Views: 0 Author: Site Editor Publish Time: 2025-08-12 Origin: Site

Quartz IR Emitters from Huai'an Infrared Heating Technology deliver the fastest industrial performance among all infrared heating element options in 2025. Their advanced design ensures rapid heat-up, superior energy savings, and consistent results in demanding environments. The quartz infrared halogen lamp market, valued at $275 million in 2025, shows 65% adoption in industrial heating due to these benefits. Robust certifications, such as TUV and Certificates of Conformity, reinforce the reliability of these industrial infrared lamps.

Quartz IR Emitters from Huai'an Infrared Heating Technology heat up fastest, reaching full temperature in 1-2 seconds.

These quartz emitters save energy by operating at 92-96% efficiency, reducing operational costs significantly.

Portable infrared heaters offer flexibility for changing industrial layouts and support quick repositioning.

Quartz IR Emitters suit many industries like plastics, automotive, food processing, electronics, and photovoltaics due to their precise and rapid heating.

Regular maintenance, including cleaning and electrical checks, keeps infrared lamps working fast and extends their lifespan.

High watt density and smart system integration improve heating speed and energy use in industrial processes.

Choosing the right infrared heater type for each application boosts productivity, product quality, and energy savings.

Runner-up brands like Infratech and Herschel also provide reliable, energy-efficient infrared heaters for various industrial and commercial uses.

Performance Overview

Industrial buyers often compare infrared heaters based on how quickly they deliver heat and how well they integrate into existing systems. Quartz IR emitters from Huai'an Infrared Heating Technology stand out for their instantaneous response, reaching full heat output in just 1-2 seconds. Infratech and other leading brands, such as Herschel and EUROLINIA, also offer reliable performance, but their response times and energy conversion rates vary. Ceramic infrared heaters typically require up to five minutes to reach full temperature, while metal-sheathed heaters take longer but offer durability for rugged environments. Portable models from these brands allow flexible installation and easy repositioning, making them suitable for dynamic production lines or temporary workstations.

Note: Rapid heat-up and high energy efficiency directly impact productivity and operational costs in industrial settings.

The following table summarizes the key metrics for the top replacement infrared heating elements in 2025:

Brand/Type | Response Time | Energy Efficiency | Compatibility | Industrial Suitability | Portable Options |

|---|---|---|---|---|---|

Huai'an Quartz IR Emitters | 1-2 seconds | 92-96% | High (modular, automated lines) | Paint drying, plastics, solar, automotive | Yes |

Infratech Quartz IR Heaters | 1-3 seconds | ~90% | High (customizable) | Food, automotive, outdoor heating | Yes |

Herschel Ceramic IR Heaters | 3-5 minutes | ~85% | Moderate (panel systems) | General process, air heating | Yes |

EUROLINIA Modular IR Panels | 2-4 seconds | ~88% | High (modular, inertia-free) | Laminating, embossing, powder coating | Yes |

Metal-Sheathed IR Heaters | 5+ minutes | ~80% | High (rugged, liquids) | Submerged, harsh environments | Yes |

Quartz IR emitters consistently deliver the fastest response and highest energy efficiency. Portable infrared heaters from each brand provide flexibility for changing industrial layouts. Compatibility with automated systems and modular production lines further enhances their value.

Infrared heating element selection depends on the specific industrial process. Huai'an Quartz IR Emitters excel in paint drying, plastic molding, and photovoltaic manufacturing, where rapid, controlled heat output is essential. Infratech infrared heaters perform well in food processing and automotive assembly, offering precise temperature control and portable solutions for spot heating. Herschel ceramic heaters suit general process heating and air warming, while EUROLINIA modular panels support laminating, embossing, and powder coating with inertia-free start/stop features. Metal-sheathed infrared heaters handle submerged or rugged applications, such as heating liquids or components in harsh environments.

Paint drying and curing: Shortens drying times and improves finish quality.

Plastic molding: Enables rapid, controlled heating for molding and thermoforming.

Photovoltaic manufacturing: Provides contactless, precise heating for glass and wafer processing.

Food processing: Delivers consistent, hygienic heat for cooking and sterilization.

Automotive: Supports fast, localized heating for assembly and repairs.

