct infrared radiation to maximize heat delivery and minimize energy loss. |

Wavelength Selection | Near, medium, or far infrared wavelengths chosen based on application to optimize absorption and heating speed. |

Rapid Heating Mechanism | Targeted infrared energy directly heats surfaces/materials without warming the air, enabling instant and uniform heat application. |

Applications | Processes like drying, curing, welding, embossing, and laminating benefit from this precise and fast heating method. |

Note: The design and quality of reflectors play a crucial role in ensuring consistent and efficient heating in industrial infrared heaters.

Infrared heaters come in several types, each tailored for specific industrial needs. The main categories include shortwave, medium-wave, and longwave heaters, as well as variations based on the heating source and construction.

Quartz IR Emitters stand out for their rapid response and high efficiency. These heaters use quartz tubes that emit short or medium-wave infrared radiation. Industries rely on them for applications requiring fast heating, such as paint drying, glass heating, and plastic molding. Huai’an Infrared Heating Technology manufactures advanced Quartz IR Emitters, including Short Wave Infrared Lamps, Fast Medium Wave Infrared Lamps, and Round Tube IR Lamps. These products deliver precise and uniform infrared heat, supporting high productivity and energy savings.

Carbon and ceramic heaters emit longwave infrared radiation. Carbon heaters use carbon fiber elements, which provide even heat distribution and energy efficiency. Ceramic heaters feature ceramic plates that emit far-infrared heat, making them suitable for processes that require gentle, deep heating. Both types offer durability, low maintenance, and environmentally friendly operation. Their space-saving designs and ability to heat irregularly shaped products make them popular in various industries.

Heater Type Category | Specific Types/Examples | Wavelength Classification | Advantages |

|---|---|---|---|

By Wavelength | Shortwave, Medium-wave, Longwave | Shortwave: 700-1400 nm | Fast heating, ideal for preheating and coating processes |

Heating Source | Gas heated radiators, Electrically heated radiators | Medium to long waves, Short to longwave | Energy efficient, instant heat, durable, improves product quality |

Specific Heater Types | Tubular/flat metallic, Ceramic, Quartz tube, Halogen tube | Long, Long, Medium/Short, Ultra-short | Uniform heating, space-saving, fast heat transfer |

Tip: Infrared heaters provide non-contact heating, which allows for quick processing of moving products and enhances product quality.

Infrared heaters offer significant energy savings in industrial environments. By directly heating objects rather than the air, these systems reduce energy waste and shorten process times. For example, in textile coating, the addition of an infrared booster oven halved drying time and saved 65,000 kWh of electricity annually. Industries such as paint drying and plastic molding report up to 90% greater efficiency compared to conventional heating methods. These improvements translate to lower operational costs and reduced environmental impact.

Huai’an Infrared Heating Technology ensures product reliability and safety by meeting international certifications and quality standards, including ISO 9000, TUV, ATEX, and IECEx. These certifications guarantee that their infrared heaters perform consistently in demanding industrial settings.

Note: Certified infrared heaters from reputable manufacturers help industries achieve energy savings, process control, and compliance with global safety standards.

Key Components

A typical industrial infrared emitter consists of several essential parts that work together to deliver precise heating.

The core of the system is an IR LED, which emits focused infrared light.

A photodiode or phototransistor acts as the receiver, detecting reflected or interrupted infrared signals.

Supporting electronics, such as operational amplifiers or comparator circuits, process the signals for accurate control.

A potentiometer allows users to adjust sensitivity, ensuring optimal detection and response.

Indicator LEDs provide immediate visual feedback when the system detects an object or change in the environment.

These components form the backbone of many infrared heaters and infrared led lights used in industrial automation, quality control, and safety systems. The integration of these elements ensures reliable performance and adaptability across various applications.

Tip: Proper arrangement and shielding of these components help maintain signal integrity and extend the lifespan of infrared heaters in demanding environments.