Portable infrared heaters adapt to various industrial needs, ensuring efficient heat output and minimal downtime across sectors.

Quartz IR Emitters from Huai'an Infrared Heating Technology represent a leap forward in industrial infrared heaters. Their medium wave technology emits infrared radiation in the 1.4 to 2.4 micrometer range, matching the absorption characteristics of many industrial materials. This alignment boosts radiant efficiency and ensures optimal heat transfer. The quartz tube construction, featuring a tungsten filament, enables rapid heat-up and precise temperature control.

Manufacturers often choose twin tube designs for these advanced heating elements. Two parallel quartz tubes increase the surface area and heat output, resulting in uniform heat distribution across the target material. This design supports consistent processing and high-quality finishes. Quartz IR Emitters deliver fast, powerful, and energy-efficient heating, making them ideal for drying, curing, and thermoforming in industrial environments. Compared to carbon infrared heaters, quartz models provide instant, high-intensity heat with a bright glow, which is essential for rapid, focused heating tasks.

Quartz IR Emitters combine innovative design and material science to maximize energy savings and heat output, setting a new standard for industrial infrared heating element performance.

Speed is critical in industrial heating applications. Quartz IR Emitters excel in this area, reaching operating temperature within seconds. Their nearly instant heat-up and fast cooling times support processes that require rapid thermal cycling and precise temperature control. Unlike ceramic infrared heaters, which may take several minutes to reach full temperature, quartz models respond quickly to on-off switching. This feature allows manufacturers to maintain productivity during frequent process interruptions.

Industrial users benefit from reduced downtime and improved throughput. For example, in automotive glass cutting, twin tube IR emitters achieve heating times between 3 to 15 seconds for glass thicknesses of 3–8 mm. The rapid response time of 1–2 seconds and precise temperature control (±1°C) enable efficient, accurate processing. These attributes contribute to significant energy savings and lower operating costs.

Performance Metric | Quartz IR Emitters | Ceramic IR Heaters |

|---|---|---|

Heat-Up Time | 1–2 seconds | 3–5 minutes |

Cooling Time | Seconds | Minutes |

Temperature Control | ±1°C | ±5°C |

Energy Savings | Up to 40% vs. halogen lamps | Up to 20% vs. air heat |

Industrial environments demand flexible and adaptable infrared heaters. Quartz IR Emitters from Huai'an Infrared Heating Technology offer superior compatibility with existing systems. Their compact size and modular design allow easy installation and integration into automated production lines. Manufacturers can control and adjust these emitters automatically using PLC or SCR regulators, achieving precise temperature management for different heating zones.

Quartz IR Emitters support direct replacement of original heating lamps from multiple well-known brands.

Output power can be finely tuned, ensuring efficient heat transfer and minimizing wasted energy.

Infrared heating systems feature modular designs and digital controls, enabling seamless integration with building automation and smart controls.

Programmable controllers optimize energy use and improve process consistency.

Quartz IR lamps are easy to install and maintain, reducing downtime and simplifying upgrades.

These features make Quartz IR Emitters a preferred choice for industries seeking advanced heating elements that deliver rapid heat output, energy savings, and reliable performance.

Quartz IR Emitters from Huai'an Infrared Heating Technology deliver unmatched speed and efficiency across a wide range of industrial sectors. Their advanced design and rapid heat-up capability make them the preferred choice for manufacturers seeking reliable and energy-efficient solutions.

Key Industries Benefiting from Quartz IR Emitters:

Plastics Manufacturing

Production lines use industrial infrared lamps to achieve precise temperature control during molding and thermoforming.

Rapid heat transfer reduces cycle times and improves product consistency.

Infrared heat lamps support automated systems, enabling high-volume output with minimal downtime.

Automotive

Automotive plants rely on industrial heat lamp technology for paint drying, glass cutting, and component curing.

Quartz IR emitters provide localized, high-intensity heat, which accelerates drying and curing processes.

Manufacturers integrate these lamps into robotic assembly lines for efficient and repeatable results.

Digital Printing

Printing facilities utilize industrial infrared lamps to dry inks and coatings quickly.

Fast medium wave infrared lamps ensure uniform drying, preventing smudging and enhancing print quality.

Modular infrared heating systems adapt to different substrates and production speeds.

Food Processing

Food processors employ infrared heat lamps for sterilization, baking, and dehydration.

Quartz IR emitters deliver hygienic, contactless heat, which preserves flavor and texture.

Energy-efficient operation supports compliance with food safety standards.

Electronics and Photovoltaics

Electronics manufacturers use industrial infrared lamps for soldering, bonding, and wafer processing.

Quartz IR emitters provide precise thermal control, which is critical for sensitive components.

Photovoltaic production lines benefit from rapid heating during glass and cell fabrication.

Tip: Selecting the right industrial infrared lamps for each application ensures optimal speed, energy savings, and product quality.

Industry-Specific Integration Table

Industry | Application | Benefits of Quartz IR Emitters |

|---|---|---|

Plastics | Molding, thermoforming | Fast cycles, uniform heating, energy savings |

Automotive | Paint drying, glass cutting | Rapid curing, localized heat, automation |

Digital Printing | Ink drying, coating | Smudge-free prints, adjustable output |

Food Processing | Baking, sterilization | Hygienic heat, flavor retention, efficiency |

Electronics | Soldering, wafer heating | Precise control, minimal thermal stress |

Photovoltaics | Cell fabrication | Contactless heating, high throughput |

Manufacturers across these sectors choose Huai'an Quartz IR Emitters for their proven reliability and performance. The modular design and compatibility with automated systems allow seamless integration into existing production lines. Industrial infrared lamps from Huai'an Infrared Heating Technology set the standard for speed, efficiency, and quality in modern manufacturing environments.

Infratech stands out among the best infrared heaters for industrial and commercial environments. The company specializes in quartz-based infrared heaters that deliver rapid, even heat distribution. Their products reach full operating temperature in as little as 1–3 seconds, making them a strong choice for facilities that require immediate warmth. Infratech designs its infrared heaters for seamless integration into automated systems and modular production lines. Many models offer portable configurations, allowing users to reposition units as workflow demands change.

Infratech’s infrared space heater models excel in outdoor and semi-enclosed spaces. Their weather-resistant construction ensures reliable performance in patios, garages, and loading docks. The company’s focus on energy efficiency helps reduce operational costs, while the ability to target specific zones minimizes wasted energy. Infratech’s best infrared heaters support both fixed and portable installations, providing flexibility for dynamic industrial layouts.

Herschel ranks among the best infrared heaters for both industrial and commercial applications. The company’s Mirror Radiant Heat Panel uses advanced infrared technology to deliver rapid, consistent warmth. Operating at surface temperatures between 185°F and 203°F, these panels provide quick heat-up times without overheating the environment. Herschel’s infrared heaters directly warm objects and people, reducing energy loss and preventing mold or condensation in humid settings. Their design and certifications confirm suitability for challenging industrial environments.

Other notable brands, such as Freek and Ceramicx, offer bespoke infrared heating solutions tailored for specific industrial needs. Freek’s systems, built on Ceramicx IR heat technology, provide fast heat-up times and precise control. These industrial infrared lamps can reduce energy consumption by up to 40% and increase production efficiency by as much as 20%. Many of these brands offer portable options, making it easy to adapt heating solutions to changing production requirements.

Herschel and similar brands deliver energy-efficient, rapid heating with strong performance in moisture-sensitive and high-precision environments.

Industrial buyers select the best infrared heaters based on application and environment. Runner-up brands excel in several scenarios:

Warehouses benefit from portable infrared heaters that deliver direct warmth to workers, overcoming insulation and volume challenges.

Office spaces and commercial environments use portable infrared heaters for zonal heating, allowing individuals to control their immediate area.

Restaurants and retail shops prefer targeted heating, which improves comfort without wasting energy on unused spaces.

Outdoor industrial areas, such as patios and garages, rely on portable infrared heaters for direct, reliable heat in open or semi-enclosed spaces.

Large industrial spaces, including workshops and warehouses, use infrared bar heaters for powerful, efficient heating of specific zones or workstations.

Manufacturing and curing processes benefit from the quick, targeted warmth of industrial infrared lamps, supporting precise temperature control.