Manufacturers select materials for infrared heaters and infrared led lights based on their emission properties and operational advantages. Ceramic and quartz are the most common choices. Ceramic emitters, available in both hollow and solid forms, excel at producing long-wave infrared radiation. Quartz emitters, including quartz cassettes and quartz-halogen or tungsten types, deliver medium-wave and short-wave infrared output. Quartz-halogen emitters feature a coiled tungsten wire sealed in quartz glass filled with inert gas. This design achieves high radiation intensity and rapid thermal response, making it ideal for processes that require quick heating and cooling cycles.

These materials enable efficient energy transfer, often exceeding 95%. They also allow engineers to tune emission wavelengths to match the absorption characteristics of target materials. This flexibility supports a wide range of industrial heating applications, from drying and curing to forming and molding. Safety and operational standards guide the selection and installation of these materials, ensuring that infrared heaters and infrared led lights operate reliably and safely.

Engineers use advanced control and modulation techniques to optimize the performance of infrared heaters and infrared led lights in industrial settings.

Power controllers operate emitters at full capacity, providing stable and consistent output.

Common control methods include phase angle control, fast pulse group control, and pulse width modulation.

Automatic power control systems use radiation pyrometers to measure the true temperature of objects, adjusting irradiation power regardless of material color.

Dynamic materials, such as vanadium dioxide (VO2), further enhance control. VO2 changes its emissivity based on temperature, acting as an insulator below 68 °C and as a metallic emitter above this threshold. This property allows infrared heaters to self-regulate, improving energy efficiency and process precision.

High-output infrared emitters can be pulsed at frequencies from 1 Hz to 200 Hz.

Modulation depth often reaches 50%, allowing precise heating control.

Integrated drive electronics enable voltage-variable frequency selection without mechanical parts.

Peak pulse temperatures remain stable, independent of pulse frequency.

These features increase accuracy and efficiency in industrial infrared heating.

Note: Effective control and modulation not only improve process outcomes but also extend the service life of infrared heaters and infrared led lights.

Infrared emitters and visible light sources differ fundamentally in their emission characteristics. Infrared emitters generate thermal radiation, producing a continuous spectrum of wavelengths primarily in the infrared range. Their peak emission wavelength shifts with temperature, following Wien's displacement law. Most infrared emitters, including infrared leds, operate at high temperatures and emit radiation due to molecular vibrations. Infrared leds produce narrowband emission, typically between 0.9 and 1.3 micrometers, while thermal emitters like silicon carbide rods and nichrome wires emit broadband infrared rays. In contrast, visible light sources emit light in discrete or broad visible wavelength ranges. Mercury and xenon arc lamps display uneven spectral intensity, with mercury lamps peaking in the near-ultraviolet and blue regions. Visible light leds use semiconductor processes to produce specific emission spectra, often combining blue light with phosphor coatings for white light. Lasers emit coherent, monochromatic light at discrete wavelengths, which differs from the broad thermal emission of infrared leds.

Note: Infrared leds excel in applications where invisible illumination and precise wavelength control are required, while visible light sources provide bright, color-rich output for general lighting and imaging.

The structural design of infrared emitters sets them apart from visible light sources. Infrared leds often incorporate quantum well and photonic crystal structures to achieve narrowband emission and precise wavelength control. These advanced micro/nanostructures, such as distorted photonic lattices and metasurfaces, enable angle-insensitive and tunable emission in the mid-infrared range. For example, a double-disk unit cell structure creates ultra-narrowband thermal emission over a wide range of angles. Infrared leds require coatings and substrates with chemical compositions tailored for infrared transmission, which must withstand harsh environments and longer wavelengths. In contrast, visible light sources rely on simpler designs, such as tungsten filaments or standard LED chips, optimized for shorter wavelengths and higher photon energies. Materials and coatings for visible light sources focus on durability and efficient transmission of visible light, while infrared leds prioritize spectral control and thermal stability.