Moisture-sensitive industries, such as pharmaceuticals and food processing, use infrared heat lamps to prevent mold and mildew without affecting humidity or oxygen levels.

Healthcare environments value the silent operation and clean air provided by these heaters.

The best infrared heaters from runner-up brands offer flexibility, energy savings, and reliable performance across diverse industrial sectors. Their portable designs and compatibility with renewable energy sources further enhance their appeal for modern facilities.

Material composition and design play a decisive role in the speed and efficiency of any infrared heating element. Manufacturers select materials such as quartz, ceramic, and carbon fiber to tailor the radiation wavelength, power output, and shape for specific industrial processes. Quartz tubes, for example, enable rapid heat-up and precise control, making them ideal for industrial infrared lamps used in plastics, automotive, and digital printing. Carbon fiber composites, especially those treated at high temperatures, deliver superior electrical and thermal conductivity. These heating elements reach surface temperatures above 100°C and provide heat outputs exceeding 3700 W/m² at low voltages, outperforming traditional Ni-Cr wire designs in both speed and efficiency.

Ceramic infrared heat lamps offer radiant efficiencies between 39% and 85%, depending on input power and installation distance. Their direct radiant heat transfer allows for instantaneous heat exchange, minimizing preheating time and supporting faster cycle times. The ability to generate heat exactly where and when needed leads to significant energy savings, reduced space requirements, and improved process automation. Industrial heat lamp designs often incorporate twin tube or modular configurations to maximize surface area and uniformity, ensuring consistent results across large production lines.

Tip: Selecting the right material and design for heating elements ensures reproducible, automated heating with response times measured in seconds, supporting high-volume manufacturing and energy savings.

Watt density, defined as the wattage per unit surface area, directly influences the heat-up time of industrial infrared lamps. Higher watt densities produce more heat in a smaller area, resulting in rapid temperature rise and faster processing. Mini-tube quartz heaters can reach watt densities up to 60 watts per square inch, enabling heat-up rates of 2.5 to 7.5 degrees Fahrenheit per second. Ceramic panel infrared heaters operate efficiently at watt densities up to 25 watts per square inch, supporting faster oven cycles and improved throughput.

FS Series heaters support watt densities up to 45 watts per square inch, providing rapid on/off response times suitable for high-temperature applications.

V-Series heaters offer fast heat-up and cool-down times, ideal for processes requiring tight temperature control and quick response.

Engineers often increase watt density within safe limits to decrease heat-up time, sometimes doubling the wattage to halve the heating period. The optimal watt density depends on the material being heated, operating temperature, and heater design. Matching watt density to process requirements ensures uniform heating, avoids hot spots, and maximizes energy savings.

System integration determines how effectively industrial infrared lamps perform within manufacturing environments. Proper specification matching ensures compatibility with existing equipment and process flows, enabling optimal heating parameters and faster response times. Mechanical installation, including secure mounting and safety measures, maintains system reliability and accessibility, preventing delays or malfunctions.

Integration Aspect | Impact on Infrared Heating Performance and Speed |

|---|---|

Specification Matching | Enables optimal heating parameters and faster response times |

Mechanical Installation | Maintains reliability and accessibility, preventing delays |

Electrical Connection | Supports consistent and rapid heating activation |

Control System Integration | Allows quick heating cycles and improved process speed |

Advanced control systems enable precise temperature management and real-time adjustments, allowing operators to start, stop, or modify heating cycles with minimal delay. Modular and customizable designs simplify upgrades and support automation, enhancing throughput and product quality. Infrared heating emitters transfer energy directly to the target surface, enabling rapid temperature ramp-up and supporting fast manufacturing processes. These integration practices collectively drive energy savings, uniform heating, and higher production speed.

Proper maintenance plays a crucial role in ensuring that industrial infrared lamps deliver fast and reliable performance. Regular upkeep not only extends the lifespan of these heating elements but also preserves their rapid heat-up capabilities. When operators neglect maintenance, even the most advanced infrared heat lamps can experience reduced efficiency and slower response times.

Industrial environments often expose infrared lamps to dust, debris, and process residues. These contaminants can accumulate on the quartz tubes or reflectors, blocking radiant energy and causing uneven heating. Technicians should schedule routine cleaning to remove buildup and restore optimal output. Using a soft, lint-free cloth and approved cleaning solutions prevents scratches and maintains the transparency of quartz surfaces.

Tip: Always allow industrial infrared lamps to cool before cleaning. This practice prevents thermal shock and protects both the lamp and the technician.

Electrical connections also require regular inspection. Loose or corroded terminals can lead to voltage drops, which reduce the effectiveness of the industrial heat lamp. Maintenance teams should check wiring, connectors, and control modules for signs of wear or overheating. Prompt replacement of damaged components ensures consistent power delivery and rapid heat-up.

A proactive maintenance plan includes:

Visual inspections: Look for discoloration, cracks, or residue on the lamp surface.

Performance monitoring: Track heat-up times and energy consumption. Sudden changes may indicate a problem.

Scheduled cleaning: Remove dust and debris from quartz tubes and reflectors.

Electrical checks: Tighten connections and replace worn parts as needed.

Documentation: Keep records of maintenance activities and lamp replacements.

Maintenance Task | Frequency | Benefit |

|---|---|---|

Visual inspection | Weekly | Early detection of wear or damage |

Cleaning | Monthly | Maintains radiant efficiency |

Electrical inspection | Quarterly | Prevents power loss and slow heating |

Performance review | Biannually | Identifies declining efficiency |

Well-maintained industrial infrared lamps consistently achieve fast heat-up times and stable operation. Facilities that invest in regular maintenance reduce unplanned downtime and maximize the return on their heating system investment. By following a structured maintenance schedule, operators ensure that their infrared heat lamps continue to meet the demanding speed and efficiency requirements of modern industry.

Consistent maintenance transforms a good industrial heat lamp into a high-performance, long-lasting solution for any production environment.

Plastics manufacturing demands precise temperature control and rapid processing. Infrared heaters deliver direct energy transfer to polymer surfaces, which increases process speed and improves product quality. Manufacturers use these systems to heat plastic sheets before embossing, laminating, molding, and thermoforming. Ceramic infrared emitters, operating in the 2.5-6 micrometer wavelength range, offer rapid response and precise temperature control. These features support fast cycle times and consistent results.

Infrared heating systems, such as the InfraLine series and IPH models, provide continuous dynamic heating on conveyors and thermoforming machines. Infrared tunnels facilitate high-speed heating and curing of moving plastic products. This technology reduces cycle times and enhances uniformity, which helps avoid defects. Combining infrared heaters with convection further optimizes energy savings and process control. Infrared welding joins plastic parts efficiently without contamination, and preheating with vibration welding minimizes particle formation. These advantages make infrared heaters the preferred choice for plastics manufacturing processes that prioritize speed and energy savings.

Food processing industries benefit from infrared heaters due to their high energy efficiency and reduced energy consumption. These systems achieve faster and more homogeneous heating, which shortens processing times and improves throughput. Infrared heaters operate as non-contact and chemical-free solutions, reducing water and chemical usage. This approach enhances both manufacturing efficiency and food safety.

Manufacturers appreciate the compact design and precise control offered by infrared heaters. Integration with other heating methods, such as convective drying, can reduce drying time by nearly half and cut energy consumption by over 60%. Infrared heaters produce no harmful emissions and improve the organoleptic quality of food products. The technology supports increased productivity, energy savings, and environmental sustainability. Food processors rely on infrared heaters for baking, sterilization, and dehydration, ensuring consistent results and compliance with safety standards.

Tip: Infrared heaters help food processors achieve faster drying and better product quality while supporting energy savings and sustainability goals.

Automotive manufacturing requires heating elements that deliver rapid heat-up and reliable performance. Quartz infrared heaters stand out for their ability to reach temperatures up to 1600°F almost instantly. These heaters emit short wavelength infrared radiation, providing intense and controlled heat for high-heat processes such as paint drying, glass cutting, and component curing.