Tip: Engineers select materials for infrared leds based on their ability to transmit infrared rays efficiently and withstand high operating temperatures.

Infrared leds and visible light sources serve distinct roles in industrial environments. Infrared leds perform reliably in harsh conditions, such as dust-filled mining sites, glare-prone areas, and complete darkness. These devices enable night vision, obstacle recognition, and 3D terrain mapping in automation systems. Infrared leds also support passive operation, making them ideal for stealth and security applications. Visible light systems excel in controlled environments that require detailed, color-rich imagery, such as warehouses for inventory tracking and quality control. However, visible light sources struggle in fluctuating light, glare, dust, or darkness, often needing supplementary lighting or filters.

Aspect | Infrared Emitters (Infrared LEDs) | Visible Light Sources (Visible LEDs) |

|---|---|---|

Wavelength Range | 780 nm to 1 mm (invisible to human eye) | 380 nm to 780 nm (visible spectrum with multiple colors) |

Visibility | Invisible, requires sensors/detectors | Visible, perceived directly by human eye |

Penetration & Effects | Strong penetration, thermal effects | Limited penetration, bright and colorful illumination |

Electrical Features | Lower forward voltage, higher rated current for stability | Higher forward voltage, lower rated current requiring control |

Primary Applications | Signal transmission, night vision, security, long-distance communication, harsh environments | Lighting, display, short-range high-speed data transmission in controlled environments |

Security Use | Widely used in infrared cameras, thermal imagers, smoke alarms, infrared curtains | Limited, mainly for visual display or surveillance footage |

Communication | Remote control, telemetry, optical isolation, optical switches | Indoor short-range wireless optical communication |

Industrial Suitability | Robust in mining, agriculture, outdoor logistics | Preferred where detailed, color-rich imagery is needed |

Complementarity | Often combined with visible LEDs for hybrid systems | Often combined with infrared LEDs for hybrid systems |

Near-infrared leds, operating in the 700 to 2500 nm range, offer strong tissue penetration with low heat, making them ideal for security surveillance, facial recognition, and quality control. For example, 940 nm infrared leds are widely used in nighttime imaging due to their invisibility and high signal-to-noise ratio. Long-wave infrared leds enable moisture detection in agriculture and component analysis in recycling. These specialized applications highlight the advantages of infrared leds in non-invasive sensing and detection tasks where visible light sources cannot perform effectively.

Callout: Hybrid systems that combine infrared leds and visible light sources optimize performance across varying industrial environments, allowing autonomous vehicles and smart factories to switch sensors based on lighting conditions.

Industrial infrared emitters require careful installation and operation to ensure safety and optimal performance. Installers should mount infrared heating panels at a height of 6 to 8 feet above the floor. This placement provides effective heat distribution and reduces the risk of accidental contact. Only qualified personnel should handle installation, service, and annual inspections. Following the manufacturer's safety guidelines remains essential for compliance and protection.

Operators should maintain clearances to combustibles, keeping at least 1 meter in front and 0.5 meters on the sides and rear unless otherwise specified. Posting warning signs and keeping the manufacturer's manual accessible helps reinforce safety protocols. All warning labels must remain attached and readable. Regularly inspect vent pipes, air inlets, and electrical connections for obstructions, damage, or corrosion. Clean reflectors and ensure they are properly mounted to maximize efficiency. In areas accessible to children or pets, use guards to prevent burns. Prefer fixed wall or ceiling-mounted panels for routine use, and avoid extension cords by using dedicated outlets. Smart controls such as thermostats, timers, and overheat sensors enhance operational safety.

Tip: Implement workplace policies that define who can adjust heaters, set inspection intervals, and outline shutdown procedures to maintain a safe environment.

Selecting the appropriate infrared emitter for an industrial application involves several critical factors. The spectral characteristics of the emitter should match the absorption properties of the material being heated. This alignment maximizes heating efficiency and ensures effective energy transfer. Consider the operating temperature and wavelength range, as higher temperatures produce shorter wavelengths and greater energy output.