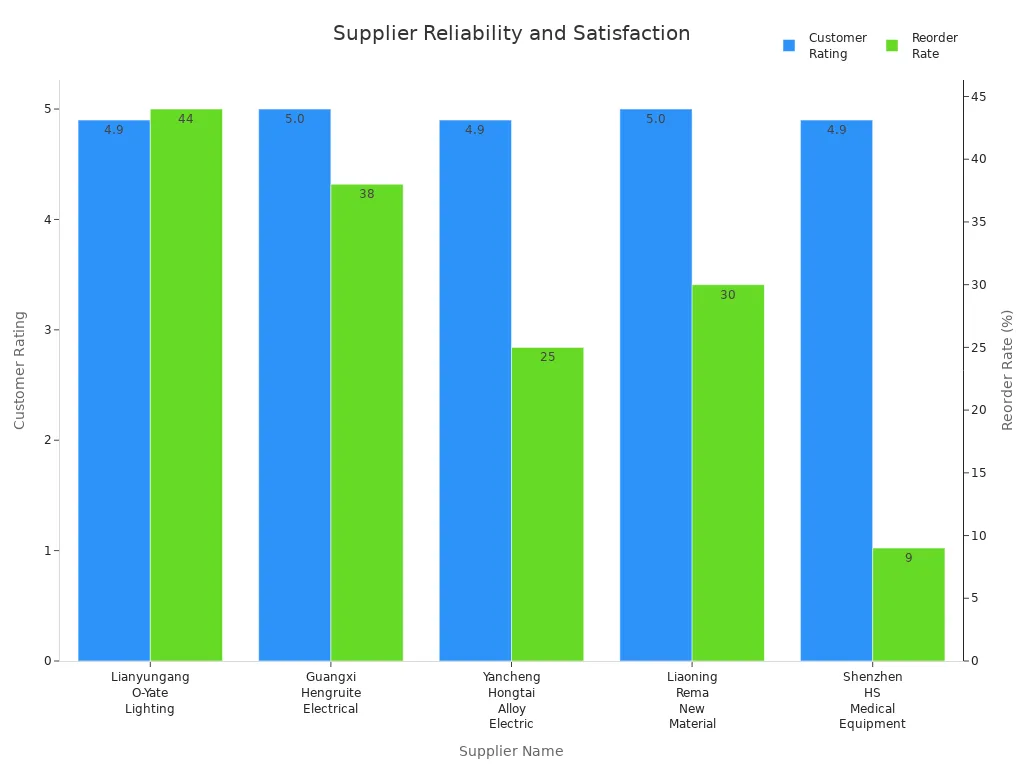

Suppliers like ISE, Inc. offer advanced silicon carbide and carbon fiber heating elements known for fast heat-up and uniform temperature control. These technologies support automotive seat heaters and other components that demand flexibility and reliability. The following table highlights top-performing suppliers in the automotive sector:

Supplier Name | Location | Years Experience | On-Time Delivery | Response Time | Customer Rating | Reorder Rate |

|---|---|---|---|---|---|---|

Lianyungang O-Yate Lighting | Jiangsu, China | 17 | 100% | ≤2 hours | 4.9 | 44% |

Guangxi Hengruite Electrical | Guangxi, China | 8 | 100% | ≤2 hours | 5.0 | 38% |

Yancheng Hongtai Alloy Electric | Jiangsu, China | 17 | 93.7% | ≤5 hours | 4.9 | 25% |

Liaoning Rema New Material | Liaoning, China | 3 | 100% | ≤1 hour | 5.0 | 30% |

Shenzhen HS Medical Equipment | Guangdong, China | 4 | 96.6% | ≤2 hours | 4.9 | 9% |

Automotive plants integrate infrared heaters into robotic assembly lines for efficient and repeatable results. These systems accelerate drying and curing, reduce downtime, and support high-volume production. Manufacturers choose quartz infrared heaters for their unmatched speed, reliability, and energy savings in automotive applications.

Electronics manufacturing requires precise thermal management and rapid, uniform heating. Many companies in this sector rely on infrared heaters to achieve these goals. These systems deliver targeted energy directly to circuit boards, semiconductors, and delicate components. This approach minimizes thermal stress and reduces the risk of damage during processes such as soldering, bonding, and wafer drying.

Engineers often select industrial infrared lamps for their ability to provide fast, contactless heating. These lamps support critical steps in electronics assembly, including reflow soldering and adhesive curing. The rapid response of infrared heat lamps ensures that temperature-sensitive materials receive consistent heat without overheating. This precision helps maintain product quality and reduces the likelihood of defects.

Manufacturers value the flexibility of modular infrared heaters. These systems integrate easily into automated production lines and cleanroom environments. Operators can adjust output power and wavelength to match the specific requirements of each process. For example, short wave industrial heat lamp models excel at heating metal contacts, while medium wave options suit plastic encapsulation and conformal coating.

Tip: Regular maintenance of infrared heaters in electronics facilities prevents dust buildup and ensures optimal performance. Clean quartz tubes and reflectors help maintain consistent heat output and extend the lifespan of the equipment.

A comparison of common electronics applications and recommended infrared heating solutions:

Application | Recommended Infrared Solution | Key Benefit |

|---|---|---|

Soldering | Short wave industrial infrared lamps | Fast, localized heating |

Wafer drying | Medium wave infrared heat lamps | Uniform, gentle heat |

Adhesive curing | Modular industrial infrared lamps | Precise temperature control |

Bonding | Customizable infrared heaters | Reduced thermal stress |

Electronics manufacturers choose infrared heaters for their speed, energy efficiency, and adaptability. These systems support high-volume production and help companies meet strict quality standards.

Infrared heaters also play a vital role in many other industries. Textile manufacturers use industrial infrared lamps to dry fabrics and set dyes quickly. This technology reduces processing time and improves colorfastness. In the wood industry, infrared heat lamps cure coatings and adhesives, resulting in smoother finishes and faster turnaround.

Pharmaceutical companies rely on industrial heat lamp systems for drying, sterilization, and tablet coating. These processes demand precise temperature control and contamination-free environments. Infrared heaters deliver contactless, hygienic heat that meets these requirements.

Aerospace and defense sectors benefit from the rapid response and uniform heating of industrial infrared lamps. These systems support composite curing, paint drying, and de-icing applications. The ability to deliver controlled heat in challenging environments makes infrared heaters a preferred choice for mission-critical operations.

Note: Selecting the right type of infrared heater for each sector ensures maximum efficiency and product quality. Consulting with experienced suppliers helps match the heating solution to the unique needs of each application.

Quartz IR Emitters from Huai'an Infrared Heating Technology deliver the fastest and most energy-efficient results for industrial infrared lamps in 2025. Recent studies show infrared heat lamps reduce processing times by up to 97% and cut energy costs by 30–50% compared to traditional ovens.

Feature | Benefit |

|---|---|

Rapid Heating Response | Maximizes output and reduces cycle times |

Energy Efficiency | Lowers operational costs |

Uniform Heating | Improves product quality |

Industrial buyers should match the right infrared heat lamp to their process needs, considering zone control, material compatibility, and certifications. For tailored solutions and expert support, consult Huai'an Infrared Heating Technology. Next steps include assessing process requirements, reviewing lamp specifications, and exploring retrofitting options to optimize performance.

Quartz infrared lamps deliver rapid heat-up and precise control. Manufacturers rely on these industrial infrared lamps for consistent performance and energy savings. Their design supports high-volume production and fast cycle times.

Portable infrared heat lamps allow flexible placement on production lines. Operators move these units to target specific areas, improving efficiency. This adaptability supports changing layouts and temporary workstations.

Infrared space heater models suit large industrial spaces. They provide direct, uniform warmth to work zones. Facilities use these heaters to maintain comfortable temperatures and reduce energy costs.

Buyers should select portable space heaters with an auto shutoff feature. This function prevents overheating and reduces fire risk. Safety certifications ensure reliable operation in demanding environments.

Industrial infrared lamps heat surfaces directly, reducing energy loss. They reach operating temperature faster than conventional systems. This efficiency lowers operational costs and increases productivity.

Infrared heat lamps offer hygienic, contactless heating. Food processors use these lamps for baking, sterilization, and dehydration. The technology preserves flavor and texture while supporting safety standards.

Operators should clean lamp surfaces regularly and inspect electrical connections. Routine maintenance ensures stable performance and fast heat-up times. Well-maintained systems extend equipment lifespan.

Portable infrared lamps work with programmable controllers and automation systems. Manufacturers adjust output and temperature zones for precise process control. Integration supports consistent quality and energy management.