Evaluate the power density and required heating speed. Rapid heating applications often benefit from short-wave or quartz tube heaters, while slower processes may require higher mass panel heaters. Material thickness also influences the choice, as thicker materials absorb a broader range of wavelengths more effectively. Environmental conditions, such as debris and air circulation, can impact performance. Infrared heating requires a clear line of sight, so keep emitter surfaces clean and free from obstructions.

Reflector type matters as well. Internal reflectors typically require less maintenance in dusty environments. Heater lifespan decreases with higher operating temperatures, so selecting a unit with a slightly higher capacity can extend service life. Product testing helps determine the optimal wavelength for specific materials and processes. Decide between electric and catalytic emitters based on process speed and temperature needs; electric emitters suit rapid, high-temperature applications, while catalytic emitters work best for slower, lower-temperature processes.

Selection Factor | Consideration Example |

|---|---|

Spectral Match | Align emitter wavelength with material absorption peak |

Operating Temperature | Higher temp = shorter wavelength, more energy |

Power Density | Rapid heating needs higher power density |

Material Thickness | Thicker materials absorb broader wavelength range |

Environmental Factors | Debris, airflow, and obstructions affect performance |

Reflector Type | Internal reflectors for dusty settings |

Heater Lifespan | Higher capacity extends service life |

Emitter Type | Electric for fast, catalytic for slow processes |

Routine maintenance ensures the longevity and efficiency of infrared emitters. Regular cleaning of the emitter and reflector removes dust and debris, maintaining optimal heat transfer. Inspect electrical connections and mounting hardware periodically to ensure safety and stability. Replace worn or damaged parts promptly to prevent failures.

Store heaters in a dry, sheltered location during off-seasons to protect them from environmental damage. Use infrared cameras as diagnostic tools to assess emitter condition. Clean fuel gas filters in gas-powered systems at least annually, and lubricate fan motor bearings as recommended by the manufacturer. Maintain spare parts such as emitters, thermocouples, and relays to minimize downtime during repairs.

Note: Well-maintained infrared heaters can operate for several thousand hours, with high-quality units exceeding 10,000 hours of service. Regular inspection and cleaning not only extend lifespan but also ensure consistent and efficient performance.

Infrared heaters deliver efficient, targeted heat by matching emitter wavelength to material needs, increasing production efficiency by at least 30% in processes like curing and drying. Facilities benefit from up to 96% energy conversion, 20–50% fuel cost savings, and low maintenance. Choosing certified infrared heaters from Huai’an Infrared Heating Technology ensures long lifespan, safety, and tailored support. For best results, users should select infrared heaters based on application, maintain regular inspections, and verify compliance with safety standards. Reliable infrared heaters improve product quality, workplace comfort, and sustainability.

Infrared emitters provide rapid, targeted heating. They reduce energy waste and improve process efficiency. Many industries choose them for precise temperature control and fast response times.

Quartz IR Emitters deliver short or medium-wave infrared radiation. They heat up quickly and suit processes needing fast temperature changes. Ceramic heaters emit long-wave infrared, offering gentle, deep heating for sensitive materials.

Infrared emitters play a key role in night vision optics. They provide invisible illumination, allowing cameras and sensors to detect objects in complete darkness without visible light.

Operators should install heaters at recommended heights, maintain clearances, and follow manufacturer guidelines. Regular inspections and cleaning help ensure safe and efficient operation.

Selecting the correct wavelength ensures maximum energy absorption by the target material. Shorter wavelengths deliver higher energy and faster heating, while longer wavelengths penetrate deeper and suit thicker or sensitive materials.

Infrared emitters convert most electrical energy into radiant heat. This direct transfer reduces energy loss and can lower operational costs by up to 50% compared to conventional systems.

Routine cleaning of emitters and reflectors, regular inspection of electrical connections, and prompt replacement of worn parts help maintain performance and extend service life.